Energy-saving lime kiln

A technology of lime kiln and kiln body is applied in the field of material calcining device, which can solve the problems of wasting heat energy, unutilized flue gas, low preheating temperature and increasing fuel consumption, etc., and achieves the effect of reducing cost, calcining thoroughly and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

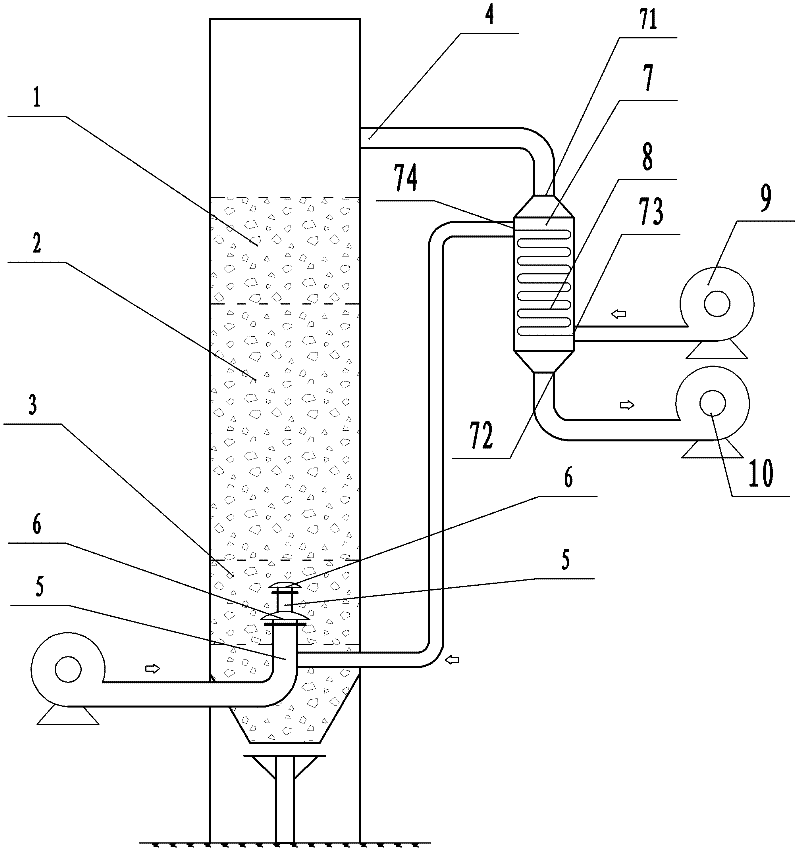

[0021] Embodiment 1: a kind of energy-saving lime kiln (see attached figure 1 ), including the vertical kiln body, the kiln body is preheating zone 1, calcining zone 2, and cooling zone 3 from top to bottom. A kiln gas discharge pipe 4 is arranged above the preheating zone. The kiln gas discharge pipe is used to discharge the flue gas in the kiln body. The temperature of the discharged flue gas is generally between 250°C and 300°C. The kiln gas discharge pipe is connected to the air inlet 71 of the heat exchanger 7, and the high-temperature flue gas discharged from the kiln body is transported into the heat exchanger through the air inlet. The blower 9 is connected, and the air outlet 72 of the heat exchanger is connected with the exhaust fan 10 . The blower blows the air at normal temperature into the heat exchange tube, and after heat exchange between the high temperature flue gas and the normal temperature air in the heat exchange tube, the flue gas is extracted by the exh...

Embodiment 2

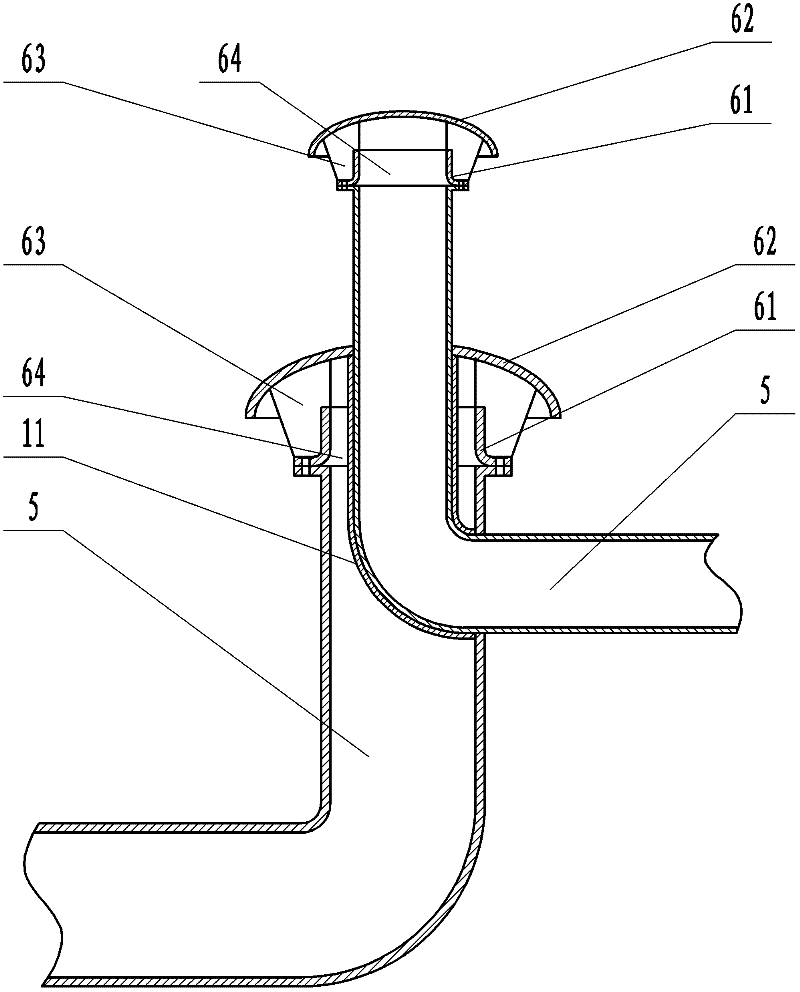

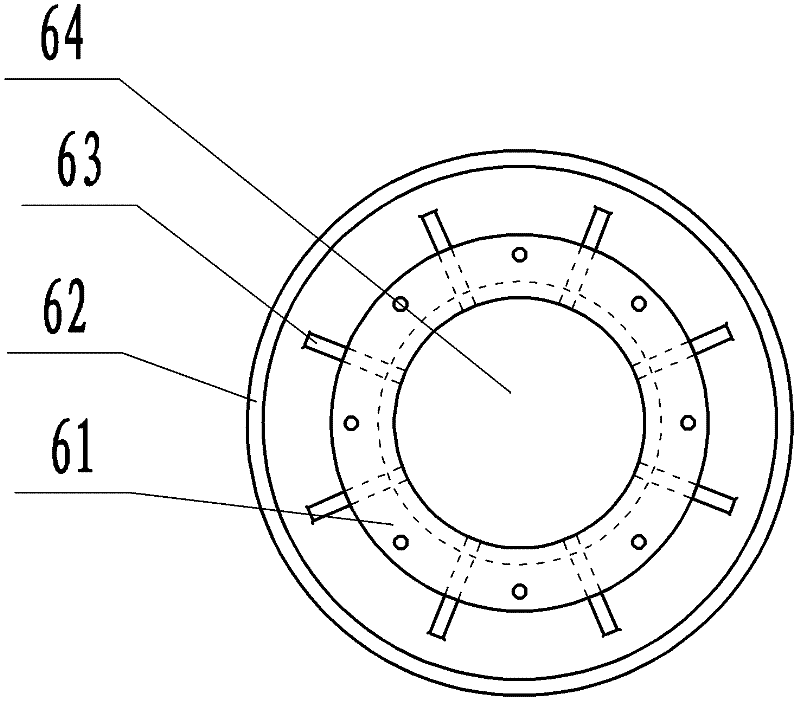

[0023] Embodiment 2: a kind of energy-saving lime kiln (see attached figure 1 ), its structure is similar to Example 1. The main difference lies in the structure of the hood 6 . Wind cap 6 comprises cap seat 61, cap tube 66 and cap 62 (see attached Figure 4 , attached Figure 5 ), the cap seat is cylindrical, and the cap seat is provided with a ventilation hole 64 adapted to the air duct 5, the end of the ventilation hole of the upper hood is closed, and the end of the ventilation hole of the lower hood is provided with a preheating air input device The through hole that the air duct fits into, and the air duct passes through the through hole. The lower end of the cap seat is provided with an outward flange, and a countersunk through hole is provided on the flange. The upper end of the air duct is provided with an outward flange, and the flange is provided with a through hole adapted to the through hole of the countersunk head. The two flanges are fitted together and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com