Double-O-shaped lime kiln

A main structure and mixing technology, applied in the field of lime kiln, can solve the problems of damage to the health of operators, inability to control in time, high labor intensity, etc., and achieve the effects of increasing output and activity, easy operation, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

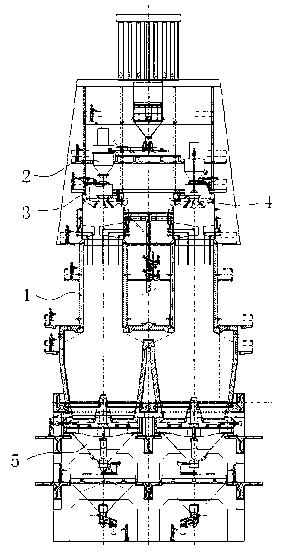

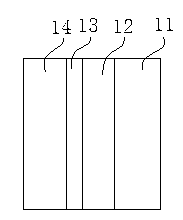

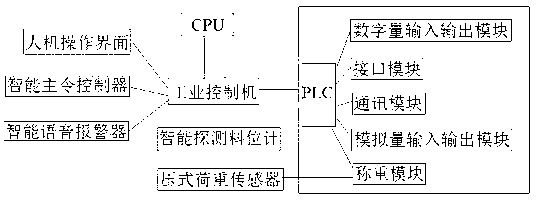

[0020] Such as figure 1 and 2 As shown, the double O-type lime kiln mainly consists of system components such as raw material conveying and mixing distribution system, kiln main structure, discharge system, dust removal system, and power equipment configured with each system. The main structure 1 of the kiln is double O-shaped; the wall of the main structure of the kiln is a fully sealed calcined structure, which consists of high alumina brick layer 11, light insulation brick layer 12, heat insulation fiber layer 13 and steel furnace shell from inside to outside. 14 compositions. The dust removal system is a bag dust removal system that mixes flue gas, dust and post dust at the same time for dust removal; the bag dust removal system includes a dust collector and several air induction hoods connected to the dust collector; the air induction hood includes electronic sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com