Sludge resource treatment device and method for treating sludge

A processing device and resource-based technology, applied in dewatering/drying/concentrating sludge treatment, combustion methods, incinerators, etc., can solve the problems of increasing processing time and cost, increasing the cost of drying raw materials, increasing the amount of exhaust gas, etc., and achieving savings Drying energy, ensure drying effect, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

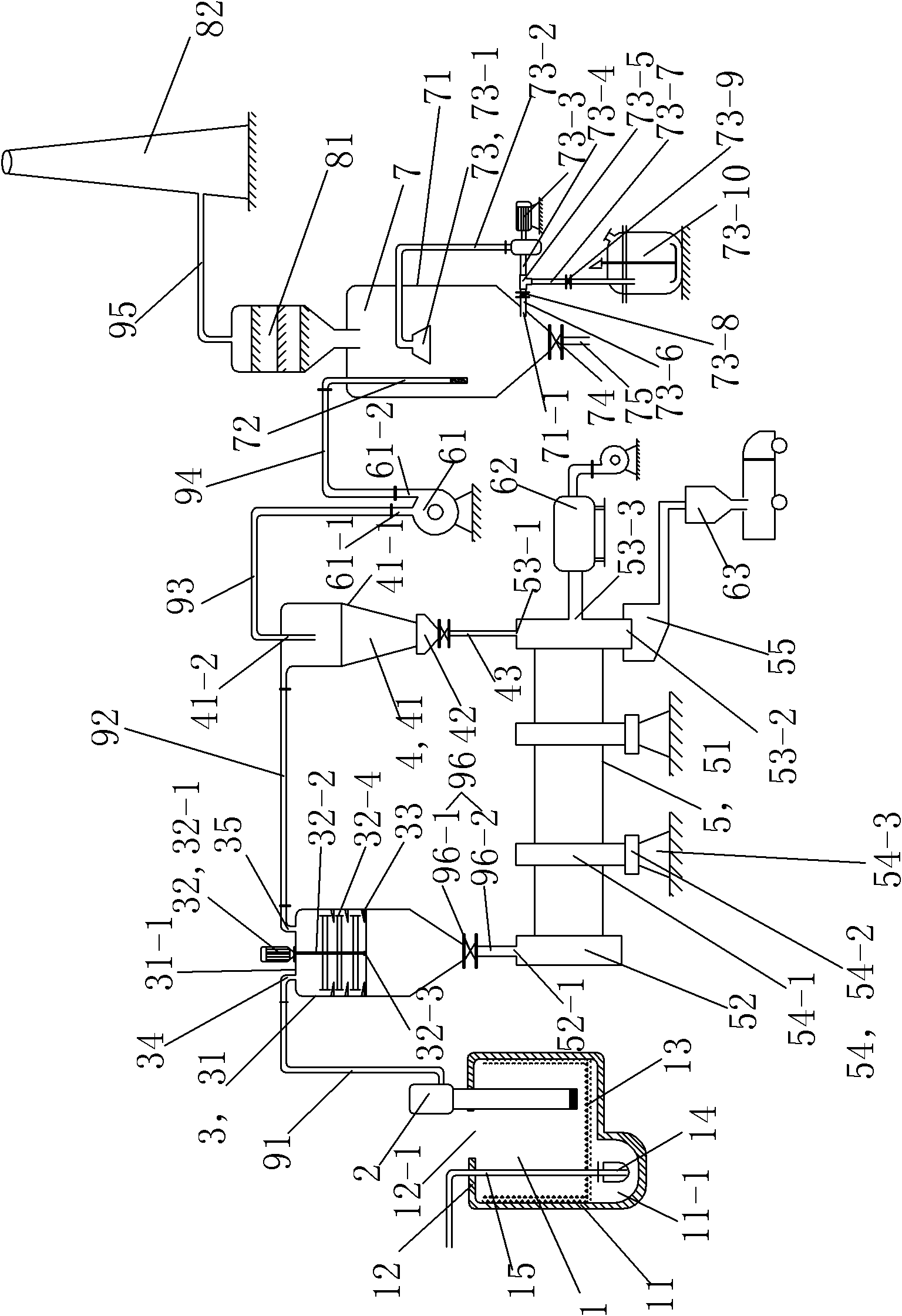

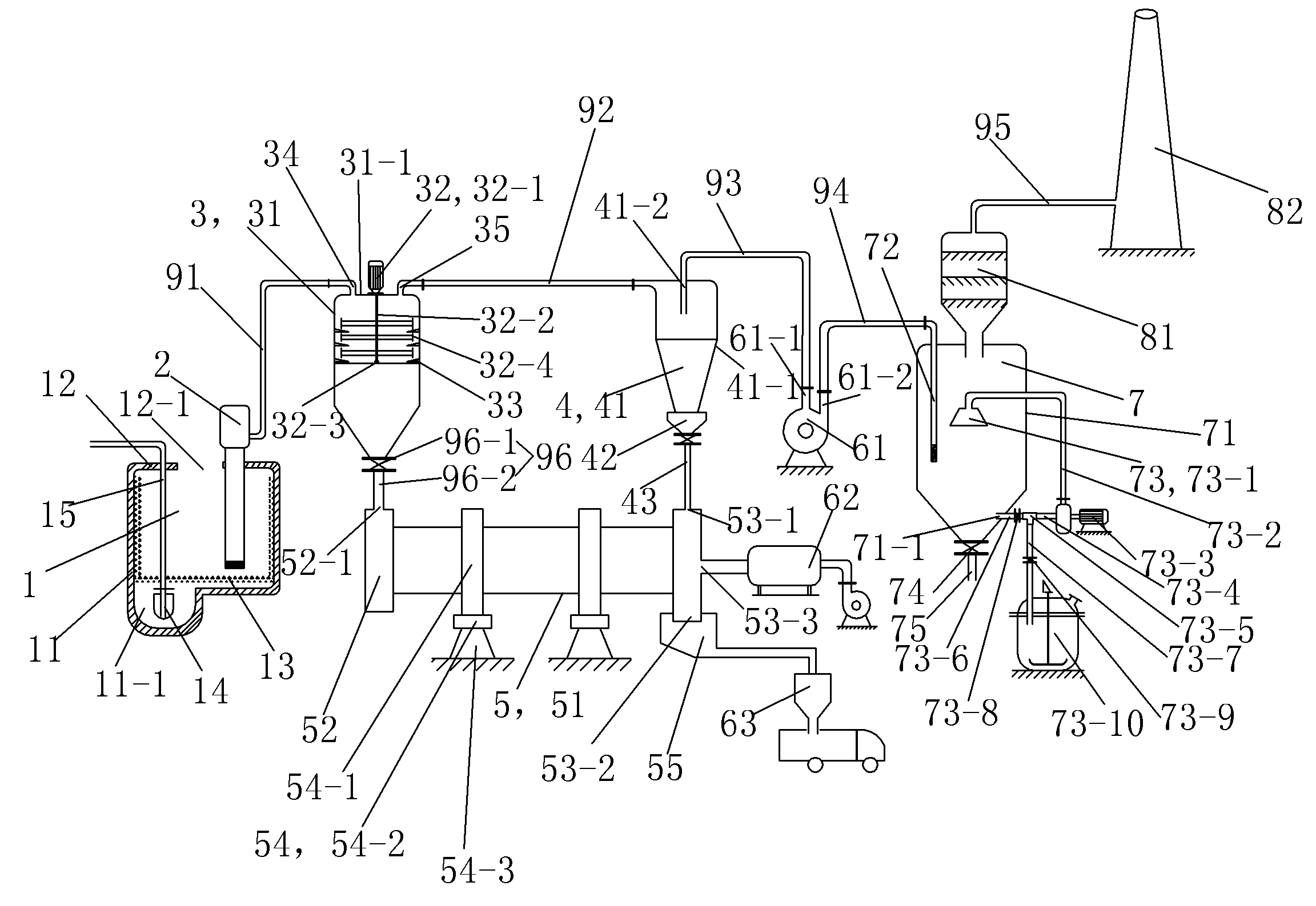

[0053] See figure 1 The sludge resource treatment device in this embodiment includes a filter tank 1, a sludge conveying device 2, a waste heat drying tower 3, a cyclone separation device 4, a rotary kiln 5, an induced draft fan 61, a hot blast stove 62, a collection tank 63, Deodorization tower 7, gas-liquid separator 81 and chimney 82. The sludge conveying device 2, the waste heat drying tower 3, the cyclone separation device 4, the induced draft fan 61 and the deodorizing tower 7 are connected through pipelines in sequence. The discharge port of the waste heat drying tower 3 and the discharge port of the cyclone separation device 4 are respectively connected with corresponding ports of the rotary kiln 5 .

[0054] The filter pool 1 includes a pool body 11 , an upper cover plate 12 , a filter screen 13 , a submerged pump 14 and an outlet pipe 15 . The side of the pool bottom of the pool body 11 is provided with a pit 11-1 sunken downward, and the submerged pump 14 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com