Method for preparing super-thick denier polyester monofilament

A technology of ultra-coarse denier and polyester, applied in the direction of melt spinning, filament/thread forming, artificial filament heat treatment, etc., can solve the problems of unstable product quality, many broken ends, and unable to produce normally, and achieve variety replacement Flexible and simple, reduce energy consumption and material consumption, and reduce the effect of investment in equipment renewal and transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

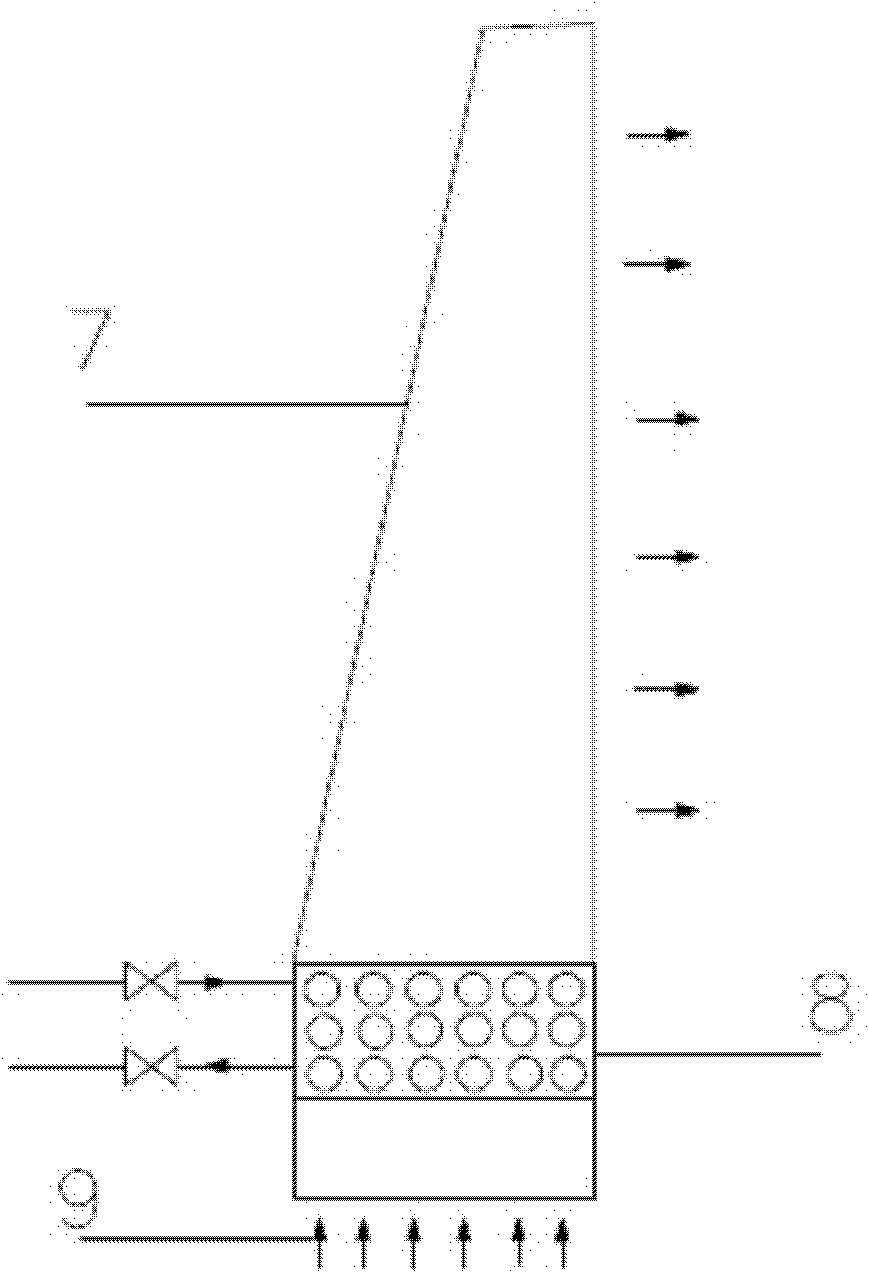

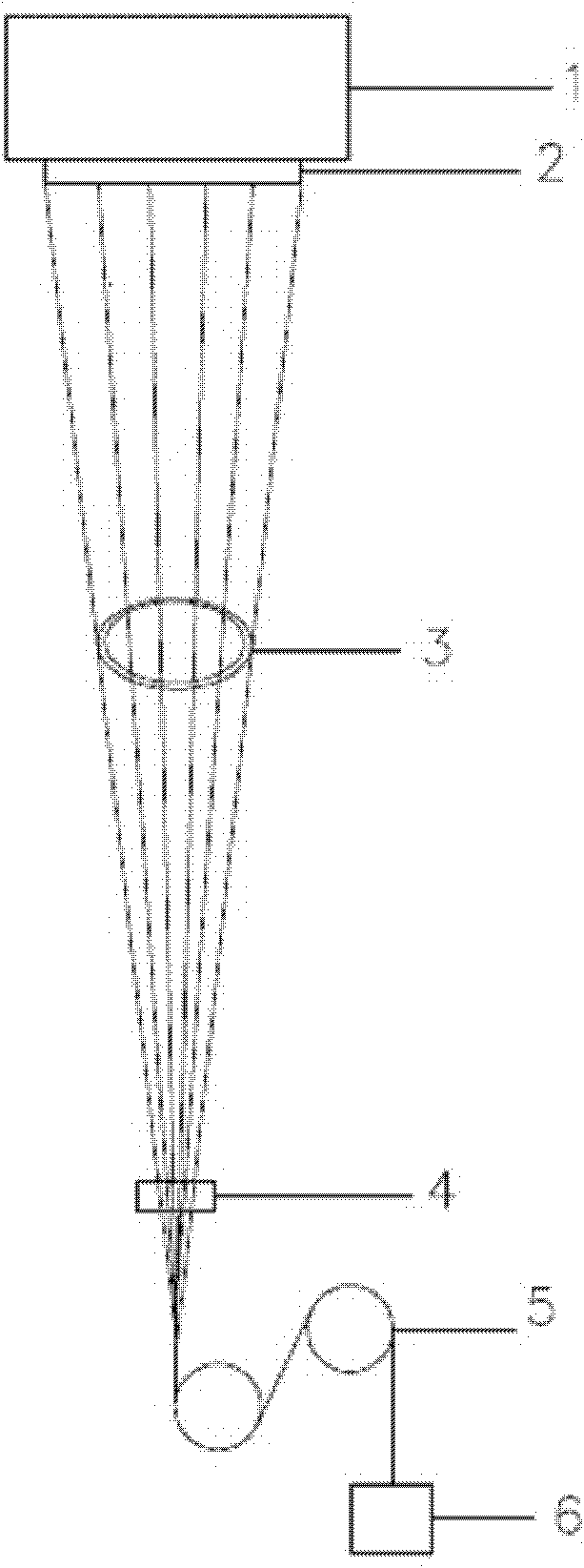

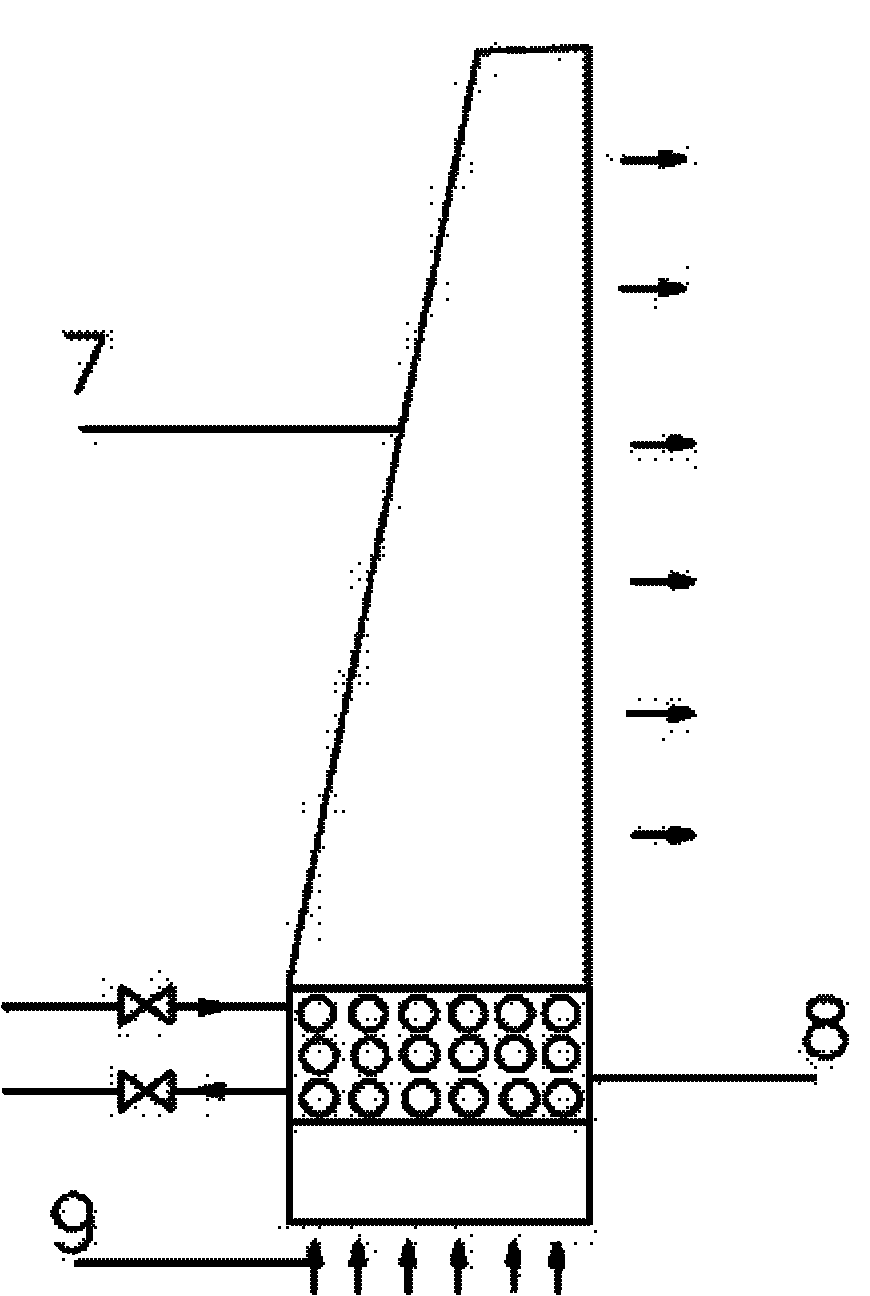

[0017] The preparation method of the ultra-coarse denier polyester monofilament described in this embodiment mainly includes the following production steps: polyester melt, booster pump, melt delivery pipeline, spinning box, metering pump, spinning assembly, Spinning side blowing, oiling, drafting and shaping, winding, the following measures are included in the step of spinning side blowing: adopting the air-conditioning wind blown out by the side blowing air conditioner by setting a water circulation cooling device 8 at the position of the spinning side blowing inlet. Secondary cooling, control the side blowing parameters after secondary cooling: temperature 17°C, humidity 75%, wind speed 0.7m / s;

[0018] In the oiling step: carry out oiling and cooling twice to the tow after being cooled by side blowing, and control the total oiling rate of the tow to 0.7%, wherein, the first oiling parameter is: oiling rate 0.2% , oil thick 13%; The oiling parameter for the second time is: ...

Embodiment 2

[0025] The preparation method of the ultra-coarse denier polyester monofilament described in this embodiment is used to produce ultra-coarse denier polyester monofilament and conventional FDY products at the same time. The preparation method of this ultra-coarse denier polyester monofilament mainly includes the following production steps : Polyester melt, booster pump, melt conveying pipeline, spinning box, metering pump, spinning assembly, spinning side air blowing, oiling, draft setting, winding, included in the spinning side blowing step The following measures: use a water circulation cooling device 8 at the inlet position of the spinning side blower to perform secondary cooling on the air-conditioning air blown out by the side blower air conditioner, and control the side blower parameters after the secondary cooling as follows: temperature 19°C, humidity 90%, wind speed 0.9m / s, other spinning positions under the control of air conditioner on the same side, still produce con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com