Method and apparatus for treating emulsified oil waste water

A technology for wastewater treatment and emulsified oil, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Complex process and other problems, to achieve the effect of saving investment and operating costs, wide COD concentration requirements, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

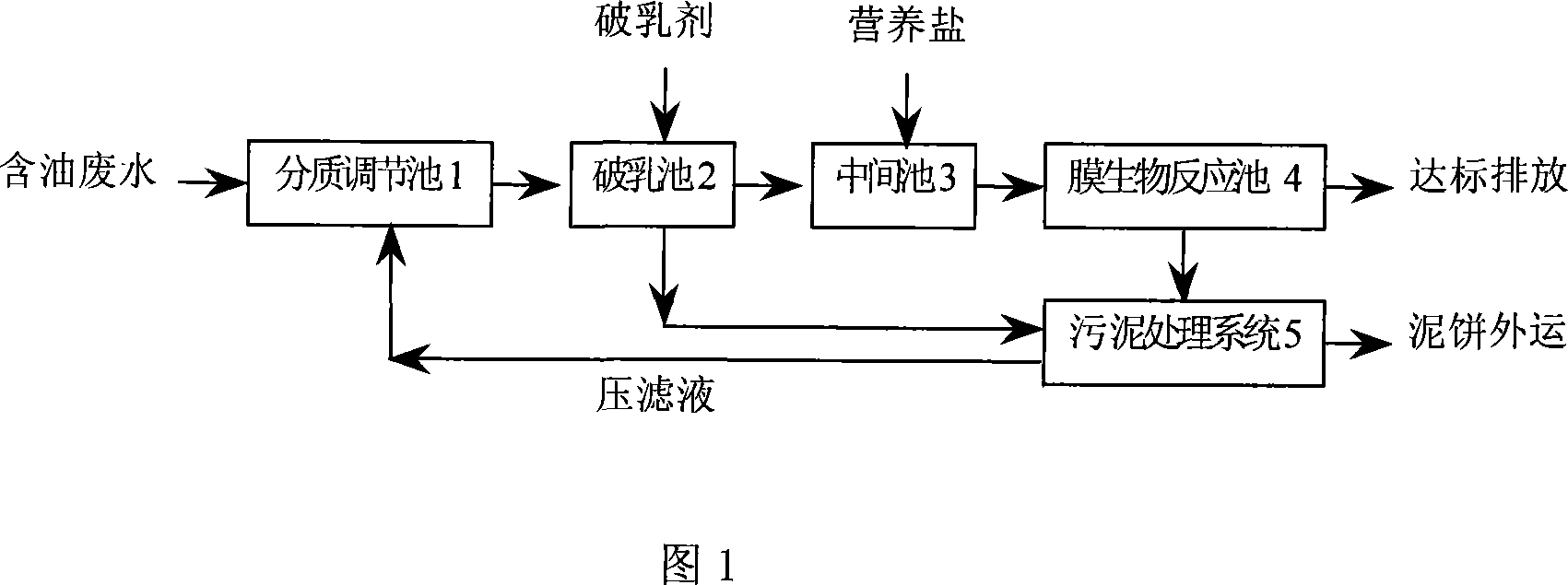

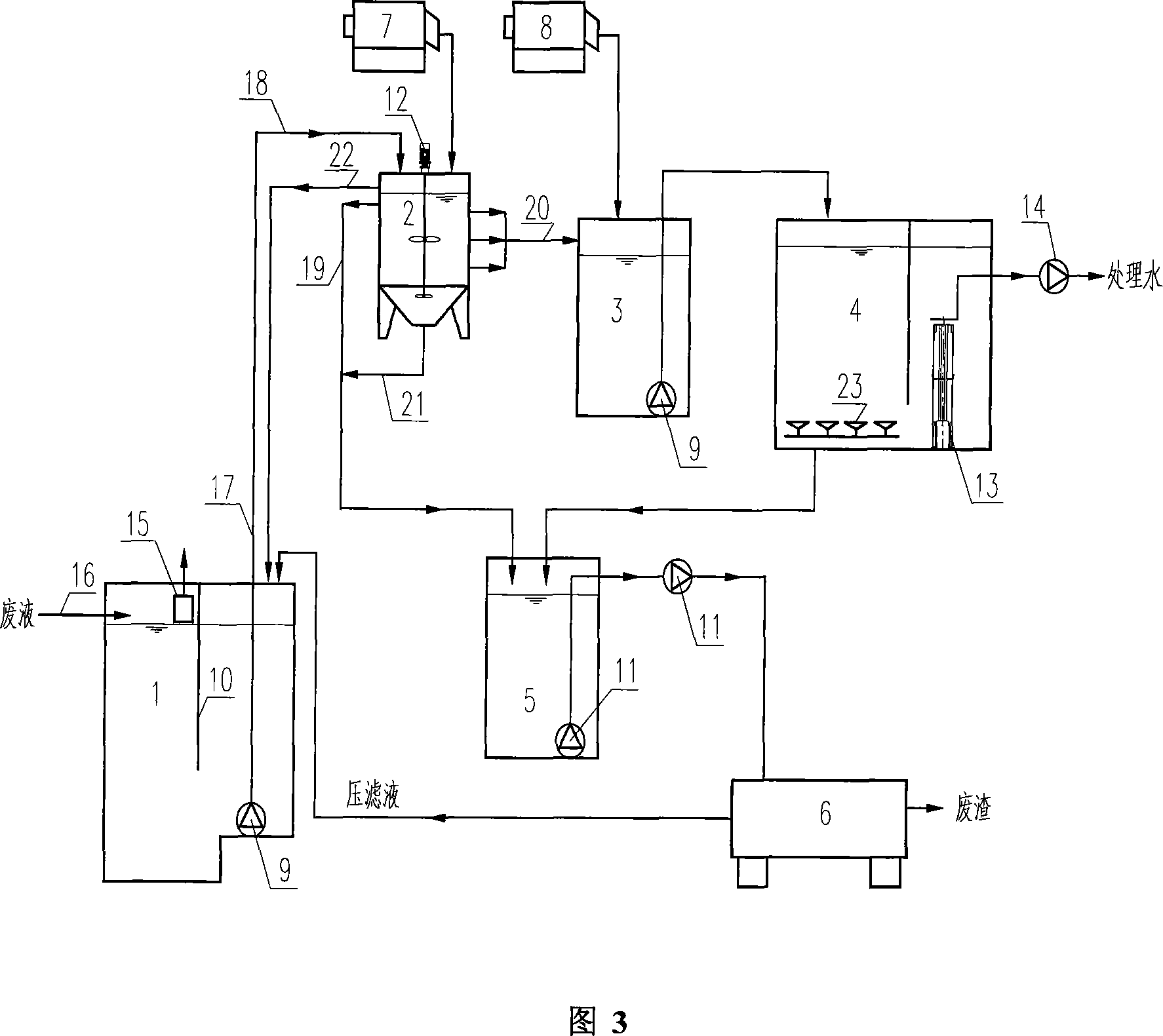

[0044] The oily waste water treated in Example 1 is emulsified oil waste liquid from an internal combustion engine plant, with COD<15000mg / L and oil concentration<3000mg / L. The daily processing capacity is 3.2t / d.

[0045] Follow the steps below to implement:

[0046] 1) Adjust the water volume and remove the upper oil slick in the quality separation adjustment tank;

[0047] The high-concentration emulsified oil waste liquid is discharged and stored in the quality separation adjustment tank for treatment, and the hydraulic retention time is 10 days, which can play a role in regulating water quality and quantity. The slick oil in the upper layer of the wastewater is intercepted by the oil separator, and then manually removed periodically or automatically skimmed by setting a float oil skimmer. The emulsified oil wastewater from which the slick oil has been removed is lifted by the submersible sewage pump located 1.0m away from the bottom of the tank to the demulsification ta...

Embodiment 2

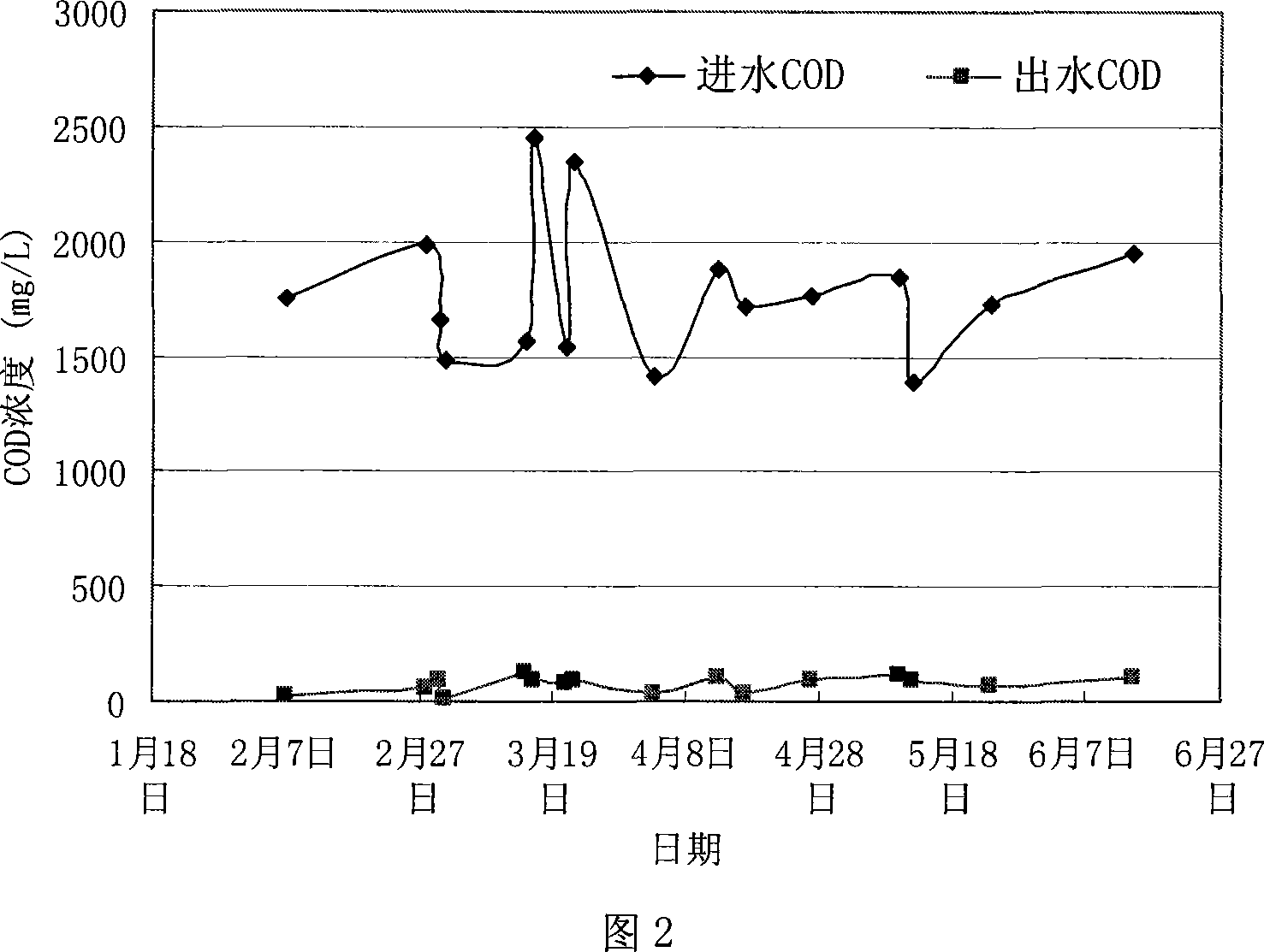

[0057] With reference to Example 1, the implementation steps are the same as in Example 1. The oily wastewater treated in Example 2 is foundry release agent and cleaning fluid oily wastewater. The COD concentration of the release agent is about 20000-40000 mg / L, and the COD concentration of the cleaning solution is about 2000-4000 mg / L. Due to the intermittent and uncertain production, the ratio of the two streams of incoming water (mold release agent and cleaning solution) entering the treatment system is uncertain and irregular.

[0058] The oily wastewater enters the separation adjustment tank, demulsification tank, intermediate tank, and membrane bioreaction tank for treatment in sequence, and the generated sludge enters the sludge storage tank and dehydrator for treatment in sequence. The daily processing capacity is 24t / d, the hydraulic retention time of the quality separation adjustment tank is 1 day, and the demulsifier is Ca(OH) 2 and FeCl 3 . The middle pool is of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com