Device of oil-sewage ship for treating sewage and method thereof

A technology for oily sewage and receiving devices, which is applied in the direction of grease/oily substance/suspton removal devices, separation methods, liquid separation, etc., and can solve the problems of large land occupation, huge processing equipment, and frequent backwashing of onshore sewage treatment plants , to achieve the effect of convenient maintenance and management, significant economic benefits, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

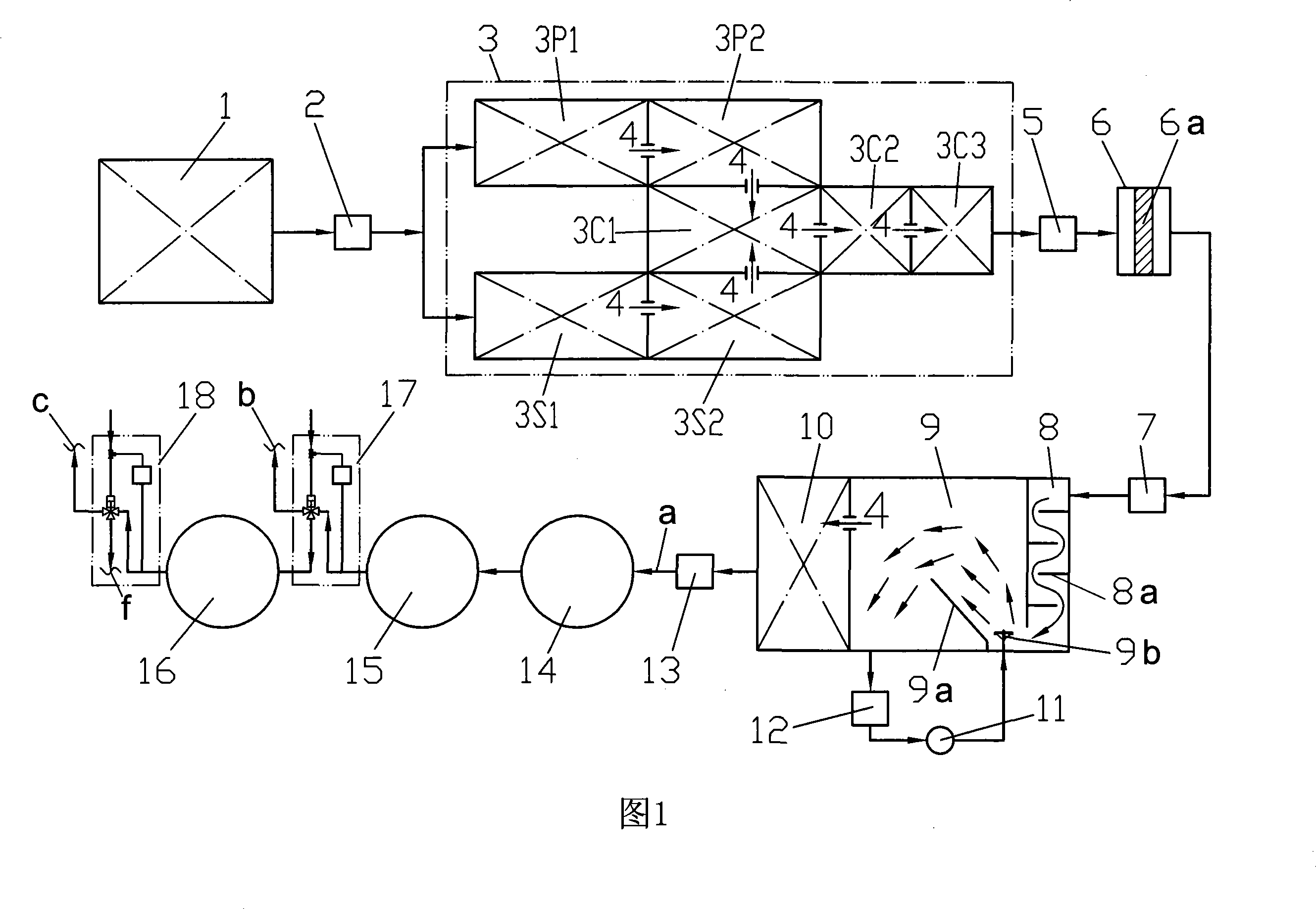

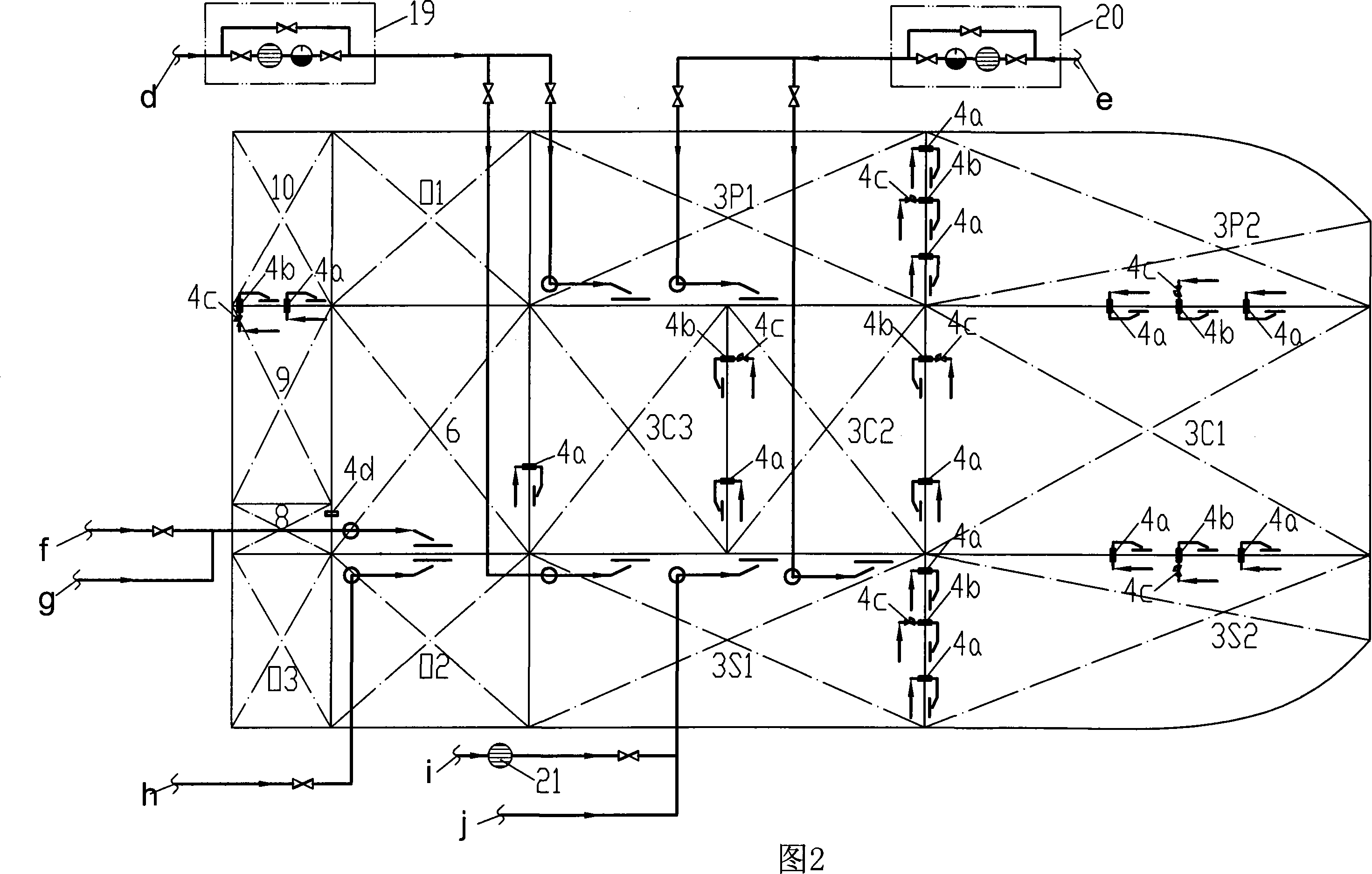

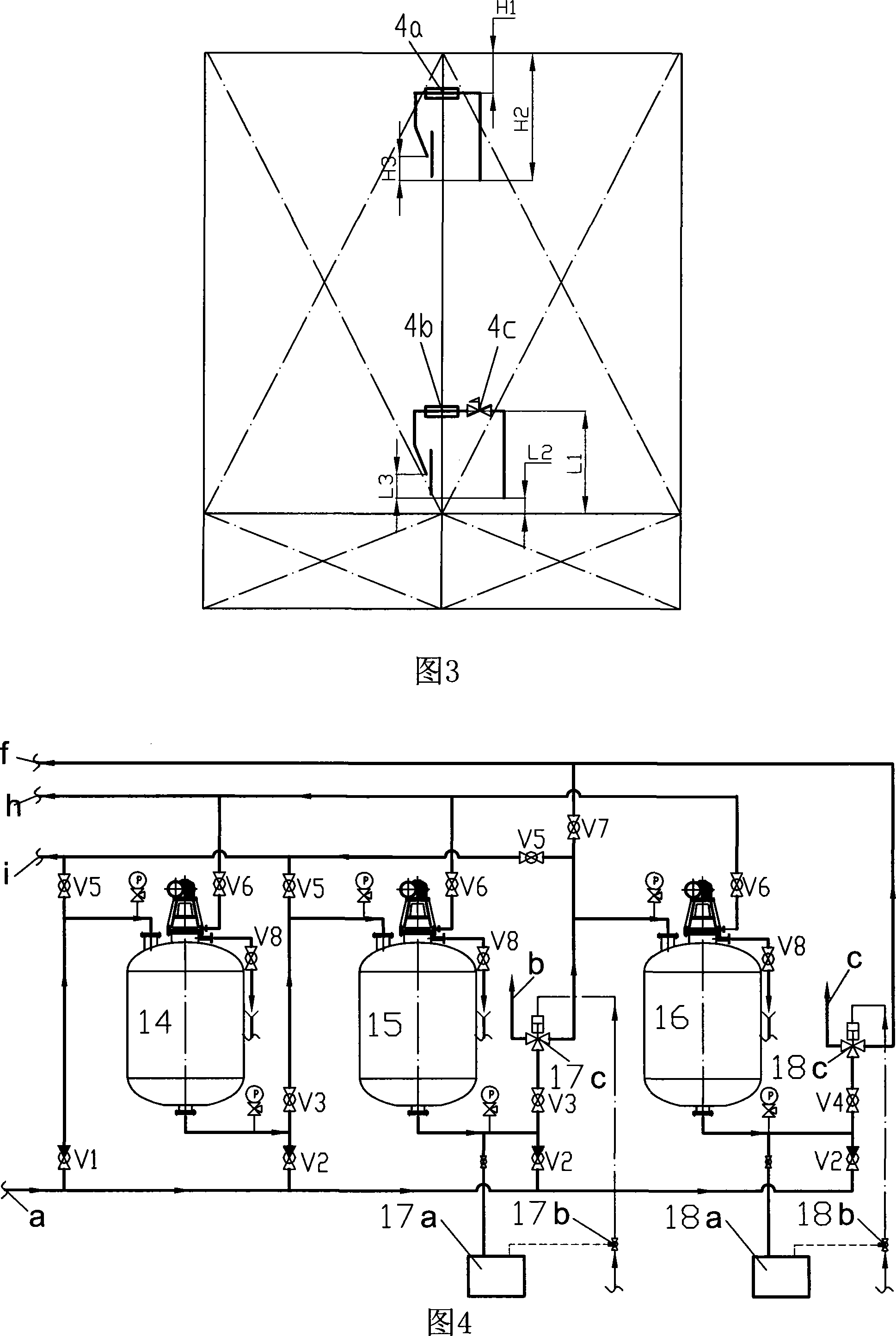

[0025] In order to gain an in-depth understanding of the device and process for treating oily sewage on this oily sewage ship, the description is as follows in conjunction with Figures 1 and 2:

[0026] The oily water in the oily water tank 1 of the ship to be received is sent to the oily water oil separation and sedimentation tank 3 by the oily water receiving device 2 . If there is tank washing water in the oily water tank 1 of the ship to be received, then use the steam reciprocating pump to pump to the oily water oil separation and sedimentation cabin 3 through the first oily water meter 19; if the oily water tank 1 of the ship to be received is tank Bottom water is then sucked to the oily sewage oil separation and sedimentation tank 3 through the second oily sewage meter 20 by a vacuum receiving device; Oily sewage oil separation sedimentation tank 3.

[0027] The oily sewage oil separation and sedimentation tank 3 has five cabins in total, the starboard side has the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com