Oil-water separation technology and equipment for spilled oil recovery robot

A technology for oil-water separation and oil spill recovery, which is applied in the direction of liquid separation, separation methods, and immiscible liquid separation, etc. It can solve the problems of decreased operating efficiency of autonomous recovery robots, low oil content in oil skimmer recovery systems, etc., and achieves market promotion Competitiveness, improvement of recovery efficiency and recovery rate, effect of increasing oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

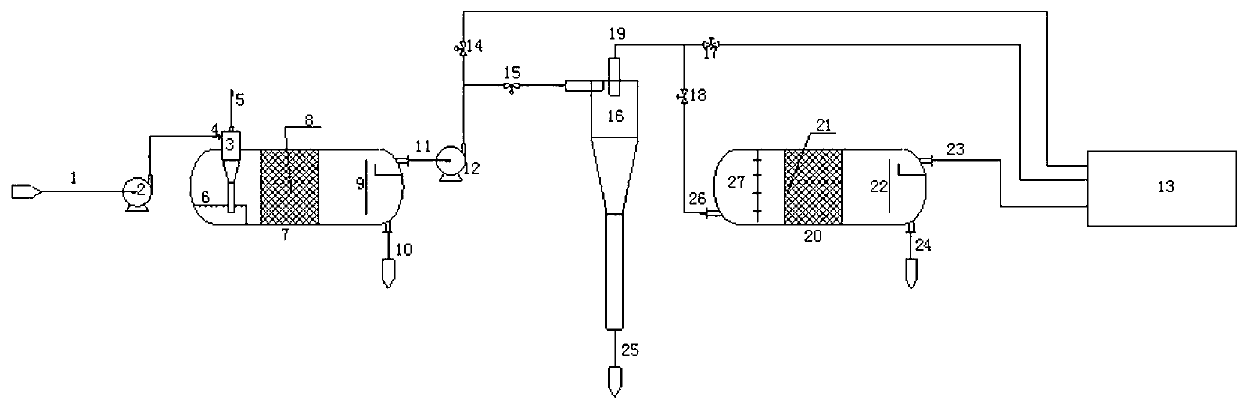

[0027] Oil skimmer recovery oil-water mixture flow rate 10m 3 / h, the oil content is 75%, after being separated by the primary oil-water separator, the oil content of the higher concentration outlet is 93.4%, and the flow rate is 8m 3 / h, delivered to the oil storage bag by the screw pump; the oil content rate of the lower concentration outlet is 1%, and the flow rate is 2 m 3 / h, discharged into the sea.

Embodiment 2

[0028] Example 2: The present invention can also be realized through the following technical solutions:

[0029] Oil skimmer recovery oil-water mixture flow rate 20m 3 / h, the oil content is 40%, after being separated by the primary oil-water separator, the oil content of the lower concentration outlet is 1%, and the flow rate is 8 m 3 / h, discharged to the sea; the oil content rate of the higher concentration outlet is 66%, and the flow rate is 12 m 3 / h, transported to the secondary oil-water separator by the screw pump; after the secondary separation, the oil content of the higher concentration outlet of the secondary oil-water separator reaches 92.7%, and the flow rate is 8.5 m 3 / h, enter the oil storage bag; the oil content rate of the lower concentration outlet is 1%, and the flow rate is 3.5m 3 / h, discharged into the sea.

Embodiment 3

[0030] Example 3: The present invention can also be realized through the following technical solutions:

[0031] The oil skimmer recovers the oil-water mixture with a flow rate of 30m 3 / h, the oil content is 5%, after being separated by the primary oil-water separator, the oil content of the lower concentration outlet is 1%, and the flow rate is 20 m 3 / h, discharged to the sea; the oil content rate of the higher concentration outlet is 13%, and the flow rate is 10m 3 / h, transported by the screw pump to the secondary oil-water separator; after the secondary separation, the oil content of the lower concentration outlet is 1%, and the flow rate is 7.5m3 / h, discharged to the sea; the oil content of the higher concentration outlet of the secondary oil-water separator reaches 49%, and the flow rate is 2.5m 3 / h, enter the third-stage oil-water separator, after the three-stage separation, the oil content rate of the lower concentration outlet of the third-stage oil-water separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com