Screening and application of yeast with high ethanol yield and low fusel oil yield in Chinese Maotai-flavor liquor production

A technology of fusel oil and ethanol, which is applied in the field of bioengineering, can solve problems such as production risks, complex processes, and various influencing factors, and achieve the effects of optimizing production processes, improving wine quality, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

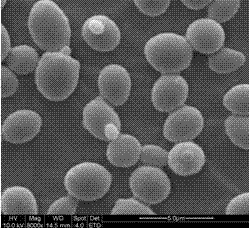

[0039] Example 1: Screening of Yeast Strains with High Ethanol Production and Low Fusel Oil Production

[0040] Dissolve 0.5g of fermented grains in 15mL sterile saline shaker and shake for 30 minutes, then dilute, spread on a TTC primary screening plate, select red colonies, and then transfer to shake flask culture for secondary screening. The content of ethanol and fusel oil was determined by specific gravity method and HS-SPME-GC-MS, and the strains with high ethanol concentration and low fusel oil concentration were screened.

[0041] TTC primary screening culture: TTC upper layer medium (g / L): glucose 5, agar 15, sterilized at 121°C for 20 minutes, when cooled to about 60°C, add TTC solution (triphenyltetrazolium hydrochloride, final concentration 0.5), immediately pour the bottom plate. TTC lower layer: YPD agar. Cultivate at 30°C for 24 hours. After visible colonies grow, pour about 12mL of TTC upper layer medium to cover the original colonies, and then incubate at 30...

Embodiment 2

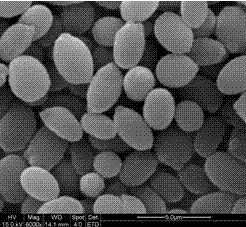

[0043] Example 2: Yeast with high ethanol production and low fusel oil production and its molecular biological identification

[0044] Molecular biological identification was carried out on the obtained yeasts with high ethanol production and low fusel oil production, and the 26srDNA fragments of the strains were amplified with yeast-specific classification and identification primers, and detected by gel electrophoresis. Sequencing comparison was then carried out to determine the species of the screened yeast. The strains were deposited in the General Microbiology Center of the China Committee for the Collection of Microbial Cultures. See Table 1 for the yeast species and preservation numbers.

[0045] Table 1 Yeast with high ethanol production and low fusel oil production

[0046] serial number

Embodiment 3

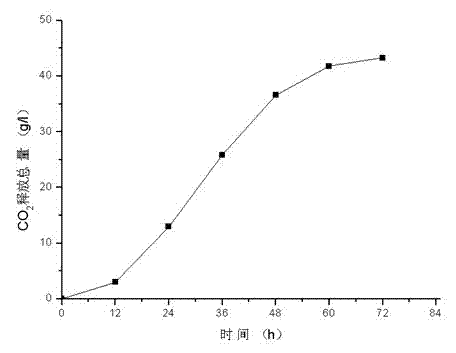

[0047] Example 3: Determination of ethanol and fusel oil produced by bacterial strain fermentation

[0048] Taking 2 strains of wine-producing yeast used in a winery as a comparison, the yeasts with different high-yield ethanol and low fusel oil yields provided by this patent were used with a pH of 5 and a sugar content of 10 o Bx Sorghum Juice Medium, 1 x 10 6 See Table 2 for the inoculum size per mL, 30°C, 150 rpm, shake flask culture for 72-96 hours, ethanol and fusel oil concentrations.

[0049] Table 2 Results of ethanol production by fermentation of yeast sorghum juice medium

[0050]

[0051] Note: The theoretical conversion rate of ethanol to sugar is 51.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com