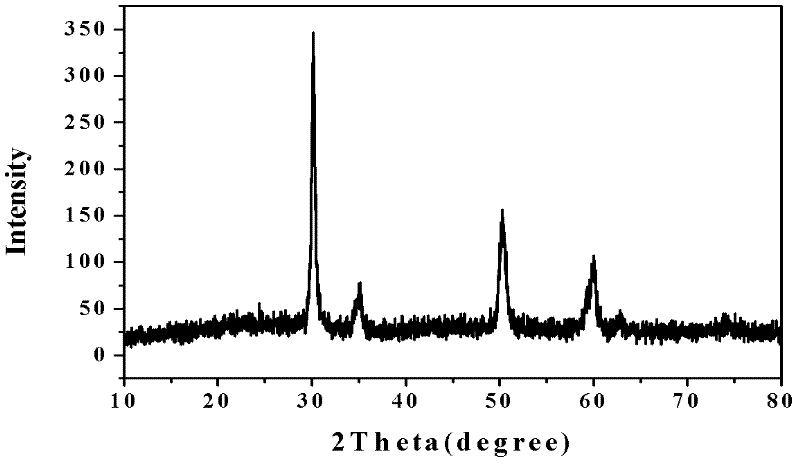

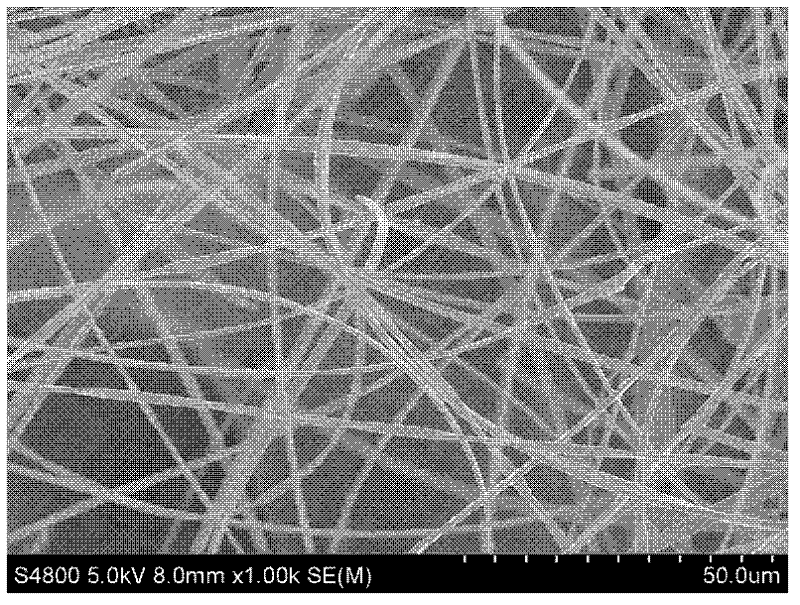

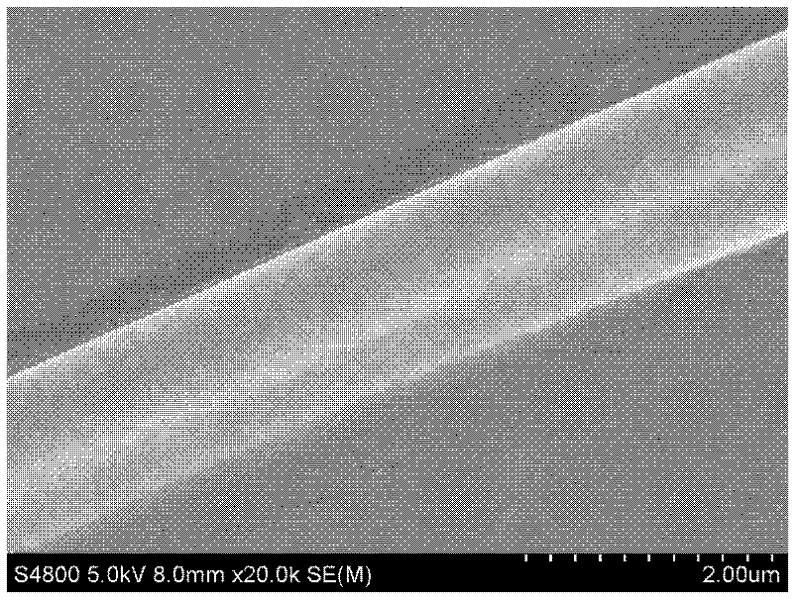

Flexible yttrium stable zirconium oxide ceramic fiber and preparation method thereof

A technology of yttrium-stabilized zirconia and ceramic fiber, which is applied in the preparation of flexible yttrium-stabilized zirconia ceramic fiber and flexible inorganic oxide fiber, can solve the problems of low strength, poor flexibility, and poor compactness, and achieve strong toughness, The effect of high density and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of sol spinning solution: add 0.3g polyvinylpyrrolidone (PVP) to 10.0g zirconium acetate solution, stir until completely dissolved, add 0.561g yttrium nitrate (Y(NO 3 ) 3 ·6H 2 0), stirred for 30mins, then added 0.528mL tetraethyl orthosilicate (TEOS), stirred until the solution was clarified, and obtained the sol spinning solution;

[0039] (2) Inject the sol-spinning solution prepared in the above steps into the electrospinning device, and under the conditions of a voltage of 20kV, a sol-spinning velocity of 2mL / h and a distance of 25.0cm between the spinning receiving plate and the electrode, the electrospinning Spinning, zirconia gel fiber is prepared under room temperature;

[0040] (3) Dry the obtained zirconia gel fiber in a 50°C oven for 12 hours, then place it in a high-temperature furnace for calcination, raise it to 600°C at a rate of 1°C / min, keep it warm for 120mins, and then heat it at a rate of 5°C / min The speed was increased to 1400° C...

Embodiment 2

[0043] (1) Preparation of sol spinning solution: add 0.3g polyvinylpyrrolidone (PVP) to 10.0g zirconium acetate solution, stir until completely dissolved, add 0.522g yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O), stirred for 25mins, then added 0.129mL tetraethyl orthosilicate (TEOS) and 0.217g aluminum nitrate (Al(NO 3 ) 3 ·6H 2 0), stirred to the clarification of solution, obtains sol spinning solution;

[0044] (2) inject the sol-spinning liquid that above-mentioned steps makes in the electrospinning device, under the conditions of voltage 20kV, sol-spinning liquid ejection speed being 2mL / h and spinning receiving distance 20.0cm, electrospinning, Zirconia gel fibers were prepared at room temperature;

[0045] (3) Put the prepared zirconia gel fiber into a 50°C oven to dry for 12 hours, then place it in a high-temperature furnace for calcination, raise the temperature to 600°C at a rate of 1.5°C / min, keep it warm for 120mins, and then heat it up at a temperature of 5°C / min. The...

Embodiment 3

[0048] (1) Preparation of sol spinning solution: add 0.567g polyvinylpyrrolidone (PVP) to 18.902g zirconium acetate solution, stir until completely dissolved, add 0.987g yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O), after stirring for 25mins, add 0.248g titanium sulfate (Ti(SO 4 ) 2 ), stirred until the solution is clarified to obtain a sol spinning solution;

[0049] (2) Inject the sol-spinning solution prepared in the above steps into the electrospinning device, and carry out under the conditions of a voltage of 20kV, a spraying speed of the sol-spinning solution of 1.5mL / h and a distance of 20.0cm between the spinning receiving plate and the electrode. Spinning, zirconia gel fiber is prepared under room temperature;

[0050] (3) Dry the obtained zirconia gel fiber in a 50°C oven for 18 hours, then place it in a high-temperature furnace for calcination, raise the temperature to 800°C at a rate of 1°C / min, and keep it warm for 60mins to obtain tetragonal phase yttrium-stabilized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com