Patents

Literature

31results about How to "Affect compactness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

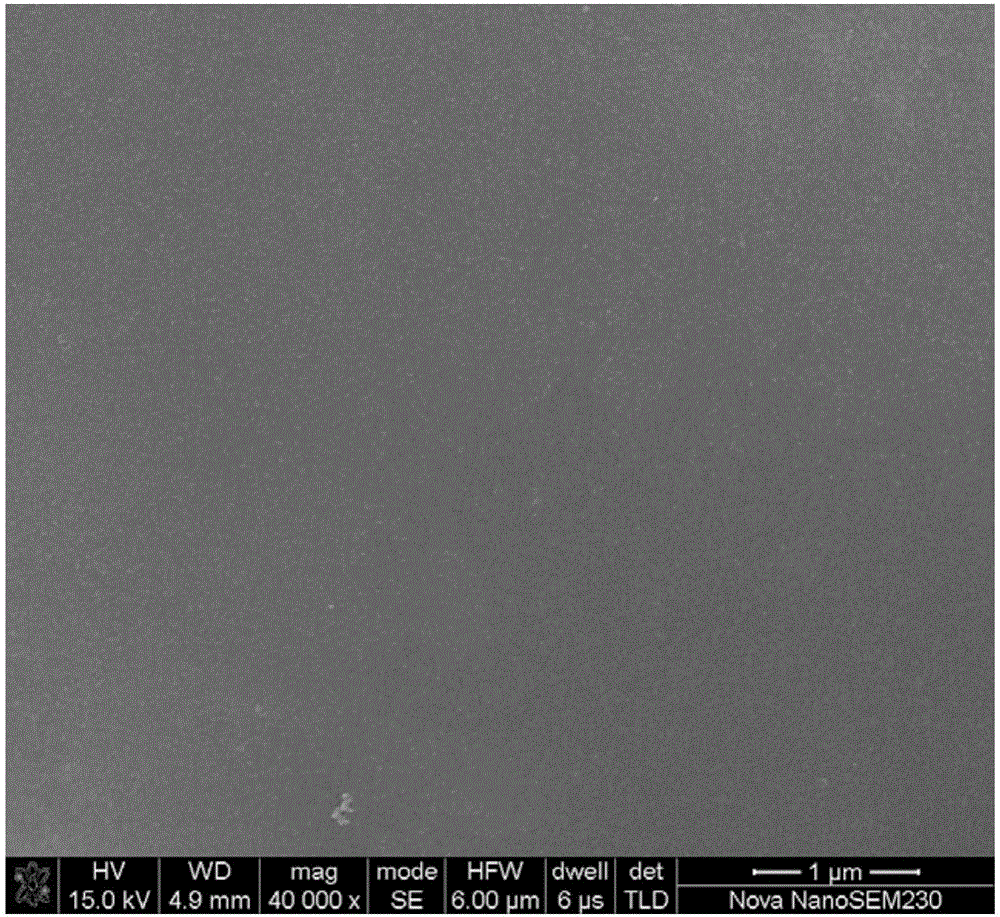

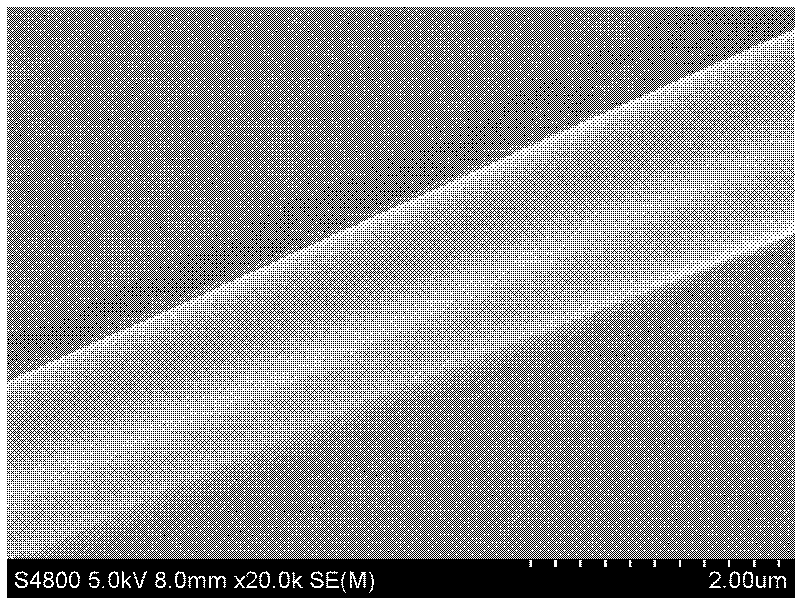

Flexible yttrium stable zirconium oxide ceramic fiber and preparation method thereof

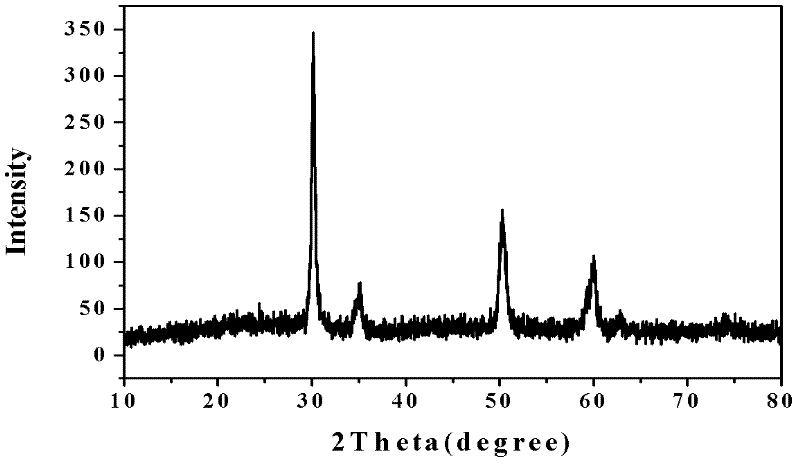

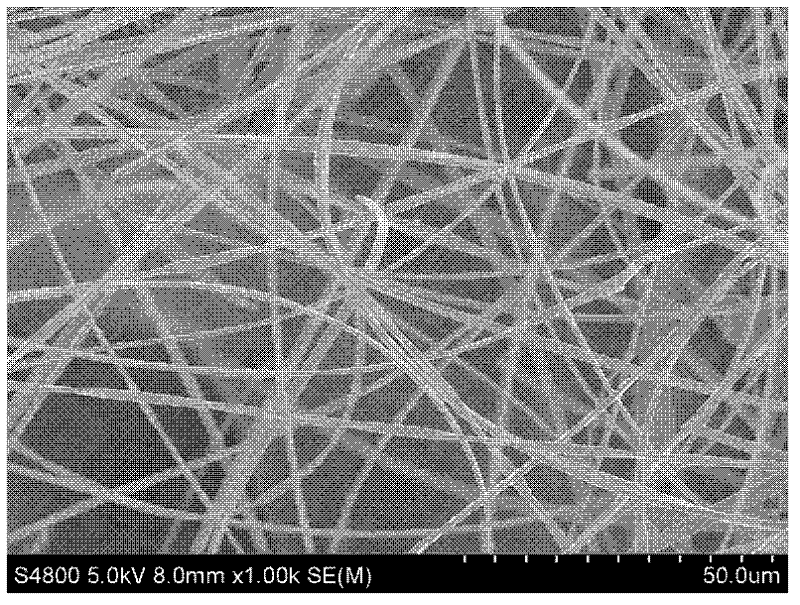

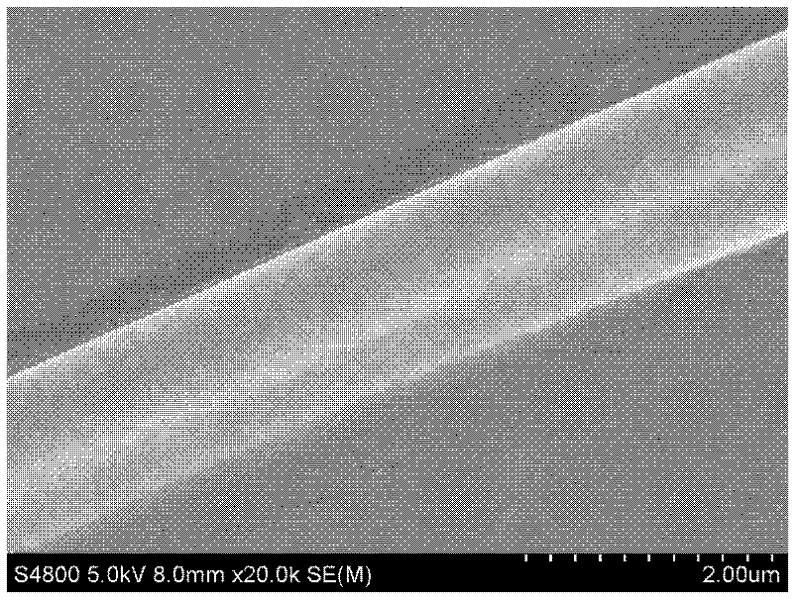

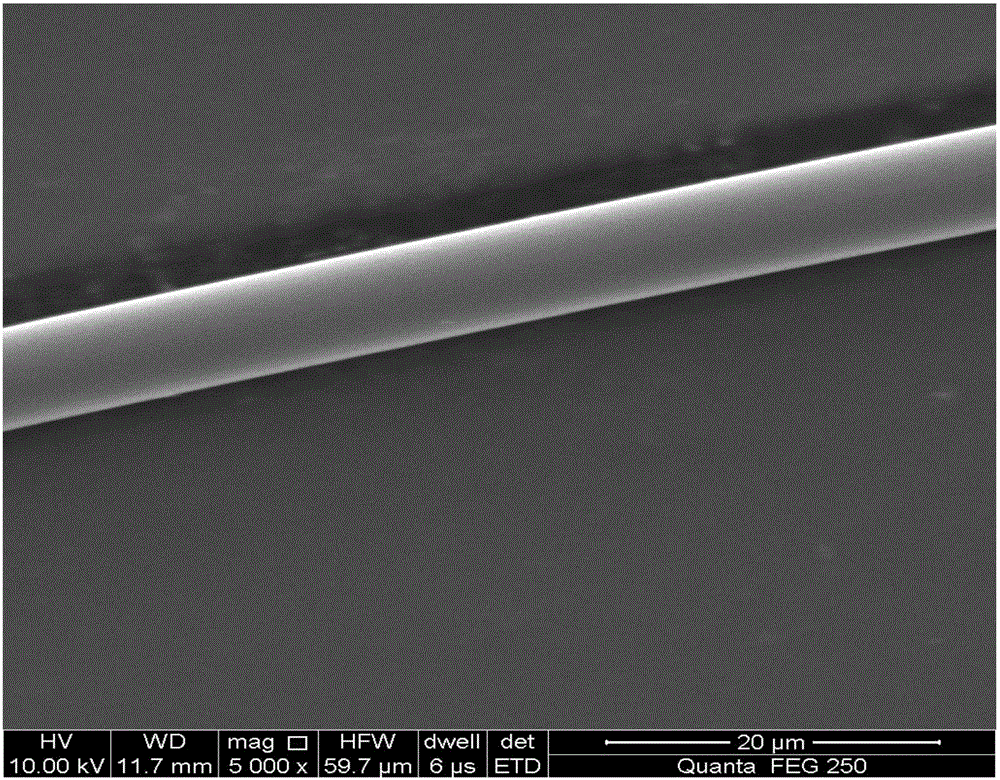

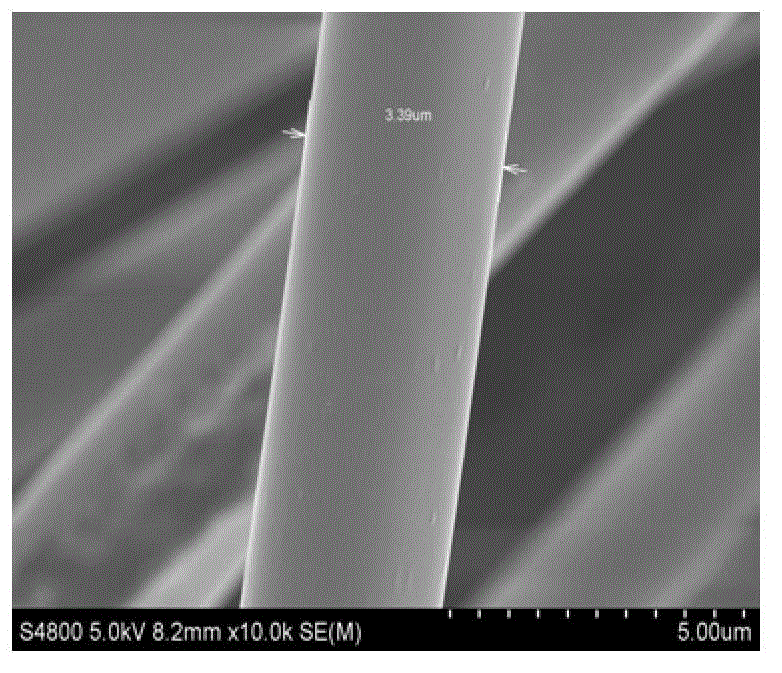

The invention relates to a flexible yttrium stable zirconium oxide ceramic fiber and a preparation method thereof. The particle diameters of zirconium oxide particles constructing the ceramic fiber are 10-400 nanometers, the diameter of the ceramic fiber is 0.5-3 mum, and the fiber is uniform and continuous, is prevented from being broken easily and has high flexibility. A zirconium oxide gel fiber is prepared by combining a sol-gel method with an electrostatic spinning technology, and the yttrium stable zirconium oxide ceramic fiber is obtained by calcining the gel fiber. The obtained yttrium stable zirconium oxide ceramic fiber has high thermal stability and excellent mechanical property, can be taken as a high-temperature catalyst carrier, a high-temperature heat insulating material aswell as a battery membrane, and can be applied to high-temperature filtering and the like. A process disclosed by the invention has high operability, and is suitable for large-scale production.

Owner:SHANDONG UNIV

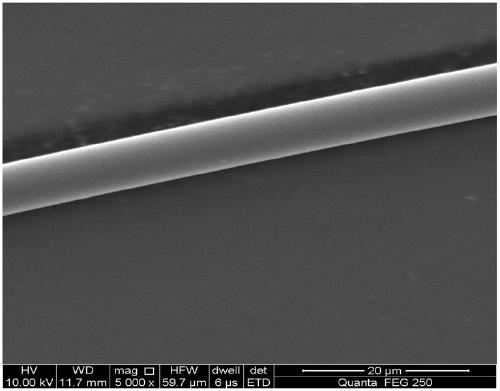

Low-density high-performance alumina-based ceramic fiber and preparation method thereof

ActiveCN106609404AImprove spinnabilityImprove performanceInorganic material artificial filamentsFiberAviation

The invention relates to a preparation method for a low-density high-performance alumina-based ceramic fiber. The method comprises the following steps: preparing spinnable alumina-based fiber precursor sol from an inorganic aluminum salt, a boron-containing additive, a silicone-containing additive and the like by using a sol-gel process; carrying out dry-process spinning so as to obtain alumina-based continuous green fibrous filaments; and subjecting the filaments to drying and sintering so as to obtain the alumina-based continuous ceramic fiber. The sol fiber prepared in the invention has good stability; preparation process is simple; the filaments can be formed without a high-molecular auxiliary agent; and the sintered fiber has low density and high strength and can be applied to high-tech fields like aviation and aerospace.

Owner:CENT SOUTH UNIV

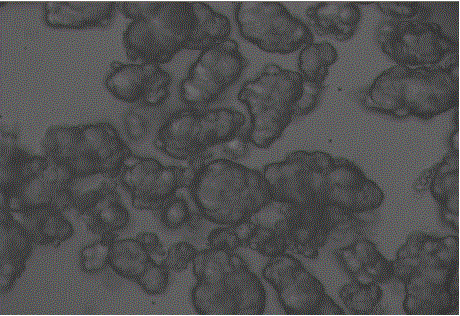

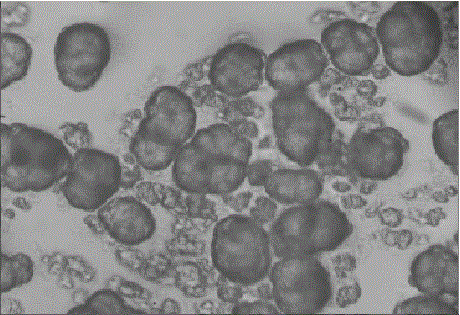

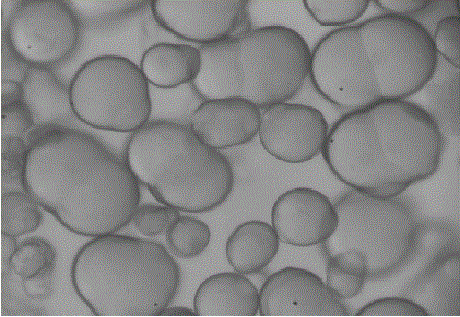

Preparation method of polyamide 6 powder for laser sintering

The invention provides a preparation method of polyamide 6 powder for laser sintering. The method comprises the following steps: mixing a polyamide 6 resin material and a solvent and putting in a reaction kettle; heating the materials to a reaction temperature in a protective atmosphere; controlling to cool the reaction kettle so that the material temperature is reduced to 70-90 DEG C, and keeping the inside-outside temperature difference in the reaction kettle within + / -25 DEG C in the cooling process; and controlling to quickly cool the materials in the kettle to below 50 DEG C. The polyamide 6 powder particles prepared in the invention have high sphericity and relatively good fluidity and are particularly suitable for the laser sintering technology.

Owner:HUNAN FARSOON HIGH TECH CO LTD

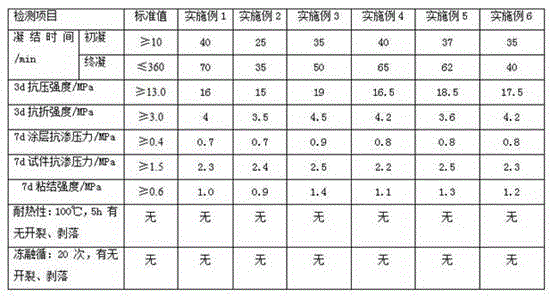

Inorganic grouting blocking material

The invention discloses an inorganic grouting blocking material, and belongs to the technical field of blocking materials. The inorganic grouting blocking material is prepared from, by mass, 75-90 parts of portland cement clinker, 3-10 parts of slag, 5-15 parts of sulphoaluminate cement, 0.5-4 parts of bentonite, 0.05-0.2 part of hydroxyethyl cellulose ester, 0.25-0.5 part of a water reducing agent, 0.005-0.1 part of lithium carbonate and 0.05-0.5 part of defoaming agent. The blocking material is mainly suitable for grouting leakage blocking of rock and soil layers, is particularly suitable for grouting leakage blocking projects for water burst in dam foundations and other parts, and has the advantages of being good in blocking effect, high in post-blocking strength, good in bonding aggregation performance and not capable of dispersing underground.

Owner:JIAHUA SPECIAL CEMENT

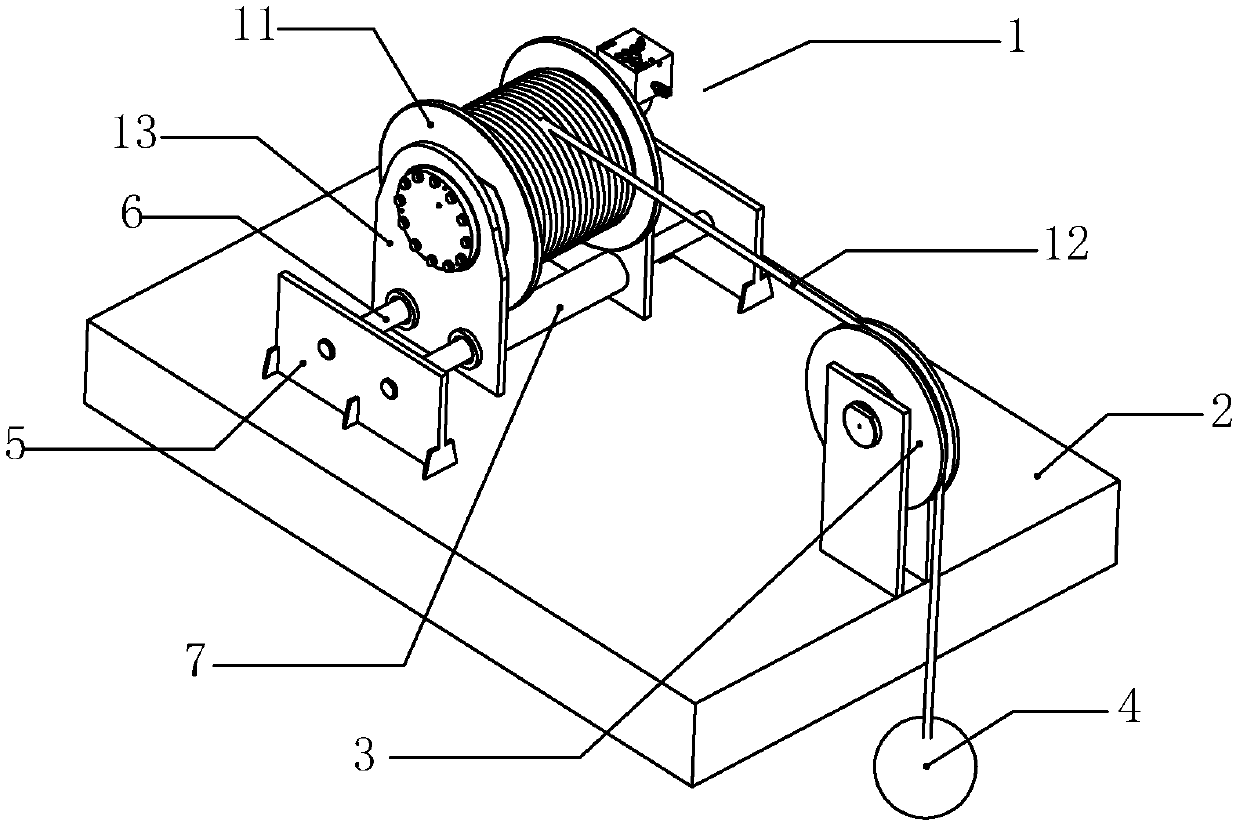

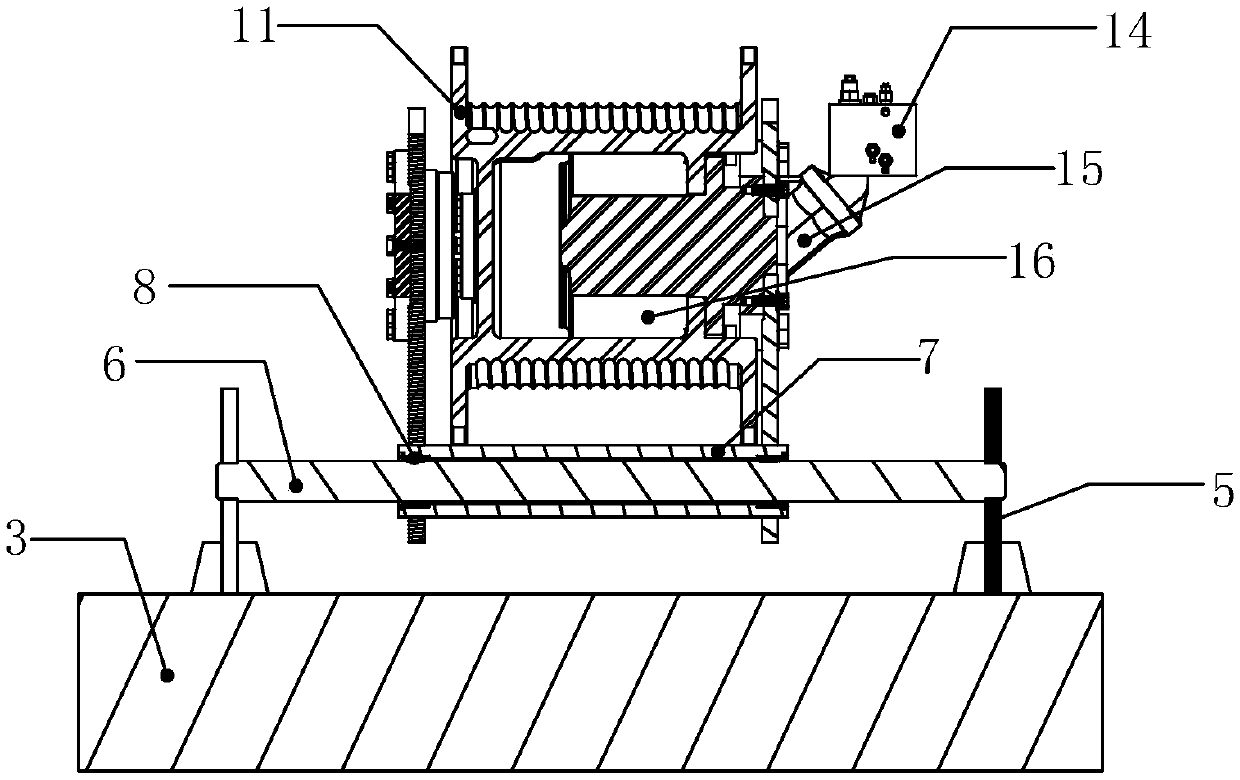

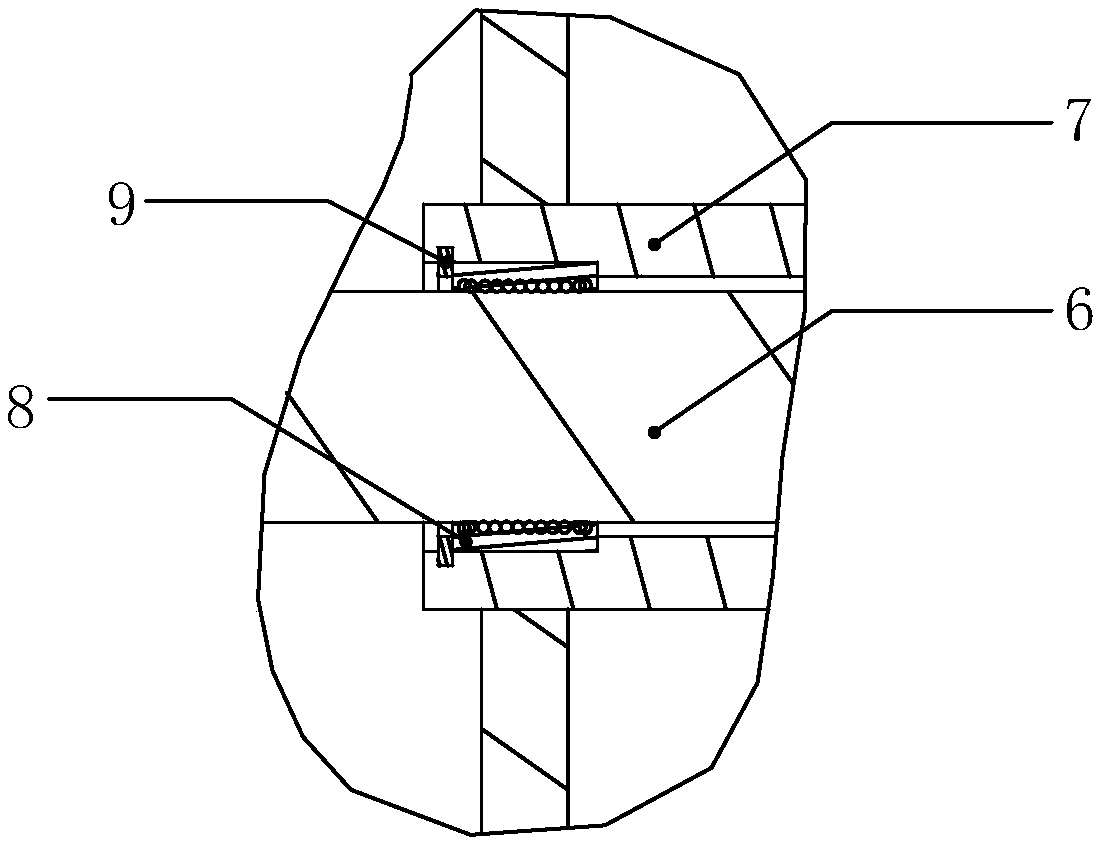

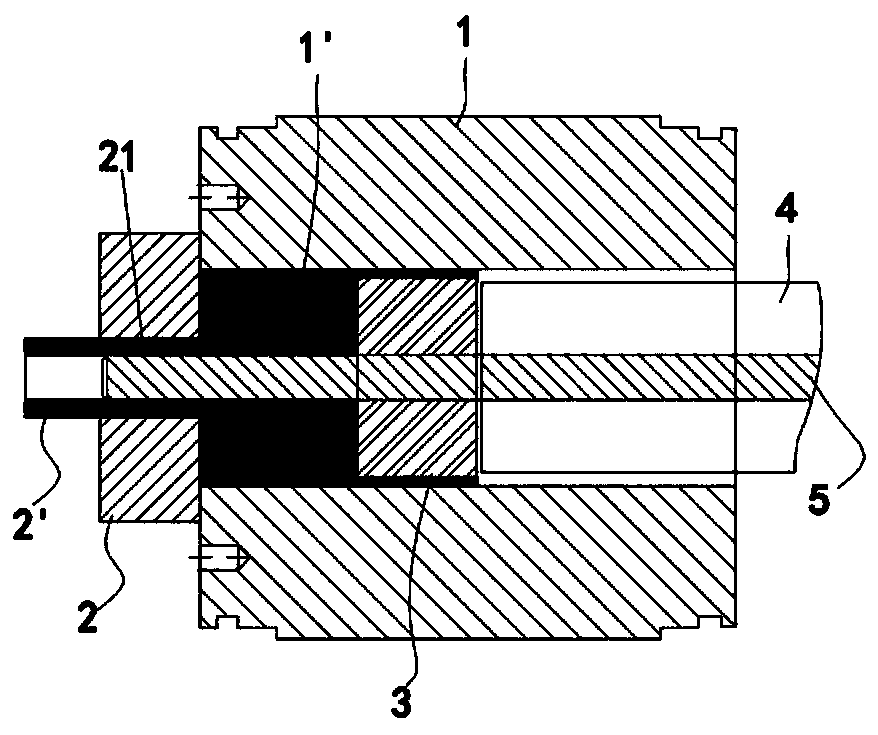

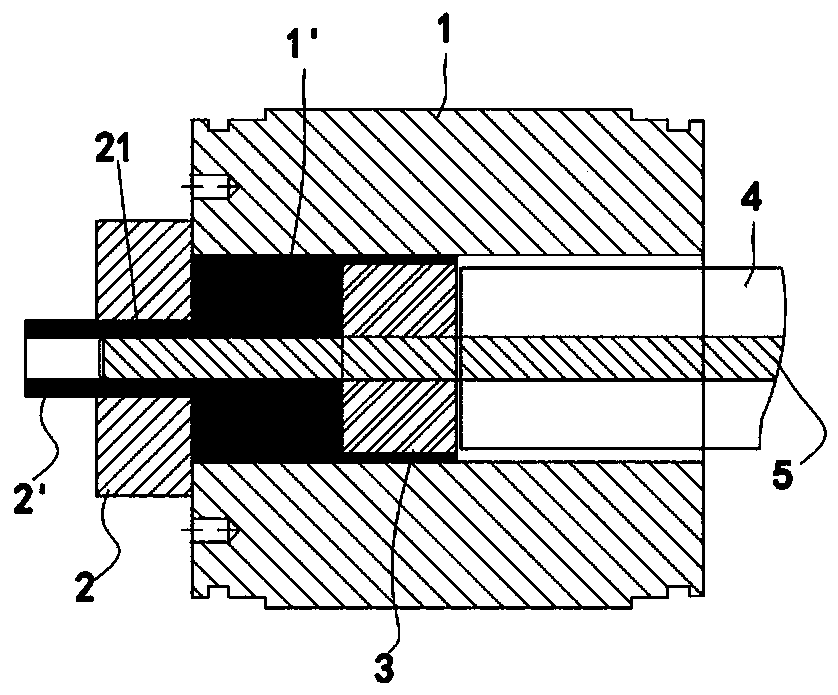

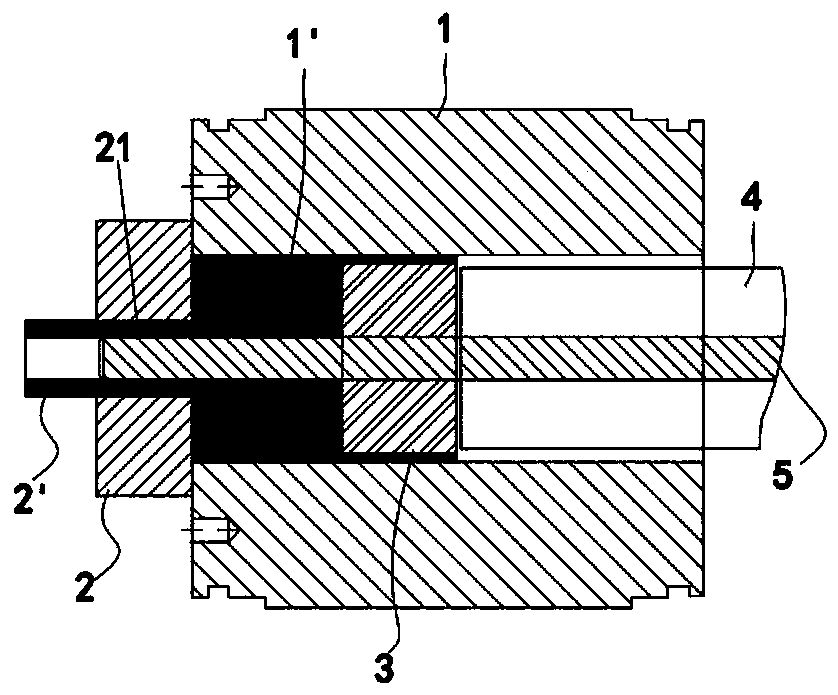

Device and method for automatic centering of rope-out deflection angle of winch

InactiveCN109553018AExtended service lifeShorten the installation distanceWinding mechanismsPull forceEngineering

The invention discloses a device and method for automatic centering of the rope-out deflection angle of a winch. The device comprises the winch and a supporting body, and a rope is wound around a winding drum of the winch; the winch is slidably arranged on the supporting body in the axis direction of the winding drum of the winch, when the winding drum of the winch rotates, an axial component of pulling force applied to the roper drives the winch to slide in the direction of the axial component, and thus the rope-out deflection angle of the winch is kept to be smaller than or equal to a presetvalue. According to the device and method for automatic centering of the rope-out deflection angle of the winch, the service life of the rope is greatly prolonged, the mounting distance between the winch and a fixed pulley can be decreased as much as possible, and thus a construction machinery structure applying the winch can be manufactured to be very compact.

Owner:埃点精细化工(上海)有限公司

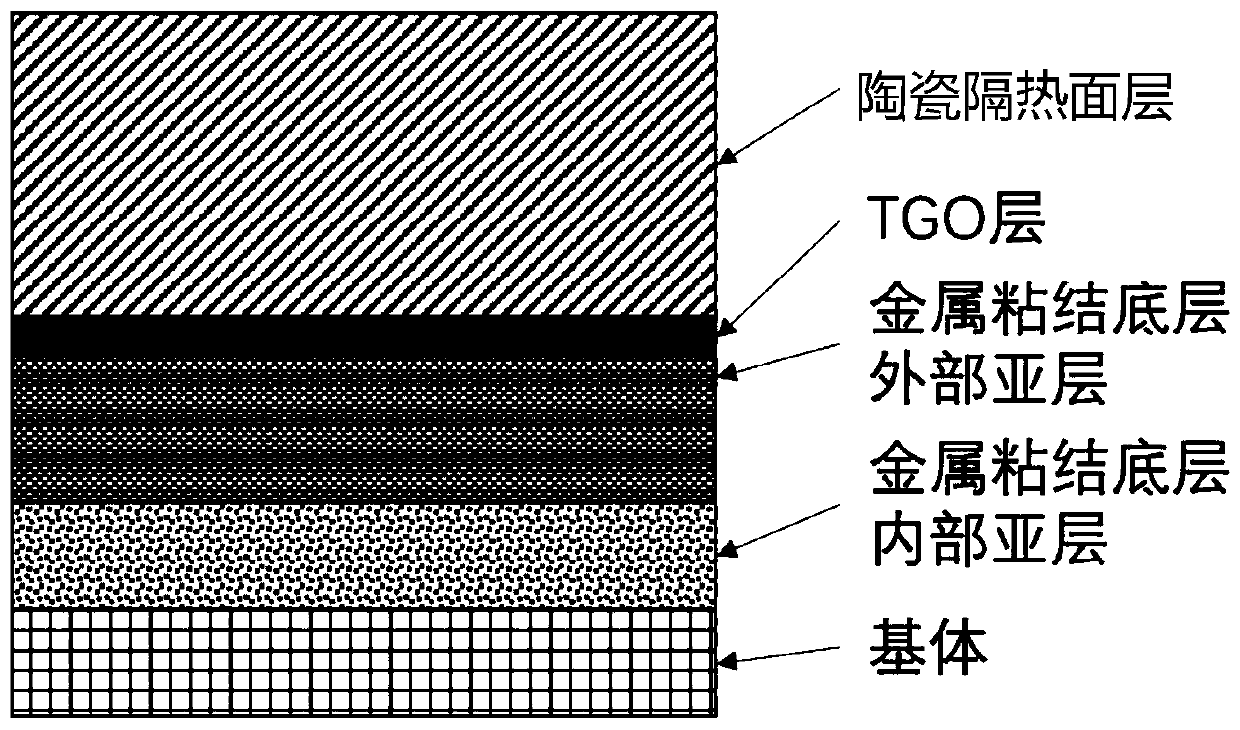

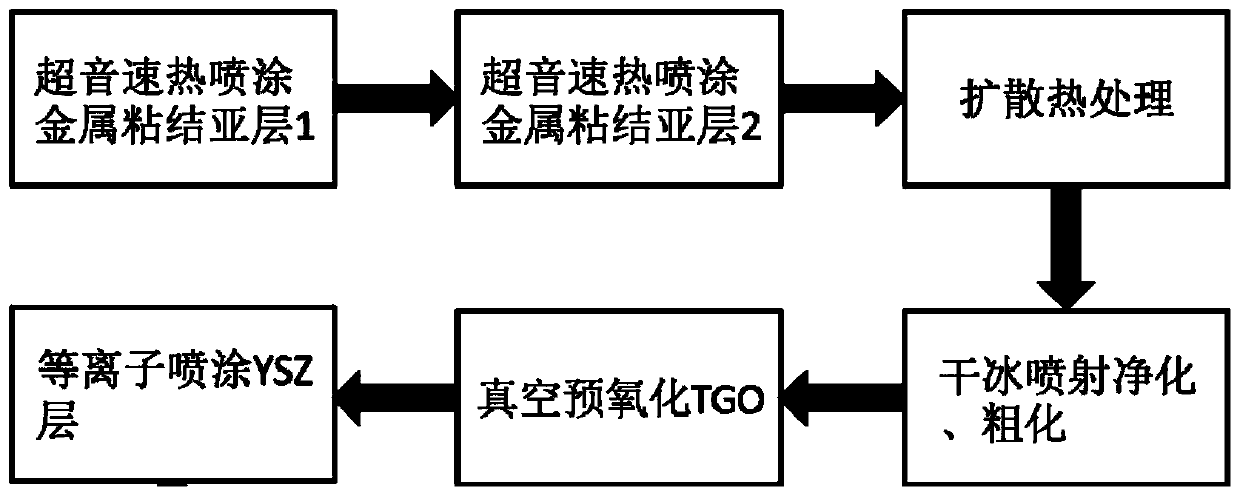

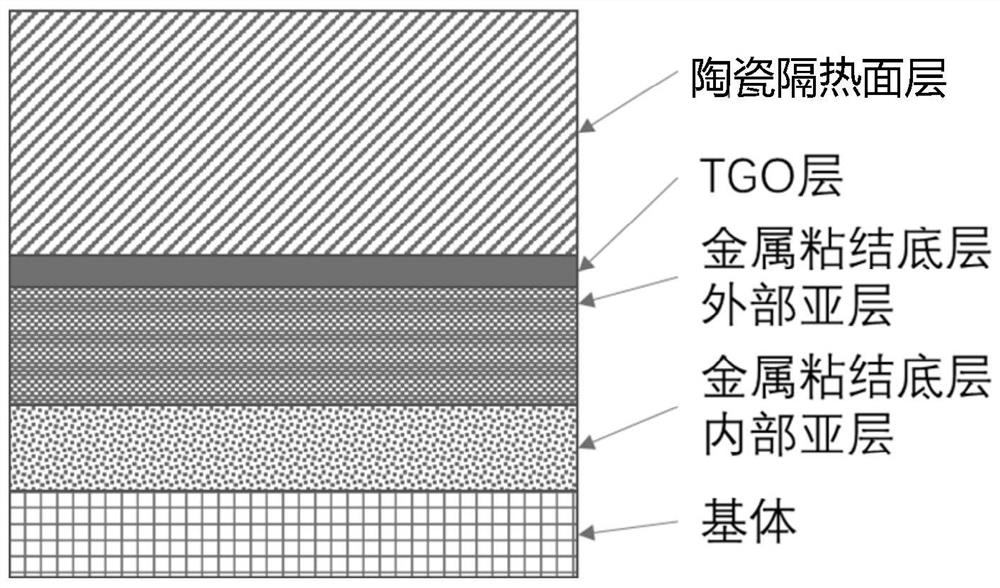

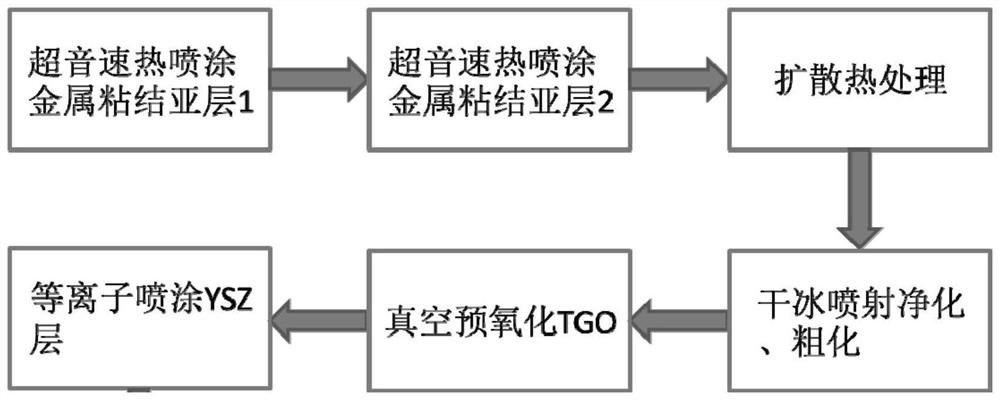

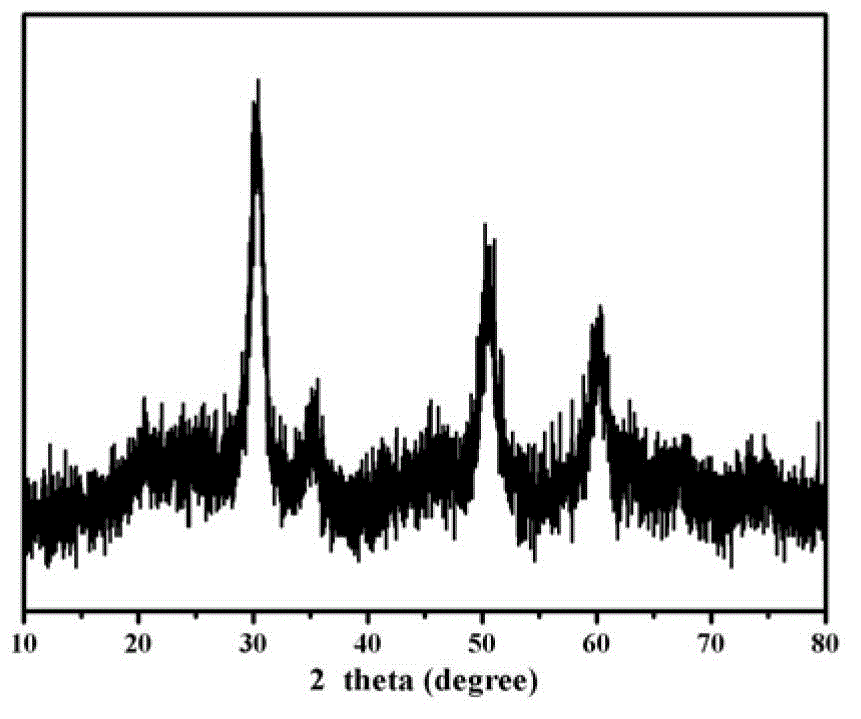

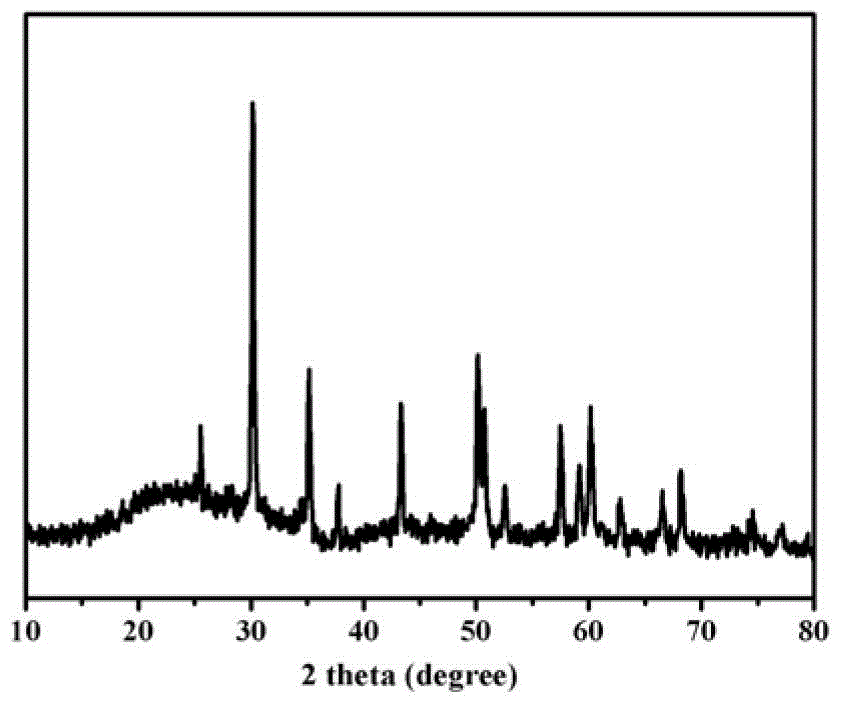

Novel preparation process for thermal barrier coating

ActiveCN109930102AHigh densityImprove selective oxidation abilityMolten spray coatingSurface layerDry ice

The invention relates to a novel preparation process for a thermal barrier coating. The novel preparation process comprises the following steps: generating a metal bonding bottom layer on the surfaceof a matrix; generating an in-situ thermal growth oxide layer (TGO); and generating a ceramic heat-insulating surface layer, wherein the TGO layer is pre-grown before the matrix serves. The TGO layercomprises alpha-aluminum oxide. A compact and continuous TGO layer which takes alpha-aluminum oxide as the principal component is preset through large-particle dry ice jetting and purifying rougheningtreatment and pre-vacuum argon gas oxidizing treatment. An oxide film has very good high-temperature oxidization resistance, prevents quick oxidization, reduces a layer thickness increase rate of theTGO layer, and achieves the purpose of reducing thermal barrier coating peel-off probability.

Owner:江苏源清动力技术有限公司

Flexible yttrium stable zirconium oxide ceramic fiber and preparation method thereof

The invention relates to a flexible yttrium stable zirconium oxide ceramic fiber and a preparation method thereof. The particle diameters of zirconium oxide particles constructing the ceramic fiber are 10-400 nanometers, the diameter of the ceramic fiber is 0.5-3 mum, and the fiber is uniform and continuous, is prevented from being broken easily and has high flexibility. A zirconium oxide gel fiber is prepared by combining a sol-gel method with an electrostatic spinning technology, and the yttrium stable zirconium oxide ceramic fiber is obtained by calcining the gel fiber. The obtained yttrium stable zirconium oxide ceramic fiber has high thermal stability and excellent mechanical property, can be taken as a high-temperature catalyst carrier, a high-temperature heat insulating material aswell as a battery membrane, and can be applied to high-temperature filtering and the like. A process disclosed by the invention has high operability, and is suitable for large-scale production.

Owner:SHANDONG UNIV

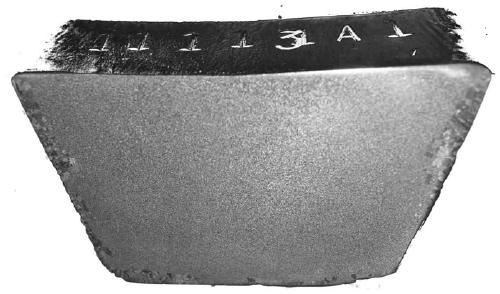

Preparation method of anti-dezincification lead-free bismuth arsenic brass pipe

The invention relates to the field of copper alloys for toilet and kitchen industries, and provides a preparation method of an anti-dezincification lead-free bismuth arsenic brass pipe. The preparation method comprises the steps of casting as a copper ingot-extrusion as a copper pipe blank-stretching-annealing-inspection of a finished copper pipe-warehousing of the finished copper pipe after smelting of the following raw materials in percentage by mass: 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, Pb not more than 0.1%, and the balance of Zn and impuritieswith a total amount not more than 0.25%.

Owner:龙岩市鸿航金属科技有限公司

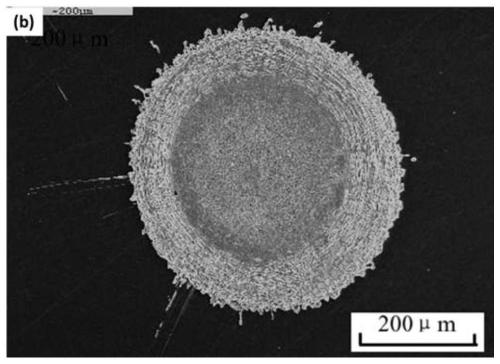

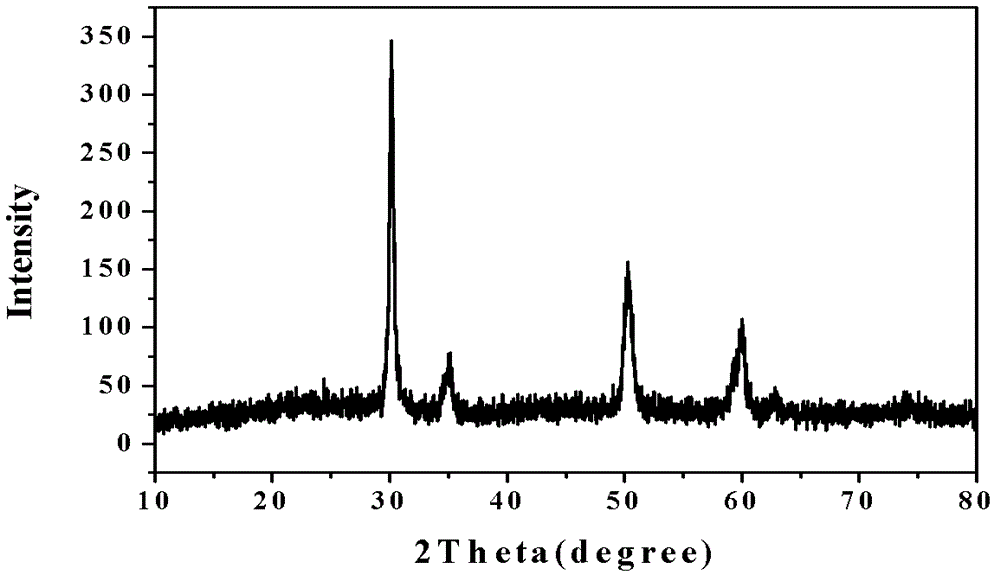

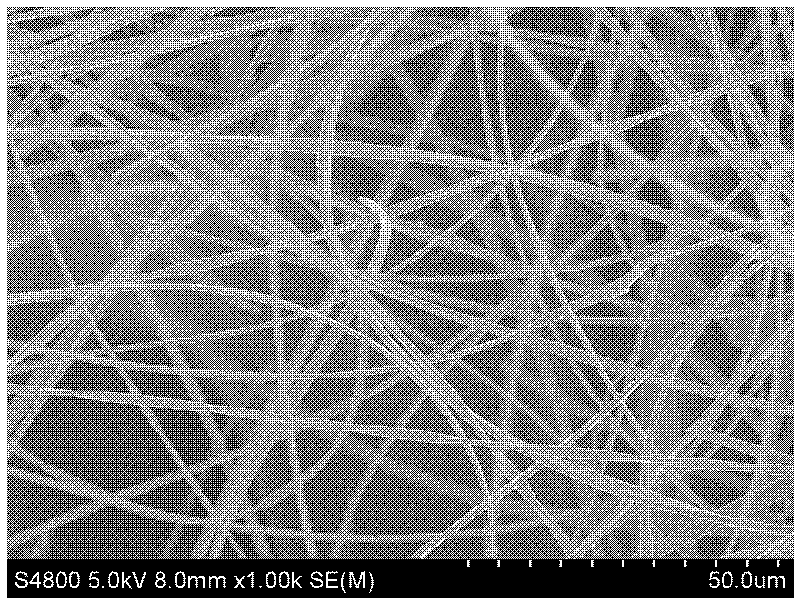

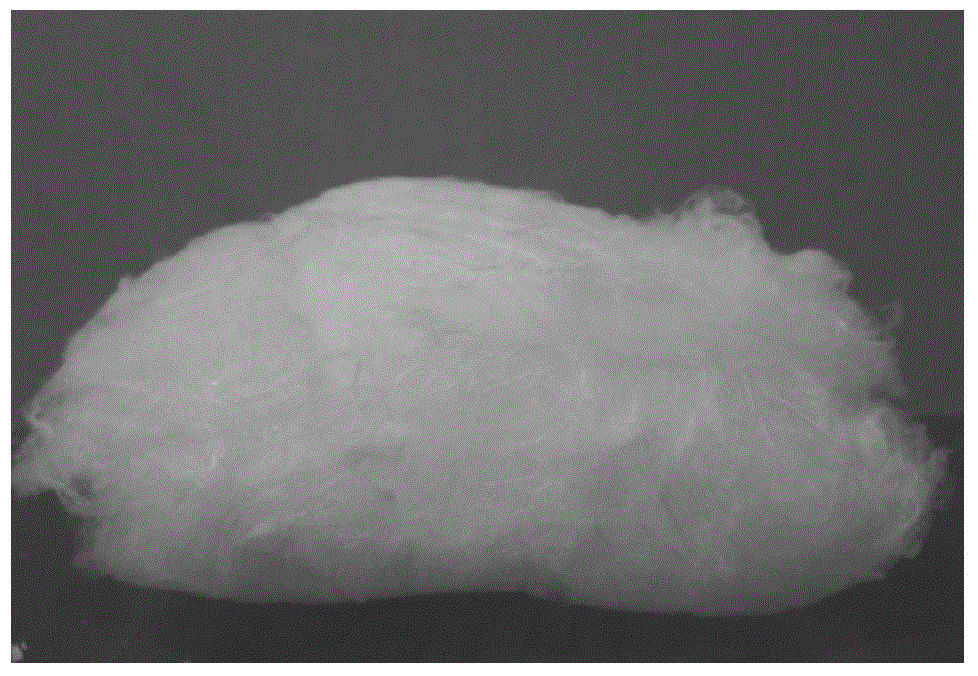

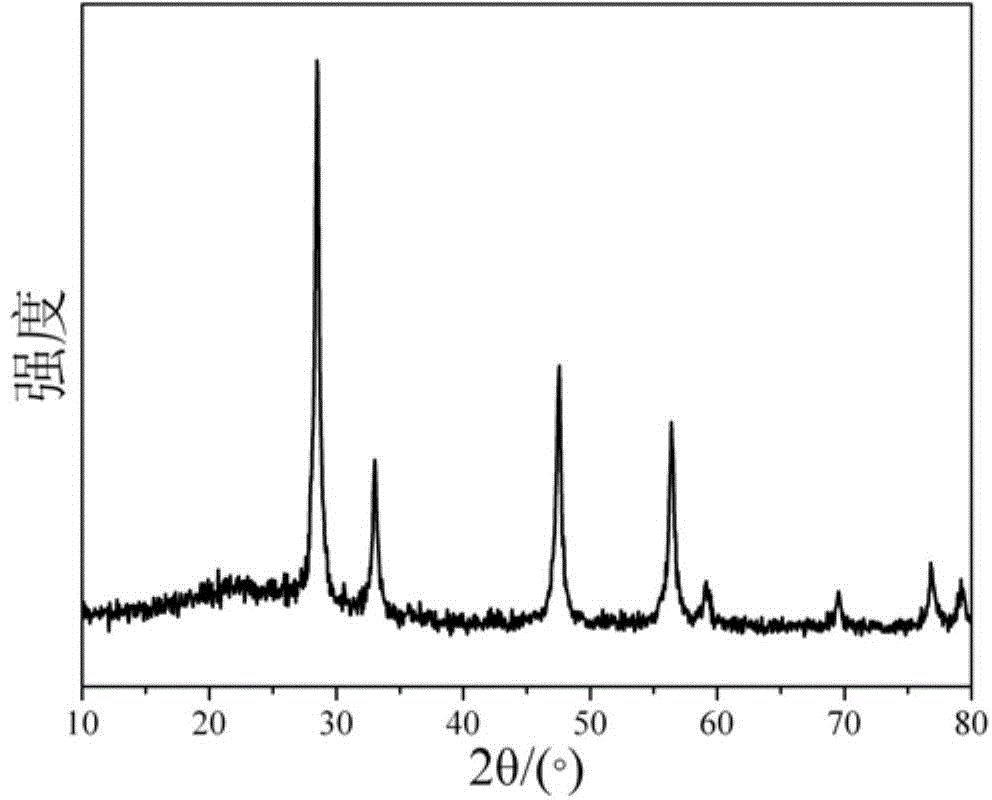

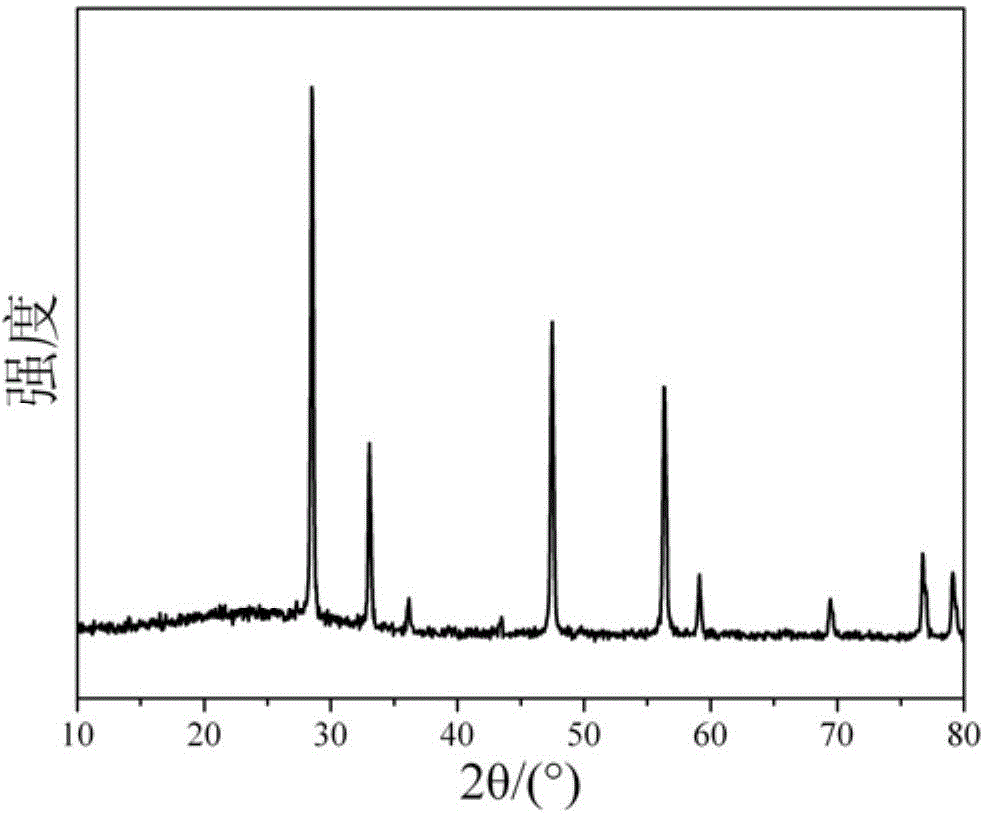

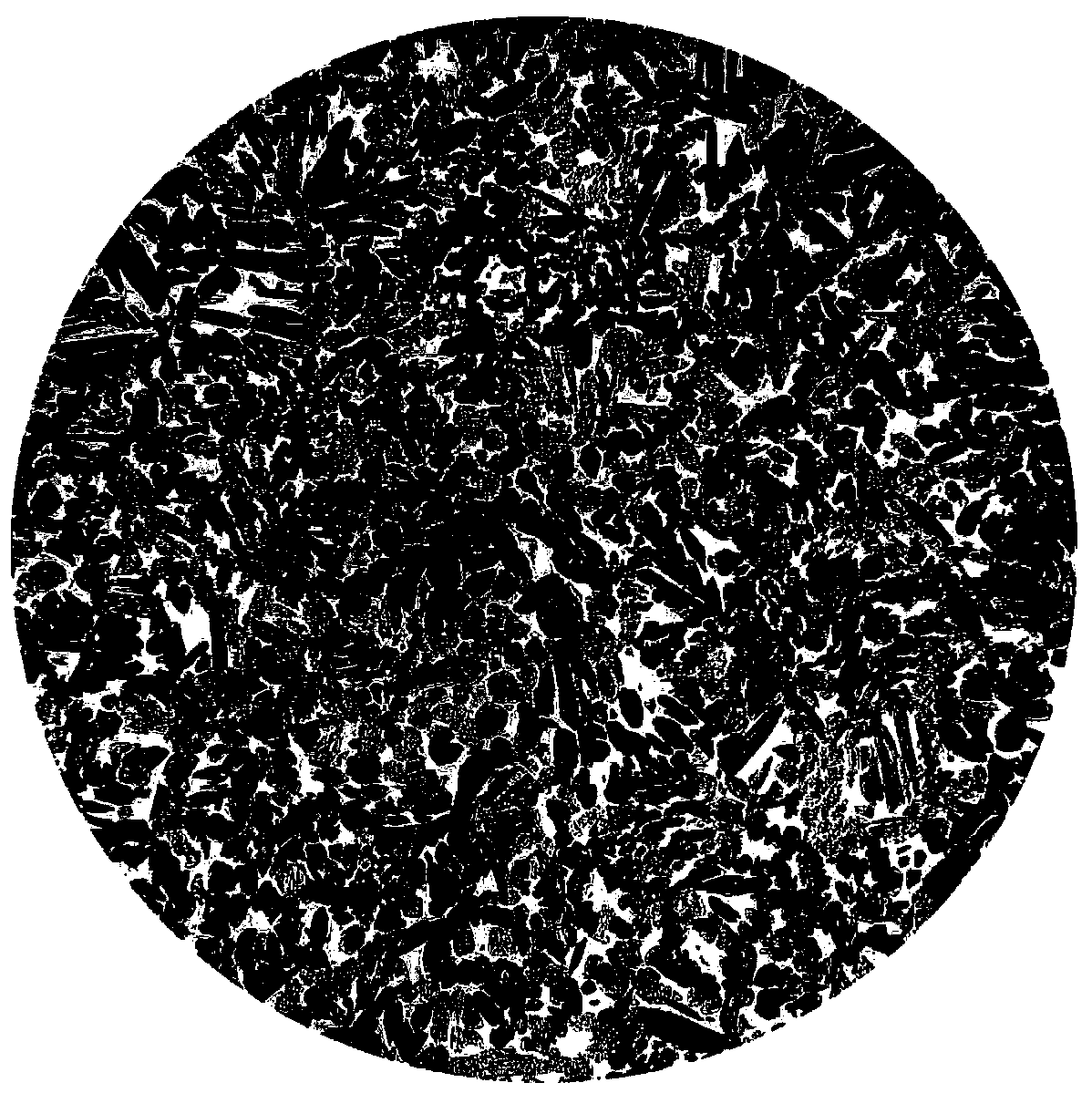

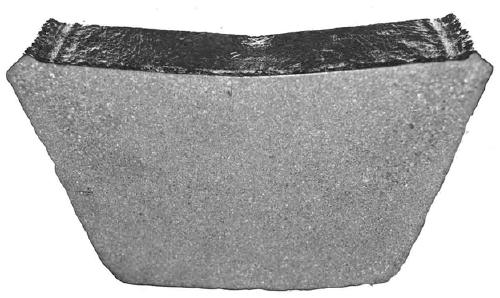

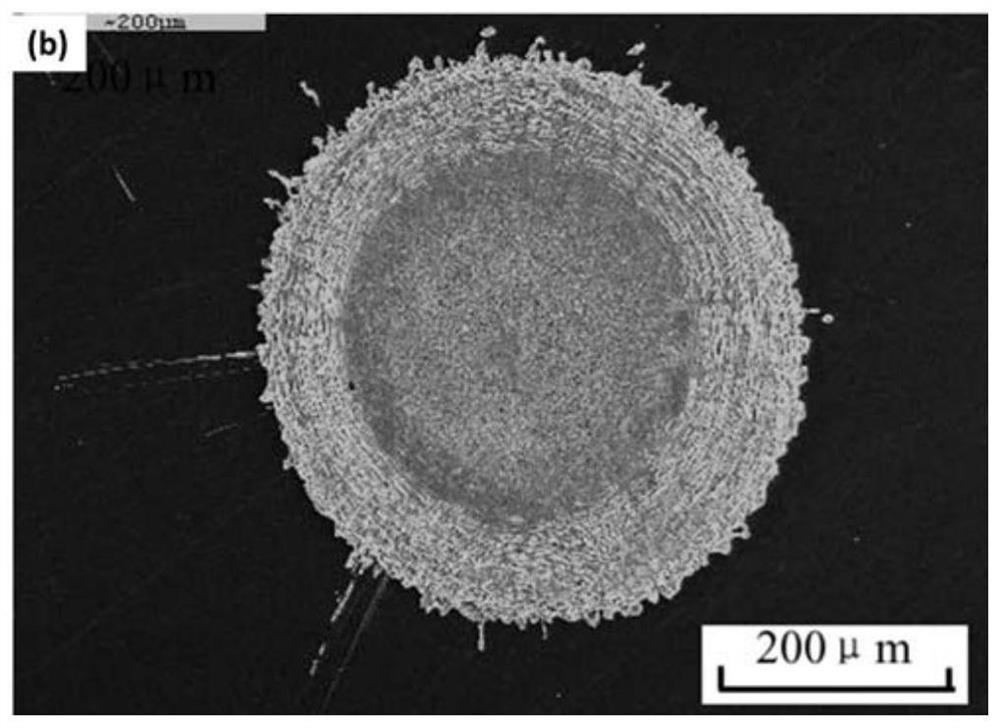

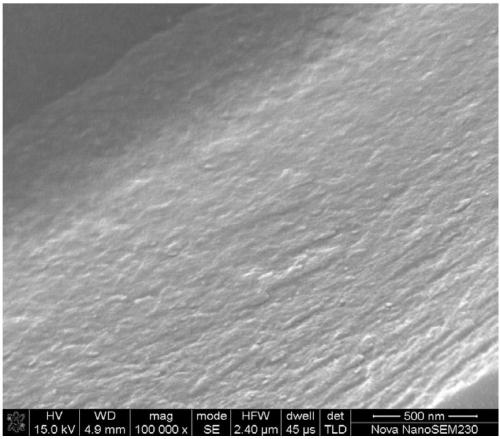

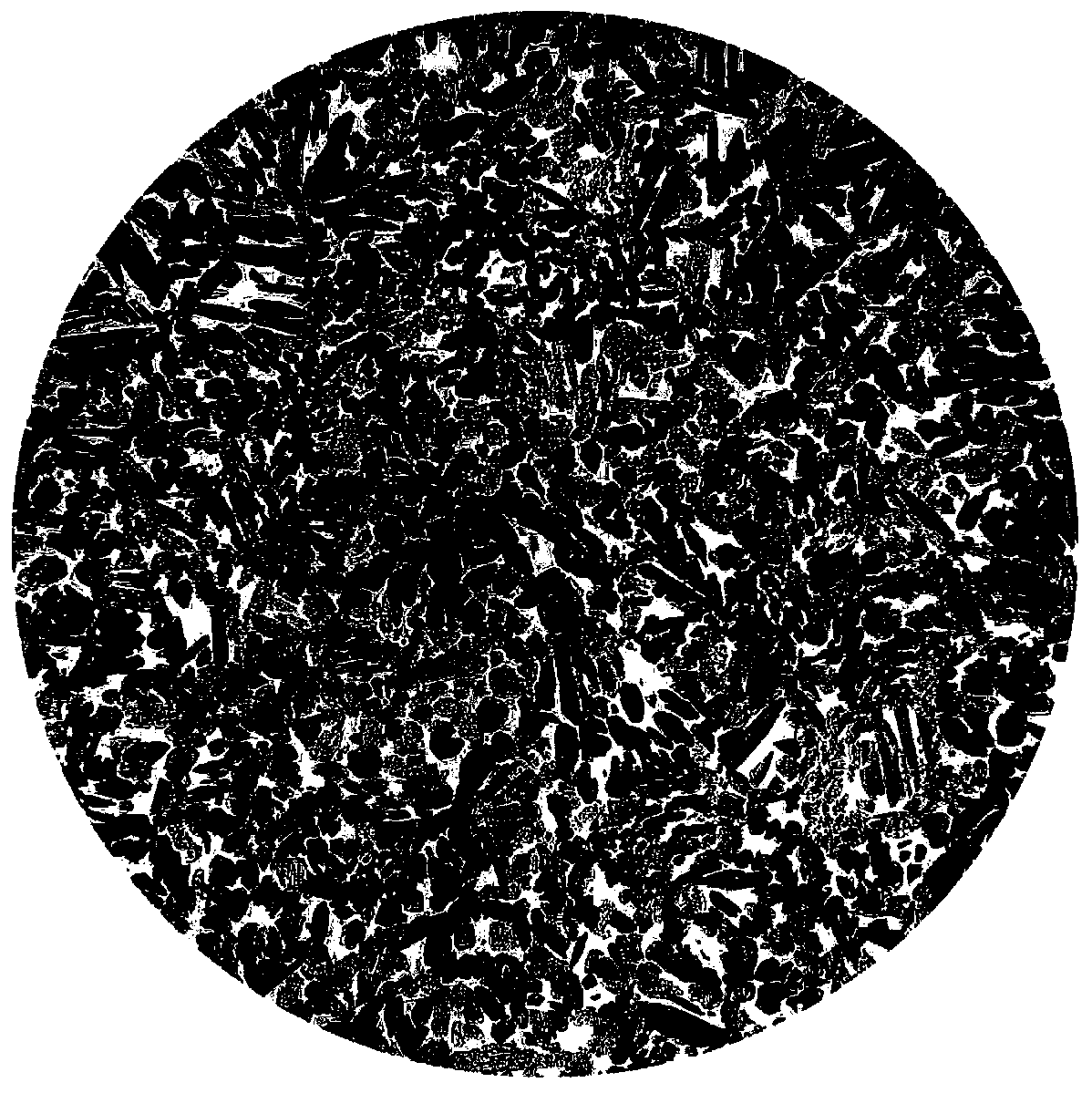

Preparation method of zirconic acid lanthanum ceramic fiber

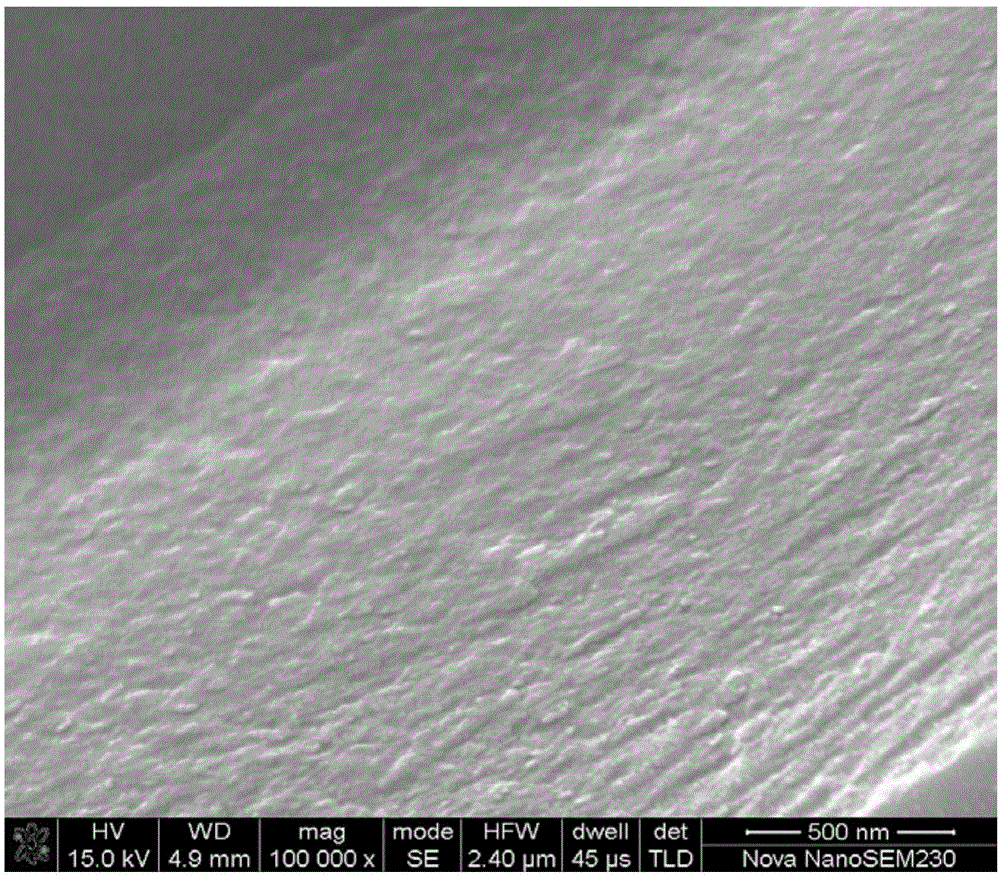

ActiveCN103553596BSmall diameterEvenly distributedInorganic material artificial filamentsFiberSpinning

The invention relates to a preparation method of a zirconic acid lanthanum ceramic fiber. The method comprises the following steps: preparing a gel fiber through a colloidal sol centrifugal fiber forming technology by using zirconium nitrate as a zirconium source, lanthanum nitrate as a lanthanum source, citric acid as a chelating agent, and water as a solvent, and calcining the gel fiber to form the zirconic acid lanthanum ceramic fiber. A precursor prepared by the invention has stable colloidal sol property and is good in filamentation property with no need of adding a polymer spinning additive. The prepared zirconic acid lanthanum ceramic fiber is good in flexibility, compact in microstructure, good in phase stability an low in heat conductivity coefficient and can be used for high-temperature thermal-insulation material, and the crystal form of the zirconic acid lanthanum ceramic fiber is pyrochlore form.

Owner:SHANDONG UNIV

Preparing method for anti-dezincification leadless bismuth arsenic extruded brass rod

The invention relates to the field of copper alloys for the bathroom and kitchen industry and provides a preparing method for an anti-dezincification leadless bismuth arsenic extruded brass rod. The preparing method comprises the step of smelting 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, smaller than 0.1% of Pb, the balance Zn and smaller than or equal to 0.25% of impurities to obtain the solid brass rod by the processes of lead casting and extruding.

Owner:龙岩市鸿航金属科技有限公司

Production method of anti-dezincification and unleaded lead-cast brass ingot

The invention relates to the field of copper alloys for kitchenware industries, and provides a production method of an anti-dezincification and unleaded lead-cast brass ingot which is good in anti-dezincification corrosion property, high in strength, and good in machining property. The production method comprises the steps that the following raw materials of, by mass, 61-63% of Cu, 0.5-0.9% of Bi,0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, less than 0.1% of Pb and the balance Zn and impurities with the total amount being less than or equal to 0.25% are smelted, and then subjected to lead casting, and the brass ingot is prepared.

Owner:龙岩市鸿航金属科技有限公司

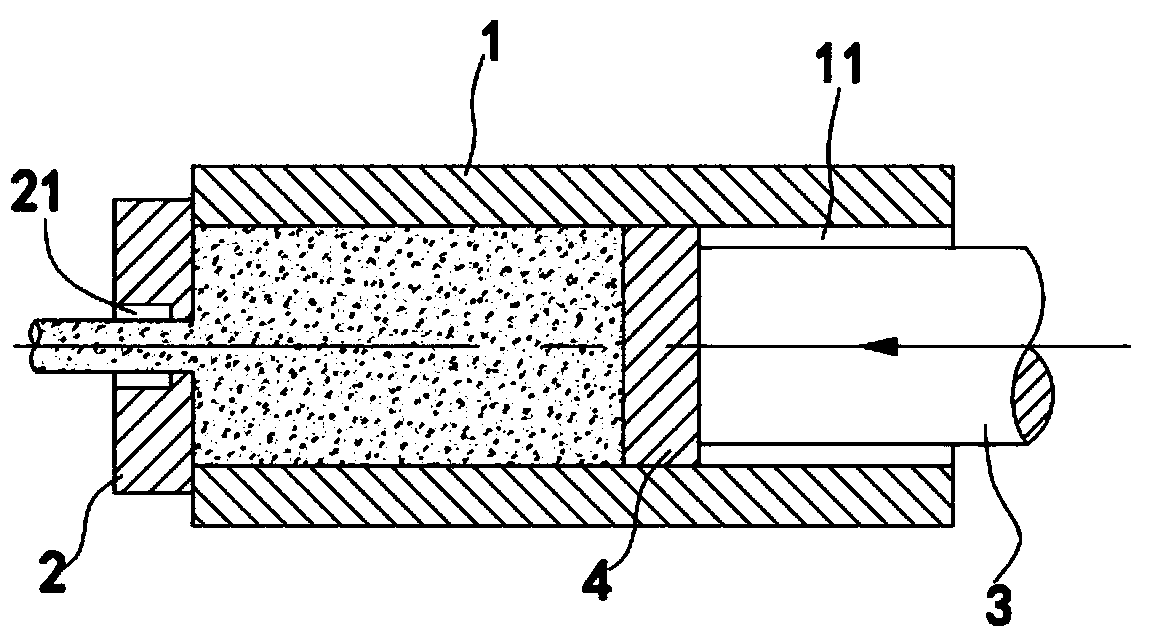

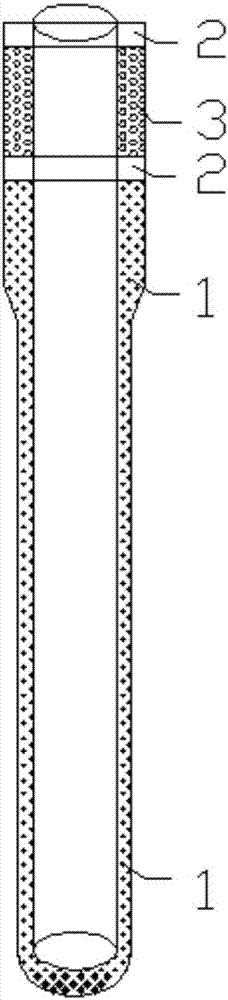

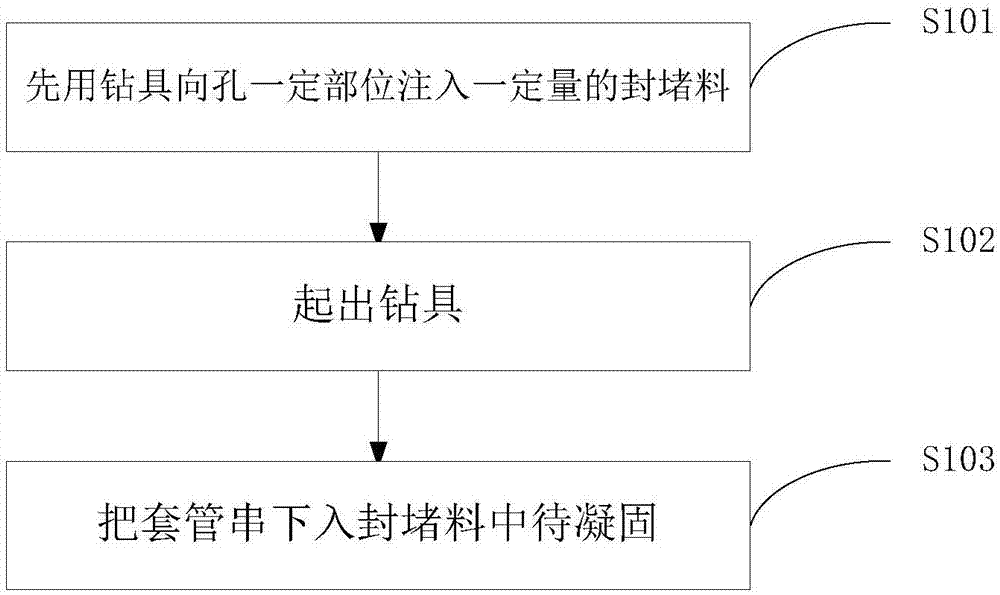

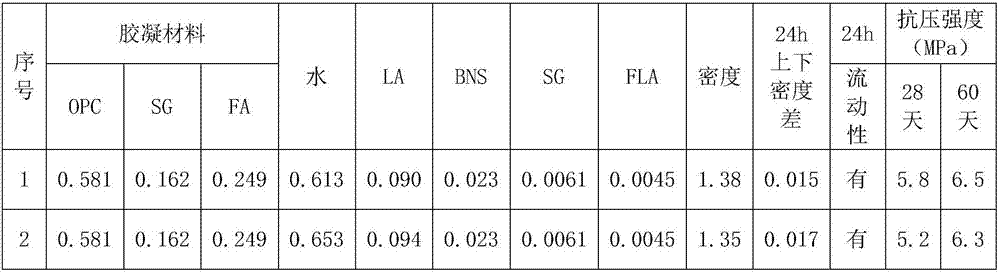

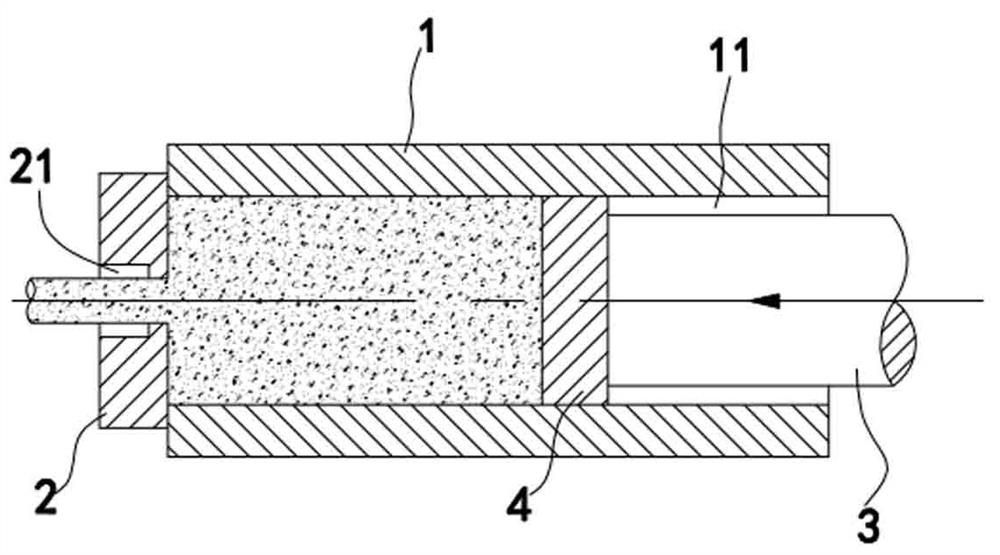

Sealing and blocking device and method for geothermal holes only extracting heat rather than water

PendingCN107288578AIncrease full rateExtend thickening timeSealing/packingPotable waterWell drilling

The invention belongs to the technical field of heat exchange of geothermal holes only extracting heat rather than water, and discloses a sealing and blocking device and method for the geothermal holes only fetching heat rather than water. A drilling slurry layer is arranged and fills the outer side of a casing pipe inside a drilled well, and the upper end of the drilling slurry layer is filled with a spacer fluid layer; the upper end of the spacer fluid layer is filled with a blocking material, and the upper end of the blocking material is filled with a spacer fluid layer; the blocking material can highly fill the annular gaps, and cement is low in flowing resistance and not prone to being leaked; the blocking material and drilling fluid are hardly mixed; and the thickening time of the blocking material is long and the mobility of the blocking material is good. As for the blocking method, the certain quantity of blocking material is injected to a certain portion of a hole with a drilling tool; the drilling tool is lifted out; and a casing pipe string is placed downhole into the blocking material to wait for solidification. The sealing and blocking device and method are more effective specific to small annular gaps or large annular gaps, are particularly suitable for sealing holes of guide pipes and casing pipes, meet the technical requirement of the heat supply technique of the geothermal holes only fetching heat rather than water, and effectively protect the blocking material for sealing holes and blocking water for pressure-bearing drinking water within 600 m underground.

Owner:李建峰

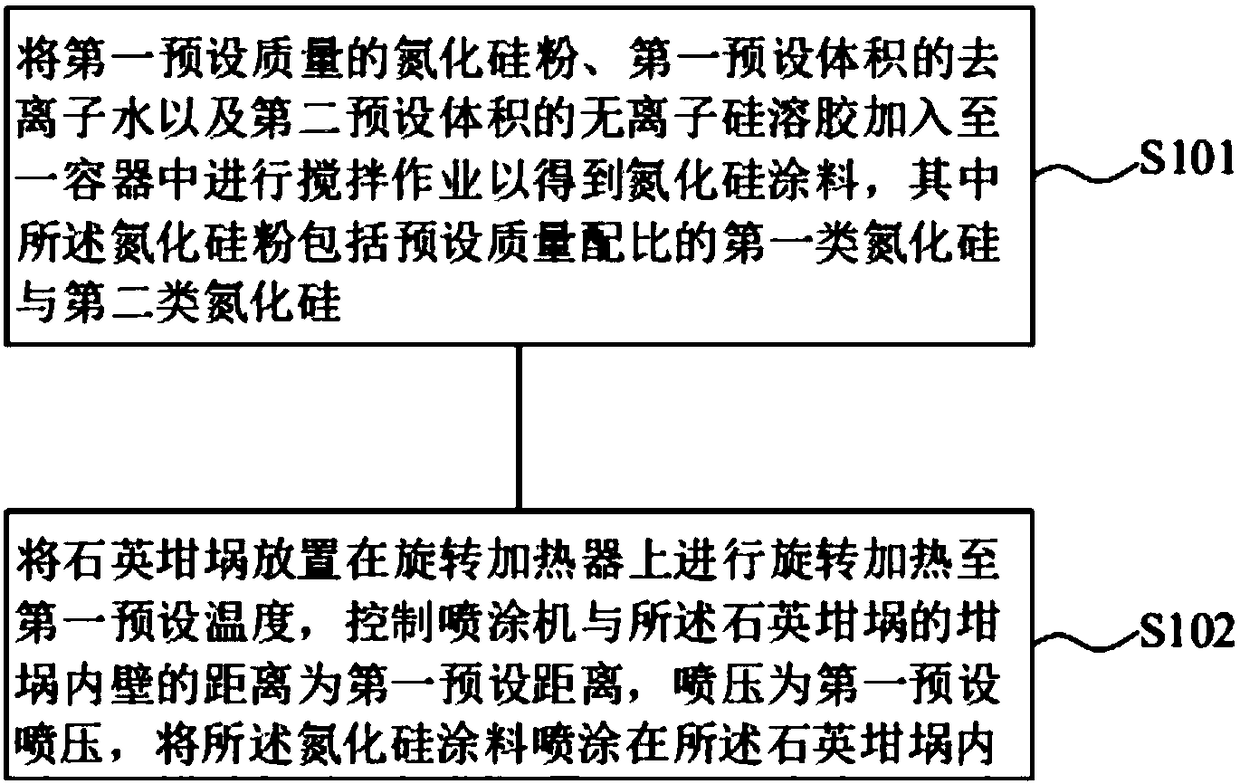

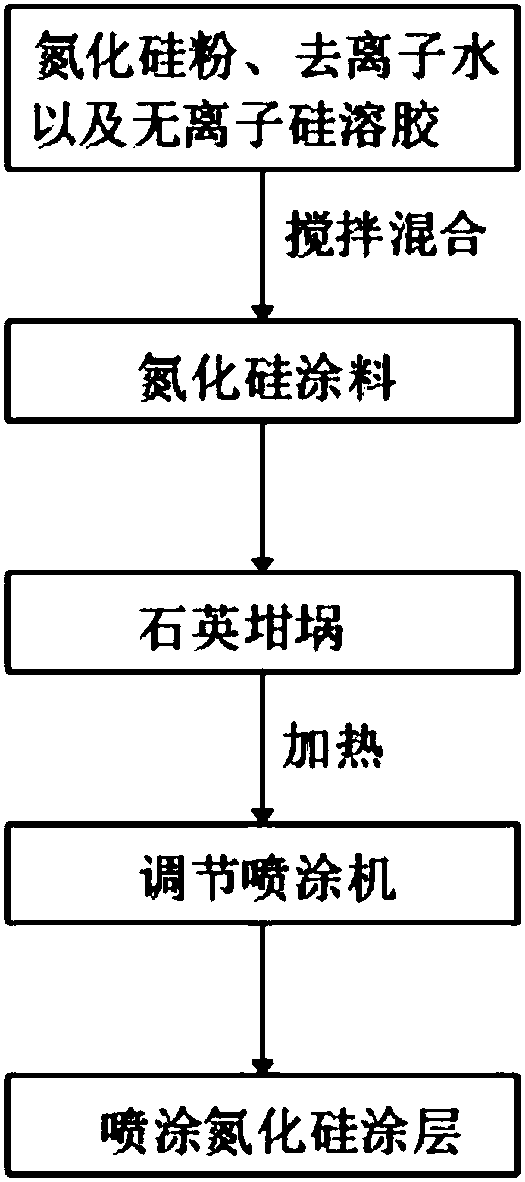

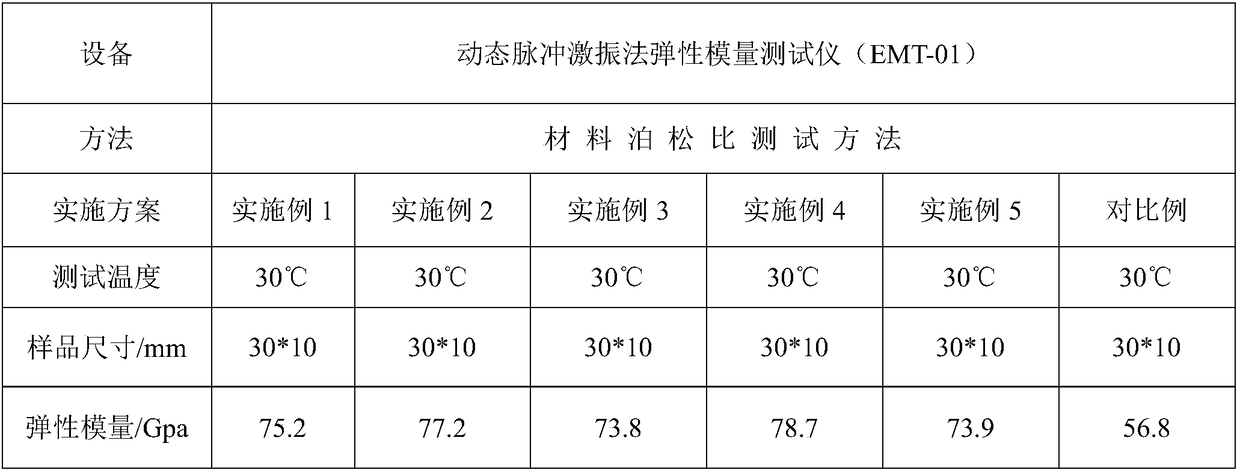

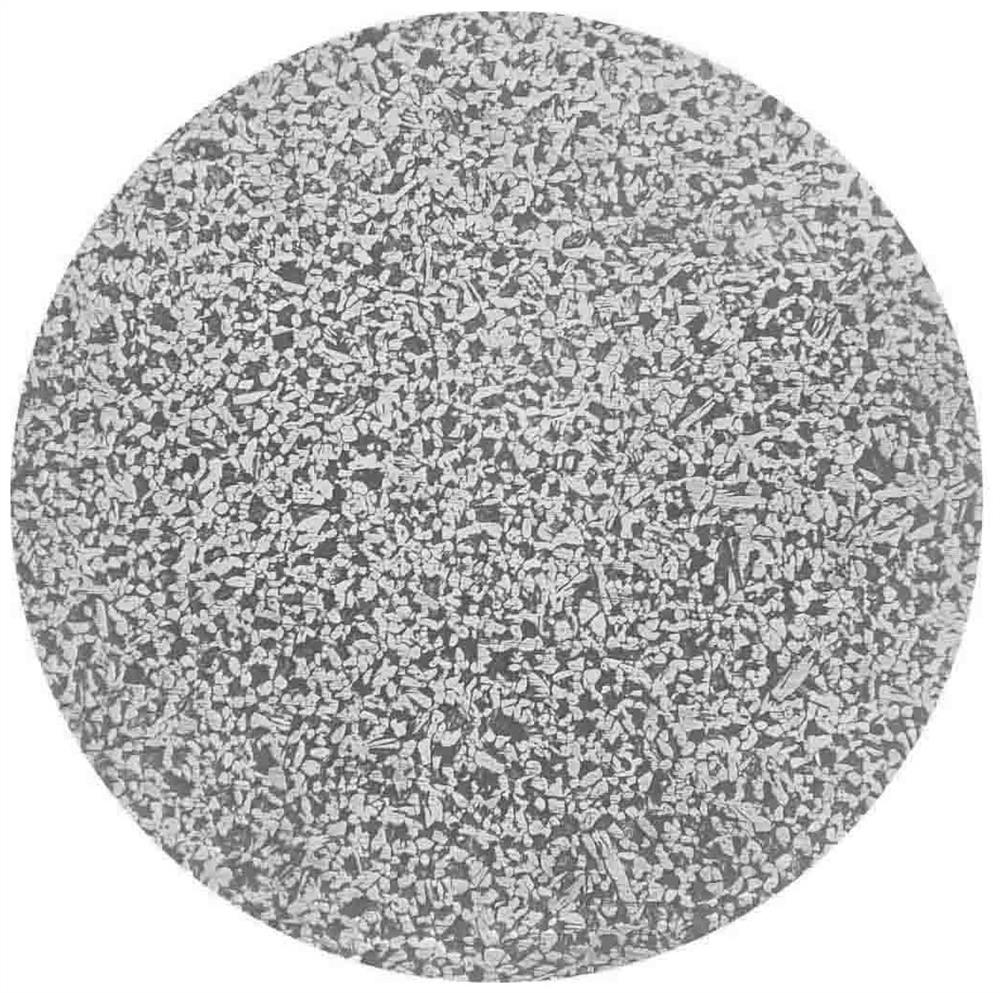

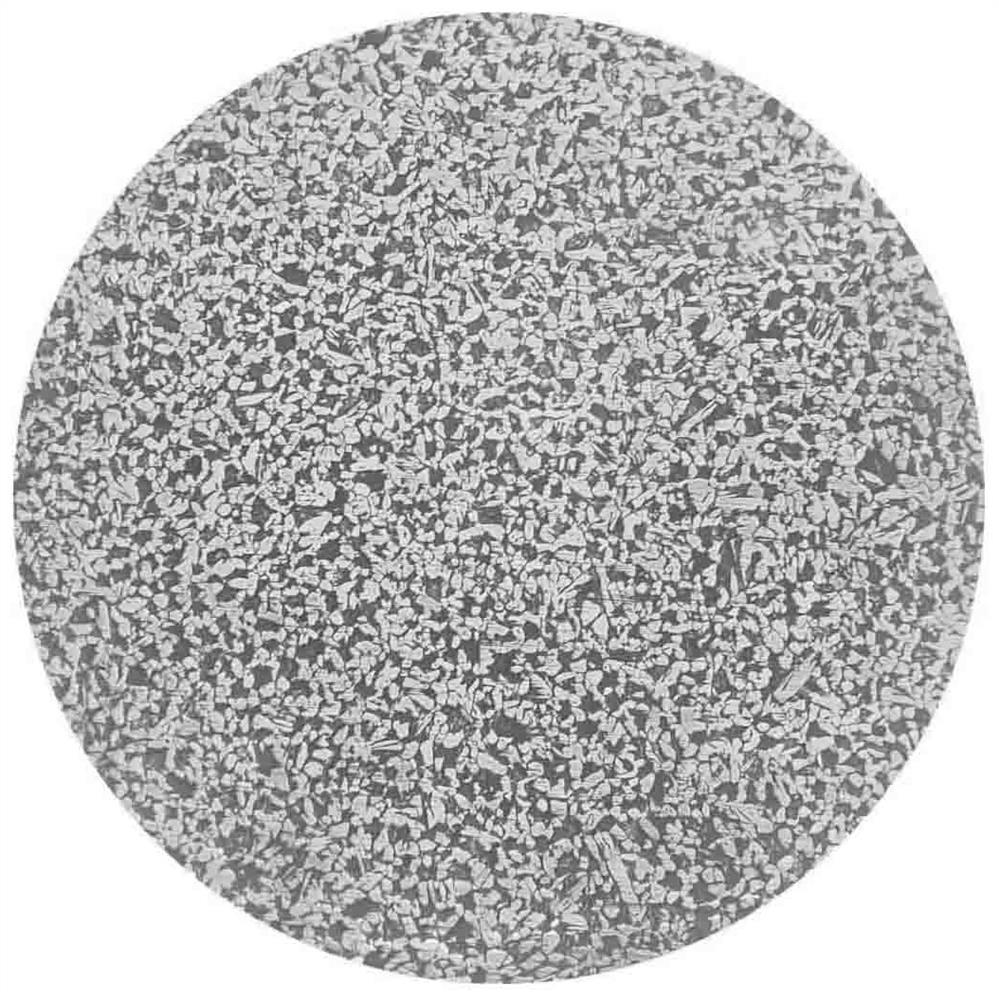

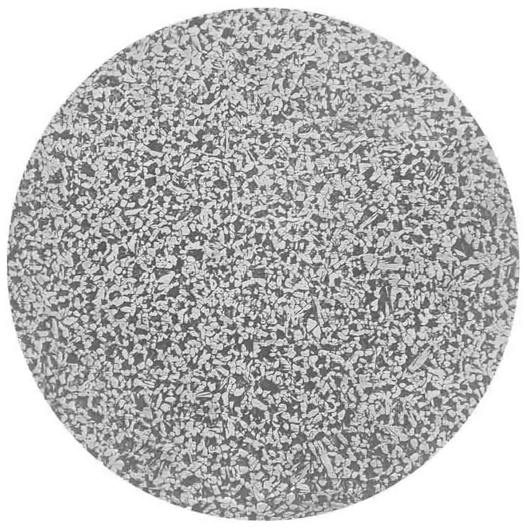

Coating production method for polycrystalline silicon ingot quartz crucible

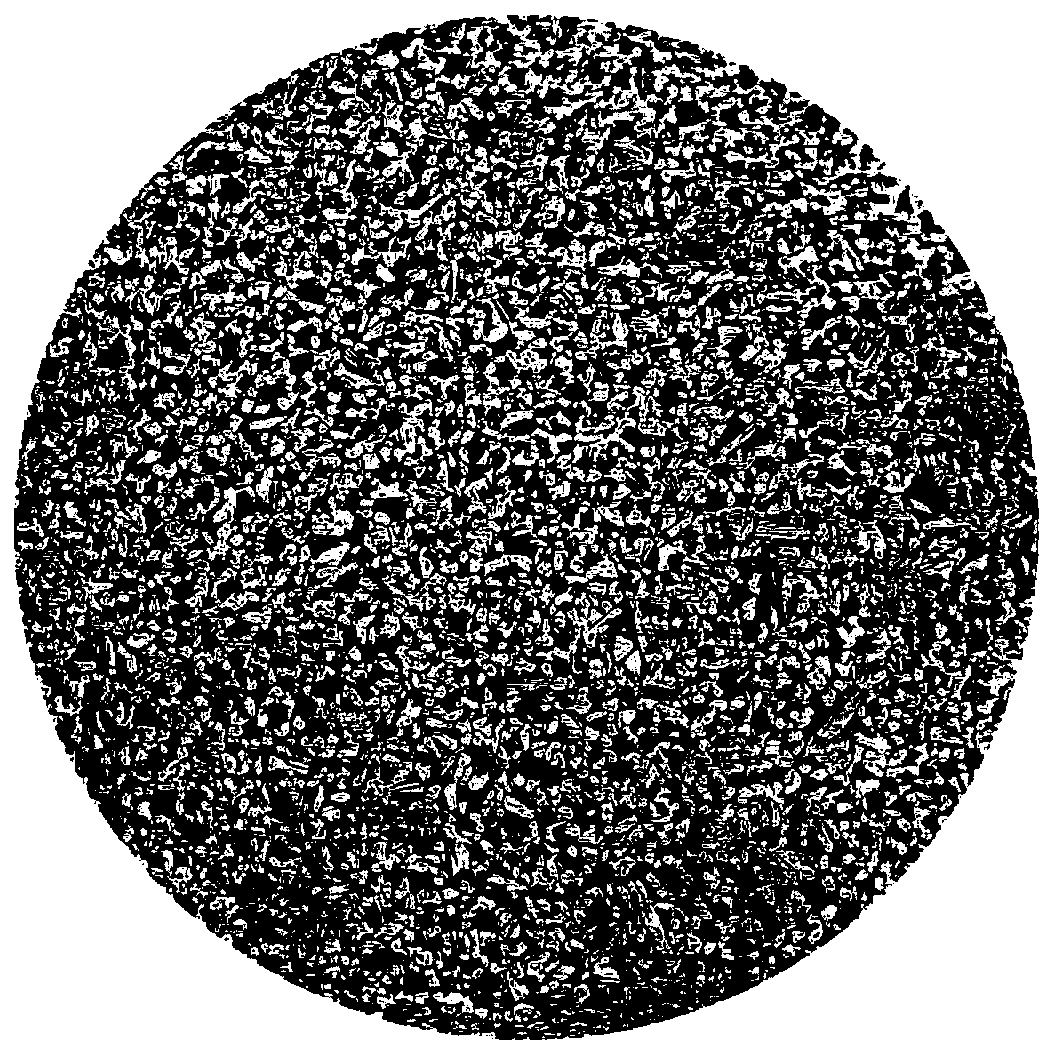

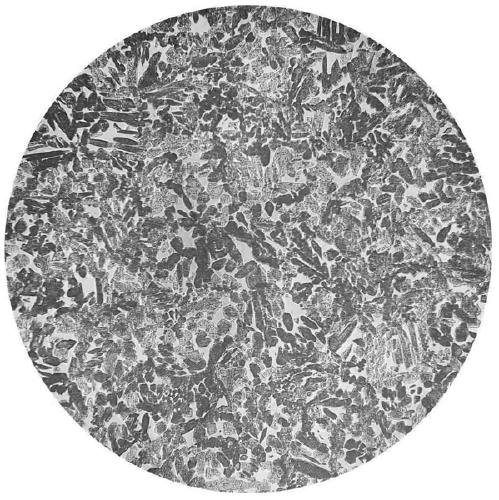

InactiveCN108455874AAffect compactnessPolycrystalline material growthCoatingsIngotPolycrystalline silicon

The invention discloses a coating production method for a polycrystalline silicon ingot quartz crucible. The method comprises the following steps: adding a first preset mass of silicon nitride powder,a first preset volume of deionized water and a second preset volume of ion-free silica sol into a container to carry out stirring operation to obtain silicon nitride coating, wherein the silicon nitride powder comprises a first class of silicon nitride and a second class of silicon nitride at a preset mass ratio; putting the quartz crucible on a rotary heater to carry out rotary heating to a first preset temperature; controlling a distance between a coating machine and the inner wall of the crucible of the quartz crucible as a first preset distance, and coating the quartz crucible with silicon ingot coating, wherein spraying pressure is first preset spraying pressure. According to the coating production method for the polycrystalline silicon ingot quartz crucible, the compactness of the silicon nitride coating is improved so as to improve the quality of a cast silicon ingot.

Owner:JINKO SOLAR CO LTD +1

Anti-dezincification lead-free bismuth arsenic brass and preparation method thereof

The invention relates to the field of copper alloys of kitchen and toilet products and provides an anti-dezincification lead-free bismuth arsenic brass with excellent anti-dezincification corrosion property, high strength and excellent processing property and a preparation method thereof. The anti-dezincification lead-free bismuth arsenic brass is prepared according to the following steps: takingthe following raw materials by weight percent: 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, less than 0.1% of Pb, and the balance of Zn and impurities in total content of not above 0.25%, melting, sampling, detecting and casting into ingot.

Owner:龙岩市鸿航金属科技有限公司

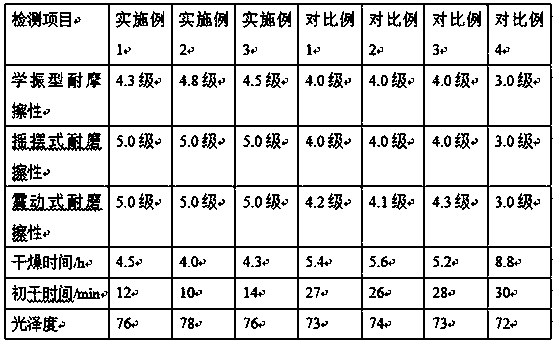

Printing glazing oil and preparation method thereof

The invention discloses printing glazing oil and a preparation method thereof and belongs to the technical field of printing. The printing glazing oil takes monomers including methyl methacrylate, 2-ethylhexyl acrylate, styrene and the like as raw materials, so that the glazing oil has good chemical stability and color protection property, and has a relatively high bearing capability to pigments and filler and a relatively good leveling property; alkyl alcohol and diketene react and then are complexed with manganese acetate to form a curing accelerant; oxidization of oil is accelerated, and oxygen in the air and the glazing oil are subjected to crosslinking reaction to form a dry coating film; the drying and film forming speed is accelerated; emery grains and quartz sand are added, and aluminum oxide and silicon dioxide are utilized to form an oleophylic surface, so that the anti-wearing performance of the glazing oil is increased and the friction coefficient is increased; tung oil andlinseed oil are added to assist film-forming and crosslinking oxidization, so that the smoothness of the glazing oil is increased and the self-leveling performance is improved; the surface of a coating is smooth and flat and the printing efficiency is improved. By adopting the printing glazing oil, the problems of current glazing oil that the wear-resisting performance is poor and the drying speed is slow are solved.

Owner:赵建平

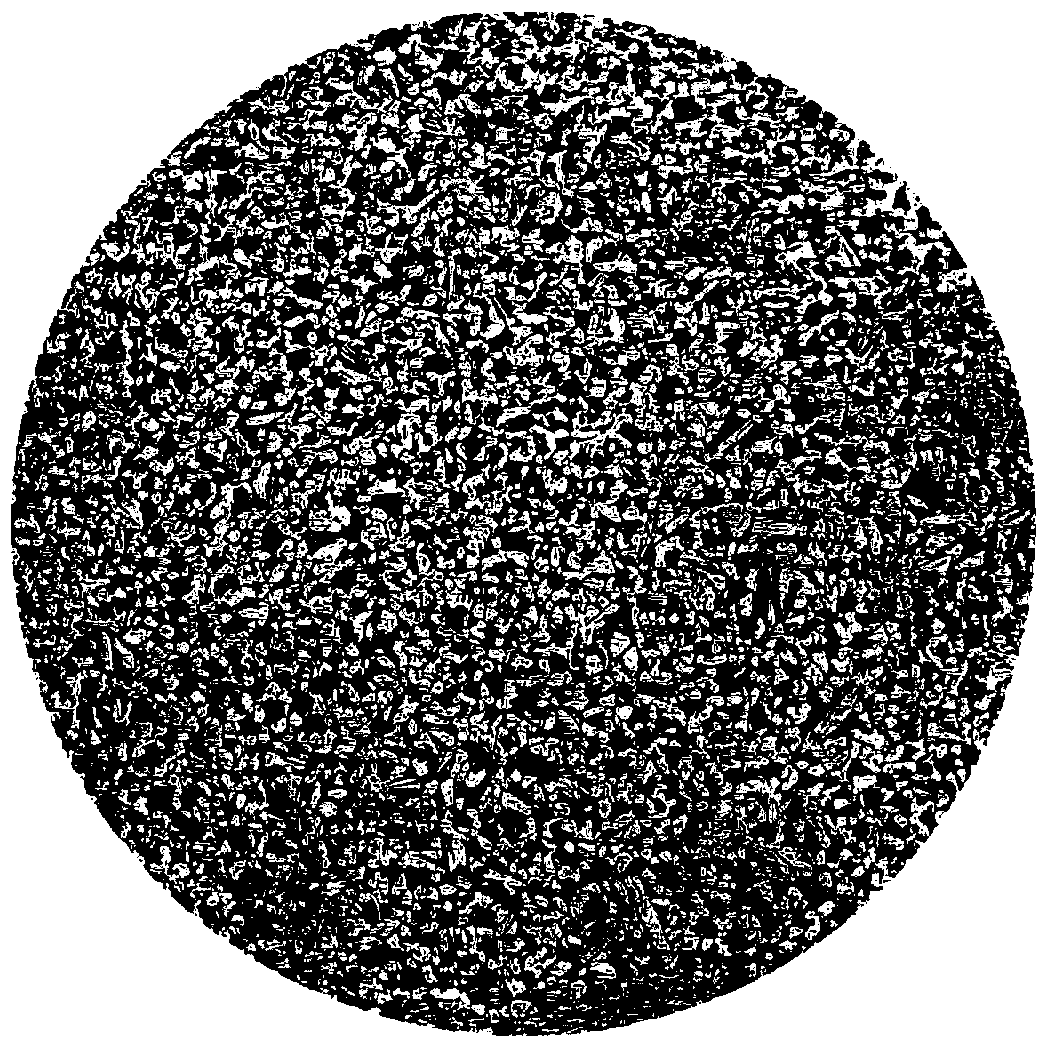

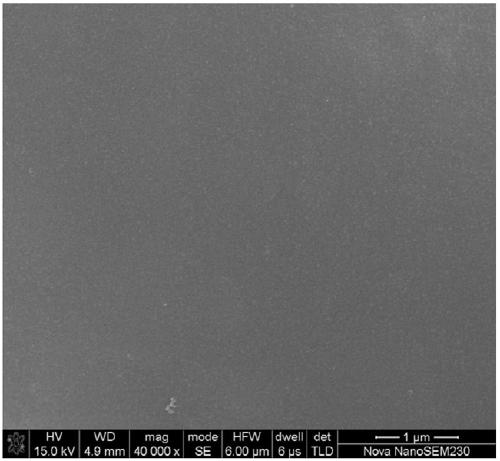

Dense ceramic gelcasting method based on low-concentration agarose and low-solid-content slurry

The invention belongs to the technical field of ceramic materials, and particularly discloses a dense ceramic gelcasting method based on low-concentration agarose and low-solid-content slurry. The method includes the steps that ceramic powder, dispersant and agarose are added into water at a time to be prepared into mixed suspension slurry with the solid phase volume fraction of 20-30% and the agarose concentration of 1.3-2.5wt%; then, after the pH of the mixed suspension slurry is regulated to be 10, the mixed suspension slurry is subjected to ball milling, defoamed and injected into a mould for heating treatment in sequence, after the mould is cooled naturally, drying is carried out in multiple steps, and a green body is obtained; finally, sintering is carried out, and ceramic with the density of 95-99% is obtained. According to the method, all the raw materials are prepared into the mixed suspension slurry with a low solid content and a low agarose concentration at a time, ball milling and vacuum defoaming are directly carried out, the mixed suspension slurry does not need to be stirred after being poured into the mould, it can be avoided that foam is carried in and influences the density of the ceramic, and a good defoaming effect and high defoaming efficiency can be achieved; besides, due to the ultralow agarose concentration, the extremely small agarose use amount and the low solid content of the ceramic slurry, the sintering cost of the high-density ceramic is low.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for preparing dezincification-resistant, lead-free, low-silicon and low-arsenic brass tubes

The invention relates to the field of copper alloys for toilet and kitchen industries and provides a method for preparing dezincification-resistant, lead-free, low-silicon and low-arsenic brass tubeswhich are good in dezincification corrosion resistance, high in strength and good in processing performance. The method comprises the steps of smelting the following raw materials in percentage by mass: 62%-65% of Cu, 0.6%-1.0% of Si, 0.07%-0.12% of As, 0.5%-0.8% of Al, 0.03%-0.1% of Fe, Pb less than 0.1% and the balance of Zn and impurities with the total amount not more than 0.35%, casting to form copper ingots, extruding to form copper tube billets, stretching, annealing, inspecting the finished copper tubes and putting the finished copper tubes into a warehouse.

Owner:龙岩市鸿航金属科技有限公司

A kind of preparation method of anti-dezincification lead-free low-silicon-arsenic brass tube

The invention relates to the field of copper alloys for toilet and kitchen industries and provides a method for preparing dezincification-resistant, lead-free, low-silicon and low-arsenic brass tubeswhich are good in dezincification corrosion resistance, high in strength and good in processing performance. The method comprises the steps of smelting the following raw materials in percentage by mass: 62%-65% of Cu, 0.6%-1.0% of Si, 0.07%-0.12% of As, 0.5%-0.8% of Al, 0.03%-0.1% of Fe, Pb less than 0.1% and the balance of Zn and impurities with the total amount not more than 0.35%, casting to form copper ingots, extruding to form copper tube billets, stretching, annealing, inspecting the finished copper tubes and putting the finished copper tubes into a warehouse.

Owner:龙岩市鸿航金属科技有限公司

A production method of anti-dezincification lead-free low-silicon lead cast arsenic brass ingot

ActiveCN107855481BAvoid burnsImprove dezincification corrosion resistanceIngotUltimate tensile strength

The invention relates to the field of copper alloys used in the toilet and kitchen industry and provides a production method for dezincification-preventing lead-free low-silicon lead casting of an arsenic brass ingot. The production method is good in dezincification corrosion preventing performance, high in strength and good in machining performance. The production method includes the step for melting the raw materials including, by mass percent, 62%-65% of Cu, 0.6%-1.0% of Si, 0.07%-0.12% of As, 0.5%-0.8% of Al, 0.03%-0.1% of Fe, smaller than 0.1% of Pb and the balance Zn and impurities withthe total amount not larger than 0.35% and then forming the brass ingot in a lead casting manner.

Owner:龙岩市鸿航金属科技有限公司

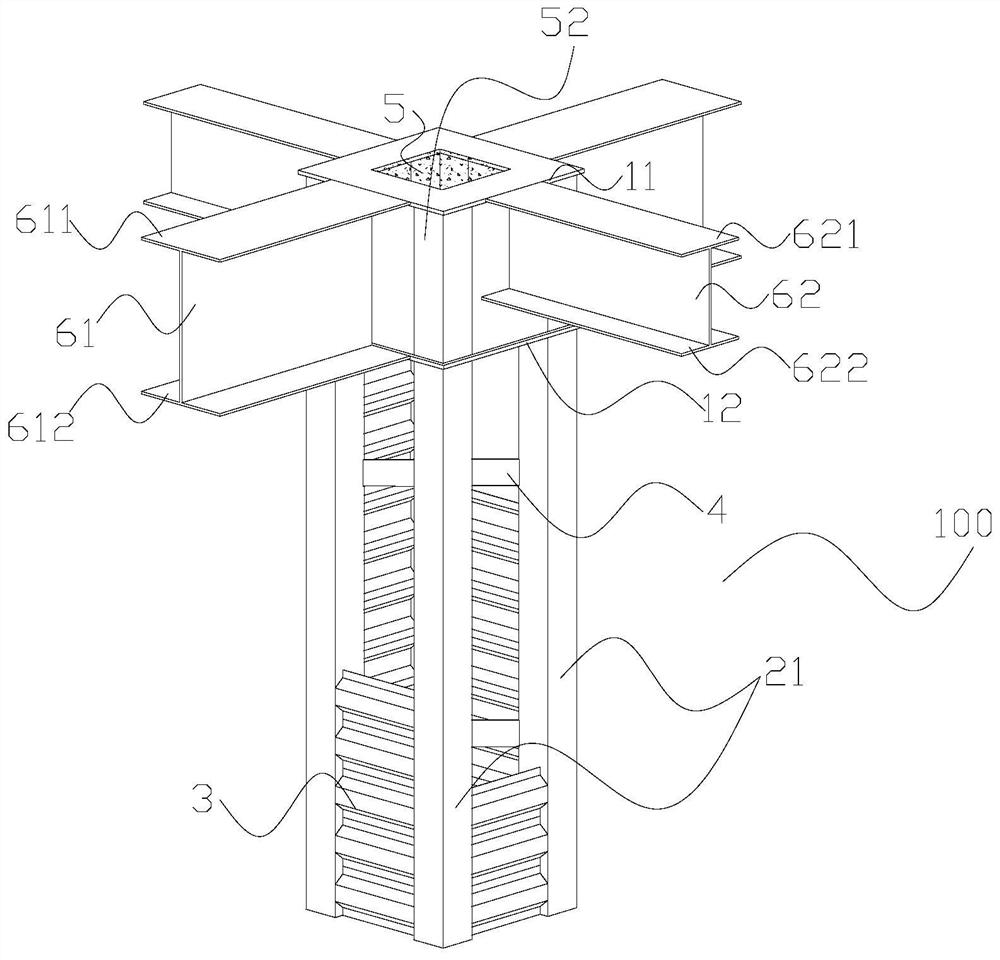

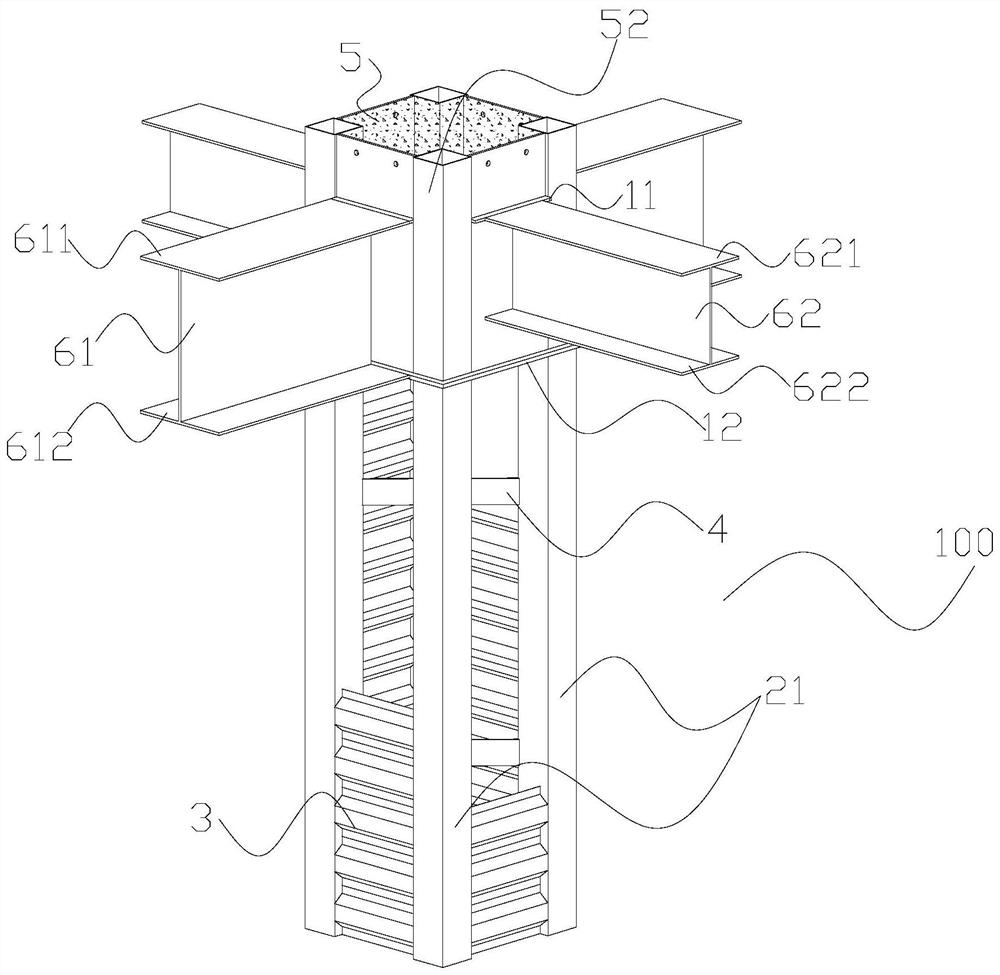

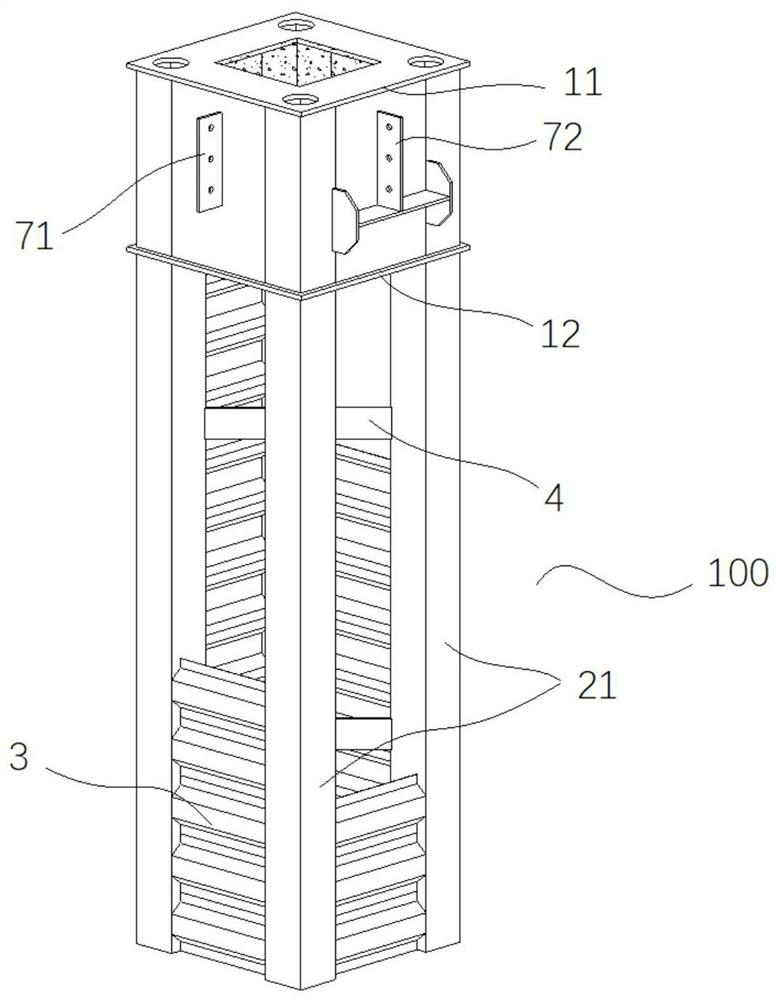

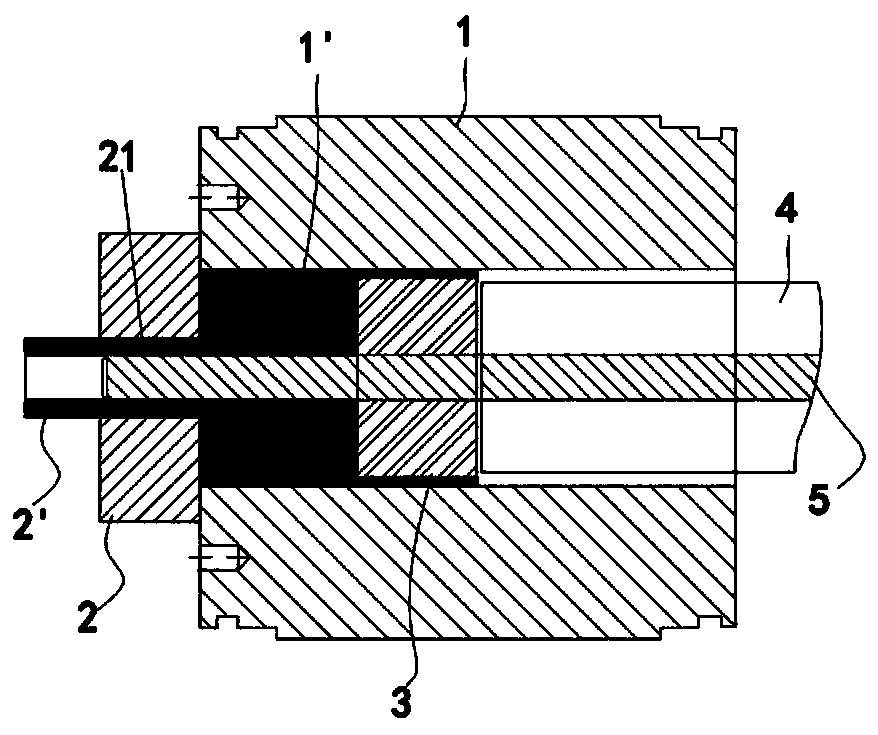

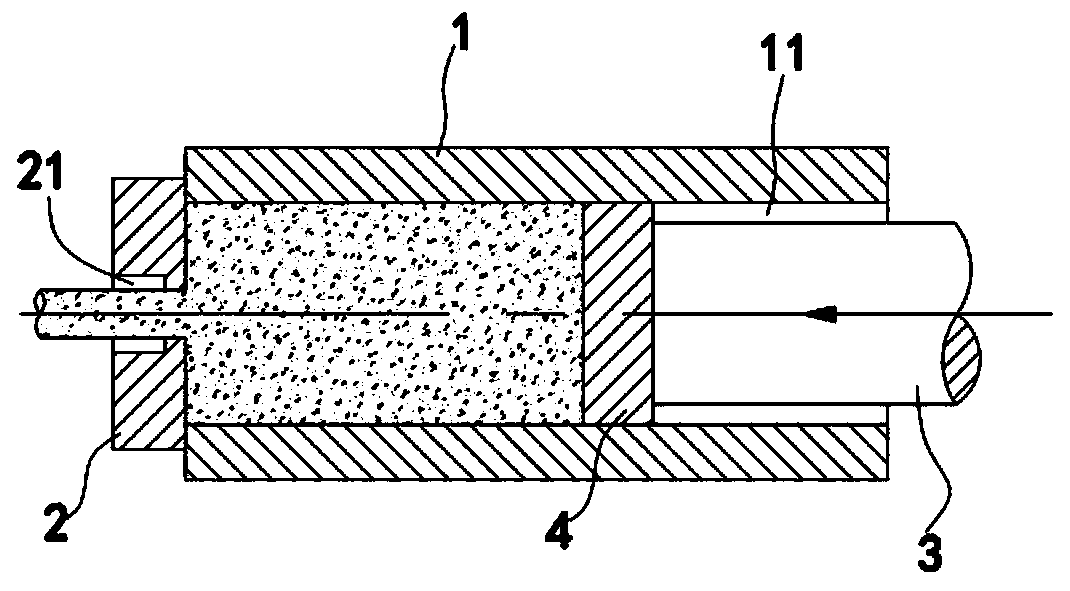

A column and its connection method with external beams

ActiveCN110552462BContributes to horizontal force balanceAffect compactnessStrutsPillarsClassical mechanicsMechanical engineering

The present invention proposes a column, which includes four corner steel pipes, and side plates are arranged between adjacent corner steel pipes. It is characterized in that an intermediate tie structure is arranged on the adjacent corner steel pipes. The structure is used to connect the second beam lower flange of the outer second beam. Preferably, the intermediate tie structure includes: a first vertical tie plate, a second vertical tie plate and a middle outer partition arranged on the adjacent corner steel pipes, and the two ends of the middle outer divider The first vertical tie plate and the second vertical tie plate are respectively connected. In addition, the invention also provides a connection method between a column and a beam. The feature of the present invention is that it can effectively transfer the horizontal force of the second external beam to the other side of the column through the beam-column node, which helps to balance the horizontal force of the external beam on both sides of the column and effectively reduces the internal force. The number of partitions should be adjusted to avoid too close spacing of internal partitions, which will affect the compactness of concrete pouring in the column.

Owner:SHANGHAI OPEN STEEL JOIST

A kind of anti-dezincification lead-free low silicon arsenic brass and preparation method thereof

Owner:龙岩市鸿航金属科技有限公司

A New Preparation Technology of Thermal Barrier Coating

The invention relates to a novel thermal barrier coating preparation process, which comprises the following steps: forming a metal bonded underlayer on the surface of a substrate; forming an in-situ thermally grown oxide layer (TGO); and forming a ceramic heat-insulating surface layer. The TGO layer is pre-grown before the substrate is put into service. The composition of the TGO layer includes alpha-alumina. In the present invention, a layer of dense and continuous TGO layer mainly composed of α-alumina is preset through large-particle dry ice jet purification and roughening treatment and pre-vacuum argon oxidation treatment. The oxide film will have good resistance to high temperature oxidation, prevent rapid oxidation, reduce the growth rate of TGO layer thickness, and achieve the purpose of reducing the occurrence probability of thermal barrier coating peeling.

Owner:江苏源清动力技术有限公司

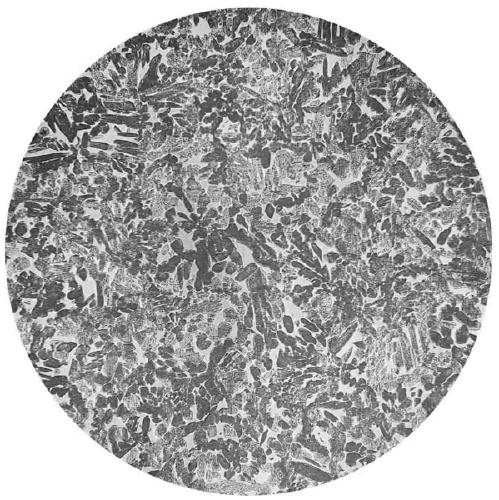

Preparation method for alumina-zirconia ceramic fiber

The invention relates to a preparation method for alumina-zirconia ceramic fiber. The method comprises the following steps: utilizing aluminium isopropoxide, formic acid, zirconium acetate and / or additive to prepare spinnable colloidal sol precursor, adopting a centrifugal fiber forming technology to prepare gel fibre, and then calcining to obtain the alumina-zirconia ceramic fiber with the diameter of 1 to 8 micrometers. The colloidal sol prepared by the invention is stable in framework, cheap in used raw materials, mild in fiber forming condition and simple in preparation process. The calcined ceramic fiber is good in flexibility and low in heat conductivity coefficient, and can be used for high temperature thermal insulation material.

Owner:SHANDONG UNIV

A low-density high-performance alumina-based ceramic fiber and its preparation method

ActiveCN106609404BImprove spinnabilityImprove performanceInorganic material artificial filamentsFiberAviation

The invention relates to a preparation method for a low-density high-performance alumina-based ceramic fiber. The method comprises the following steps: preparing spinnable alumina-based fiber precursor sol from an inorganic aluminum salt, a boron-containing additive, a silicone-containing additive and the like by using a sol-gel process; carrying out dry-process spinning so as to obtain alumina-based continuous green fibrous filaments; and subjecting the filaments to drying and sintering so as to obtain the alumina-based continuous ceramic fiber. The sol fiber prepared in the invention has good stability; preparation process is simple; the filaments can be formed without a high-molecular auxiliary agent; and the sintered fiber has low density and high strength and can be applied to high-tech fields like aviation and aerospace.

Owner:CENT SOUTH UNIV

Gel-casting method for dense ceramics based on low-concentration agarose and low-solid slurry

InactiveCN106278290BAffect compactnessReduce organic contentCeramic shaping apparatusHigh densityFree cooling

The invention belongs to the technical field of ceramic materials, and particularly discloses a dense ceramic gelcasting method based on low-concentration agarose and low-solid-content slurry. The method includes the steps that ceramic powder, dispersant and agarose are added into water at a time to be prepared into mixed suspension slurry with the solid phase volume fraction of 20-30% and the agarose concentration of 1.3-2.5wt%; then, after the pH of the mixed suspension slurry is regulated to be 10, the mixed suspension slurry is subjected to ball milling, defoamed and injected into a mould for heating treatment in sequence, after the mould is cooled naturally, drying is carried out in multiple steps, and a green body is obtained; finally, sintering is carried out, and ceramic with the density of 95-99% is obtained. According to the method, all the raw materials are prepared into the mixed suspension slurry with a low solid content and a low agarose concentration at a time, ball milling and vacuum defoaming are directly carried out, the mixed suspension slurry does not need to be stirred after being poured into the mould, it can be avoided that foam is carried in and influences the density of the ceramic, and a good defoaming effect and high defoaming efficiency can be achieved; besides, due to the ultralow agarose concentration, the extremely small agarose use amount and the low solid content of the ceramic slurry, the sintering cost of the high-density ceramic is low.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A kind of preparation method of anti-dezincification lead-free bismuth arsenic extruded brass rod

The invention relates to the field of copper alloys for the bathroom and kitchen industry and provides a preparing method for an anti-dezincification leadless bismuth arsenic extruded brass rod. The preparing method comprises the step of smelting 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, smaller than 0.1% of Pb, the balance Zn and smaller than or equal to 0.25% of impurities to obtain the solid brass rod by the processes of lead casting and extruding.

Owner:龙岩市鸿航金属科技有限公司

Dezincification-resistant lead-free low-silicon arsenic brass and preparation method thereof

The invention relates to the field of copper alloys for kitchen and bathroom industries and provides a dezincification-resistant lead-free low-silicon arsenic brass which is good in dezincification corrosion resistance property and processing property and high in strength and a preparation method of the dezincification-resistant lead-free low-silicon arsenic brass. The method includes the steps that the following raw materials including, by mass, 62-65% of Cu, 0.6-1.0% of Si, 0.07-0.12% of As, 0.5-0.8% of Al, 0.03-0.1% of Fe, less than 0.1% of Pb and the balance Zn and no larger than 0.35% ofimpurities in total amount are smelted, refined and subjected to furnace front detection and casting, and then a low-silicon arsenic brass ingot of which the content of Pb is less than 0.1% is obtained.

Owner:龙岩市鸿航金属科技有限公司

A kind of production method of anti-dezincification lead-free casting brass ingot

ActiveCN107876715BAvoid burnsImprove dezincification corrosion resistanceIngotUltimate tensile strength

The invention relates to the field of copper alloys for kitchenware industries, and provides a production method of an anti-dezincification and unleaded lead-cast brass ingot which is good in anti-dezincification corrosion property, high in strength, and good in machining property. The production method comprises the steps that the following raw materials of, by mass, 61-63% of Cu, 0.5-0.9% of Bi,0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, less than 0.1% of Pb and the balance Zn and impurities with the total amount being less than or equal to 0.25% are smelted, and then subjected to lead casting, and the brass ingot is prepared.

Owner:龙岩市鸿航金属科技有限公司

A kind of preparation method of anti-dezincification lead-free bismuth arsenic brass tube

The invention relates to the field of copper alloys for toilet and kitchen industries, and provides a preparation method of an anti-dezincification lead-free bismuth arsenic brass pipe. The preparation method comprises the steps of casting as a copper ingot-extrusion as a copper pipe blank-stretching-annealing-inspection of a finished copper pipe-warehousing of the finished copper pipe after smelting of the following raw materials in percentage by mass: 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, Pb not more than 0.1%, and the balance of Zn and impuritieswith a total amount not more than 0.25%.

Owner:龙岩市鸿航金属科技有限公司

A preparation method of anti-dezincification lead-free low-silicon extruded arsenic brass rod

ActiveCN107805737BAvoid burnsImprove dezincification corrosion resistanceUltimate tensile strengthSilicon

The invention relates to the field of a copper alloy used in the kitchen and toilet industry, and provides a manufacturing method for an anti-dezincification lead-free low-silicon extruded arsenic brass rod which is good in anti-dezincification-corrosion performance, high in strength and good in machining performance. The anti-dezincification lead-free low-silicon extruded arsenic brass rod comprises the following raw materials in percentage by mass: 62-65% of Cu, 0.6-1.0% of Si, 0.07-0.12% of As, 0.5-0.8% of Al, 0.03-0.1% of Fe, less than 0.1% of Pb, the balance of Zn and impurities with thetotal amount lower than 0.35%; and after the raw materials are smelted, the solid brass rod is obtained through injection casting and extrusion techniques.

Owner:龙岩市鸿航金属科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com