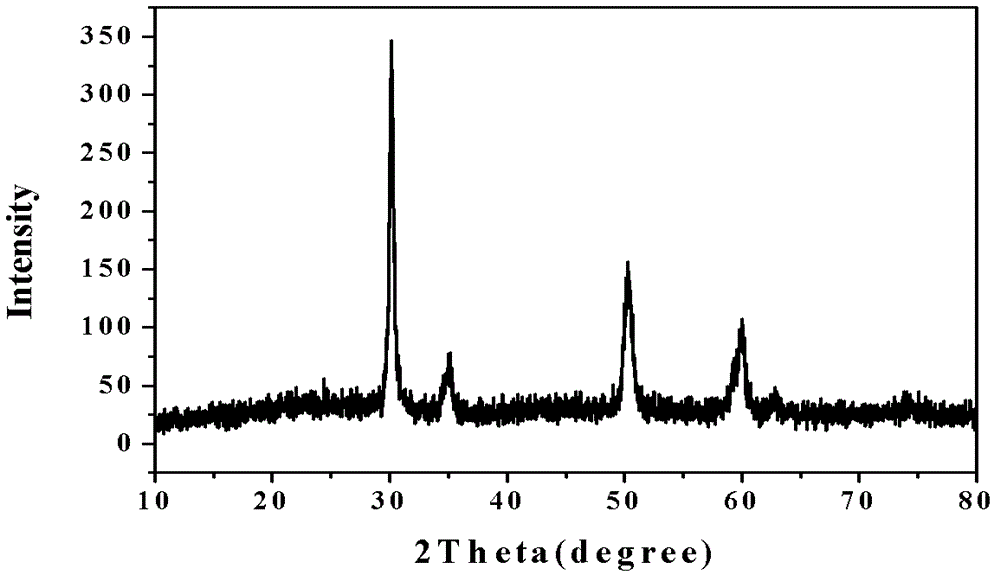

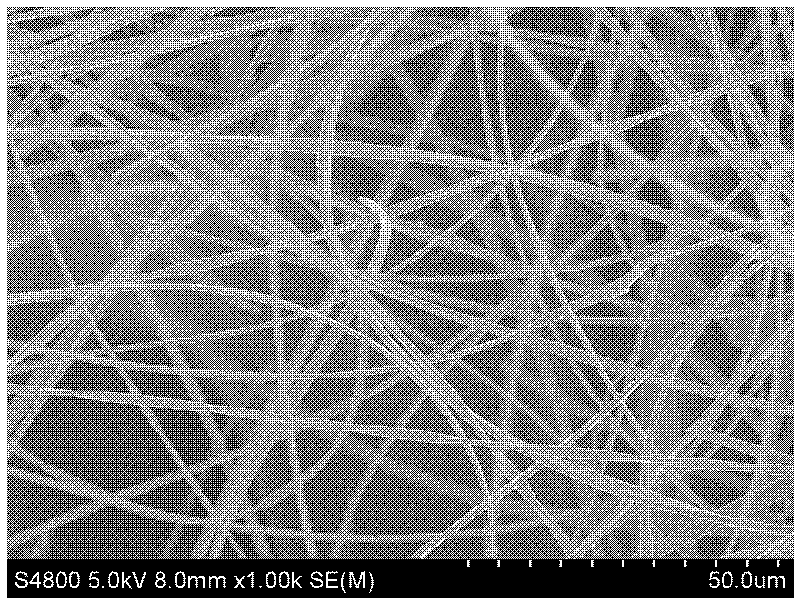

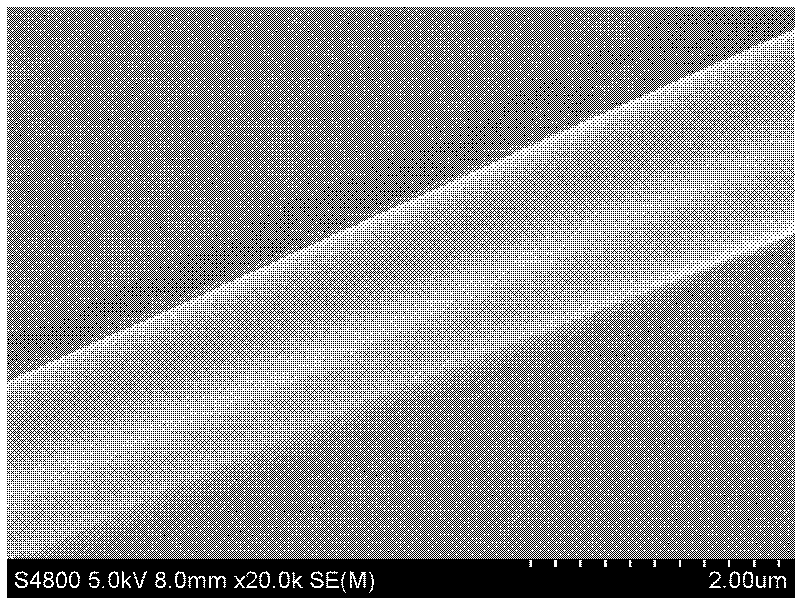

Flexible yttrium stable zirconium oxide ceramic fiber and preparation method thereof

A technology of yttrium-stabilized zirconia and ceramic fiber, which is applied in the preparation of flexible yttrium-stabilized zirconia ceramic fiber and flexible inorganic oxide fiber, can solve the problems of poor flexibility, poor compactness, and low strength, and achieve high density , strong toughness, and the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of sol spinning solution: add 0.3g polyvinylpyrrolidone (PVP) to 10.0g zirconium acetate solution, stir until completely dissolved, add 0.561g yttrium nitrate (Y(NO 3 ) 3 ·6H 2 0), stirred for 30mins, then added 0.528mL tetraethyl orthosilicate (TEOS), stirred until the solution was clarified, and obtained the sol spinning solution;

[0039] (2) Inject the sol-spinning solution prepared in the above steps into the electrospinning device, and under the conditions of a voltage of 20kV, a sol-spinning velocity of 2mL / h and a distance of 25.0cm between the spinning receiving plate and the electrode, the electrospinning Spinning, zirconia gel fiber is prepared under room temperature;

[0040] (3) Dry the obtained zirconia gel fiber in a 50°C oven for 12 hours, then place it in a high-temperature furnace for calcination, raise it to 600°C at a rate of 1°C / min, keep it warm for 120mins, and then heat it at a rate of 5°C / min The speed was increased to 1400° C...

Embodiment 2

[0043] (1) Preparation of sol spinning solution: add 0.3g polyvinylpyrrolidone (PVP) to 10.0g zirconium acetate solution, stir until completely dissolved, add 0.522g yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O), stirred for 25mins, then added 0.129mL tetraethyl orthosilicate (TEOS) and 0.217g aluminum nitrate (Al(NO 3 ) 3 ·6H 2 0), stirred to the clarification of solution, obtains sol spinning solution;

[0044] (2) inject the sol-spinning liquid that above-mentioned steps makes in the electrospinning device, under the conditions of voltage 20kV, sol-spinning liquid ejection speed being 2mL / h and spinning receiving distance 20.0cm, electrospinning, Zirconia gel fibers were prepared at room temperature;

[0045] (3) Put the prepared zirconia gel fiber into a 50°C oven to dry for 12 hours, then place it in a high-temperature furnace for calcination, raise the temperature to 600°C at a rate of 1.5°C / min, keep it warm for 120mins, and then heat it up at a temperature of 5°C / min. The...

Embodiment 3

[0048] (1) Preparation of sol spinning solution: add 0.567g polyvinylpyrrolidone (PVP) to 18.902g zirconium acetate solution, stir until completely dissolved, add 0.987g yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O), after stirring for 25mins, add 0.248g titanium sulfate (Ti(SO 4 ) 2 ), stirred until the solution is clarified to obtain a sol spinning solution;

[0049] (2) Inject the sol-spinning solution prepared in the above steps into the electrospinning device, and carry out under the conditions of a voltage of 20kV, a spraying speed of the sol-spinning solution of 1.5mL / h and a distance of 20.0cm between the spinning receiving plate and the electrode. Spinning, zirconia gel fiber is prepared under room temperature;

[0050] (3) Dry the obtained zirconia gel fiber in a 50°C oven for 18 hours, then place it in a high-temperature furnace for calcination, raise the temperature to 800°C at a rate of 1°C / min, and keep it warm for 60mins to obtain tetragonal phase yttrium-stabilized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com