Preparation method of polyamide 6 powder for laser sintering

A technology of laser sintering and polyamide, applied in the field of preparation of polyamide 6 powder, can solve the problems of low fluidity, low sphericity of powder materials, poor quality effect of laser sintering process, etc., and achieve the effect of reducing temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

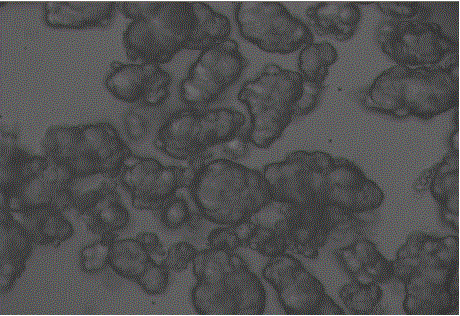

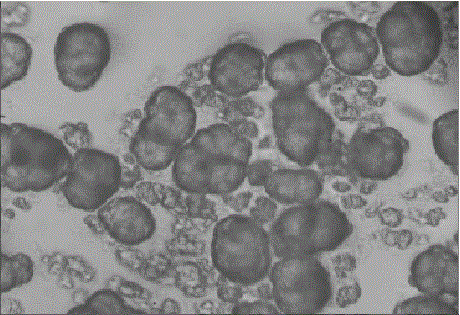

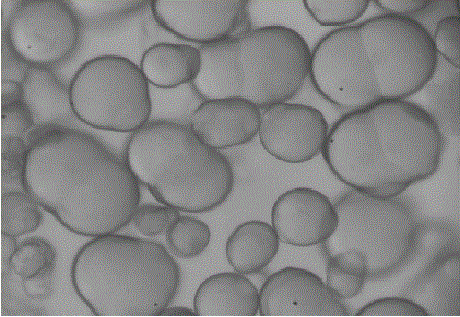

Image

Examples

Embodiment 1

[0027] A preparation method of polyamide 6 powder for laser sintering, comprising the steps of:

[0028] Step 1: 4 kg of polyamide 6 resin material and 24 kg of solvent are placed in a closed reaction kettle, wherein the solvent is mixed with methanol and water in a ratio of 45:55. The reaction kettle was pumped down to 0.01MPa, and then filled with nitrogen until the pressure inside the kettle was 0.4MPa. Under the condition of stirring, the heat conduction oil outside the reaction kettle was heated to 190°C, and the temperature of the material in the kettle was heated to 155°C and maintained at this temperature for 120min. .

[0029] Step 2: Adjust the cooling rate of the reactor by adjusting the cooling water flow rate of the reactor. The cooling rate of the material in the reactor is about 1.0°C / min. During the cooling process, the temperature outside the reactor is always about 30°C higher than the temperature of the material. When the material temperature is controlled ...

Embodiment 2

[0032] A preparation method of polyamide 6 powder for laser sintering, comprising the steps of:

[0033] Step 1: 4 kg of polyamide 6 resin material and 24 kg of solvent are placed in a closed reaction kettle, wherein the solvent is mixed with methanol and water in a ratio of 45:55. The reaction kettle was pumped down to 0.01MPa, and then filled with nitrogen until the pressure inside the kettle was 0.4MPa. Under the condition of stirring, the heat conduction oil outside the reaction kettle was heated to 190°C, and the temperature of the material in the kettle was heated to 155°C and maintained at this temperature for 120min. .

[0034] Step 2: Adjust the cooling rate of the reactor by adjusting the cooling water flow rate of the reactor. The cooling rate of the material in the reactor is about 1.0°C / min. During the cooling process, the temperature outside the reactor is always about 20°C higher than the temperature of the material. When the material temperature is controlled ...

Embodiment 3

[0037] A preparation method of polyamide 6 powder for laser sintering, comprising the steps of:

[0038] Step 1: 4 kg of polyamide 6 resin material and 24 kg of solvent are placed in a closed reaction kettle, wherein the solvent is mixed with methanol and water in a ratio of 45:55. The reaction kettle was pumped down to 0.01MPa, and then filled with nitrogen until the pressure inside the kettle was 0.4MPa. Under the condition of stirring, the heat conduction oil outside the reaction kettle was heated to 190°C, and the temperature of the material in the kettle was heated to 155°C and maintained at this temperature for 120min. .

[0039] Step 2: Adjust the cooling rate of the reactor by adjusting the cooling water flow of the reactor. The cooling rate of the material in the reactor is about 1.0°C / min. During the cooling process, the temperature outside the reactor is always about 10°C higher than the temperature of the material. When the material temperature is controlled to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com