Preparation method of zirconic acid lanthanum ceramic fiber

A technology of ceramic fiber and lanthanum zirconate, which is applied in the field of preparation of lanthanum zirconate ceramic fiber, can solve the problems such as the preparation of lanthanum zirconate ceramic fiber, which has not been patented, hinders the practical application in the field of high temperature heat insulation, and has poor fiber flexibility. To achieve the effect of easy control of microstructure, good filamentation and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of spinnable precursor sol

[0037] 78.6g zirconium nitrate (Zr(NO 3 ) 4 ·3H 2 O), 86.6g lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) and 42.0g citric acid (C 6 h 8 o 7 ·H 2 O) Adding them to an appropriate amount of water, stirring until clear and transparent; mixing the three solutions at room temperature, stirring until clear and transparent, then aging in a water bath at 60°C to a viscosity of 80Pa·s to obtain a spinnable sol;

[0038] (2) Centrifugal fiber formation to prepare gel fibers

[0039] The sol prepared in step (1) is centrifuged into fibers, and the process conditions are: the diameter of the spinning hole is 0.3mm, the spinning speed is 9000r / min, the temperature in the spinning barrel is 25°C, and the relative humidity is 25%;

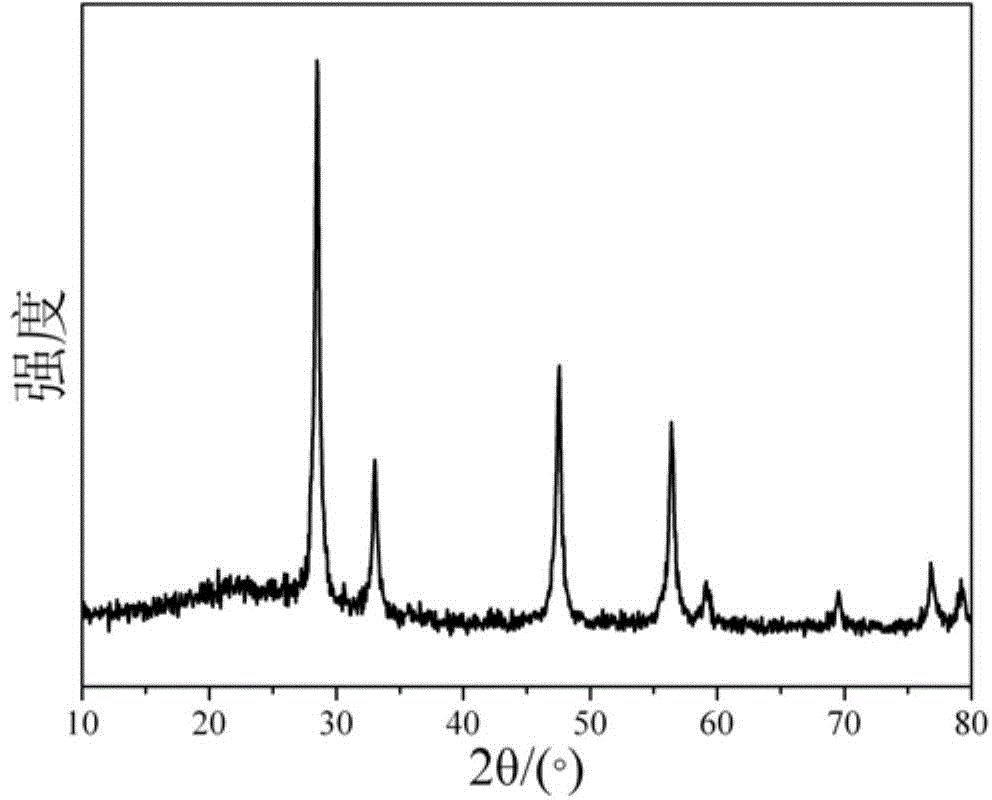

[0040] (3) The gel fiber prepared in step (2) is ceramicized. The process conditions are: the temperature is raised from room temperature to 600 ° C at a heating rate of 3 ° C / min, and the temperature is ...

Embodiment 2

[0044] As described in Example 1, the difference is:

[0045] In step (1), citric acid (C 6 h 8 o 7 ·H 2 O) is 50.2g; Step (2) is with embodiment 1.

[0046] The process condition of gel fiber ceramicization in step (3) is: the temperature rises from room temperature to 600° C. at a rate of 1° C. / min, keeps at this temperature for 2 hours, and then rises to 900° C. at a rate of 5° C. / min. At this temperature for 1h, lanthanum zirconate (La 2 Zr 2 o 7 ) ceramic fibers, and finally raised to 1100°C at a heating rate of 15°C / min, and kept at this temperature for 2 hours to obtain pyrochlore-type lanthanum zirconate (La 2 Zr 2 o 7 )Ceramic fiber.

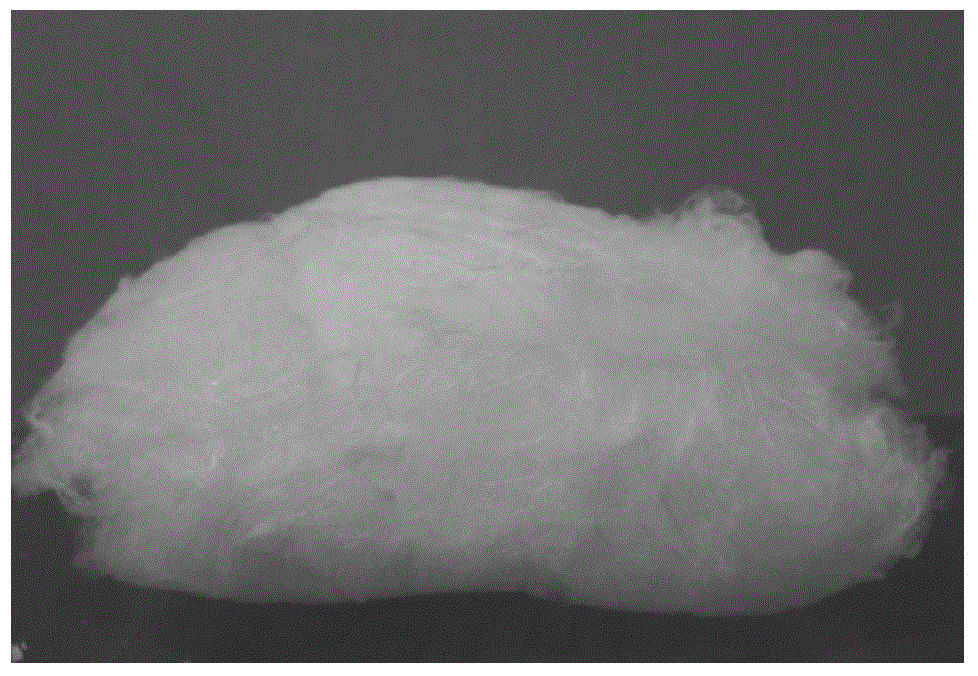

[0047] The obtained ceramic fiber is lanthanum zirconate (La 2 Zr 2 o 7 ) fibers with a diameter of 2 to 5 μm, the appearance of the fibers is fluffy, and the thermal conductivity is 0.062W / (m·K).

Embodiment 3

[0049] As described in Example 1, the difference is: in step (1), lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) is 82.2g; Step (2) is with embodiment 1.

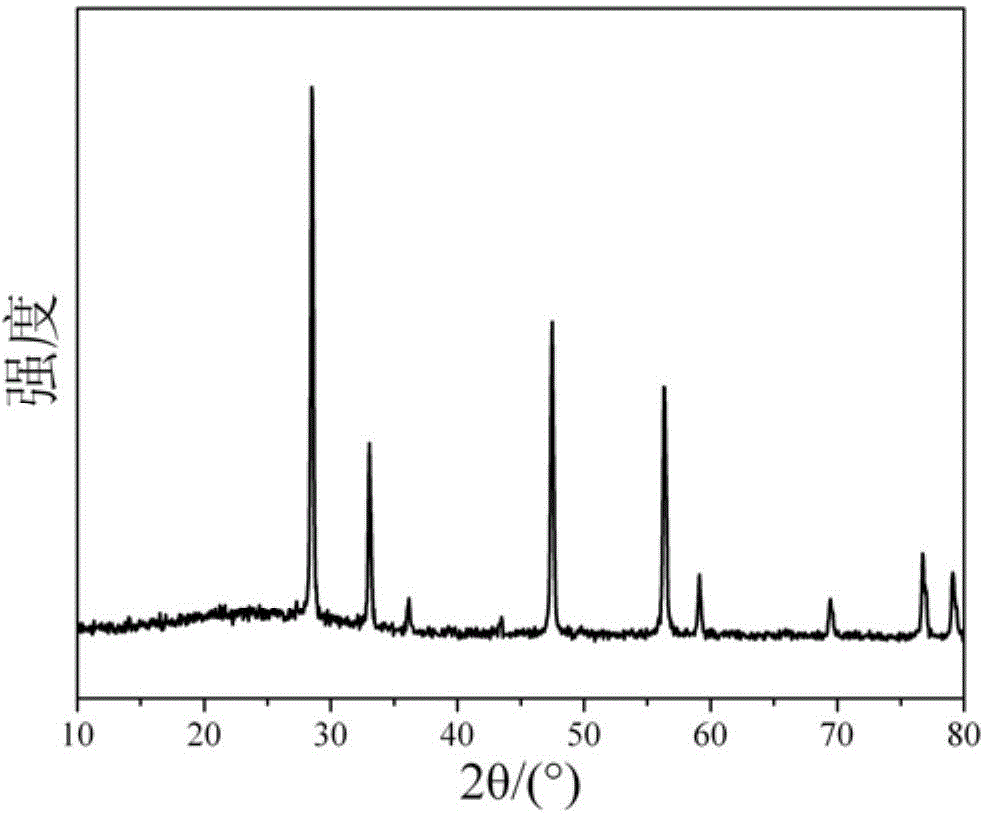

[0050] Obtain the lanthanum zirconate (La 2 Zr 2 o 7 ) ceramic fiber and finally raised to 1200°C at a heating rate of 15°C / min, and kept at this temperature for 1h to obtain lanthanum zirconate (La 2 Zr 2 o 7 )Ceramic fiber.

[0051] The obtained ceramic fiber is lanthanum zirconate (La 2 Zr 2 o 7 ) fibers with a fiber diameter of 2-5 μm and a thermal conductivity of 0.059W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com