Low-density high-performance alumina-based ceramic fiber and preparation method thereof

A kind of aluminum oxide, high-performance technology, applied in the direction of inorganic raw material artificial filament, etc., can solve the problems of short fiber, reduced strength, poor fiber compactness, etc., and achieve the effect of simple process, stable performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of sol: add 28.14g Al(NO 3 )·9H 2 O, dissolved to a clear solution, added 42.20 g CH 3 COOAl(OH) 2 1 / 3H 3 BO 3 , the mixed solution was stirred at room temperature until it became transparent, 25.04 g of silica sol was added, and the mixed solution was aged in a water bath at 45°C.

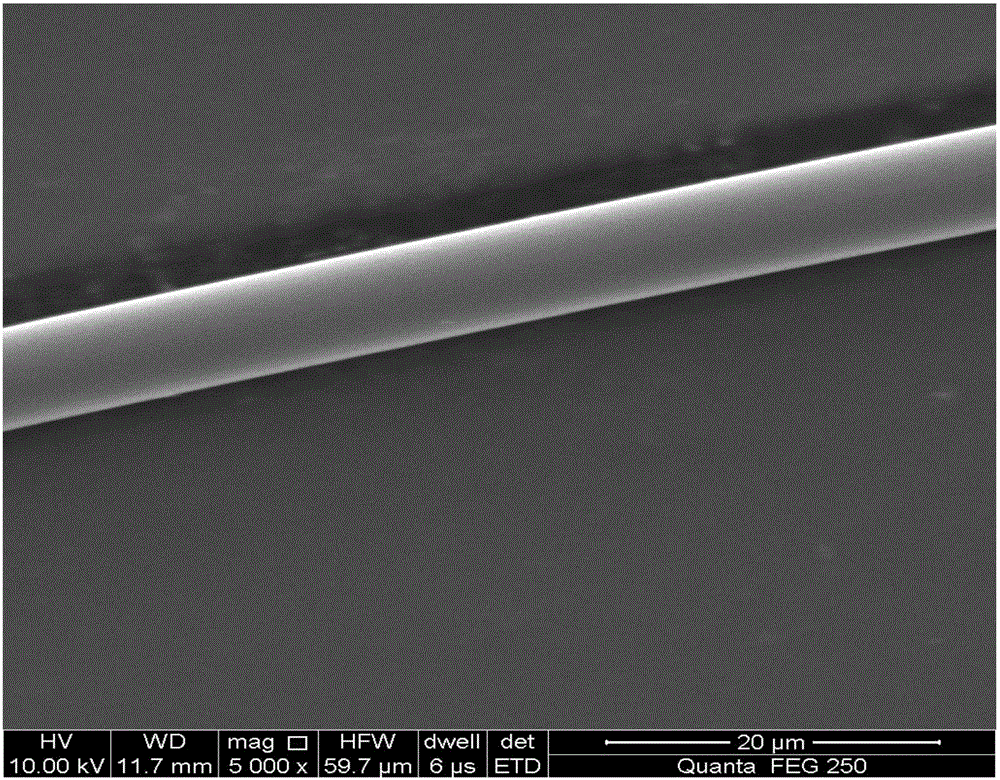

[0043] (2) Dry spinning: the sol obtained in step (1) is spun by a dry spinning machine to obtain alumina cellulose filaments. Dry spinning process conditions: spinneret pressure 520KPa, spinneret hole diameter 0.07mm, tunnel air temperature 30°C, collection roller line speed 18m / min.

[0044] (3) Cellulose filament firing: heat up from room temperature to 600°C at a speed of 2°C / min, and keep at this temperature for 1 hour, then raise the temperature from 600°C to 1000°C at a speed of 10°C / min, and keep at this temperature 30min to obtain alumina-based continuous ceramic fibers.

[0045] The sol prepared by the above-mentioned method does not need to add spinning aid...

Embodiment 2

[0047] (1) Preparation of sol: add 11.35g AlCl to 90.00g deionized water 3 ·6H 2 O, dissolved to a clear solution, added 42.20 g CH 3 COOAl(OH) 2 1 / 3H 3 BO 3 , the mixed solution was stirred at room temperature until it became transparent, 25.04 g of silica sol was added, and the mixed solution was aged in a water bath at 45°C.

[0048] Step (2) is the same as in Example 1.

[0049] (3) Cellulose filament firing: heat up from room temperature to 600°C at a speed of 15°C / min, and keep at this temperature for 1 hour, then raise the temperature from 600°C to 1000°C at a speed of 10°C / min, and keep at this temperature 2h, alumina-based continuous ceramic fibers were obtained.

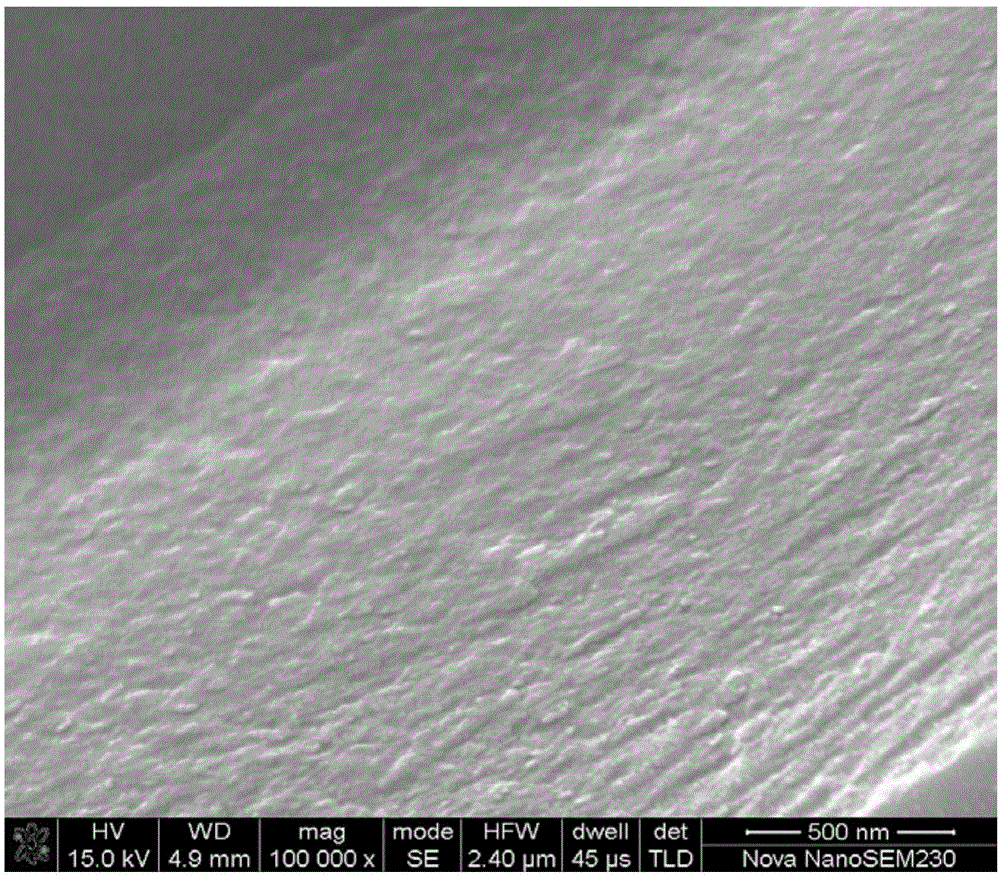

[0050] The resulting alumina-based continuous ceramic fiber has a diameter of 6-15 μm and a density of 2.6 g / cm 3 , the tensile strength is 1.4GPa, the modulus of elasticity is 145GPa, where Al 2 o 3 content of 62%, SiO 2 Content is 24%, B 2 o 3 The content is 14%, and the average particle diame...

Embodiment 3

[0052] As described in Example 1, the difference is: Al(NO 3 )·9H 2 The amount of O added is 15.00g, and 42.20g CH is added 3 COOAl(OH) 2 1 / 3H 3 BO 3 , Silica sol add-on is 22.70g, other is with embodiment 1.

[0053] The obtained alumina-based continuous ceramic fiber has a diameter of 6-15 μm and a density of 2.67 g / cm 3 , the tensile strength is 1.65GPa, the modulus of elasticity is 150GPa, where Al 2 o 3 content of 62%, SiO 2 Content is 24%, B 2 o 3 The content is 14%, and the average particle size of the particles constituting the fiber is about 35nm. The fiber diameter was measured by SEM, and the tensile strength and elastic modulus were measured by single fiber strength tester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com