Device and method for automatic centering of rope-out deflection angle of winch

An automatic centering and hoisting machine technology, which is applied in hoisting devices, spring mechanisms, etc., can solve the problems of unfavorable service life of steel wire ropes and unfavorable compact construction machinery structures, and achieves convenient installation, compact construction machinery structure, and long installation distance. The effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

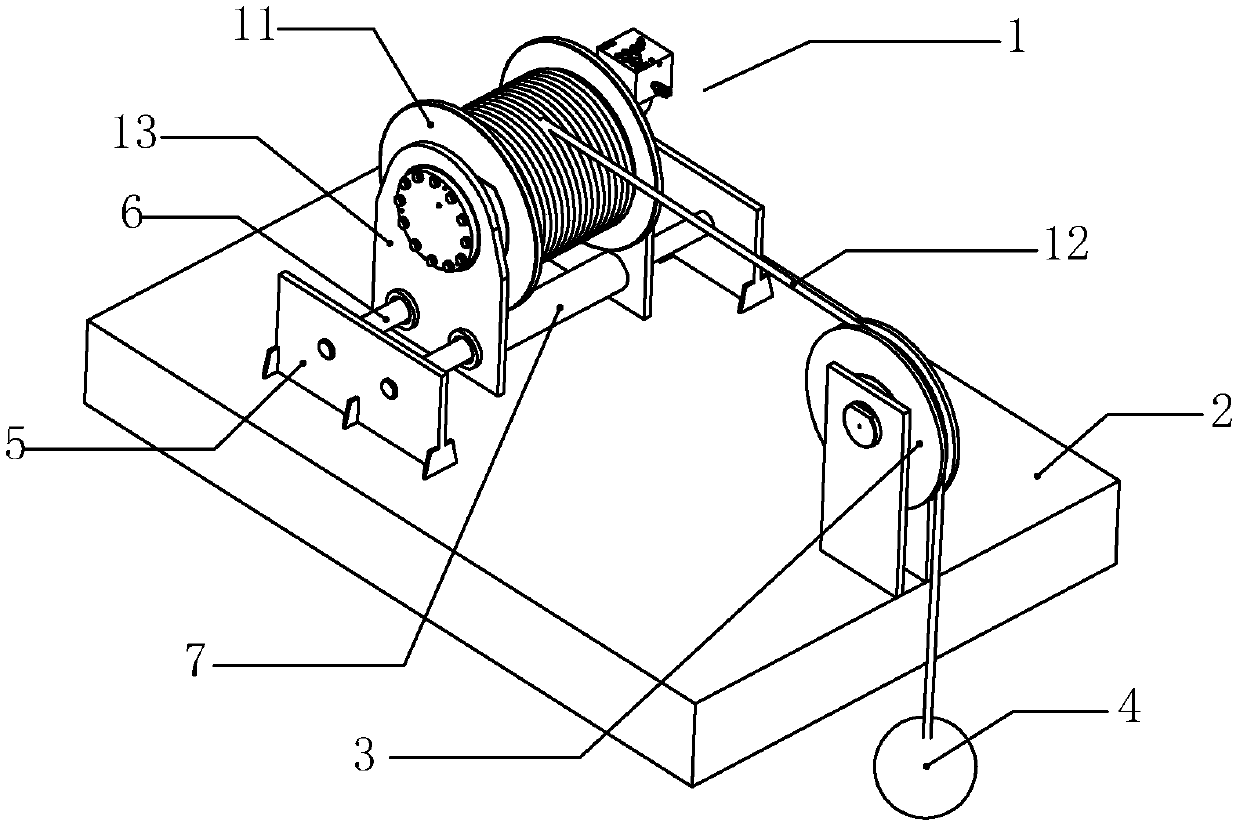

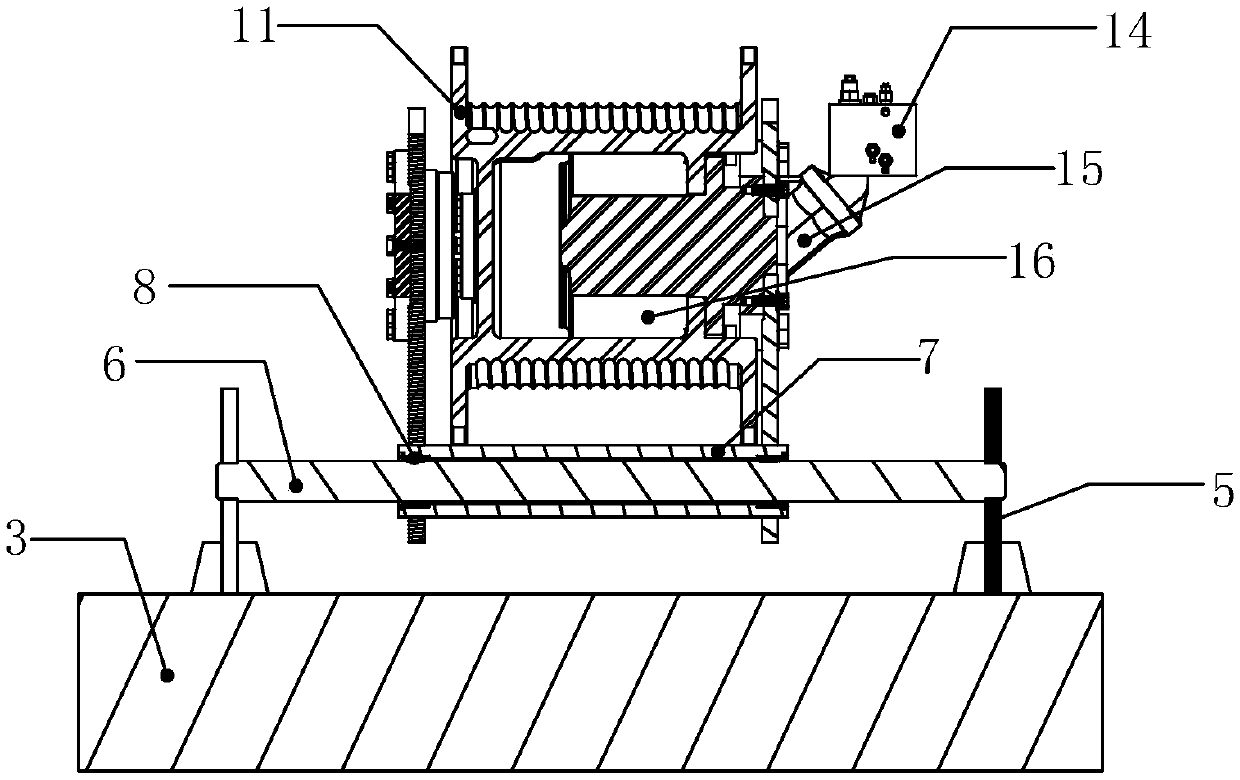

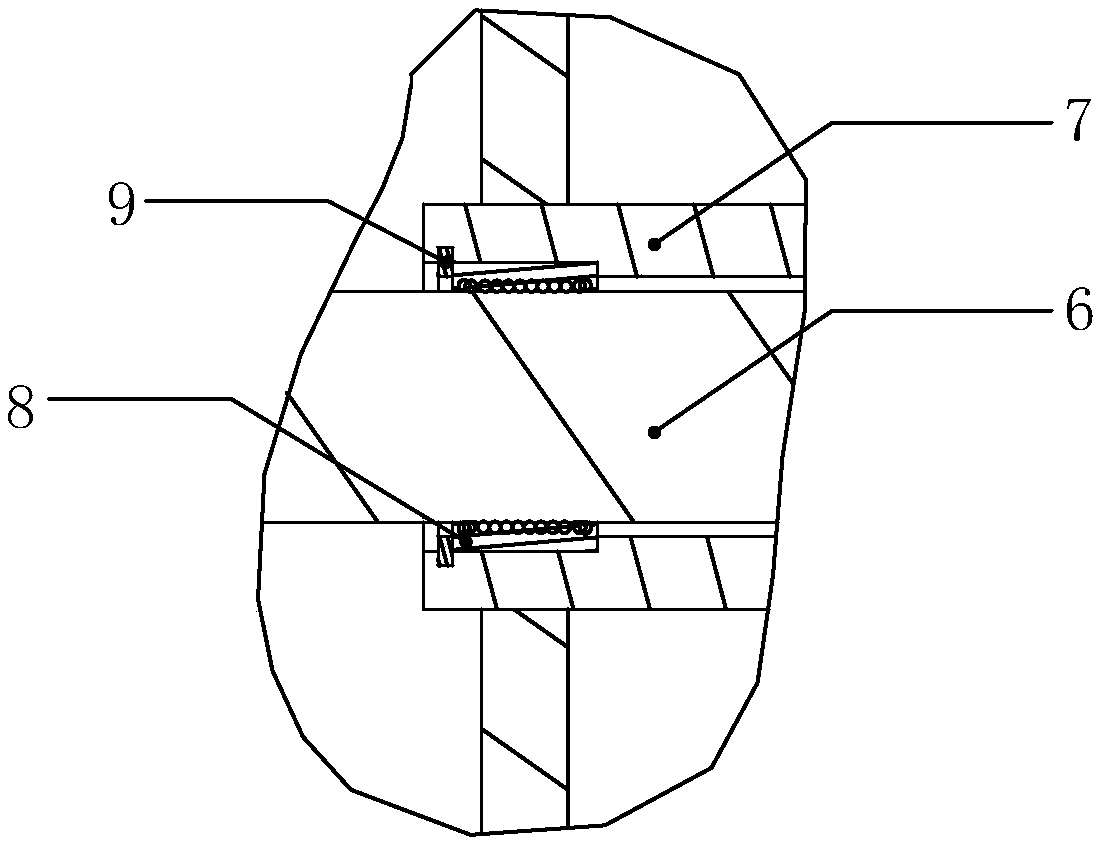

[0024] Examples, see Figure 1-Figure 5 As shown, the automatic centering device of a hoisting machine's rope deflection angle according to the present invention includes a hoisting machine 1 and a supporting body 2, and a rope is wound on the drum 11 of the hoisting machine 1; the hoisting machine 1 can slide along the axial direction of the drum 11. It is arranged on the supporting body 2. When the hoist 1 is in operation, the axial component force of the pulling force on the rope drives the hoist 1 to slide along the direction of the axial component, so that the rope-out angle of the hoist 1 is kept less than or equal to the predetermined set value. The preset value is specifically 2°, which meets the requirements of the national standard GB / T1955-2008. The rope is specifically a steel wire rope 12, but not limited thereto. The supporting body 2, as the carrier of the hoist 1, can have any structure, size, etc., and the supporting body 2 can be a separate component, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com