Preparation method for alumina-zirconia ceramic fiber

A technology of zirconia ceramics and alumina, which is applied in the field of preparation of alumina-zirconia ceramic fibers, can solve the problems of high energy consumption and poor compactness of ceramic fibers, and achieve improved high temperature performance, small thermal conductivity and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of sol: add 90mL of formic acid to 480mL of water to make a solution, then add 136g of aluminum isopropoxide and stir to hydrolyze until transparent, then add 75g of zirconium acetate solution, mix well and age in a water bath at 60°C until the viscosity of the sol is 30Pa·s .

[0044] (2) Centrifugal fiber formation: the sol obtained in step (1) is formed into fibers by a centrifugal spinning machine to obtain alumina-zirconia gel fibers. The fiber-forming process conditions are: the diameter of the spinning hole is 0.30mm, the rotation speed of spinning is 3500r / min, and the spinning temperature is 30°C.

[0045] (3) Gel fiber ceramicization: raise the temperature from room temperature to 500°C at a rate of 2°C / min, keep at this temperature for 2 hours, and then increase from 600°C to 950°C at a rate of 5°C / min C, keep warm at this temperature for 2h.

[0046] The obtained fiber is γ-Al 2 o 3 -Tetragonal ZrO 2 Composite ceramic fiber, fiber diamet...

Embodiment 2

[0048] (1) Sol preparation: Add 80mL formic acid to 450mL water to make a solution, then add 136g aluminum isopropoxide and stir until transparent, then add 103g zirconium acetate solution, mix well and age in a water bath at 50°C to a sol with a viscosity of 40Pa s .

[0049] (2) Centrifugal fiber formation: the sol obtained in step (1) is formed into fibers by a centrifugal spinning machine to obtain alumina-zirconia gel fibers. The fiber-forming process conditions are: the diameter of the spinning hole is 0.30mm, the rotation speed of spinning is 5000r / min, and the spinning temperature is 35°C.

[0050] (3) Gel fiber ceramicization: raise the temperature from room temperature to 600°C at a heating rate of 1°C / min, and keep at this temperature for 2 hours, and then rise from 600°C to 950°C at a heating rate of 10°C / min C, keep warm at this temperature for 2h.

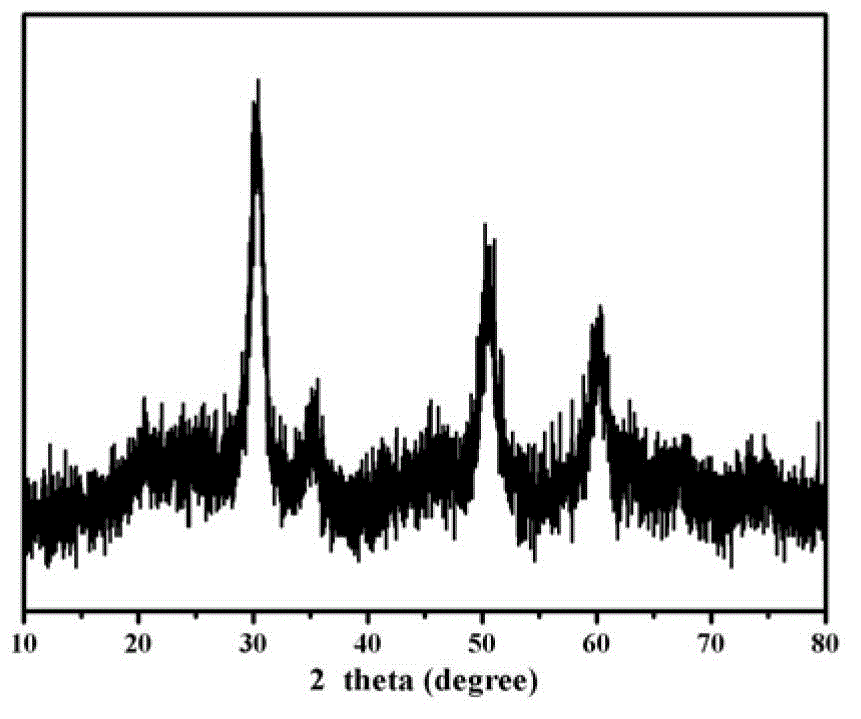

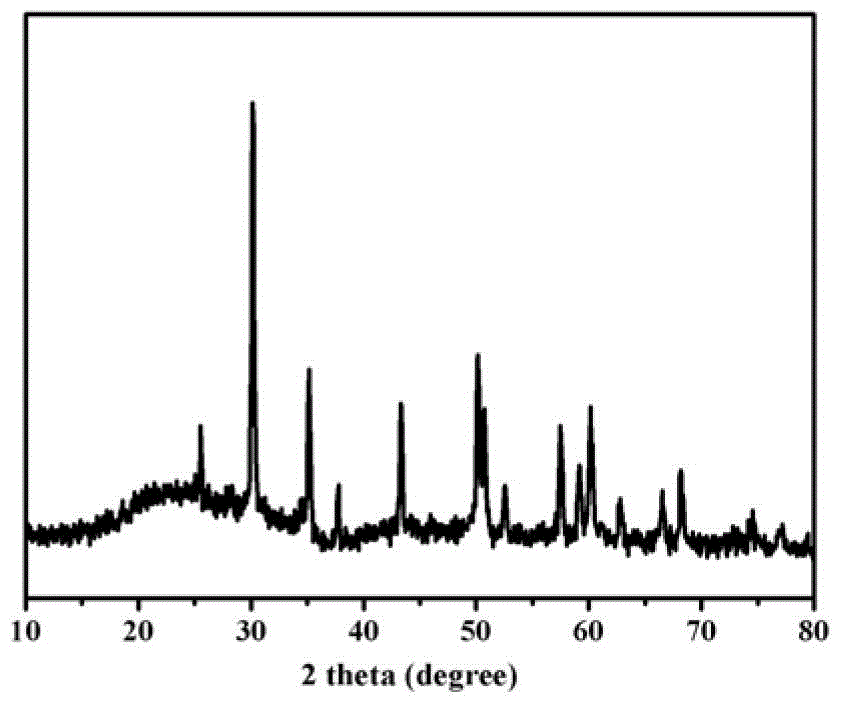

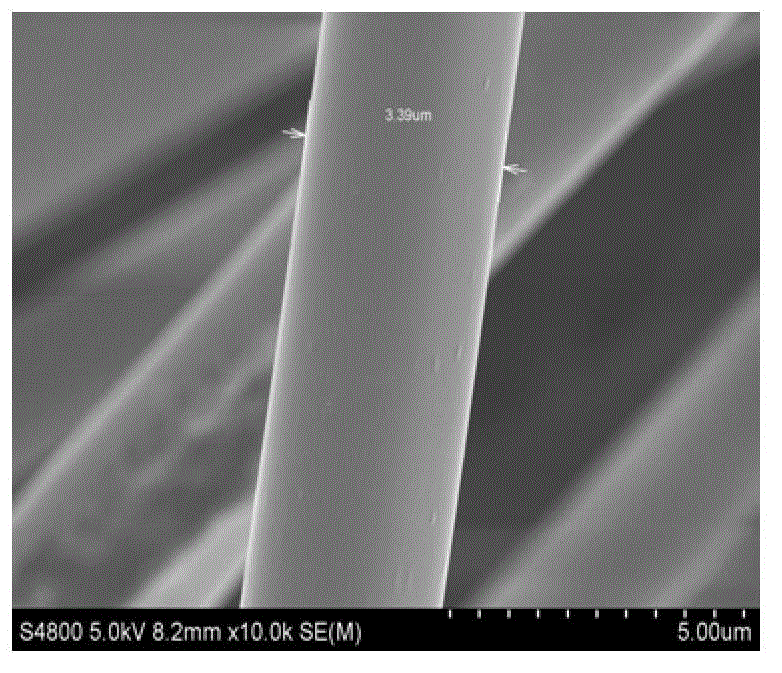

[0051] The XRD spectrogram of gained ceramic fiber is as figure 1 as shown, image 3 is the SEM photo of the ob...

Embodiment 3

[0053] (1) Preparation of sol: add 70mL of formic acid to 450mL of water to make a solution, then add 136g of aluminum isopropoxide and stir until transparent, then add 154g of zirconium acetate solution, mix well and age in a water bath at 50°C to a sol with a viscosity of 50Pa·s .

[0054] (2) Centrifugal fiber formation: the sol obtained in step (1) is formed into fibers by a centrifugal spinning machine to obtain alumina-zirconia gel fibers. Centrifugal fiber forming, the process conditions are: the diameter of the spinning hole is 0.30mm, the rotation speed of spinning is 5000r / min, and the spinning temperature is 35°C.

[0055] (3) Gel fiber ceramicization: raise the temperature from room temperature to 600°C at a heating rate of 1°C / min, and keep at this temperature for 2 hours, and then rise from 600°C to 950°C at a heating rate of 10°C / min C, keep warm at this temperature for 3h.

[0056] The obtained fiber is γ-Al 2 o 3 -Tetragonal ZrO 2 Composite ceramic fiber,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com