Coating production method for polycrystalline silicon ingot quartz crucible

The technology of a quartz crucible and a production method is applied in the field of coating production of a polycrystalline silicon ingot quartz crucible, and can solve problems such as affecting the compactness of the coating and affecting the quality of the ingot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

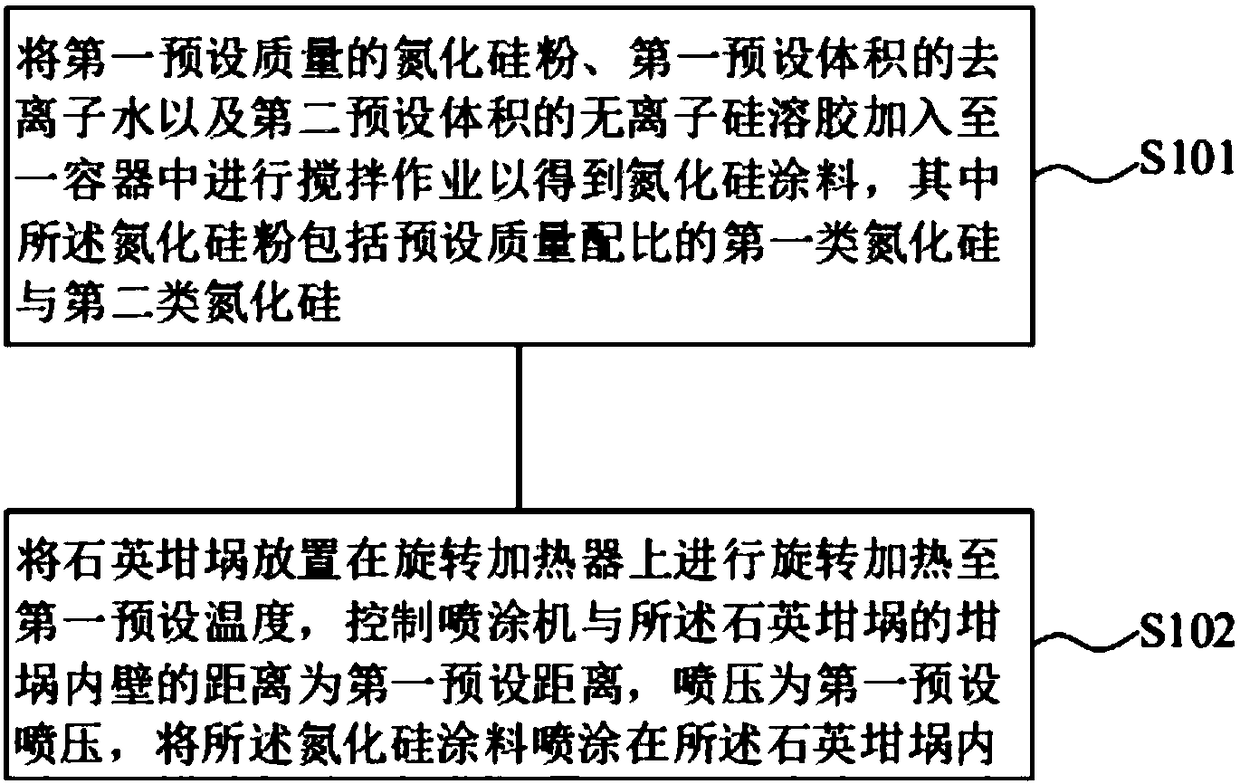

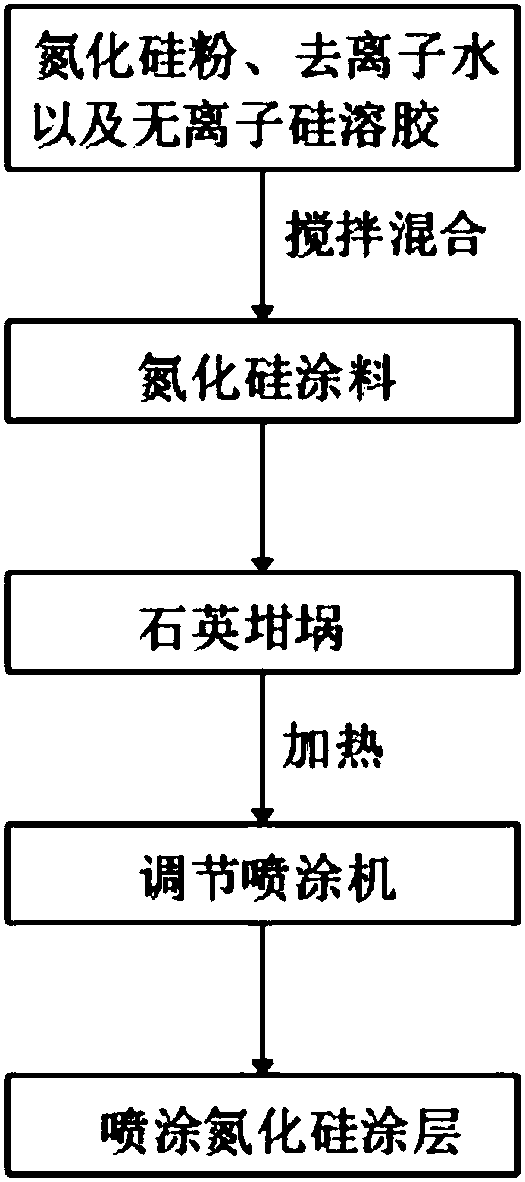

[0037] The coating preparation method of the polysilicon ingot quartz crucible proposed by the present embodiment is as follows:

[0038] (1) First weigh 800g of silicon nitride powder (wherein the weight ratio of silicon nitride A to silicon nitride B is 6:4), then use a measuring cylinder to measure 1500ml of deionized water and 350ml of ion-free silicon Sol.

[0039] Pour the above-mentioned silicon nitride powder, deionized water and unexampled silica sol into a container containing a stirrer. Stir rapidly at a stirring speed of 350 rpm for 5 min, and then continue stirring at a stirring speed of 260 rpm for 5 min.

[0040] (2) Put the quartz crucible on the rotary heater, start the rotary heater to heat the quartz crucible (the temperature of the inner wall of the quartz crucible can reach 140° C.). Then the distance between the spray gun of the spraying machine and the wall of the quartz crucible is controlled at 25 cm, the spray pressure is adjusted to 30 par, and the...

Embodiment 2

[0044] (1) First weigh 850g of silicon nitride powder (the weight ratio of silicon nitride A to silicon nitride B is 13:7), and then measure 1500ml of deionized water and 370ml of ion-free silicon with a graduated cylinder. Sol.

[0045] Pour the above-mentioned silicon nitride powder, deionized water and unexampled silica sol into a container containing a stirrer. Stir rapidly at a stirring speed of 350 rpm for 5 min, and then continue stirring at a stirring speed of 260 rpm for 5 min.

[0046] (2) Put the quartz crucible on the rotary heater, start the rotary heater to heat the quartz crucible (the temperature of the inner wall of the quartz crucible can reach 140° C.). Then the distance between the spray gun of the spraying machine and the wall of the quartz crucible is controlled at 25 cm, the spray pressure is adjusted to 30 par, and the spraying machine is turned on for spraying.

[0047] During the spraying process, use an infrared temperature measuring gun to measure...

Embodiment 3

[0050] (1) First weigh 820g of silicon nitride powder (the weight ratio of silicon nitride A to silicon nitride B is 63:37), then measure 1350ml of deionized water and 350ml of ion-free silicon with a graduated cylinder Sol.

[0051] Pour the above-mentioned silicon nitride powder, deionized water and unexampled silica sol into a container containing a stirrer. Stir rapidly at a stirring speed of 350 rpm for 5 min, and then continue stirring at a stirring speed of 260 rpm for 5 min.

[0052] (2) Put the quartz crucible on the rotary heater, start the rotary heater to heat the quartz crucible (the temperature of the inner wall of the quartz crucible can reach 140° C.). Then the distance between the spray gun of the spraying machine and the wall of the quartz crucible is controlled at 25 cm, the spray pressure is adjusted to 30 par, and the spraying machine is turned on for spraying.

[0053] During the spraying process, use an infrared temperature measuring gun to measure the...

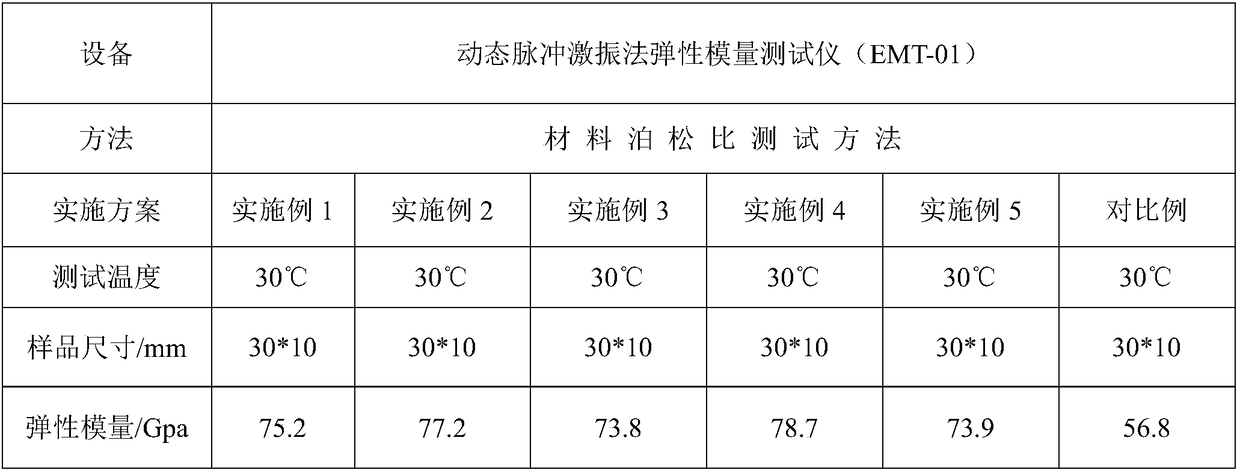

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com