Multi-effect anti-fouling coating and construction method thereof

An antifouling coating and construction method technology, applied in the field of coatings, can solve problems such as anti-fouling self-cleaning, anti-graffiti, anti-sticking and anti-corrosion, increased surface adhesion, and difficult to remove graffiti, etc., to achieve Anti-fouling, self-cleaning, weather resistance, fast surface drying, low construction equipment and low construction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

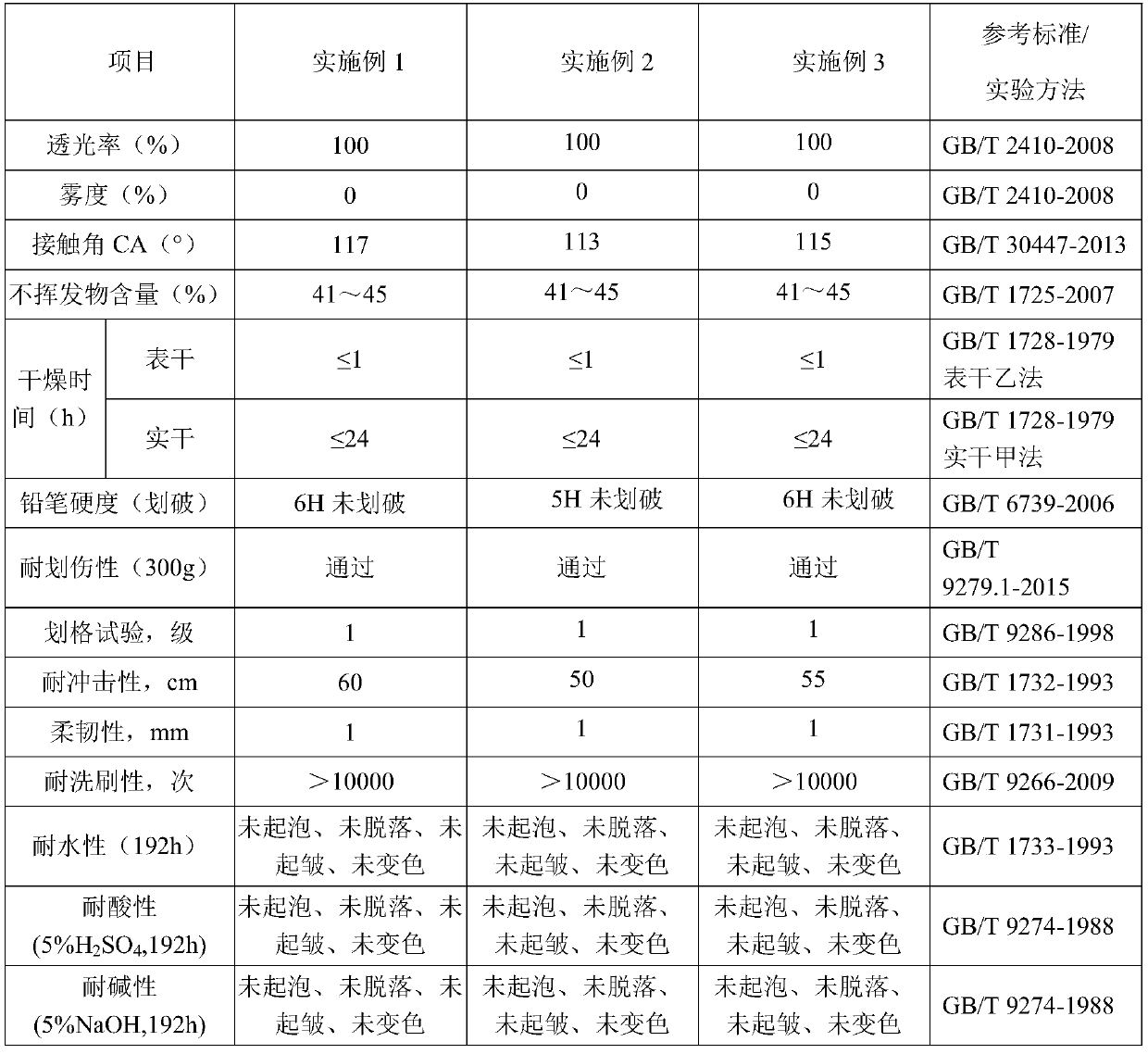

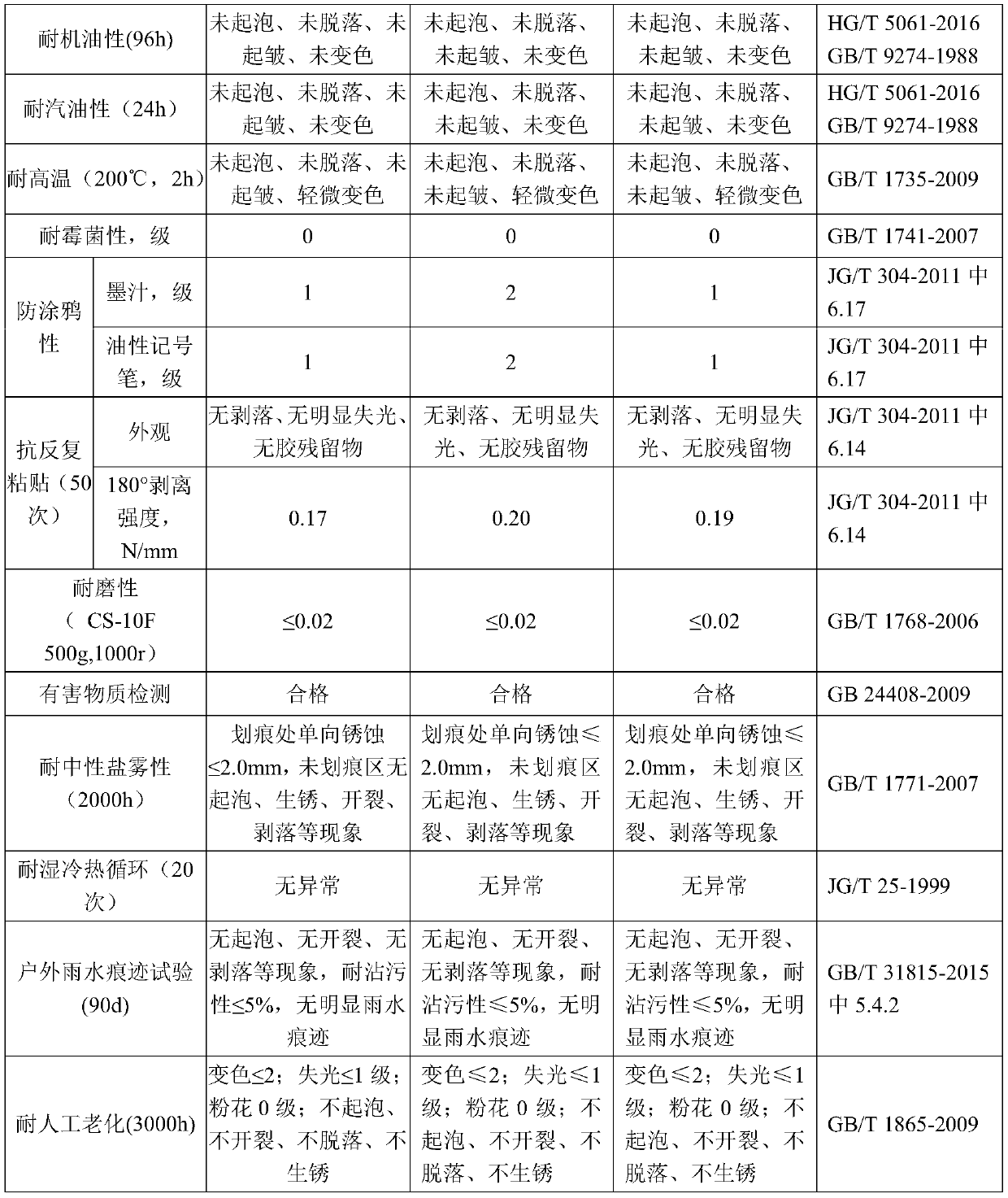

Embodiment 1

[0032] Embodiment 1 of the present invention provides a kind of multi-effect antifouling paint, comprises component A and component B, and wherein component A comprises the component of following weight parts: 45 parts of fluorine silicon modified polyester resins containing hydroxyl, Fluorosilicone-modified special hydrophobic antistatic agent 1 part, SHP-50 silane-based hydrophobic recovery agent 1 part, benzimidazole anti-mold and anti-algae agent 0.5 part, substituted aromatic hydrocarbon anti-mold and anti-algae agent 0.5 part, acrylate leveling 1 part of acrylate wetting and dispersing agent, 2 parts of silicone defoamer, 48 parts of solvent (the solvent is mixed with butyl acetate and xylene at 1:1); component B includes 50 parts of HDI trimer , 50 parts of solvent (the solvent is butyl acetate and xylene mixed according to 1:1); the mass ratio of component A and component B is 4:1.

[0033] Present embodiment 1 also provides a kind of construction method of multi-effec...

Embodiment 2

[0039] Embodiment 2 of the present invention provides a kind of multi-effect antifouling paint, comprises component A and component B, and wherein component A comprises the component of following parts by weight: 40 parts of fluorosilicone modified polyester resins containing hydroxyl, Fluorosilicone-modified special hydrophobic antistatic agent 0.5 parts, SHP-50 silane-based hydrophobic recovery agent 0.5 parts, benzimidazole anti-mold and anti-algae agent 0.25 parts, substituted aromatic hydrocarbon anti-mold and anti-algae agent 0.25 parts, acrylate leveling 0.5 parts of solvent, 0.5 parts of acrylate wetting and dispersing agent and 3 parts of silicone defoamer, 54.5 parts of solvent (the solvent is mixed with butyl acetate and xylene according to 1:1); component B includes 30 parts of MDI trimer , 70 parts of solvent (the solvent is butyl acetate and xylene mixed according to 1:1); the mass ratio of component A and component B is 10:1.

[0040] The construction method of ...

Embodiment 3

[0042] Embodiment 3 of the present invention provides a kind of multi-effect antifouling paint, comprises component A and component B, and wherein component A comprises the component of following parts by weight: 42.5 parts of hydroxyl-containing fluorine silicon modified polyester resins, Fluorosilicone-modified special hydrophobic antistatic agent 2 parts, SHP-50 silane-based hydrophobic recovery agent 2 parts, benzimidazole anti-mold and anti-algae agent 1 part, substituted aromatic hydrocarbon anti-mold and anti-algae agent 1 part, acrylate leveling 2 parts of solvent, 2 parts of acrylate wetting and dispersing agent, 5 parts of silicone defoamer, 42.5 parts of solvent (the solvent is mixed with butyl acetate and xylene according to 1:1); component B includes 40 parts of TDI trimer , 60 parts of solvent (the solvent is butyl acetate and xylene mixed according to 1:1); the mass ratio of component A and component B is 7:1.

[0043] The construction method of the multi-effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com