Low-temperature non-foaming anti-staining soaping agent as well as preparation method and application thereof

An anti-soaping agent and low-temperature technology, applied in the field of textile printing and dyeing, can solve the problems of complex formula composition, and achieve the effects of reducing the number of washings, reducing foam and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

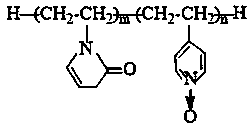

Embodiment 1

[0025] In this example, a method for preparing a low-temperature non-foaming anti-staining soaping agent is provided, which is configured according to the following steps: Step S1) The following components are configured in parts by weight: vinylpyrrolidone and vinylpyridine-N-oxide 30 parts of copolymers, 5 parts of sodium carbonate, 13 parts of cetyltrimethylammonium bromide, 2 parts of polyether modified silicone antifoaming agent, 50 parts of water; step S2) configures in step S1) 30 parts of vinylpyrrolidone and vinylpyridine-N-oxide copolymer, 5 parts of sodium carbonate, 13 parts of cetyltrimethylammonium bromide, and 2 parts of polyether modified silicone defoamer were added to Add 50 parts of water into the reaction kettle, and stir fully at room temperature to obtain a low-temperature non-foaming anti-staining soaping agent.

Embodiment 2

[0027] In this example, a method for preparing a low-temperature non-foaming anti-staining soaping agent is provided, which is configured according to the following steps: Step S1) The following components are configured in parts by weight: vinylpyrrolidone and vinylpyridine-N-oxide 25 parts of copolymers, 3 parts of sodium bicarbonate, 10 parts of cetyltrimethylammonium bromide, 2 parts of polyether modified silicone defoamer, 60 parts of water; step S2) will step S1) 25 parts of copolymer of vinylpyrrolidone and vinylpyridine-N-oxide, 3 parts of sodium bicarbonate, 10 parts of cetyltrimethylammonium bromide, 2 parts of polyether modified silicone defoamer Add it to a reaction kettle, add 60 parts of water, and stir it fully at room temperature to obtain a low-temperature non-foaming anti-staining soaping agent.

Embodiment 3

[0029] In this example, a method for preparing a low-temperature non-foaming anti-staining soaping agent is provided, which is configured according to the following steps: Step S1) The following components are configured in parts by weight: vinylpyrrolidone and vinylpyridine-N-oxide 28 parts of copolymers, 2 parts of sodium metasilicate pentahydrate, 10 parts of octadecyl polyoxyethylene ammonium bromide, 2 parts of polyether modified silicone defoamer, 57 parts of water; Step S2) will 28 parts of the copolymer of vinylpyrrolidone and vinylpyridine-N-oxide configured in step S1), 2 parts of sodium metasilicate pentahydrate, 10 parts of octadecyl polyoxyethylene ammonium bromide, polyether modified Add 3 parts of non-toxic silicone antifoaming agent into the reaction kettle, add 57 parts of water, and stir thoroughly at room temperature to obtain a low-temperature non-foaming anti-staining soaping agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com