Bionic stirring machine for injection grout, hybrid power bionic stirring system and slurrying method of hybrid power bionic stirring system

A mixer and grouting technology, applied in the directions of mixing operation control, mixing operation control device, cement mixing device, etc., can solve the problem that it is difficult to quantitatively control the amount of slurry material, the performance of the slurry does not meet the expected requirements, the environment and ecology. Adverse effects and other problems, to achieve the effect of improving supply efficiency and quality, easy maintenance, and easy pulping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The specific embodiments of the present invention are described below so that those skilled in the art can understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those of ordinary skill in the art, as long as various changes Within the spirit and scope of the present invention defined and determined by the appended claims, these changes are obvious, and all inventions and creations using the concept of the present invention are included in the protection list.

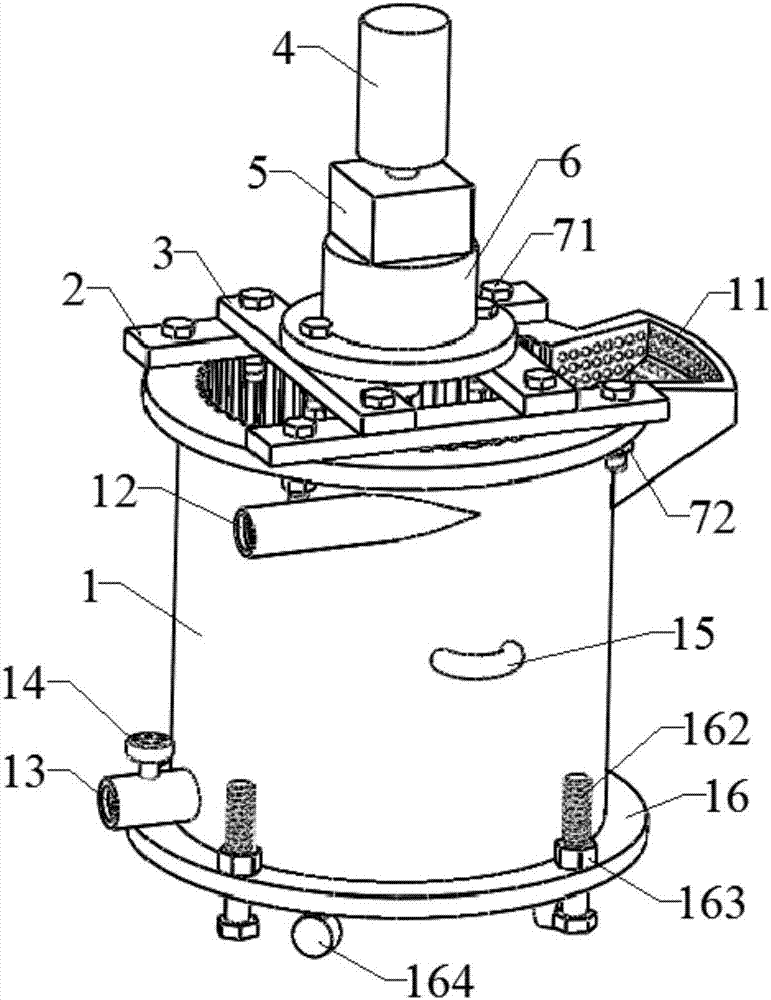

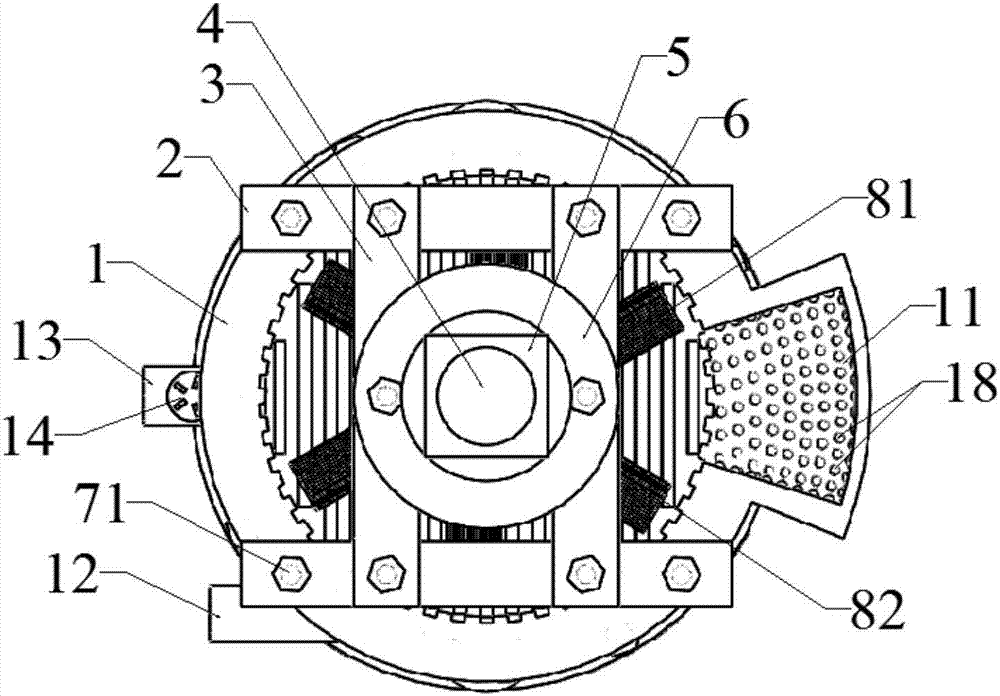

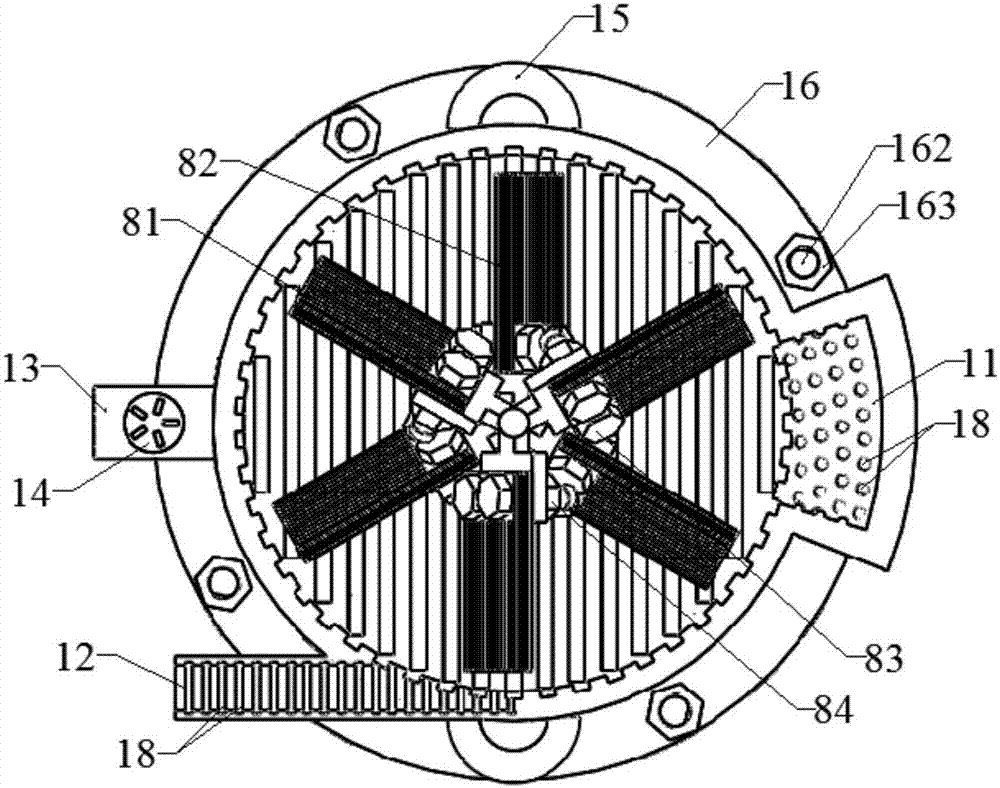

[0082] Such as Figure 1 to Figure 6 As shown, the bionic mixer for grouting includes a mixing tank 1 with a feed inlet and a slurry outlet pipe 13, and the bottom surface of the mixing bucket 1 is a slope 17 facing the slurry outlet pipe 13, where the bottom surface of the mixing bucket 1 is The inclination angle is 5°-35°, so that the slurry in the cavity of the mixing tank 1 has a tendency to flow to the slurry outlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com