Method for synthesizing anatase phase titanium dioxide nanometer particle by microreactor

A technology of hydrated titanium dioxide and titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problem that the high density of the film affects the photocatalytic performance, and achieve the effect of strong redox ability, good stability and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

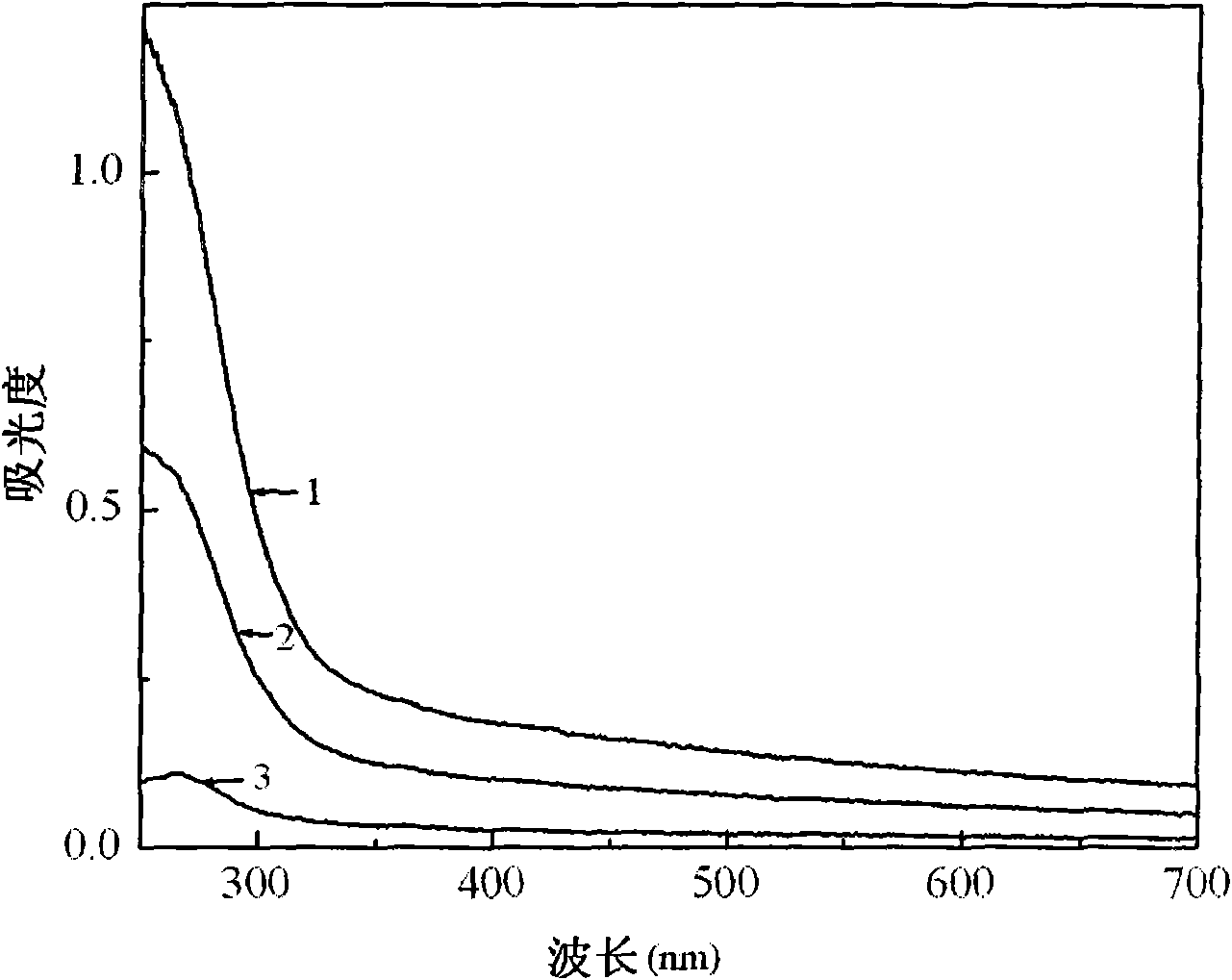

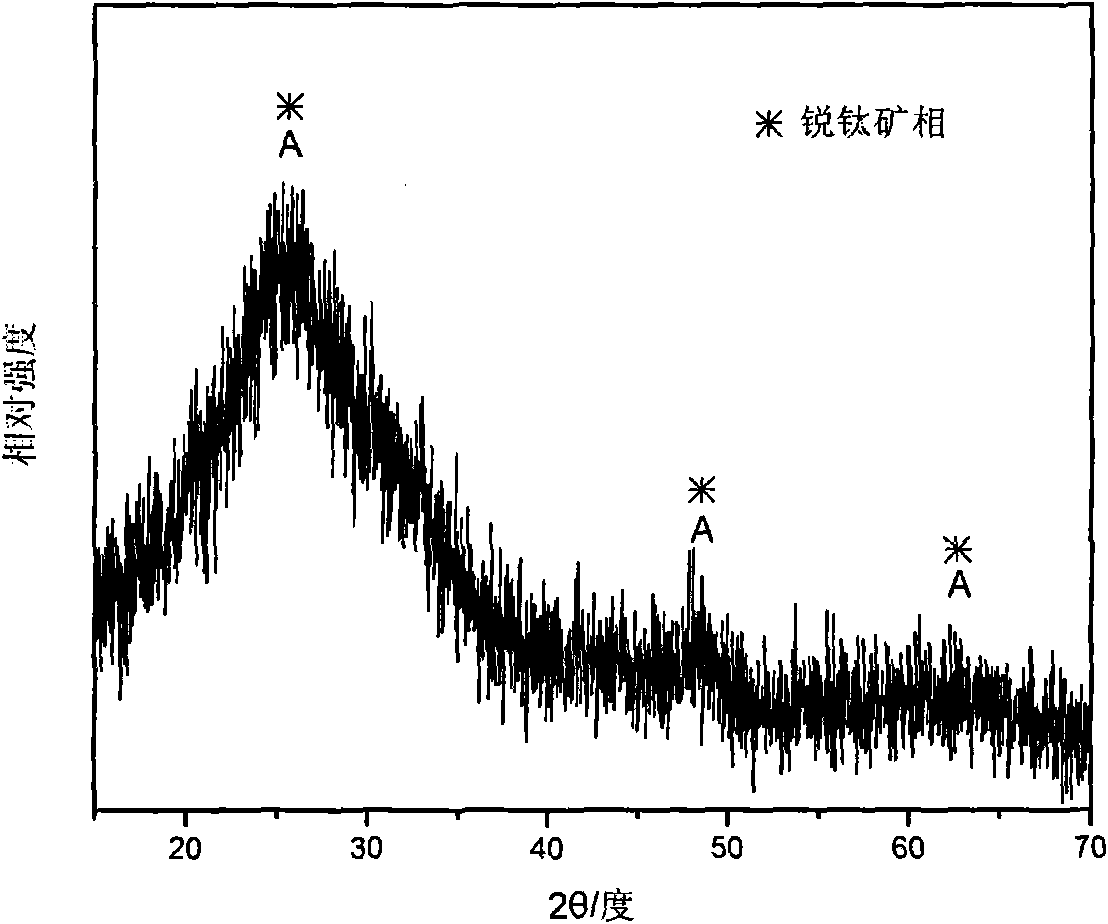

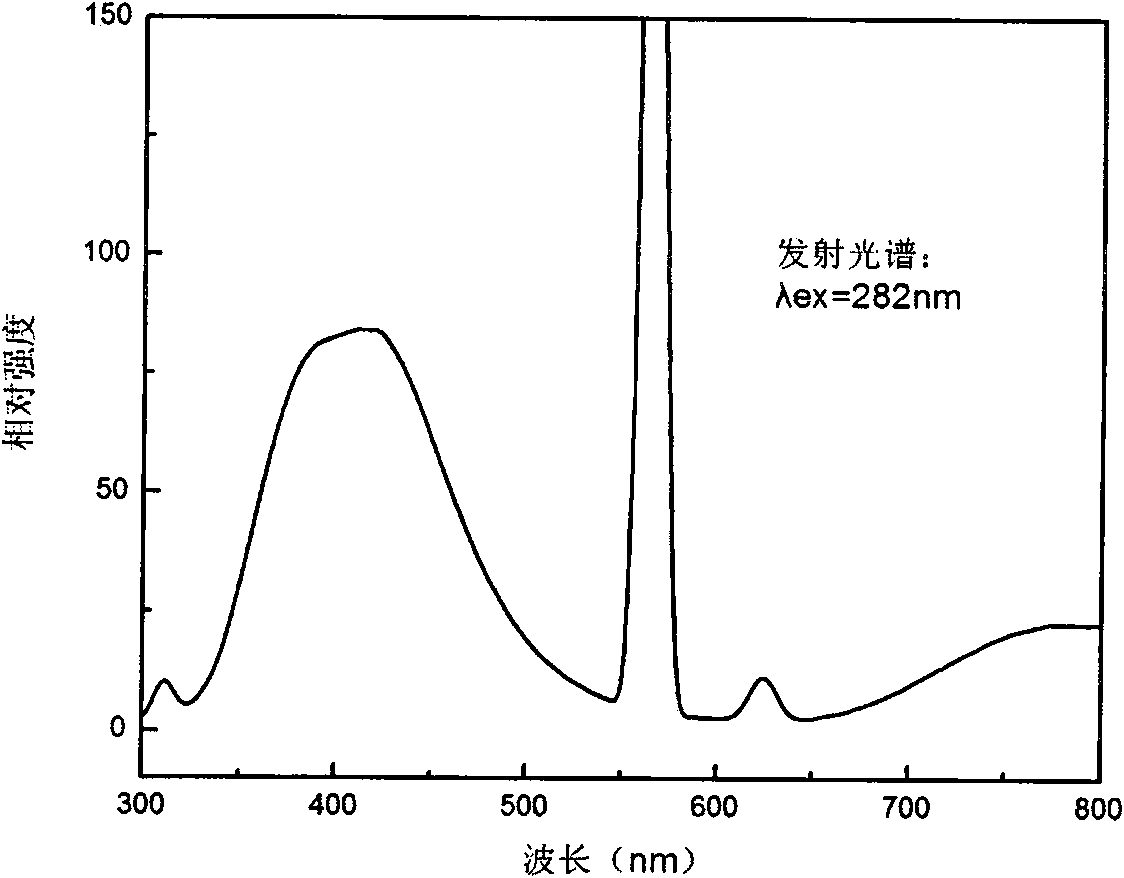

[0034] Add 0.5M sodium hydroxide solution dropwise to 0.5M titanium tetrachloride solution at room temperature, and neutralize to pH approximately equal to 7 to obtain a white precipitate. Wash it repeatedly with distilled water to obtain a gel-like solid. Take 30 grams of wet precipitate ( It is converted to 4 grams of titanium dioxide.) Disperse it in 180 ml of hydrogen peroxide (30wt%) and degelatinize at 30°C for 6 hours to obtain an orange transparent peroxytitanic acid aqueous solution or sol. The content of titanium dioxide in the solution is 0.24M , The pH value is about 6. Dilute the peroxy titanic acid aqueous solution or sol with ethylene glycol at 2:58, measure 10 mL into the syringe, and seal with silicone grease to prevent leakage. Push the reaction solution into the capillary with a micro-propelling pump, and complete the nucleation and growth stage in a constant temperature oil bath at 180°C for 40 seconds. After the reaction, the product is received in a sample bo...

Embodiment 2

[0037] Add 2M ammonia water dropwise to the 1M titanium oxysulfate solution at 70℃, keep hydrolyzing for 6 hours, neutralize to a weak alkaline pH value of about 8 to obtain a white precipitate, repeatedly wash with distilled water to obtain a gel-like solid, take the wet precipitation Disperse 15 grams (2 grams into titanium dioxide) in about 90 milliliters of hydrogen peroxide (35wt%) and dissolve the gel at room temperature for 2 hours to obtain an orange-yellow transparent peroxytitanic acid hydrosol with a pH of about 6 . After diluting the peroxytitanic acid aqueous solution or sol and deionized water at a mass ratio of 1:5, take a portion and dilute it with ethylene glycol at a ratio of 1:9, measure 10 mL into the syringe, and seal with silicone grease to prevent leakage. Push the reaction solution into the capillary with a micro-propelling pump, and complete the nucleation and growth stage in a constant temperature oil bath at 180°C for 120 seconds. After the reaction, the...

Embodiment 3

[0039] After heating the 0.5mol / L titanium sulfate solution to 50°C, add 1.5mol / L ammonia solution dropwise to the solution, heat and hydrolyze for 10 hours, and neutralize to a pH of about 7, to obtain a white precipitate, which is repeatedly washed with distilled water to obtain Gel-like solid, take 40 g of wet precipitate (6.2 g converted to titanium dioxide), disperse it in 280 ml of hydrogen peroxide (35wt%) solution, and debond for 12 hours to obtain orange-yellow transparent peroxytitanic acid hydrosol, pH The value is approximately 6. Dilute the peroxy titanic acid aqueous solution or sol with ethylene glycol at a ratio of 1:59, measure 10 mL into the syringe, and seal with silicone grease to prevent leakage. Push the reaction solution into the capillary with a micro-propelling pump, and complete the nucleation and growth stage in a constant temperature oil bath at 180°C for 80 seconds. After the reaction, the product is received in a sample bottle to obtain an EG dispersi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com