High-efficiency Fe-SCR integrated catalyst preparation method

A monolithic catalyst and high-efficiency technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as coatings, and achieve the effect of simple preparation method, improved catalytic performance, and easy steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

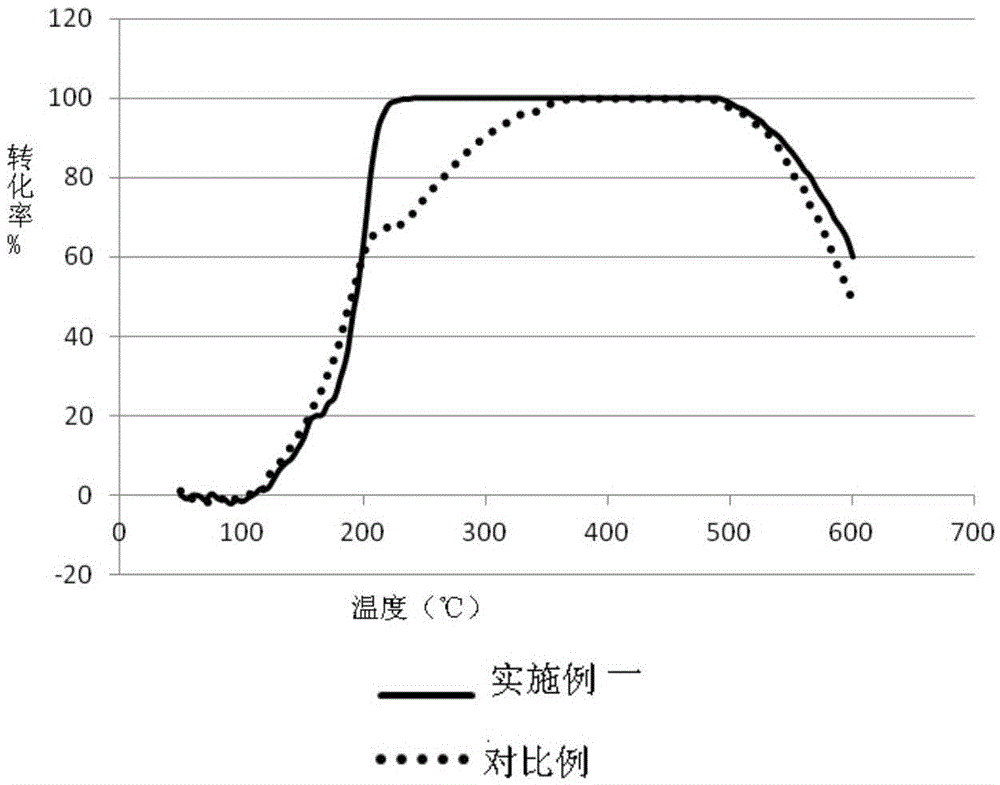

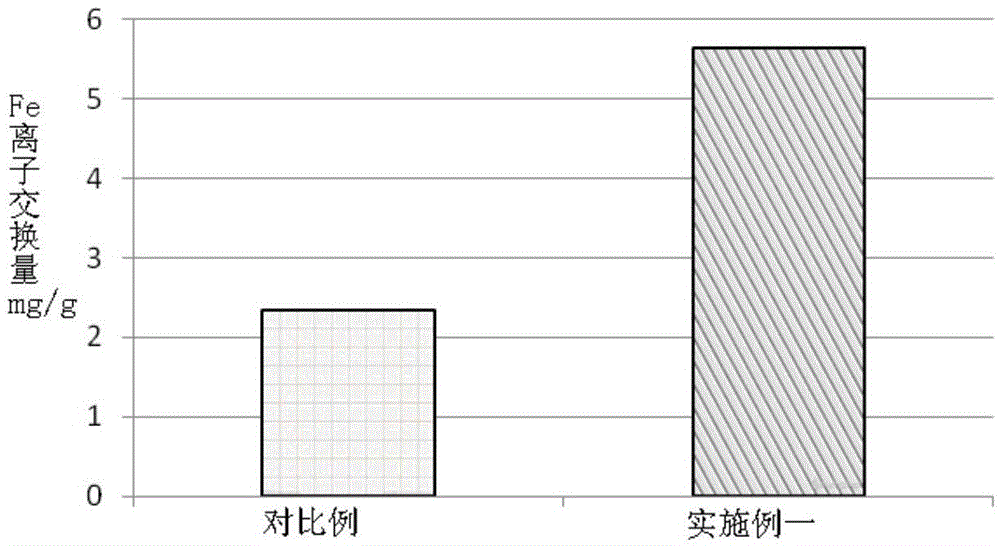

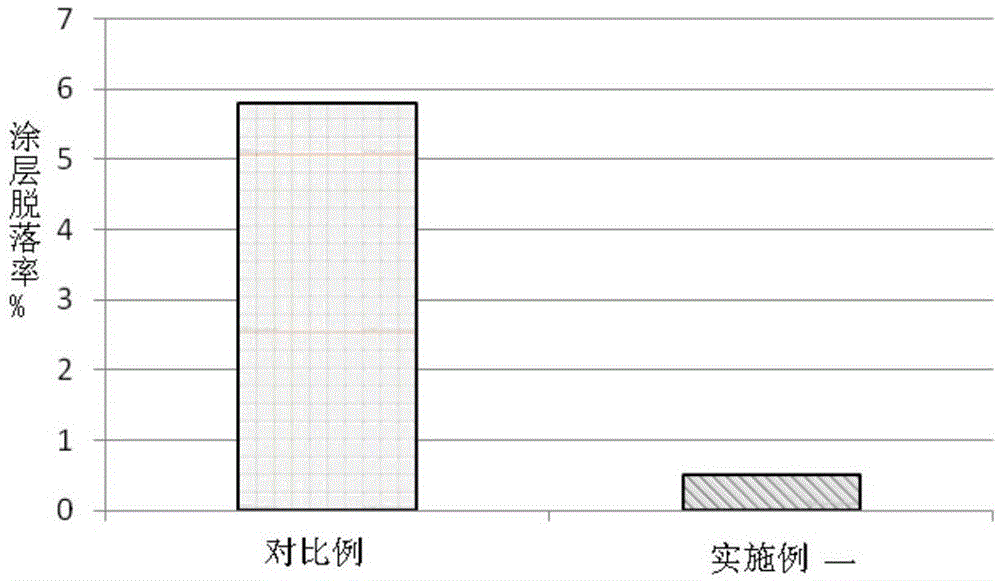

Embodiment 1

[0029] Embodiment one: a kind of preparation method of efficient Fe-SCR monolithic catalyst comprises the following steps:

[0030] (1) Fe molecular sieve ion exchange technology

[0031] a. FeCl 3 Add to deionized water and mix, heat in water bath to 50°C, wait for FeCl 3 Completely dissolve to obtain the exchange liquid. According to the Fe source / β molecular sieve mass ratio of 0.5, add β molecular sieve to the exchange liquid, continue to heat up to 90°C, and stir evenly for 5 hours to perform ion exchange;

[0032] b. After the ion exchange is completed, cool the exchange solution and pass it into a filter press for washing. After the eluate is colorless, place the molecular sieve in an oven and dry at 120°C for 5 hours for use.

[0033] c. Put the dried molecular sieve into a roasting furnace, raise the temperature to 450° C. at a rate of 2° C. / min, keep it warm for 1 hour, and cool it in the furnace for use to obtain Fe molecular sieve.

[0034] (2) Stir the pseudo-b...

Embodiment 2

[0050] Embodiment two: a kind of preparation method of high-efficiency Fe-SCR monolithic catalyst comprises the following steps:

[0051] (1) Molecular sieve ion exchange:

[0052] a. FeCl 3 Add it into deionized water, stir evenly, heat in a water bath to 50°C, wait until the Fe source is completely dissolved to make an exchange liquid, according to the Fe source / β molecular sieve mass ratio of 0.6, add β molecular sieve to the exchange liquid, and continue heating to 80°C , stirring for 5h for ion exchange;

[0053] b. After the ion exchange, cool the exchange liquid and pass it into the filter press for washing. After the eluate is colorless, put the molecular sieve into the oven and dry it at 120°C for 5 hours for use;

[0054] c. putting the dried molecular sieve into a roasting furnace for roasting, and cooling to room temperature after roasting to obtain Fe molecular sieve;

[0055] (2) Add pseudo-boehmite to deionized water and stir well, according to H + / Pseudobo...

Embodiment 3

[0060] Embodiment three: a kind of preparation method of high-efficiency Fe-SCR monolithic catalyst comprises the following steps:

[0061] (1) Molecular sieve ion exchange:

[0062] a. Fe(NO 3 ) 3 Add it into deionized water, stir evenly, heat in a water bath to 50°C, and wait until Fe(NO 3 ) 3 Completely dissolve to make an exchange liquid. According to the Fe source / SSZ-13 molecular sieve mass ratio of 0.7, add molecular sieves to the exchange liquid, continue heating to 90°C, and stir for 5 hours to perform ion exchange;

[0063] b. After the ion exchange is completed, cool the exchange liquid and pass it into a filter press for washing. After the eluate is colorless, put the molecular sieve into an oven and dry at 120°C for 6 hours for use;

[0064] c. putting the dried molecular sieve into a roasting furnace for roasting, and cooling to room temperature after roasting to obtain Fe molecular sieve;

[0065] (2) Add pseudo-boehmite to deionized water and stir well, ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com