Silicon-modified alumina, as well as preparation method and application thereof

A technology of alumina and silicon modification, applied in chemical instruments and methods, catalyst carriers, chemical/physical processes, etc., to achieve excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

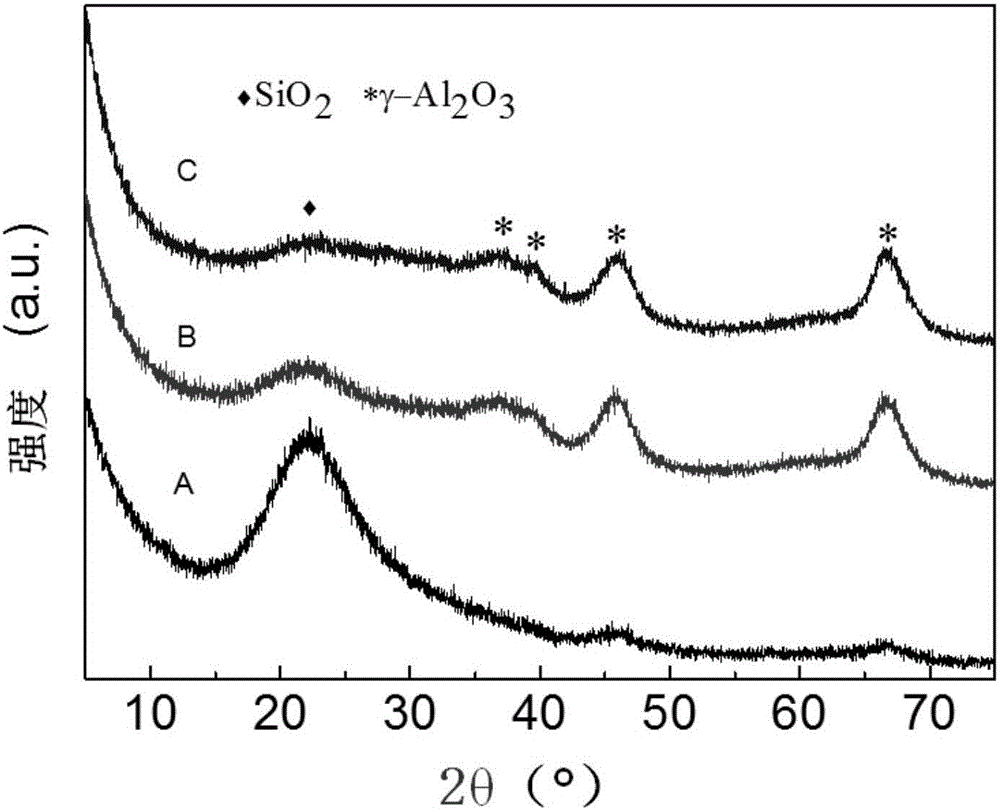

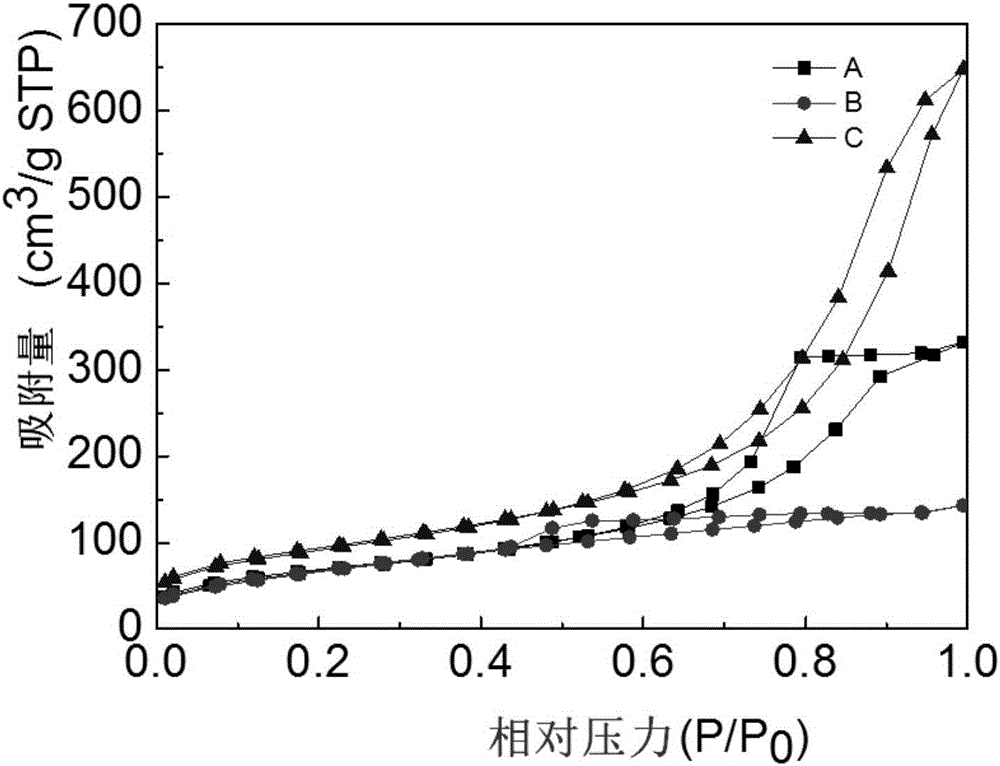

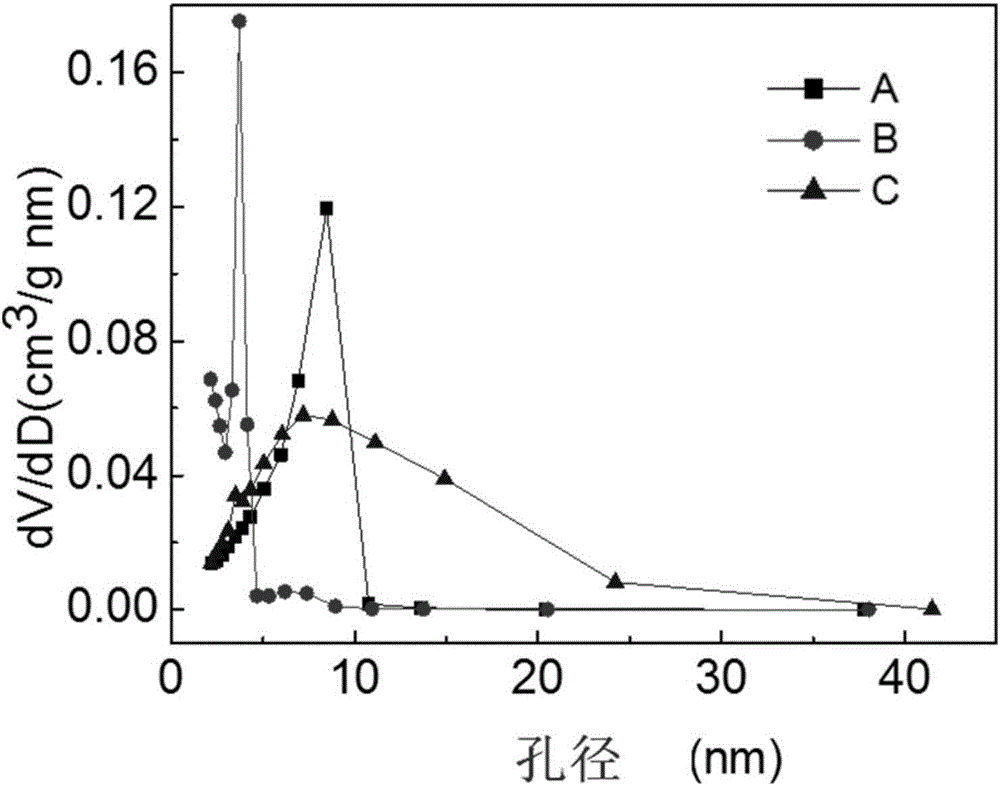

Embodiment 1

[0042] This example provides a method for preparing silicon-modified alumina, and by using this method, silicon-modified alumina whose surface is rich in B acid is prepared. The specific preparation steps include:

[0043] (1) 22g of pseudo-boehmite is added to 50mL of deionized water for beating for 5-10min to obtain pseudo-boehmite slurry; 5mL of 6mol / L hydrochloric acid solution is added dropwise to the pseudo-boehmite slurry to make it Acidification peptization, continuous stirring for 1 hour after the dropwise addition, to obtain pseudo-boehmite sol;

[0044] (2) Add 12 g of silica sol dropwise to the above-mentioned pseudo-boehmite sol to obtain the first mixture;

[0045] (3) Adjust the pH value of the first mixture to 1-2 with 6mol / L hydrochloric acid solution, then add 50mL of deionized water therein, and continue the reaction for 20h in a water bath at 30°C to obtain the second mixture;

[0046] (4) Crystallizing the second mixture at 120° C. for 18 hours to obtain ...

Embodiment 2

[0049] This example provides a method for preparing silicon-modified alumina, and by using this method, silicon-modified alumina with improved pore volume and surface B acid content is obtained. The specific preparation steps include:

[0050] (1) 22g of pseudo-boehmite is added to 50mL of deionized water for beating for 5-10min to obtain pseudo-boehmite slurry; 5mL of 6mol / L hydrochloric acid solution is added dropwise to the pseudo-boehmite slurry to make it Acidification peptization, continuous stirring for 1 hour after the dropwise addition, to obtain pseudo-boehmite sol;

[0051] (2) Add 12 g of silica sol dropwise to the above-mentioned pseudo-boehmite sol to obtain the first mixture;

[0052] (3) Adjust the pH value of the first mixture to 5-6 with ammonia solution, then add 50 mL of deionized water therein, and continue the reaction for 20 h in a water bath at 30° C. to obtain the second mixture;

[0053] (4) Crystallizing the second mixture at 120° C. for 18 hours to...

Embodiment 3

[0056] This example provides a method for preparing silicon-modified alumina, and this method is used to obtain silicon-modified alumina with large pores. The specific preparation steps include:

[0057] (1) 22g of pseudo-boehmite is added to 50mL of deionized water for beating for 5-10min to obtain pseudo-boehmite slurry; 5mL of 6mol / L hydrochloric acid solution is added dropwise to the pseudo-boehmite slurry to make it Acidification peptization, continuous stirring for 1 hour after the dropwise addition, to obtain pseudo-boehmite sol;

[0058] (2) Add 12 g of silica sol dropwise to the above-mentioned pseudo-boehmite sol to obtain the first mixture;

[0059] (3) Adjust the pH value of the first mixture to 10-11 with an ammonia solution, then add 50 mL of deionized water therein, and continue the reaction for 20 h in a water bath at 30° C. to obtain the second mixture;

[0060] (4) Crystallizing the second mixture at 120° C. for 18 hours to obtain a third mixture;

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com