Hydrolysable ultraviolet curing adhesive and method for preparing same

A technology of curing glue and ultraviolet rays, applied in the direction of adhesives, polyether adhesives, adhesive types, etc., to achieve the effects of easy coating, strong fluidity, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

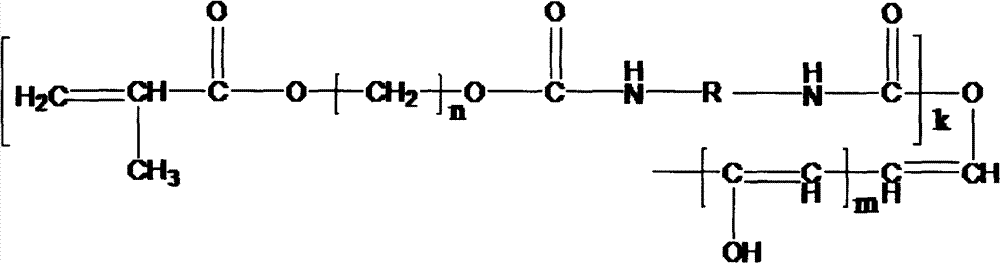

Image

Examples

preparation example Construction

[0015] Preparation of prepolymer A: Weigh 72g of hydroxypropyl methacrylate and put it in a three-necked flask, raise the temperature to 110°C for 2 hours and vacuum dehydrate it, then lower it to 30°C, add 116.6g of 3-isocyanate methylene-3,5 , 5-trimethylcyclohexyl isocyanate (IPDI), heated to 55 degrees to react for 2.5h to obtain polyurethane intermediate prepolymer.

[0016] Weigh 100g of polyethylene glycol dimethacrylate and place it in a three-necked flask, stir and add 200g of polyvinyl alcohol with a molecular weight of 12,000, stir to make it evenly mixed, heat up to 110°C and vacuum dehydrate for 2 hours, then drop to 35°C, add 29g of the intermediate prepolymer was stirred to make it evenly mixed, then added and heated to 75°C for 3.5h reaction to obtain polyvinyl alcohol-modified polyurethane acrylate A.

[0017] Preparation of prepolymer B: Weigh 79.2g of hydroxypropyl methacrylate and put it in a three-necked flask, raise the temperature to 110°C and vacuum deh...

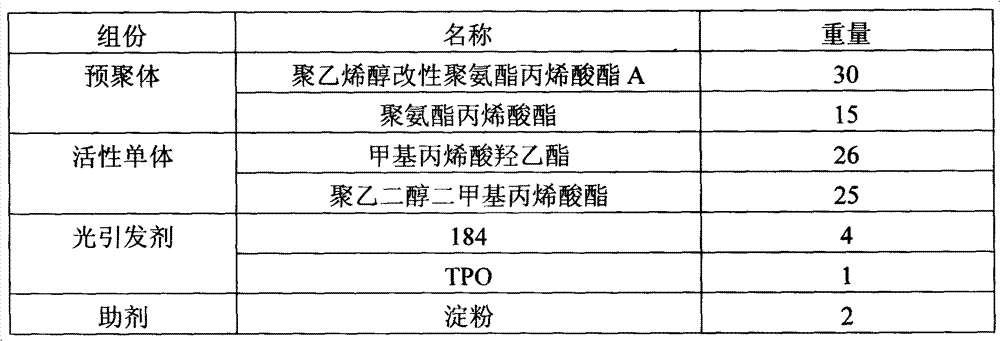

Embodiment 1

[0022] Embodiment 1: prepare the ultraviolet curable adhesive according to the following table proportioning. Take 16g of hydroxyethyl methacrylate and 25g of polyethylene glycol dimethacrylate in a three-necked flask, raise the temperature to 115°C and vacuum dehydrate for 2 hours, cool down to room temperature, add 42g of polyvinyl alcohol modified polyurethane acrylate A, Stir to dissolve 15g of polyurethane acrylate, 4g of photoinitiator 184 and 1g of TPO, and finally add 2g of starch and stir evenly to obtain a polyvinyl alcohol-modified polyurethane acrylate UV-curable adhesive.

[0023]

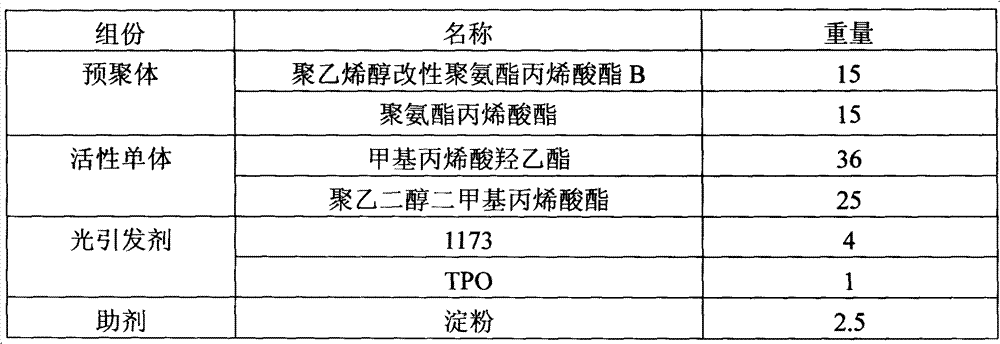

Embodiment 2

[0024] Embodiment 2: Prepare polyvinyl alcohol-modified polyurethane acrylate UV adhesive according to the ratio in the following table. Preparation method is with embodiment 1.

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com