B acid-enriched mesoporous alumina, as well as preparation method and application thereof

A mesoporous alumina, B acid technology, used in alumina/hydroxide preparation, chemical instruments and methods, cracking, etc., can solve the change of alumina acidity without specific characterization and testing, and the pore structure is not The problems such as obvious improvement have been achieved, and the effect of good application prospect, high pore volume and high B/L ratio has been achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a kind of B-acid-rich mesoporous alumina, and the steps of preparing the B-acid-rich mesoporous alumina include:

[0050] (1) 22g of pseudo-boehmite is added to 50mL of deionized water and beaten for 5-10min to obtain a pseudo-boehmite slurry; 30mL of 1mol / L hydrochloric acid solution is added dropwise to the pseudo-boehmite slurry to make it Acidify and peptize, and continue stirring for 10-15 minutes after the dropwise addition to obtain pseudo-boehmite sol.

[0051] (2) In above-mentioned pseudo-boehmite sol, add dropwise the aqueous solution of 0.03mol ammonium fluorosilicate with 40mL deionized water dissolving, then add dropwise the aqueous solution of 13g Pluronic P123 with 40mL deionized water dissolving, obtain the first mixture.

[0052] (3) The first mixture was reacted at 60-90° C. for 6 hours, cooled after the reaction, and then adjusted to pH 11 with ammonia water, and aged in a water bath at 75° C. for 24 hours to obtain the seco...

Embodiment 2

[0055] This embodiment provides a kind of B-acid-rich mesoporous alumina, and the steps of preparing the B-acid-rich mesoporous alumina include:

[0056] (1) 22g of pseudo-boehmite is added to 50mL of deionized water and beaten for 5-10min to obtain a pseudo-boehmite slurry; 30mL of 1mol / L hydrochloric acid solution is added dropwise to the pseudo-boehmite slurry to make it Acidify and peptize, and continue stirring for 10-15 minutes after the dropwise addition to obtain pseudo-boehmite sol.

[0057] (2) In the above-mentioned pseudo-boehmite sol, add dropwise the aqueous solution of 0.045mol ammonium fluorosilicate with 40mL deionized water dissolving, then add dropwise the aqueous solution of 13g Pluronic P123 dissolved with 40mL deionized water, to obtain the first mixture.

[0058] (3) The first mixture was reacted at 60-90° C. for 6 hours, cooled after the reaction, and then adjusted to pH 11 with ammonia water, and aged in a water bath at 75° C. for 24 hours to obtain t...

Embodiment 3

[0061] This embodiment provides a kind of B-acid-rich mesoporous alumina, and the steps of preparing the B-acid-rich mesoporous alumina include:

[0062] (1) 22g of pseudo-boehmite is added to 50mL of deionized water and beaten for 5-10min to obtain a pseudo-boehmite slurry; 30mL of 1mol / L hydrochloric acid solution is added dropwise to the pseudo-boehmite slurry to make it Acidify and peptize, and continue stirring for 10-15 minutes after the dropwise addition to obtain pseudo-boehmite sol.

[0063] (2) in above-mentioned pseudo-boehmite sol, add dropwise the aqueous solution of 0.06mol ammonium fluorosilicate with 40mL deionized water dissolving, then add dropwise the aqueous solution of 13g Pluronic P123 with 40mL deionized water dissolving, obtain the first mixture.

[0064] (3) The first mixture was reacted at 60-90° C. for 6 hours, cooled after the reaction, and then adjusted to pH 11 with ammonia water, and aged in a water bath at 75° C. for 24 hours to obtain the seco...

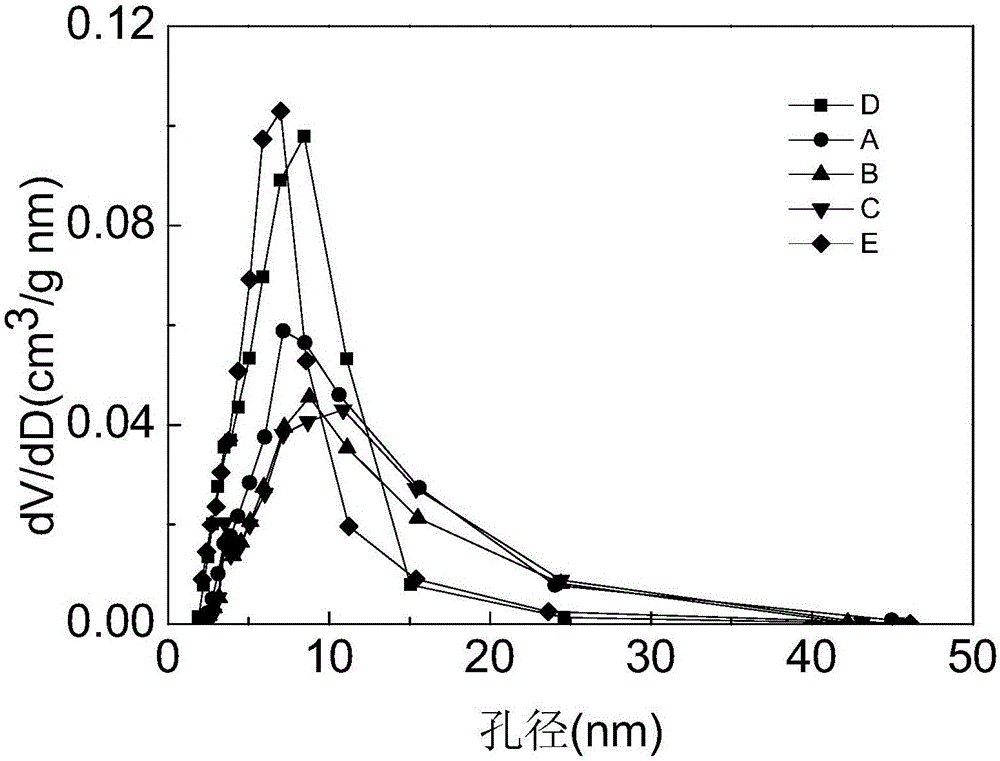

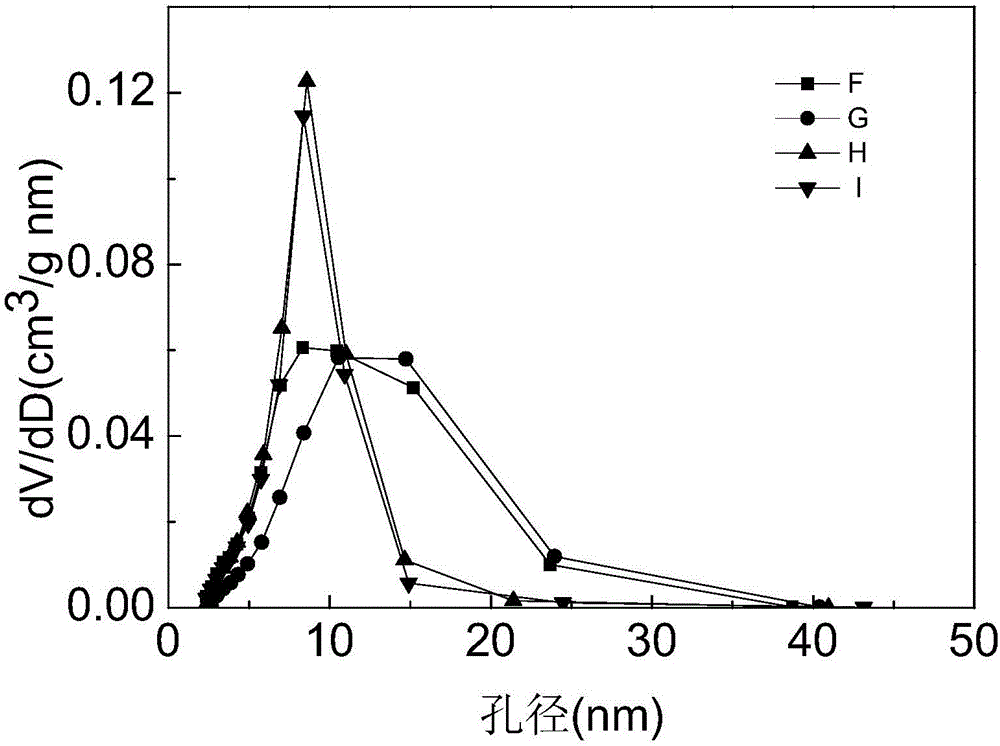

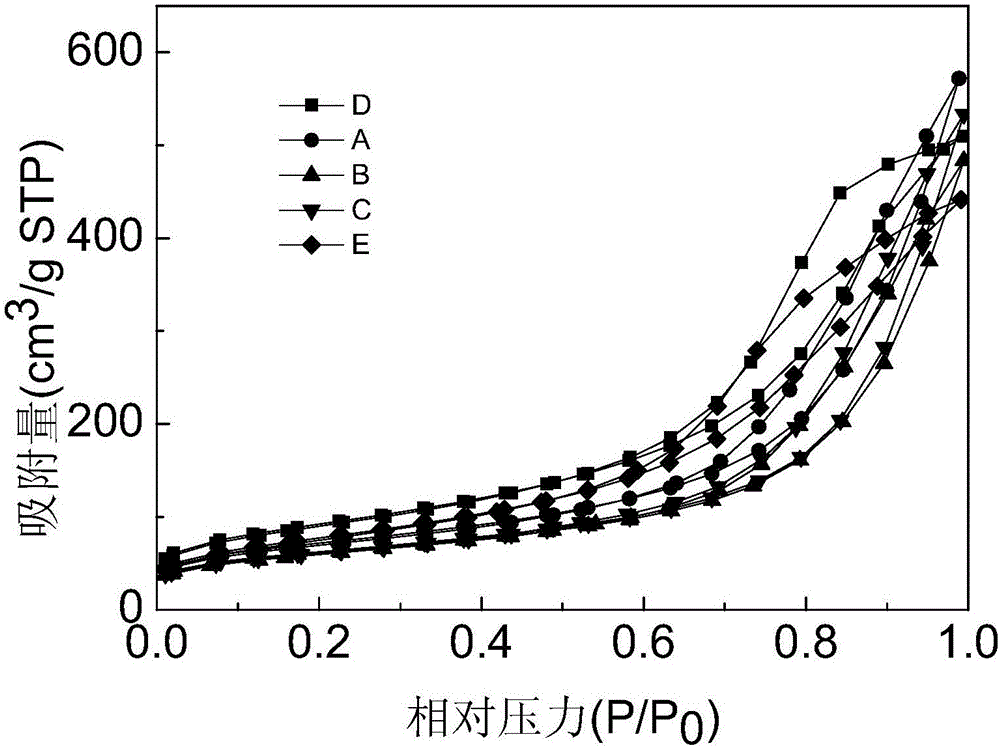

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com