Preparation method of amino silane modified gamma-Al2O3 thin film

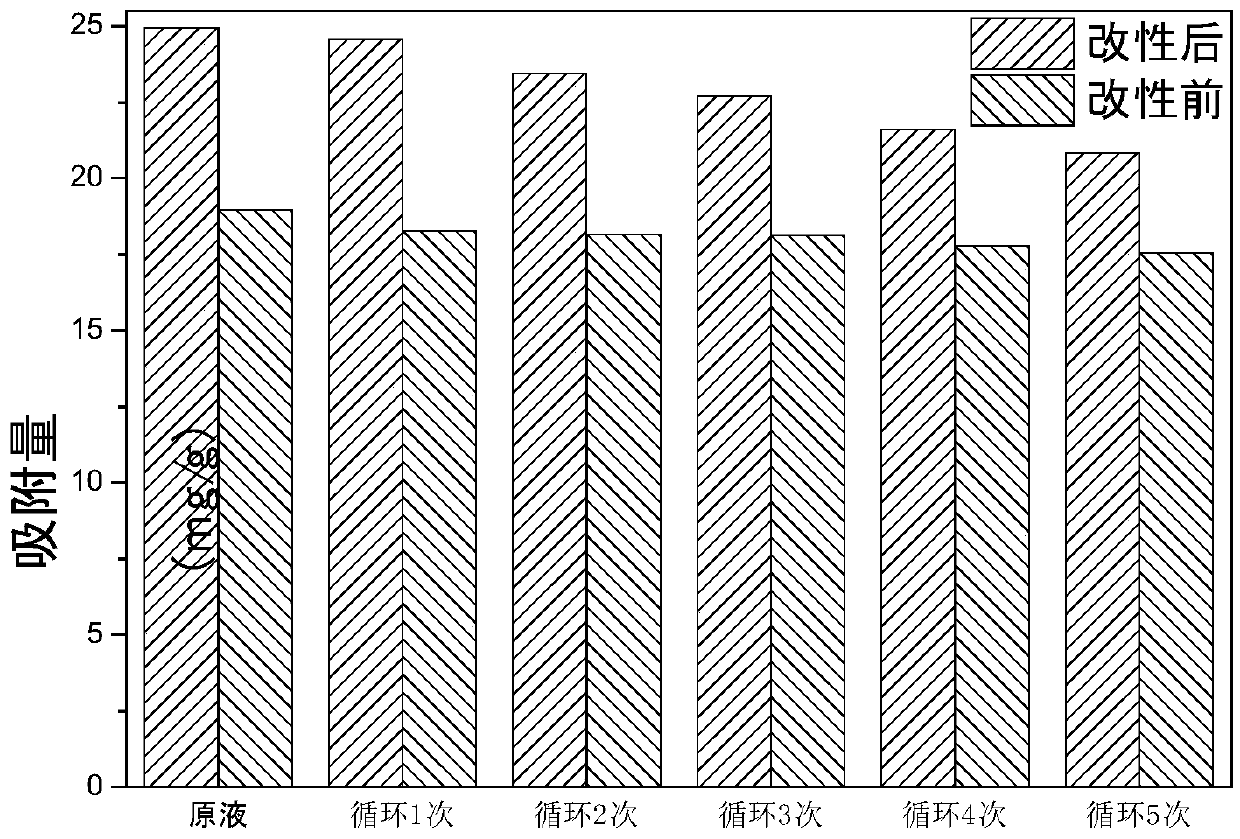

A technology of aminosilane and film, which is applied in the preparation and application of aminosilane graft modified γ-Al2O3-based composite materials, can solve the problems of good adsorption performance, and achieve the effect of stable chemical properties and good cycle regeneration adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Disperse 3g of industrial pseudo-boehmite powder in 50ml of deionized water, add 0.86ml of glacial acetic acid with a mass fraction of 99.5% to dissolve the gel, stir for 2 hours and mix with 0.5g of The PVA solutions were mixed, and the stirring was continued for 6 h at room temperature to obtain a uniform mixed sol. The obtained sol was casted on a polytetrafluoroethylene sheet after being hydrothermally heated at 120°C for 12 hours, dried at room temperature for 48 hours and peeled off. γ-Al 2 o 3 film.

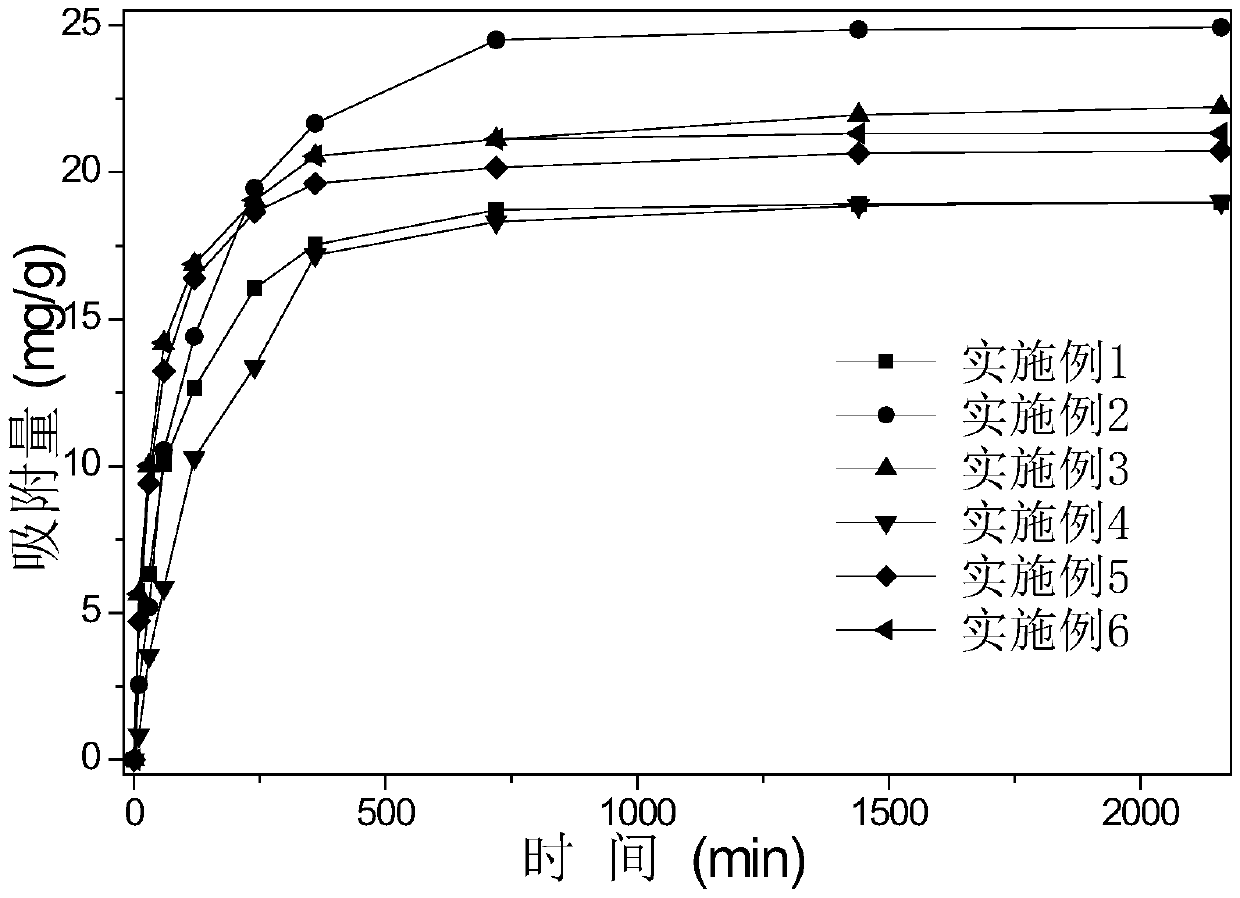

[0024]When adsorbing 100ml, 50mg / L Cr(Ⅵ) solution, adjust the pH to 3 with a hydrochloric acid solution with a concentration of 1mol / L, then add 0.2g of unmodified alumina film sample, and set the parameters of the constant temperature oscillation box to 25°C, 150r / min. The adsorption kinetic curve of Cr(Ⅵ) on unmodified alumina film is shown in figure 1 , the adsorption removal rate of Cr(Ⅵ) is 75.9%, and the adsorption capacity is 18.97mg / g.

Embodiment 2

[0026] Disperse 3g of industrial pseudo-boehmite powder in 50ml of deionized water, add 0.86ml of glacial acetic acid with a mass fraction of 99.5% to degelize, stir for 2 hours and mix with 0.5g of The PVA solutions were mixed, and the stirring was continued for 6 h at room temperature to obtain a uniform mixed sol. The obtained sol was casted on a polytetrafluoroethylene sheet after being hydrothermally heated at 120°C for 12 hours, dried at room temperature for 48 hours and peeled off. Unmodified alumina films were used for later use. 1 g of unmodified alumina film was dried at 110 °C for 2 h before use, and then placed in N 2 Reflux in a protected three-neck flask with 50ml of toluene solution at 85°C for 1 hour, then add 0.2ml of deionized water, then add 1ml of aminopropyltrimethoxysilane after 2 hours and continue to reflux for 18 hours. After washing once and twice with 20ml of absolute ethanol, vacuum-dry at 60°C for 6 hours. The sample is for use. The sample is ami...

Embodiment 3

[0030] Disperse 3g of industrial pseudo-boehmite powder in 50ml of deionized water, add 0.86ml of glacial acetic acid with a mass fraction of 99.5% to degelize, stir for 2 hours and mix with 0.5g of The PVA solutions were mixed, and the stirring was continued for 6 h at room temperature to obtain a uniform mixed sol. The obtained sol was casted on a polytetrafluoroethylene sheet after being hydrothermally heated at 120°C for 12 hours, dried at room temperature for 48 hours and peeled off. Unmodified alumina film. 1g of unmodified alumina film was dried at 110°C for 2h before use, and then placed in N 2 Reflux in a protected three-necked flask filled with 75°C and 50ml of absolute ethanol solution for 1 hour, then add 0.2ml of deionized water, add 2ml of aminopropyltrimethoxysilane after 2 hours, and continue to reflux for 12 hours. After washing with water and ethanol for 3 times, it was vacuum-dried at 60°C for 6 hours to prepare a modified film sample.

[0031] When adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com