Pretreatment method of chemical plating conductive magneto-conductive glass fibre

A glass fiber, conductive and magnetically permeable technology, applied in the field of pretreatment of electroless plating conductive and magnetically conductive glass fiber, can solve the problems of weak adhesion, difficult to meet the requirements of coating adhesion, easy to fall off, etc., to achieve high coating adhesion, enhanced Good chemical adsorption capacity and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

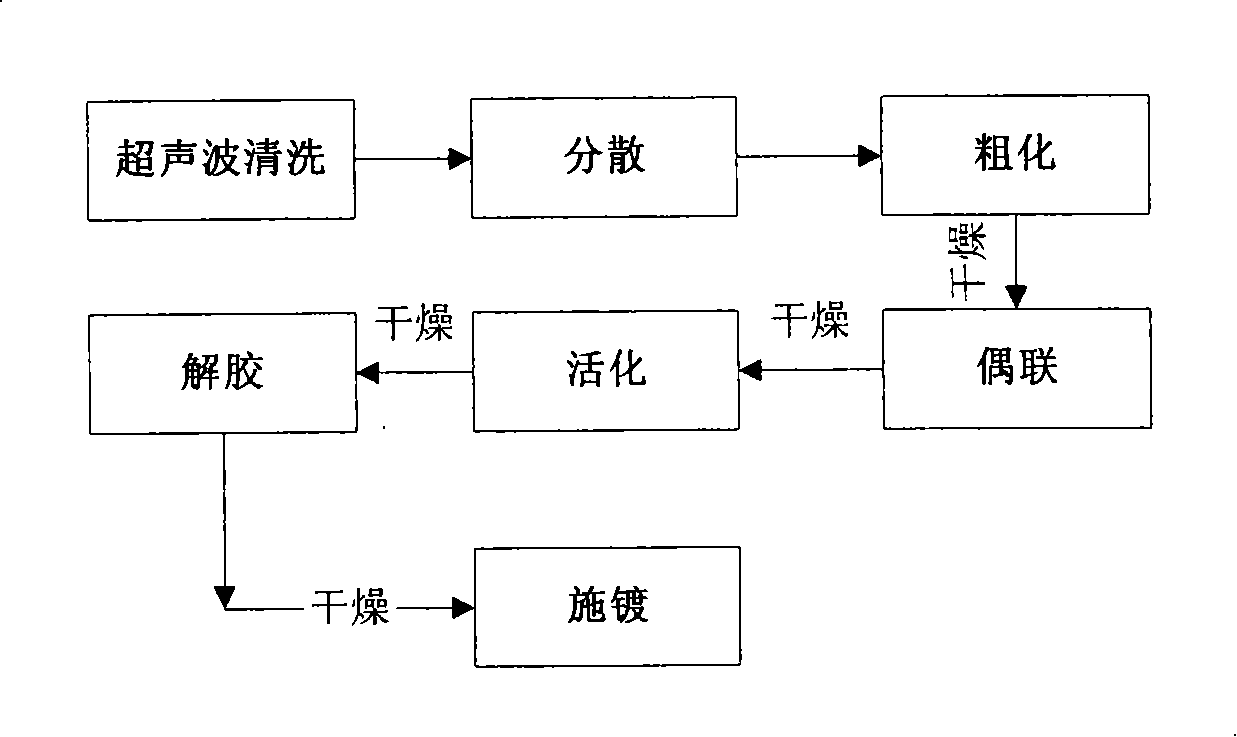

[0029] The present invention will be further described now in conjunction with accompanying drawing:

[0030] First prepare the pretreatment solution:

[0031] (1) Preparation of the dispersion: add 0.8 mg of sodium polyacrylate (molecular weight less than 2000) to 100 ml of distilled water;

[0032] (2) Preparation of coarsening solution: add 2g ammonium chloride and 10ml phosphoric acid solution in 100ml distilled water;

[0033] (3) Preparation of coupling solution: add 1ml of coupling agent KH550 into 34ml of absolute ethanol;

[0034] (4) Activation solution preparation: use palladium chloride, stannous chloride, urea, concentrated hydrochloric acid, sodium chloride and distilled water to prepare four solutions A, B, C, and D, and then further prepare the activation solution, basic composition and experiment The operation is as follows:

[0035] 【A.0.03gPdCl 2 +2.5ml concentrated hydrochloric acid +2.5ml distilled water]

[0036] 【B.1.2gSnCl 2 +10ml concentrated hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com