Multifunctional graphene/high-molecular composite material water permeable membrane, preparation method, and application thereof

A technology of composite materials and high molecular polymers, applied in the field of multifunctional graphene/polymer composite material permeable membranes and its preparation, to achieve the effects of improved acid and alkali resistance, antibacterial and anti-pollution capabilities, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

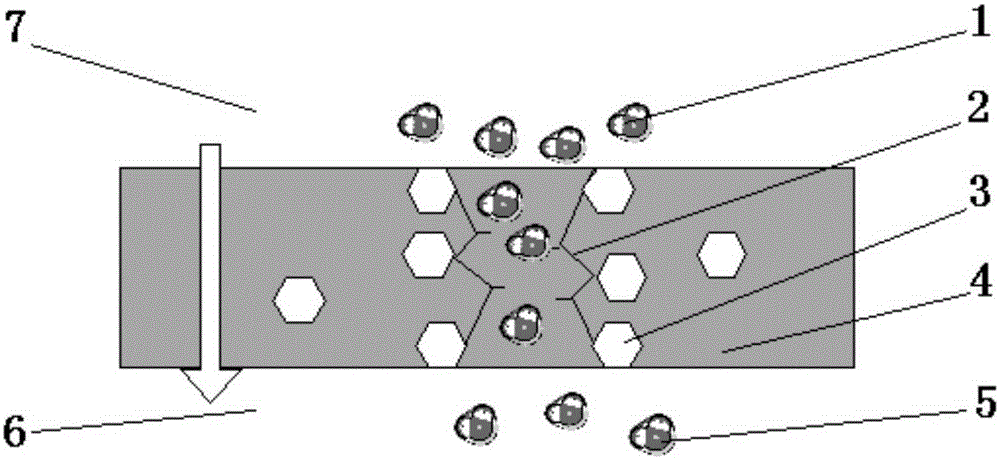

[0050] According to another aspect of the present invention, the present invention provides the preparation method of above-mentioned multifunctional graphene / polymer composite water-permeable membrane, and it comprises the steps:

[0051] A) Under constant temperature conditions selected from the range of 10-100°C, the moisture-permeable high molecular polymer is dissolved in various organic solvents in a predetermined time and order to form a solution, and fully stirred to mix evenly;

[0052] B) adding graphene or graphene composite material to the solution obtained in the previous step, fully stirring to mix uniformly; and

[0053] C) Film formation process: The solution obtained in step B) is applied to one or both surfaces of the microporous substrate at a temperature in the range of 10-200°C.

[0054] According to a specific technical solution of the present invention, the preparation method of the multifunctional graphene / polymer composite water-permeable membrane furt...

Embodiment 1

[0084] Firstly, under the constant temperature condition of 45-50°C, the pre-selected moisture-conducting polymer (KX-1) is dissolved in the corresponding organic solvent mixture, and fully stirred until the mixture is uniform.

[0085] Then, add the pre-selected antioxidant (d1) to the obtained solution, and stir well until the mixture is uniform.

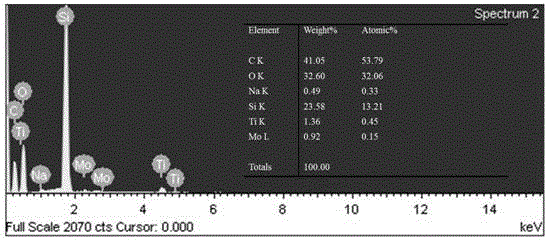

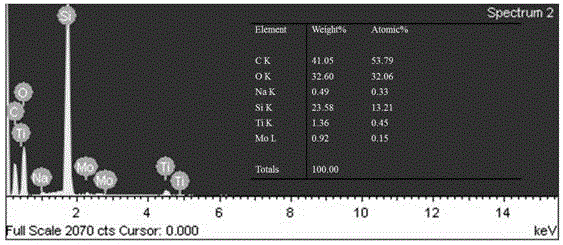

[0086] Then, add graphene oxide / silver / titanium dioxide composite material (GC-1) to the solution obtained in the previous step, and stir well to mix evenly.

[0087] Finally, a film is formed at a temperature of 60°C, and the solution obtained in the previous step is applied to the surface of the preselected microporous substrate (c1), and cross-linked after the film forming process, and the microporous substrate (c1) Forms a continuous coating of cross-linked water-permeable polymer. A uniform film material with a thickness of 150 μm was formed.

[0088] After testing, the obtained membrane material has good water permeability...

Embodiment 2

[0090] First, under the constant temperature condition of 50°C, the moisture-conducting high molecular polymer (PM-3) was dissolved in the corresponding organic solvent mixture, fully stirred until completely dissolved, then mixed, and continued to stir until uniformly mixed.

[0091] Then, add the pre-selected antioxidant (d3) to the obtained solution, and stir well until the mixture is uniform.

[0092] Then, add graphene oxide / silver / titanium dioxide composite material (GC-2) to the solution obtained in the previous step, and stir well to mix evenly.

[0093] Finally, a film is formed at a temperature of 70°C, and the solution obtained in the previous step is applied to both sides of the microporous substrate (c2), and cross-linked after the film forming process to form a continuous film with the microporous substrate (c2). A coating of cross-linked water-permeable polymers. A uniform film material with a thickness of 120 μm was formed.

[0094] After testing, the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com