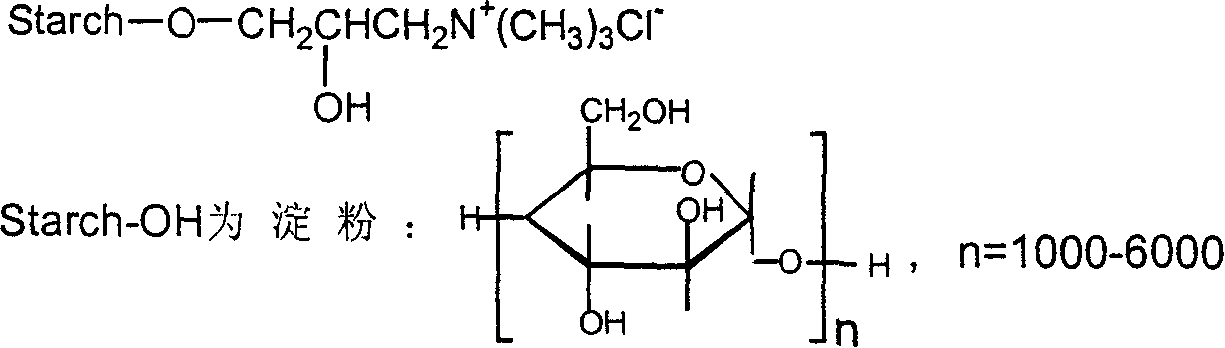

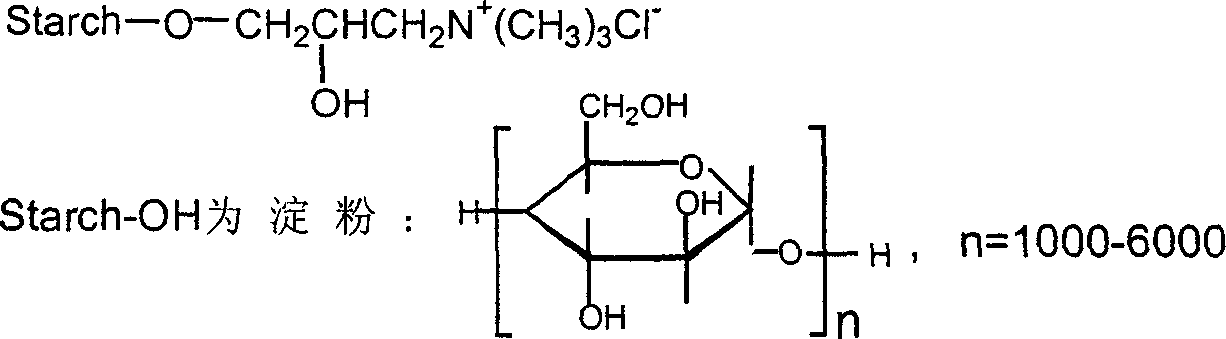

High degree of substitution quaternary ammonium cationic starch flocculating agent and method for synthesizing same

A cationic starch, high degree of substitution technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of low reaction conversion rate and high equipment and process requirements, and achieve the effects of high purity, increased economic benefits, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

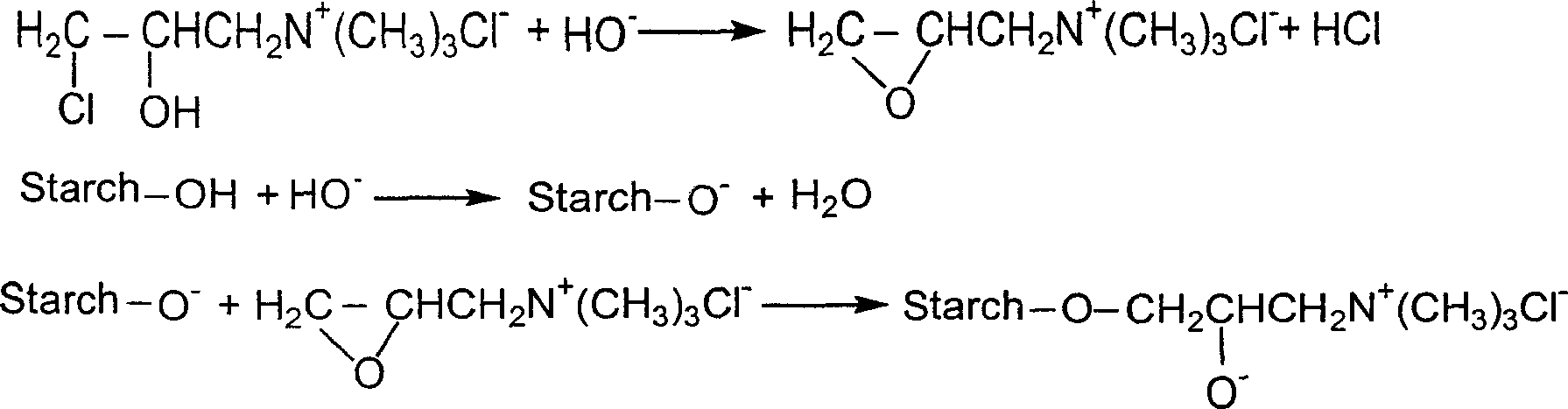

Method used

Image

Examples

Embodiment 1

[0025] Add 25g of absolute dry cornstarch (water 12.56%), 5mL of 50% sodium hydroxide and 3mL of isopropanol into a glass bottle equipped with a stirrer, stir for 15min, and then alkalize at 50°C for 1h. Mix 5mL of quaternary ammonium salt solution (15g of 3-chloro-2-hydroxypropyltrimethylammonium chloride dissolved in 5mL of water) and 5mL of 10% sodium hydroxide solution and spray it on the starch surface as evenly as possible, then add 2.5g of diethanolamine, stirred and mixed evenly at room temperature, pre-dried in vacuum at 60°C until the water content of the starch dropped to about 20%, and then reacted at 90°C for 3h. Crush to get white fine powder cationic starch product.

Embodiment 2

[0027] Add 25g absolute dry tapioca starch (moisture content 13.16%), 5mL 50% sodium hydroxide and 4mL methanol into a glass bottle equipped with a stirrer, stir for 15min, alkalinize at 50°C for 1h, then add 15g N-(2, 3-epoxychloropropyl)trimethylammonium chloride (GTA) and 2 g of urea were mixed evenly at room temperature, then pre-dried in vacuum at 60° C. until the water content of the starch dropped to about 17%, and then reacted at 90° C. for 3 hours. Crush to get white fine powder cationic starch product.

Embodiment 3

[0029]Add 25g of absolute dry cornstarch (moisture 12.56%), 5mL of 50% sodium hydroxide and 4ml of isopropanol into a glass bottle equipped with a stirrer, stir for 15min, alkalinize at 50°C for 1h, and then add 20g of N-(2 , 3-epichloropropyl)trimethylammonium chloride (GTA) and 1mL fatty alcohol polyoxyethylene ether, stirred and mixed at room temperature, and reacted in vacuum at 80°C for 3h. Crush to get white fine powder cationic starch product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com