Chromium slag processing method for chemical-biological coupling reduction of hexavalent chrome

A treatment method, hexavalent chromium technology, applied to the removal of solid waste, etc., to achieve the effect of simple process, simplified equipment, and accelerated dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

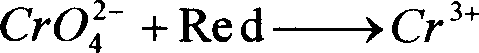

Method used

Image

Examples

Embodiment 1

[0020] 1) Take 1 ton of chromium slag A (the concentration of water-soluble hexavalent chromium in the slag is 1.5%, and the concentration of acid-soluble hexavalent chromium is 0.8%), add 1 ton of water, and use a ball mill to crush the chromium slag into 160-200 mesh, while ball milling , while adding 1 ton of solution containing 6% sulfuric acid and 4% ferrous sulfate to the ball mill, during the ball milling process, the pH value of the control system is 8.5-10.5;

[0021] 2) Transfer the ball-milled solid-liquid mixture to another stirred reactor, continue to add 1 ton of 15% dilute sulfuric acid and 16% ferrous sulfate mixed solution, then continue to stir for 1h, and the system temperature in the whole process is controlled at 20°C ;

[0022] 3) Add 0.5 tons of composite bacteria liquid composed of SRB, Pseudomonas putida and Escherichia coli into the reactor and mix with the mixture, continue to stir for 0.5h, then put it into another container and leave it for 2 days;...

Embodiment 2

[0025] 1) Take 1 ton of chromium slag B (the concentration of water-soluble hexavalent chromium in the slag is 0.7%, and the concentration of acid-soluble hexavalent chromium is 0.4%), add 2 tons of water, and use a ball mill to crush the chromium slag into 80-120 mesh, while ball milling , while adding 1 ton of 9% sulfuric acid and 4.0% sodium sulfite solution to the ball mill, during the ball milling process, the pH of the control system is 7.5-9.0;

[0026] 2) transfer the ball-milled solid-liquid mixture to another stirred reactor, continue to add 0.9 tons of 8% dilute sulfuric acid, and then continue to stir for 5 hours, and control the system temperature during the whole process to 90°C;

[0027] 3) Add 0.8 tons of composite bacteria liquid composed of SRB, Pseudomonas putida and Escherichia coli into the reactor, continue to stir for 0.5h, then put it into a container and leave it for 10 days;

[0028] The result: the concentration of hexavalent chromium in the water is...

Embodiment 3

[0030] 1) Take 1 ton of chromium slag C (the concentration of water-soluble hexavalent chromium in the slag is 1.0%, and the concentration of acid-soluble hexavalent chromium is 0.6%), add 1 ton of water, and use a ball mill to crush the chromium slag into 120-160 mesh, while ball milling , while adding 1 ton of solution containing 2% sulfuric acid to the ball mill, during the ball milling process, the pH value of the control system is 8.5-9.5;

[0031] 2) Transfer the ball-milled solid-liquid mixture to another stirred reactor, continue to add 1.0 tons of 15% dilute sulfuric acid and 1.0 tons of 4% sodium sulfide solution, and then continue to stir for 2 hours. The system temperature in the whole process is controlled at 90°C ;

[0032] 3) Add 0.5 ton of composite bacteria liquid composed of SRB, Pseudomonas putida and Escherichia coli into the reactor, continue to stir for 1 hour, then put it into a container and leave it for 6 days;

[0033] The result: the concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com