Method for directly producing chrome-base alloy steel by comprehensively using calcium-free chrome slag

A calcium-free chromium slag and chromium-based alloy technology, applied in the direction of improving process efficiency, electric furnace, furnace type, etc., can solve problems such as waste of scarce resources, and achieve the effect of thorough detoxification, saving chromium resources, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

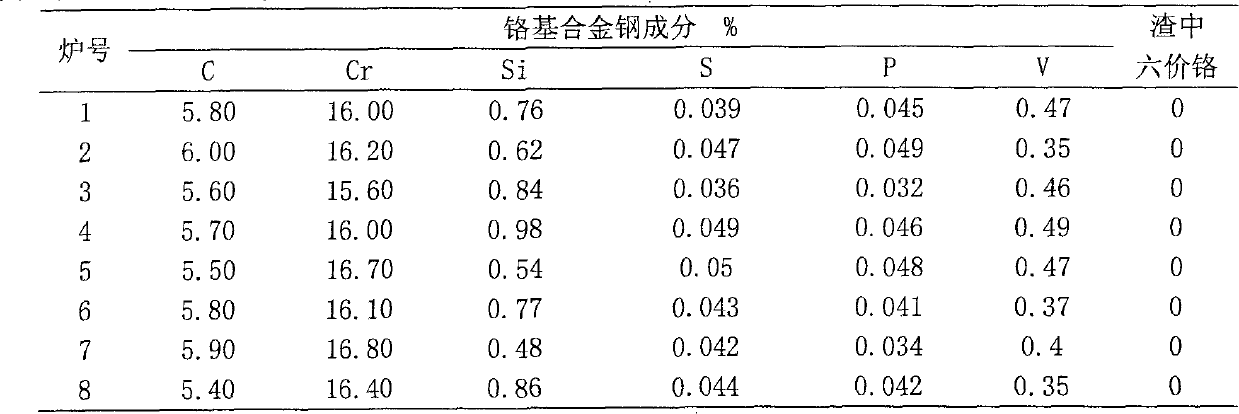

Embodiment 1

[0048] The raw materials are calcium-free chromium slag and local Dahe coal, and the slagging agent is silica. Among them, the chemical composition of Dahe coal is: C70%, Fe 2 o 3 1.29%, MgO0.75%, CaO1.08%, SiO 2 10.65%, Al 2 o 3 4.88%, other ingredients 11.35%. The chemical composition of silica is: SiO 2 90.83%, MgO3.65%, Al 2 o 3 1.28%, Fe 2 o 3 0.86%, other ingredients 3.38%. The electric furnace used in this example is a 630kVA DC submerged arc furnace with a capacity of 1.3 tons, a furnace body diameter of φ1.8m, a height of H1.5m, an effective inner diameter of φ0.95m, and an effective height of 0.92m. Composite masonry with carbon bricks and magnesia bricks. The electric furnace adopts double electrode power supply. The specific steps are carried out in the following order:

[0049] 1. First add 200kg of Dahe coal to 1000kg of calcium-free chromium slag, and mix the mixed raw materials with a mixer.

[0050] 2. Use a ball forming machine to press the mixt...

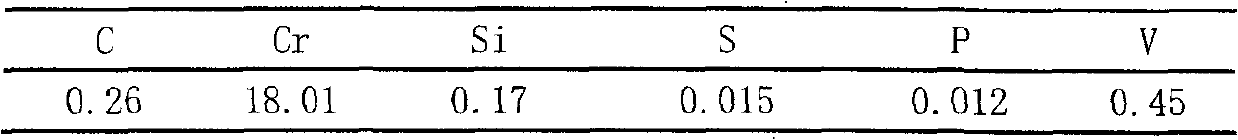

Embodiment 2

[0057] The raw materials are calcium-free chromium slag and local Dahe coal, and the slagging agent is silica. Among them, the chemical composition of Dahe coal is: C70%, Fe 2 O 3 1.29%, MgO0.75%, CaO1.08%, SiO 2 10.65%, Al 2 O 3 4.88%, other ingredients 11.35%. The chemical composition of silica is: SiO 2 90.83%, MgO3.65%, Al 2 O 3 1.28%, Fe 2 O 3 0.86%, other ingredients 3.38%. The electric furnace used in this example is a 630kVA DC submerged arc furnace with a capacity of 1.3 tons, a furnace body diameter of φ1.8m, a height of H1.5m, an effective inner diameter of φ0.95m, and an effective height of 0.92m. Composite masonry with carbon bricks and magnesia bricks. The electric furnace adopts double electrode power supply. The specific steps are carried out in the following order:

[0058] 1. First add 200kg of Dahe coal to 1000kg of calcium-free chromium slag, and mix the mixed raw materials with a mixer.

[0059] 2. Use a ball forming machine to press the mixt...

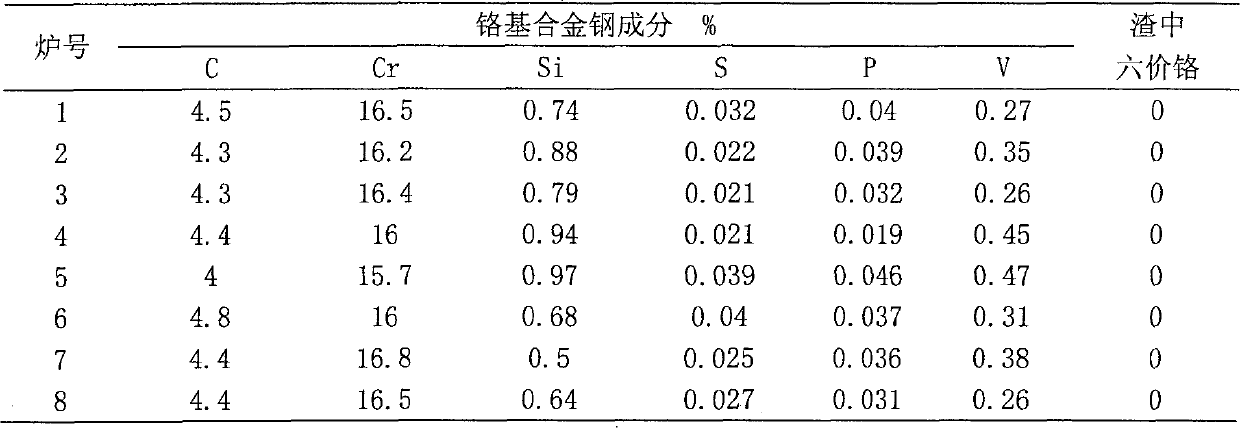

Embodiment 3

[0067] The raw materials are calcium-free chromium slag and local Dahe coal, and the slagging agent is silica. Among them, the chemical composition of Dahe coal is: C70%, Fe 2 O 3 1.29%, MgO0.75%, CaO1.08%, SiO 2 10.65%, Al 2 O 3 4.88%, other ingredients 11.35%. The chemical composition of silica is: SiO 2 90.83%, MgO3.65%, Al 2 O 3 1.28%, Fe 2 O 3 0.86%, other ingredients 3.38%. The electric furnace used in this example is a 630kVA DC submerged arc furnace with a capacity of 1.3 tons, a furnace body diameter of φ1.8m, a height of H1.5m, an effective inner diameter of φ0.95m, and an effective height of 0.92m. Composite masonry with carbon bricks and magnesia bricks. The electric furnace adopts double electrode power supply. The specific steps are carried out in the following order:

[0068] 1. First add 230kg of Dahe coal to 1000kg of calcium-free chromium slag, and mix the mixed raw materials with a mixer.

[0069] 2. Use a ball forming machine to press the mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com