Hydraulic bag concrete using industrial solid wastes

A technology for solid waste and moulded bagged concrete, applied in the field of moulded bagged concrete, can solve problems such as hidden dangers of life and property safety of residents, occupation of land, pollution of the environment, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

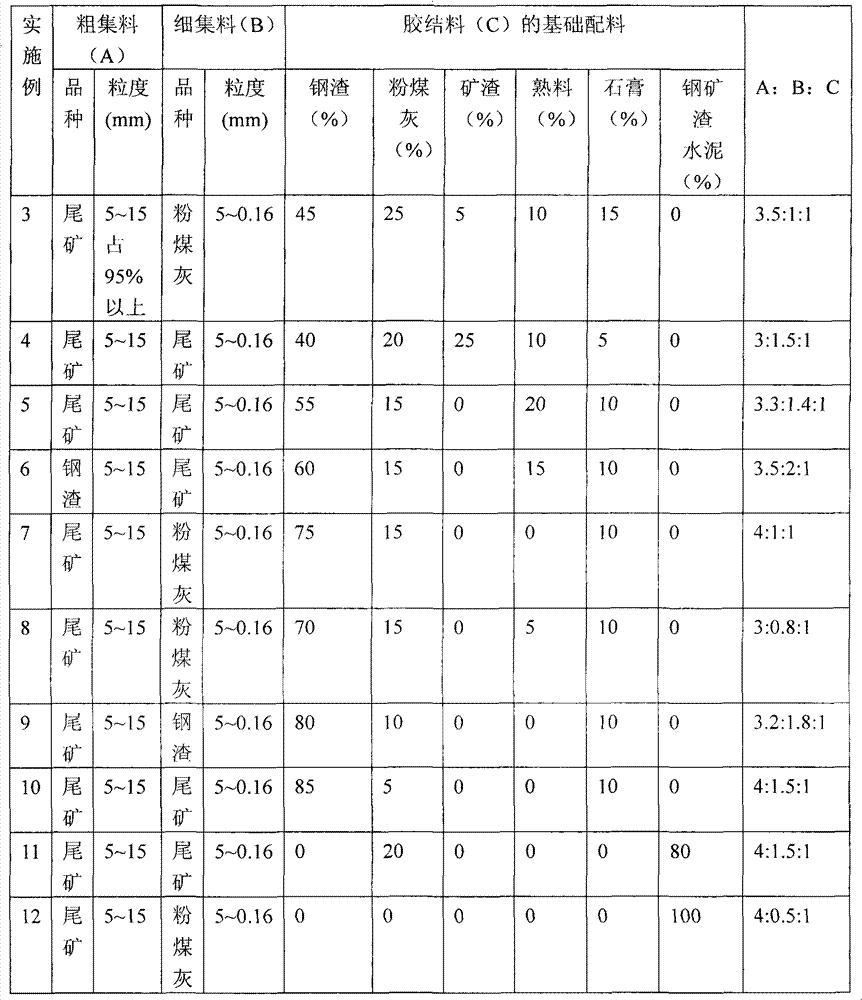

Examples

Embodiment 1

[0037] Stir and mix the five parts of coarse aggregate, fine aggregate, cementing material, alkali-resistant glass fiber, and water. The content (weight) range of each component is: coarse aggregate: fine aggregate: cementing material = 3:1: 1. Water: cementing material = 0.45, the measurement of alkali-resistant glass fiber is added, accounting for 4% of the weight of the cementing material, and the fiber length is 5-15 mm.

[0038] The coarse aggregate used is iron ore tailings, the particle size of which ranges from 5 to 15 mm, accounting for more than 95%, and the sulfur content and clay content of the tailings are less than 1% and 3% respectively.

[0039] The used fine aggregate is iron ore tailings, and the particle size range of the fine aggregate is 5-0.16 mm, accounting for more than 95%.

[0040] The cement used is industrial waste such as steel slag, fly ash, slag, industrial waste gypsum, and 1% Na 2 SiO 3 (The modulus is 3.26) as an alkaline activator, it is ma...

Embodiment 2

[0044] Stir and mix the coarse aggregate, fine aggregate, cementing material, polypropylene fiber, water and other five parts. The content (weight) range of each component is: coarse aggregate: fine aggregate: cementing material = 3: 1.5: 1 , water: cementitious material=0.35 (using water reducer), polypropylene fiber is added, and the added amount accounts for 0.1% of cementitious material composition.

[0045] The coarse aggregate used is steel slag with a particle size ranging from 5 to 15 mm, which accounts for more than 95%, and is hot-splashed converter slag accumulated for more than one year. The basicity coefficient is 1.6, and the stability inspection is qualified.

[0046] The fine aggregate used is river sand, the particle size of fine aggregate is 5-0.16 mm, and the river sand is obtained locally.

[0047] The cement used is steel slag, a small amount of 52.5MPa Portland cement clinker, fly ash, slag, industrial waste gypsum, etc., and 1% Na 2 SiO 3 +CaCl 2 As a...

Embodiment 3

[0051] Coarse aggregate: fine aggregate: cementing material = 3.5: 1: 1, water: cementing material (hereinafter referred to as "water-binder ratio") = 0.85, fine aggregate adopts 5 ~ 0.16 mm low-calcium pulverized coal accounting for more than 95% Gray slag. The additional reinforcing fiber is alkali-resistant glass fiber, the fiber length is 5-10 mm, and the added amount is 5% of the total amount of cement. The cementing material preparation process is "mixing after grinding", and the added alkaline activator is KOH, which is 1% of the cementing material. The 28-day age compressive strength of the obtained mold bag concrete sampling test meets the requirements of the C20 concrete label. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com