Detoxification method of chromium-containing slag entering metallurgical blast furnace by using coal spraying process form

A technology for harmless treatment and chromium slag, applied in the fields of iron and steel metallurgy and environmental protection, can solve the problems of falling molten iron production, secondary pollution, difficult popularization and application, etc., and achieve the effect of full recycling and less links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

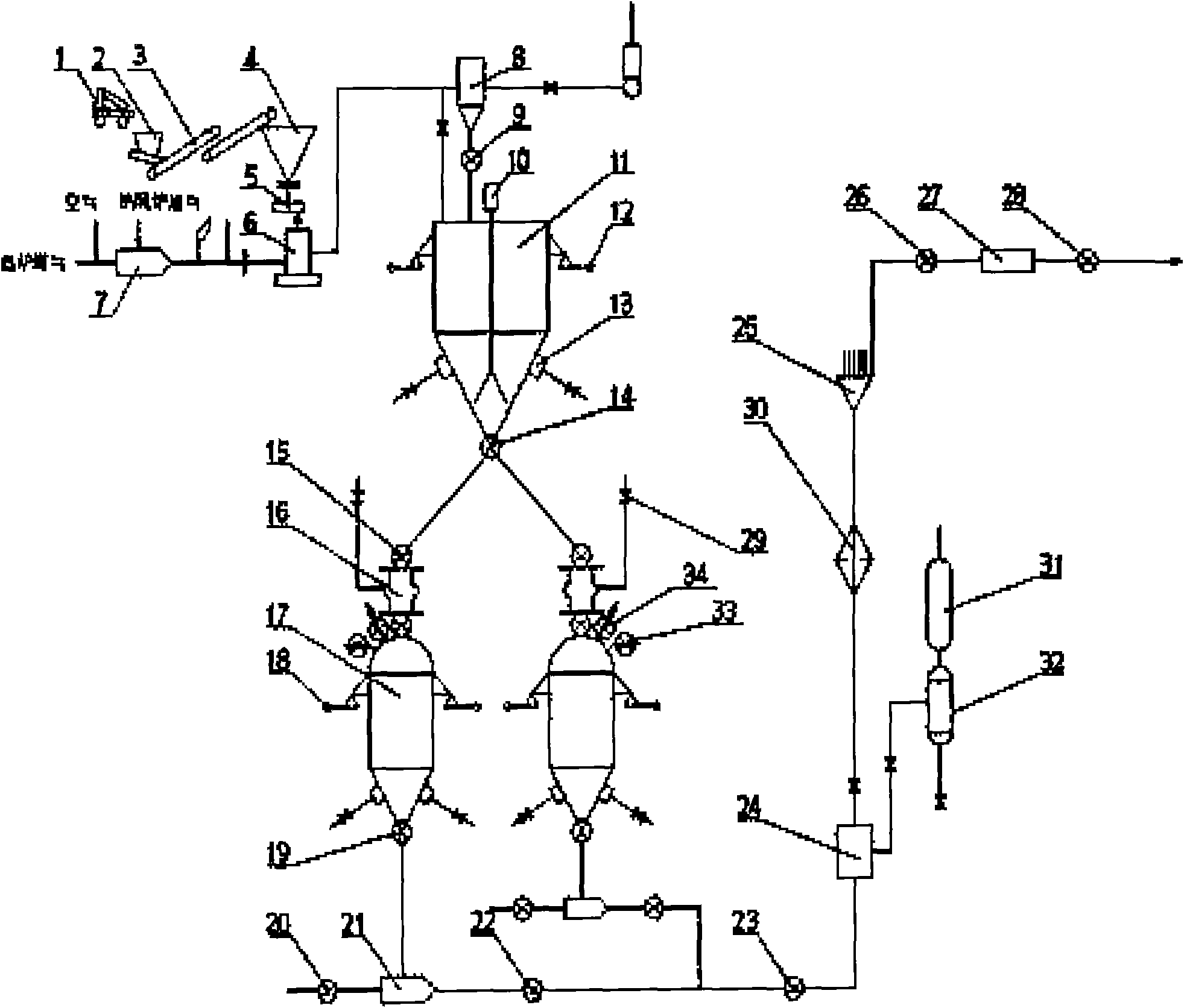

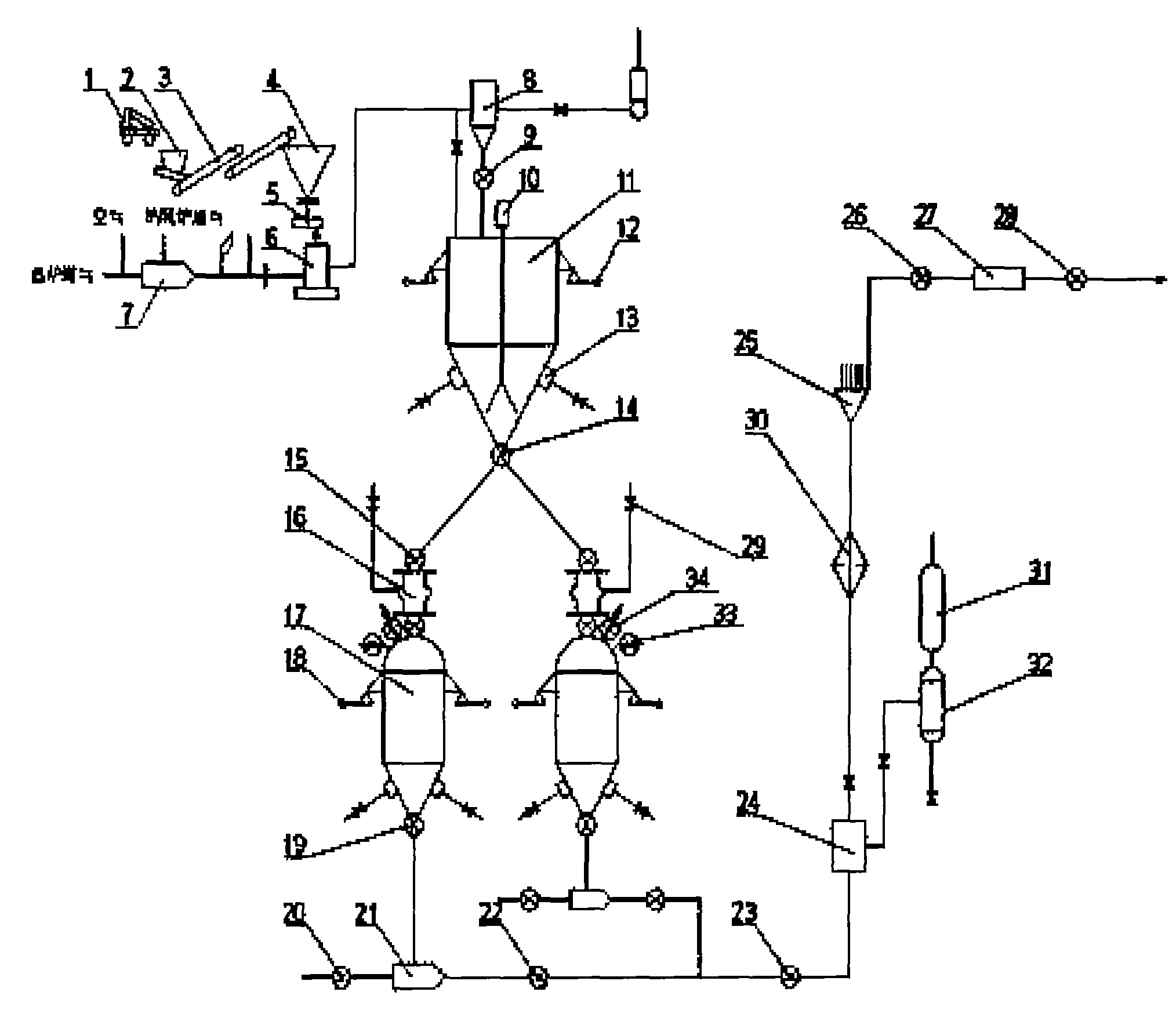

Method used

Image

Examples

Embodiment 1

[0019] 1. Raw material treatment: prepare the chromium slag in the slag yard of the chromium slag production plant, including drying and grinding. The moisture content of the chromium slag drying is less than 1-10%, and the required particle size for grinding is -200 mesh 20-80 %.

[0020] 2. Transport the dried and ground chromium slag to the coal injection system of the blast furnace with a sealed tank car, and then send it into the sealed bin of the blast furnace by pneumatic means, and then mix it into the coal mill in the coal injection system by the feeder according to the set metering Inside, in the coal mill 6, the chromium slag and coal powder are fully ground and mixed, and sent into the coal powder bin with dry compressed air, and then enter the mixer through the injection tank, and then the mixed Chromium slag and coal powder are sprayed into the hearth of the blast furnace through the spray gun 27 via compressed air; the proportion of chromium slag mixed into the ...

Embodiment 2

[0025] 1. Raw material treatment: Dry the chromium slag to make the water content less than 4%, and grind it finely to make the particle size -200 mesh more than 70%;

[0026] 2. Transport the dried and finely ground chromium slag to the coal injection system of the blast furnace with a sealed tank car, and send it to the sealed bin of the blast furnace by means of a pneumatic pump through a sealed pipeline, and then mix it into the coal injection system according to the set metering by the feeder In the coal mill in the system, in the coal mill 6, the chromium slag and coal powder are fully ground and mixed, and then sent into the coal powder bin with dry compressed air, and then enter the mixer through the injection tank , and then the mixed chromium slag and coal powder are sprayed into the hearth of the blast furnace through the spray gun 27 via compressed air; wherein the ratio of chromium slag mixed into the coal powder is 5% of the weight of the coal powder.

[0027] 3....

Embodiment 3

[0031] 1. Raw material treatment: Dry the chromium slag to make the water content less than 5%, and grind it finely to make the particle size -200 mesh more than 60%;

[0032] 2. The dried and ground chromium slag is transported to the coal injection system of the blast furnace by a sealed tank car, sent to the sealed bin of the blast furnace through a sealed pipeline by a pump, and then mixed into the grinding chamber in the coal injection system by the feeder according to the set metering. In the coal machine, in the coal mill 6, the chromium slag and coal powder are fully ground and mixed, and then sent into the coal powder bin with dry compressed air, and then enter the mixer through the injection tank, and then the mixed Uniform chromium slag and coal powder are sprayed into the hearth of the blast furnace through the spray gun 27 via compressed air; wherein the ratio of chromium slag mixed into the coal powder is 10% of the weight of the coal powder.

[0033] 3. Spray th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com