Chromium residue detoxifying process

A chromium slag and process technology, applied in the field of chromium slag detoxification, can solve the problems of not finding a chromium slag detoxification process, long detoxification reduction time, harsh reaction conditions, etc., so as to extend the effective reduction reaction time, shorten the redox reaction time, Overcome the effects of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

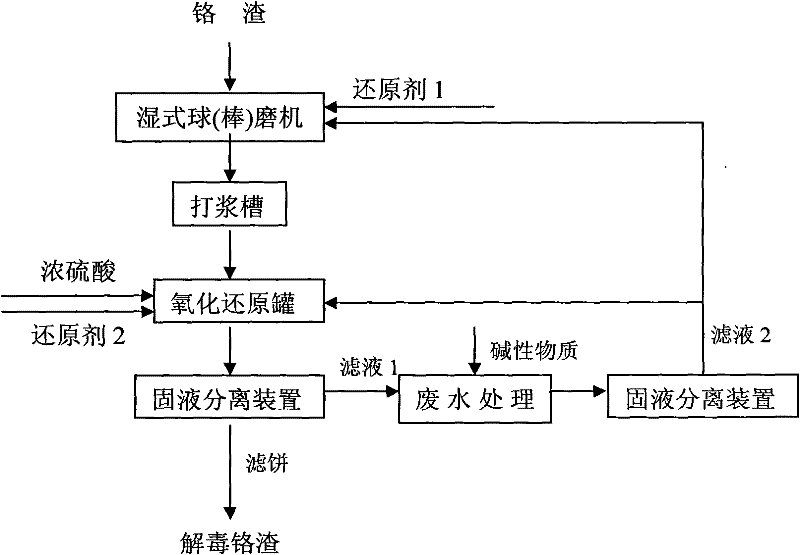

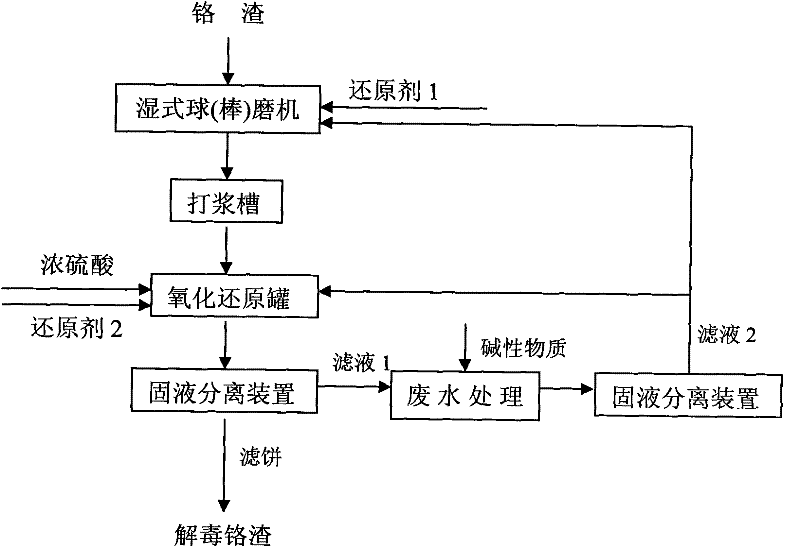

[0047] Process flow chart as shown in the accompanying drawing:

[0048] In the first step, chromium slag and reducing agent 1 are placed in a wet ball (rod) mill, ground and pulverized to 200 mesh, water-soluble and acid-soluble hexavalent chromium (Cr 6+ ) continuously dissolves, and the dissolved water-soluble (Cr 6+ ) continuously undergoes the first reduction reaction with reducing agent 1 to convert to trivalent chromium (Cr 3+ ), to detoxify the chromium slag initially. Among them, reducing agent 1 is sodium sulfide (Na 2 S), its dosage is to reduce 90% of the total amount of hexavalent chromium in the measured chromium slag to trivalent chromium as a criterion.

[0049] In the second step, the chromium slag after preliminary detoxification in the first step is put into the beating tank, and circulating water is introduced into the beating tank to prepare the chromium slag slurry, and the concentration is controlled to be 40 Baume degrees, and then the chromium slag ...

Embodiment 2

[0052] The difference with Example 1 is: in the second step, the mass concentration of concentrated sulfuric acid is 98%; in the third step, after solid-liquid separation, an alkaline substance NaOH is added in the obtained filtrate 1 to adjust the pH of the filtrate 1 The value is up to 6, and the Mg in it is to be measured 2+ 、Al 3+ , Fe 3+ 、Cr 3+ After the precipitation, the solid-liquid separation is performed again, and the obtained filtrate 2 is returned to the wet ball (rod) mill and the beating tank for recycling; the others are the same as in Example 1.

Embodiment 3

[0054] The difference from Example 1 is that in the third step, after solid-liquid separation, an alkaline substance CaO is added to the obtained filtrate 1 to adjust the pH value of the filtrate 1 to 8, and the Mg therein is to be measured. 2+ 、Al 3+ , Fe 3+ 、Cr 3+ and SO 4 2- After the precipitation, the solid-liquid separation is performed again, and the obtained filtrate 2 is returned to the wet ball (rod) mill and the beating tank for recycling; the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com