Method for microwave heating detoxication for flying ash from incineration of refuse

A technology of waste incineration fly ash and microwave heating, which is applied to the removal of solid waste, etc., to achieve the effect of high speed and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

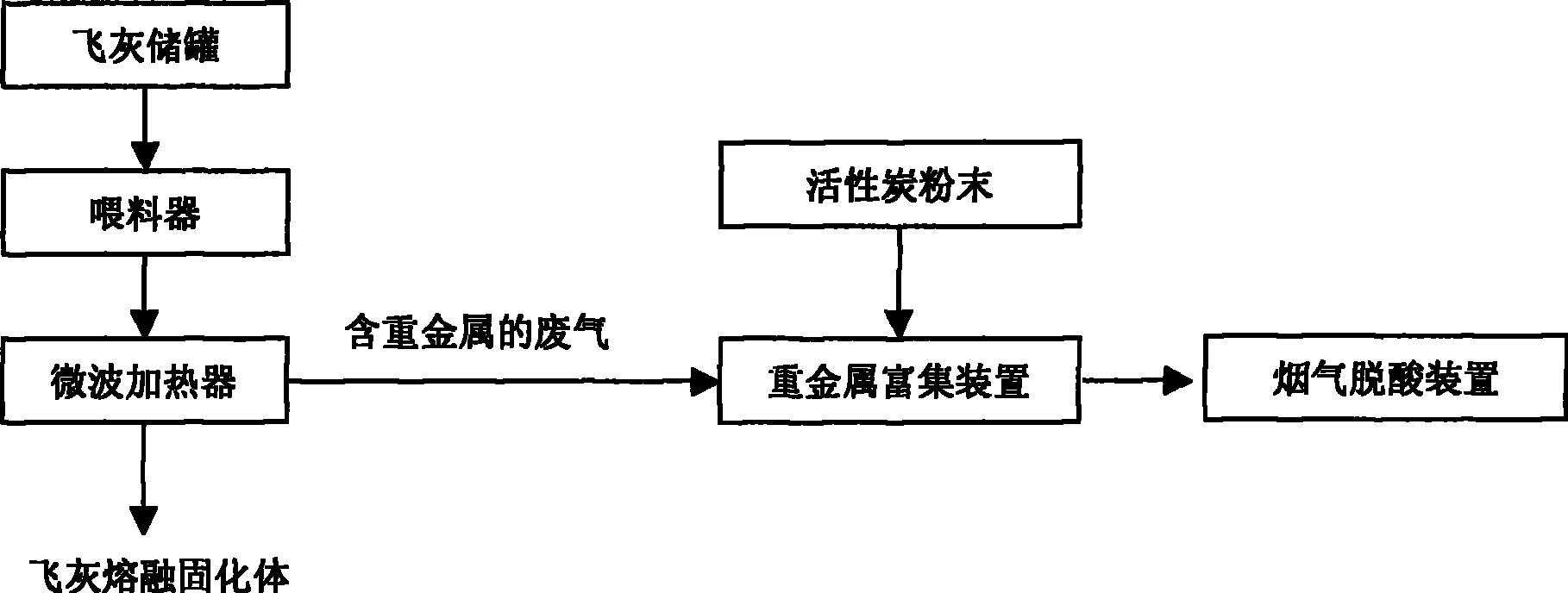

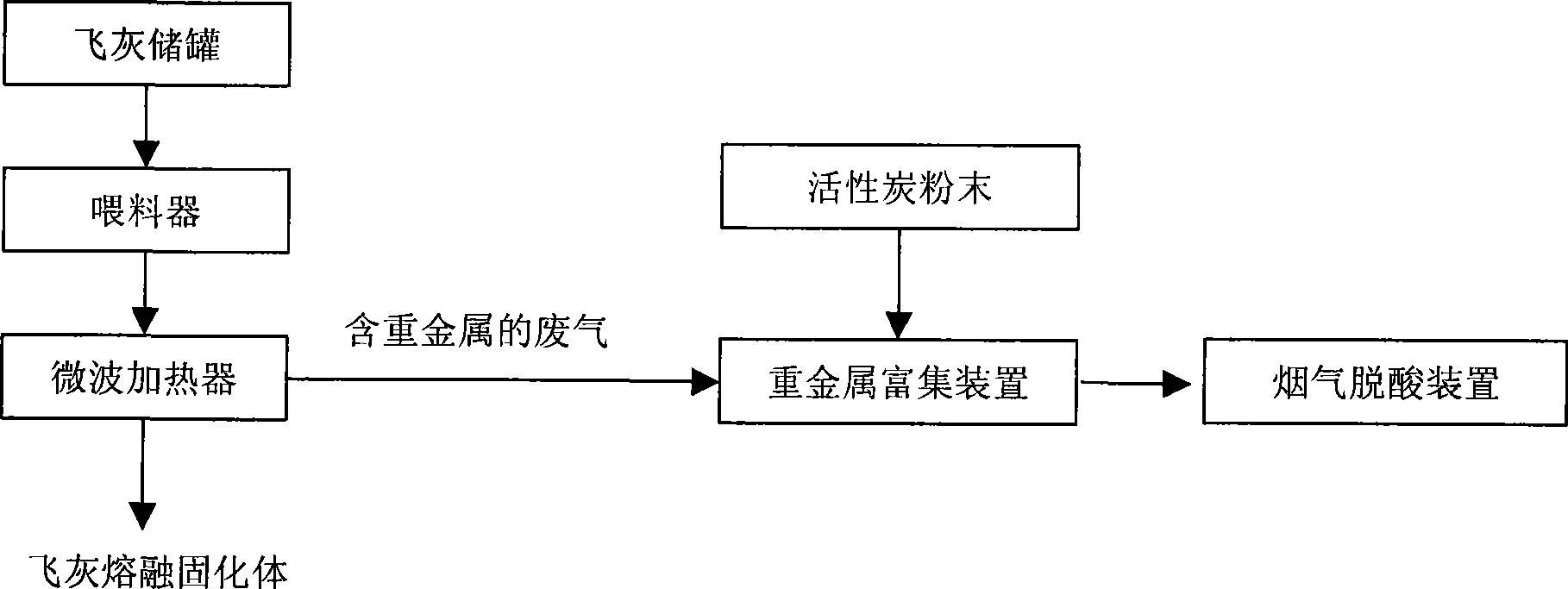

Method used

Image

Examples

Embodiment 1

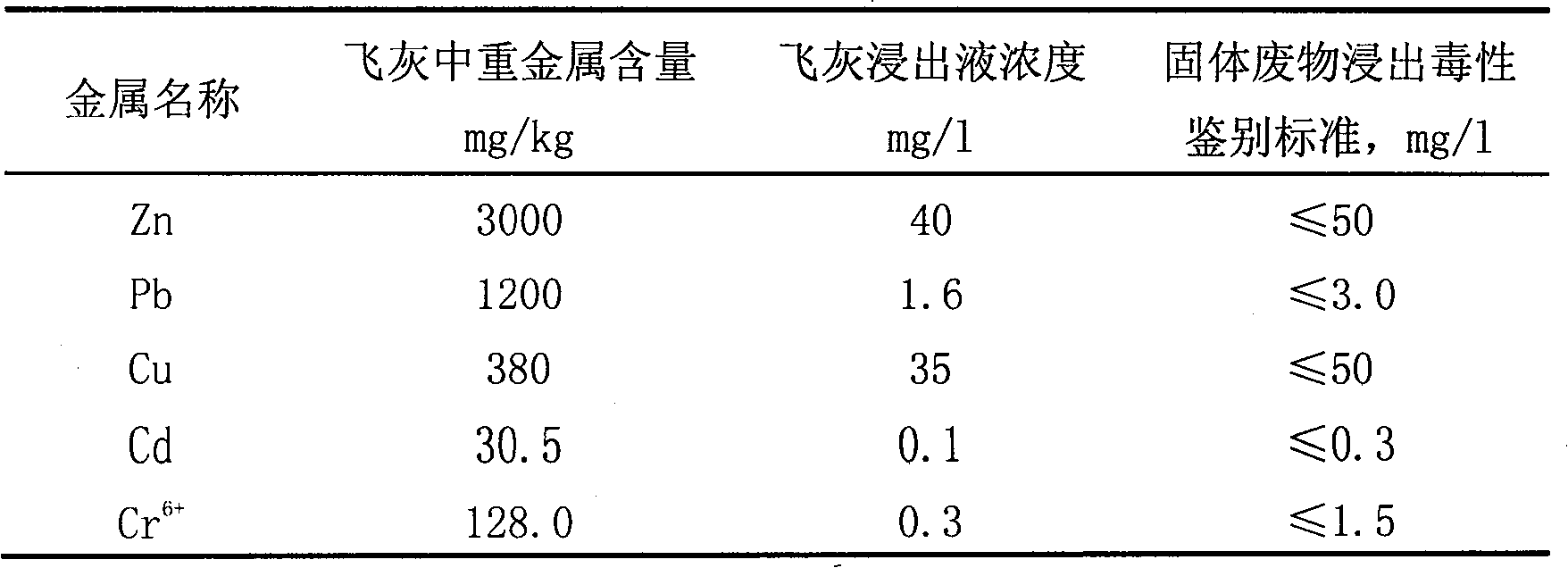

[0027] The waste incineration fly ash was taken and placed in the fly ash storage tank, and the types and quantities of heavy metals in the waste incineration fly ash were determined by scanning inductively coupled plasma emission spectroscopy (ICP-AES). The results are shown in Table 1.

[0028] Table 1

[0029]

[0030] It can be seen from Table 1 that the leaching toxicity of various heavy metals contained is lower than the solid waste leaching toxicity identification standard (GB5085.3-1996), which meets the emission requirements. It only needs to use microwave heating to decompose and remove dioxins in waste incineration fly ash. The feeding speed and discharging speed are both set at 2.5t / h, the heating temperature is 850°C, and the residence time of fly ash in the microwave heater is 10min. Waste incineration fly ash flows into the feeder from the bottom of the fly ash storage tank, and then enters the microwave heater through the outlet of the feeder. When the firs...

Embodiment 2

[0040] The waste incineration fly ash was placed in the fly ash storage tank, and the types and quantities of heavy metals in the waste incineration fly ash were determined by scanning inductively coupled plasma emission spectroscopy (ICP-AES). The results are shown in Table 4.

[0041] Table 4

[0042]

[0043] It can be seen from Table 4 that the leaching toxicity of various heavy metals contained is higher than the solid waste leaching toxicity identification standard (GB5085.3-1996). The feeding speed and discharging speed are set to be 0.2t / h, the heating temperature is 1200°C, and the residence time of fly ash in the microwave heater is 60min. The fly ash flows out from the bottom of the fly ash storage tank into the feeder, and then feeds into the microwave heater through the outlet of the feeder. When the first batch of fly ash 10kg enters the microwave heater, start the microwave power supply and stop the feeder Feeding, after the temperature indicated by the temp...

Embodiment 3

[0052] The waste incineration fly ash was taken and placed in the fly ash storage tank, and the types and quantities of heavy metals in the incineration fly ash were determined by scanning inductively coupled plasma emission spectroscopy (ICP-AES). The measurement results are shown in Table 7.

[0053] Table 7

[0054]

[0055] It can be seen from Table 7 that the leaching toxicity of only two heavy metals, Zn and Pb, is higher than the identification standard for leaching toxicity of solid waste (GB5085.3-1996). The ash is placed in a fly ash storage tank. Set both the feeding speed and the discharging speed to be 1.0t / h, the heating temperature is 1000°C, and the residence time of the fly ash in the microwave heater is 30min. The fly ash flows out from the bottom of the fly ash storage tank into the feeder, and then enters the microwave heater through the outlet of the feeder. When the first batch of fly ash 15kg enters the microwave heater, start the microwave power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com