Beneficiation method of ilmenite

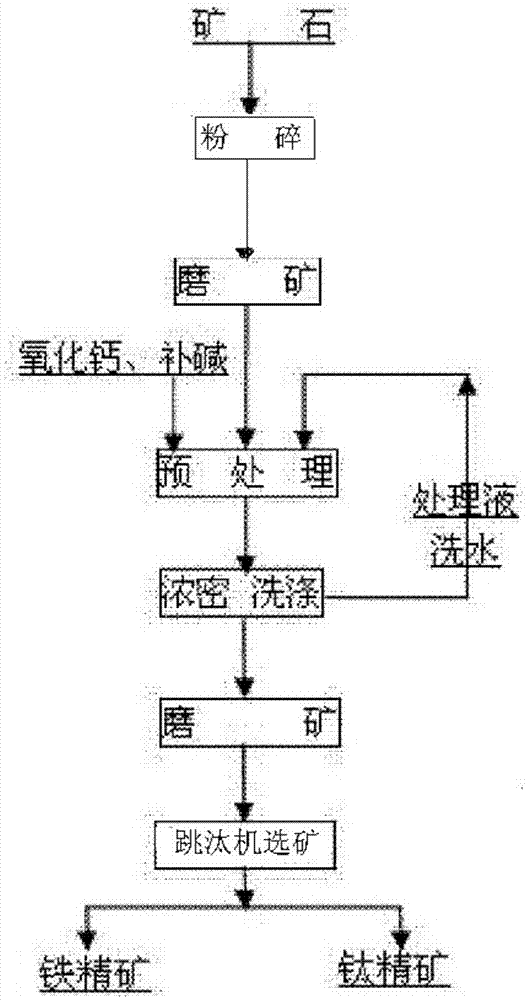

A beneficiation method and ilmenite technology, which are applied in the field of ilmenite raw ore beneficiation to prepare iron concentrate and ilmenite concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The treated ilmenite raw ore contains 32.16% iron and 12.11% iron dioxide, and a small amount of hydroxide feed and calcium oxide are added to the recycled treated liquid and washing solution to make the alkali concentration 450g / L, which is the same as 90% Mix vanadium-titanium magnetite with a particle size of less than 200 mesh, pressurize and heat up to 100°C, pretreat with oxygen for 4 hours, and flash cool to obtain pretreated pulp, filter and wash to obtain a solid intermediate product, and then ball mill. At the same time, under the magnetic field of 800 Oersted, the iron concentrate containing 59.31% iron and 4.01% iron dioxide was obtained by magnetic separation, and the iron concentrate containing 20.15% titanium dioxide was obtained at the same time. The recovery rate of iron was 82.23%, and that of titanium was 85.12%.

Embodiment 2

[0037] The treated ilmenite raw ore contains 32.16% iron and 12.11% iron dioxide, and a small amount of hydroxide feed and calcium oxide are added to the recycled treated liquid and washing solution to make the alkali concentration 500g / L, which is the same as 90% Mix vanadium-titanium magnetite with a particle size of less than 200 mesh, pressurize and heat up to 1200C, pretreat with oxygen for 4.5 hours, and flash cool to obtain a pretreated pulp, filter and wash to obtain a solid intermediate product, and then ball mill. At the same time, under a magnetic field of 900 Oersted, magnetic separation obtained iron concentrates containing 61.1% iron and 3.7% iron dioxide, and iron concentrates containing 20% titanium dioxide. The recovery rate of iron was 78.5%, and that of titanium was 87.8%.

Embodiment 3

[0039] The treated ilmenite raw ore contains 38.32% iron and 10.35% iron dioxide, and a small amount of hydroxide feed and calcium oxide are added to the recycled treated liquid and washing solution to make the alkali concentration 550g / L, which is the same as 90% Mix vanadium-titanium magnetite with a particle size of less than 200 mesh, pressurize and heat up to 150°C, pretreat with oxygen for 5 hours, and flash cool to obtain a pretreated slurry, filter and wash to obtain a solid intermediate product, and then ball mill. At the same time, under the magnetic field of 1000 Oersted, the iron concentrate containing 62.31% iron and 3.89% iron dioxide was obtained by magnetic separation, and the iron concentrate containing 20.02% titanium dioxide was obtained at the same time. The recovery rate of iron was 79.98%, and that of titanium was 80.99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com