Magnetic iron-carbon composite material, preparation method and application thereof

A technology of carbon composite materials and magnetic iron, which is applied in the preparation of hydroxyl compounds, organic compounds, chemical instruments and methods, etc., can solve the problems of harsh preparation conditions, uneven particles, and inaccurate weight percentage of iron, etc. The effect of the degree of contact, the promotion of the reaction, and the advantage of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 iron MOF precursor MIL-53

[0032] Iron MOF materials (MOF, metal organic framework) are complexes of iron ions and organic compounds, including MIL-53, MIL-68, MIL-88, MIL-100, MIL-101, MOF-74, etc.

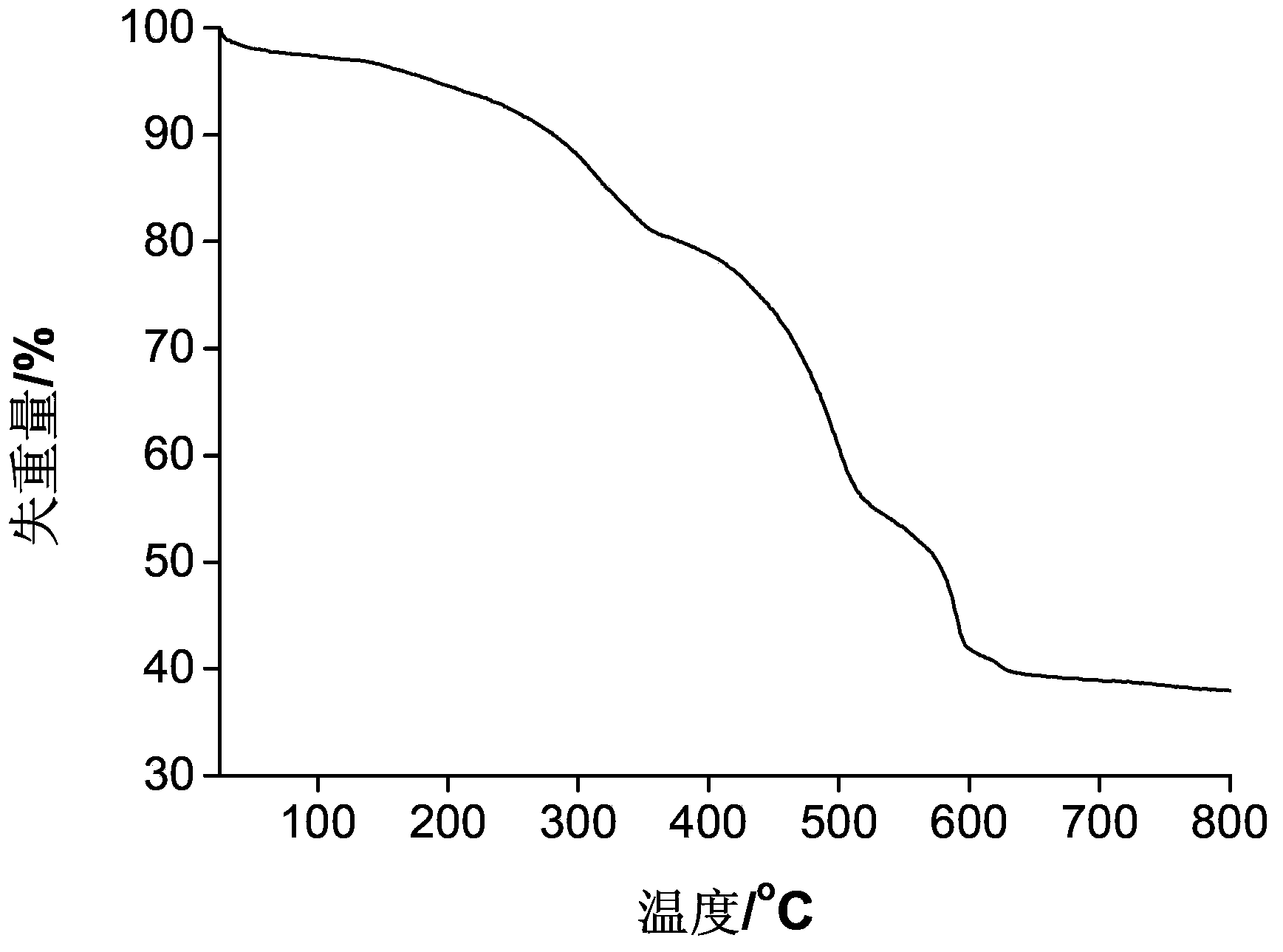

[0033] In the present embodiment, iron salt 2.7g FeCl 3 ·6H 2 O mixed with organic ligand 1.66g terephthalic acid, dissolved in 100ml N, N-dimethylformamide (DMF) solvent and stirred until clarified, put into a stainless steel reaction kettle lined with polytetrafluoroethylene, and 12 Hours from room temperature to 150 ° C, and then reacted at this temperature for 3 days, cooled and filtered to obtain a yellow solid. Such as figure 1 A thermogravimetric map of MIL-53 is shown, figure 1 It shows that the organic matter begins to decompose at 350°C, and the carbonization of the organic matter is complete at 700°C.

Embodiment 2

[0034] Example 2 Preparation of iron MOF precursor MIL-100

[0035] Mix 0.83g of iron powder, 2.06g of trimesic acid, 0.6ml of hydrofluoric acid (40%), and 1.14ml of nitric acid (65%) in 80ml of deionized water. In a stainless steel reaction kettle, it took 8 hours to rise from room temperature to 150° C., then reacted at this temperature for 4 days, cooled and filtered to obtain a solid.

Embodiment 3

[0036] Embodiment 3 Preparation of magnetic iron-carbon composite material

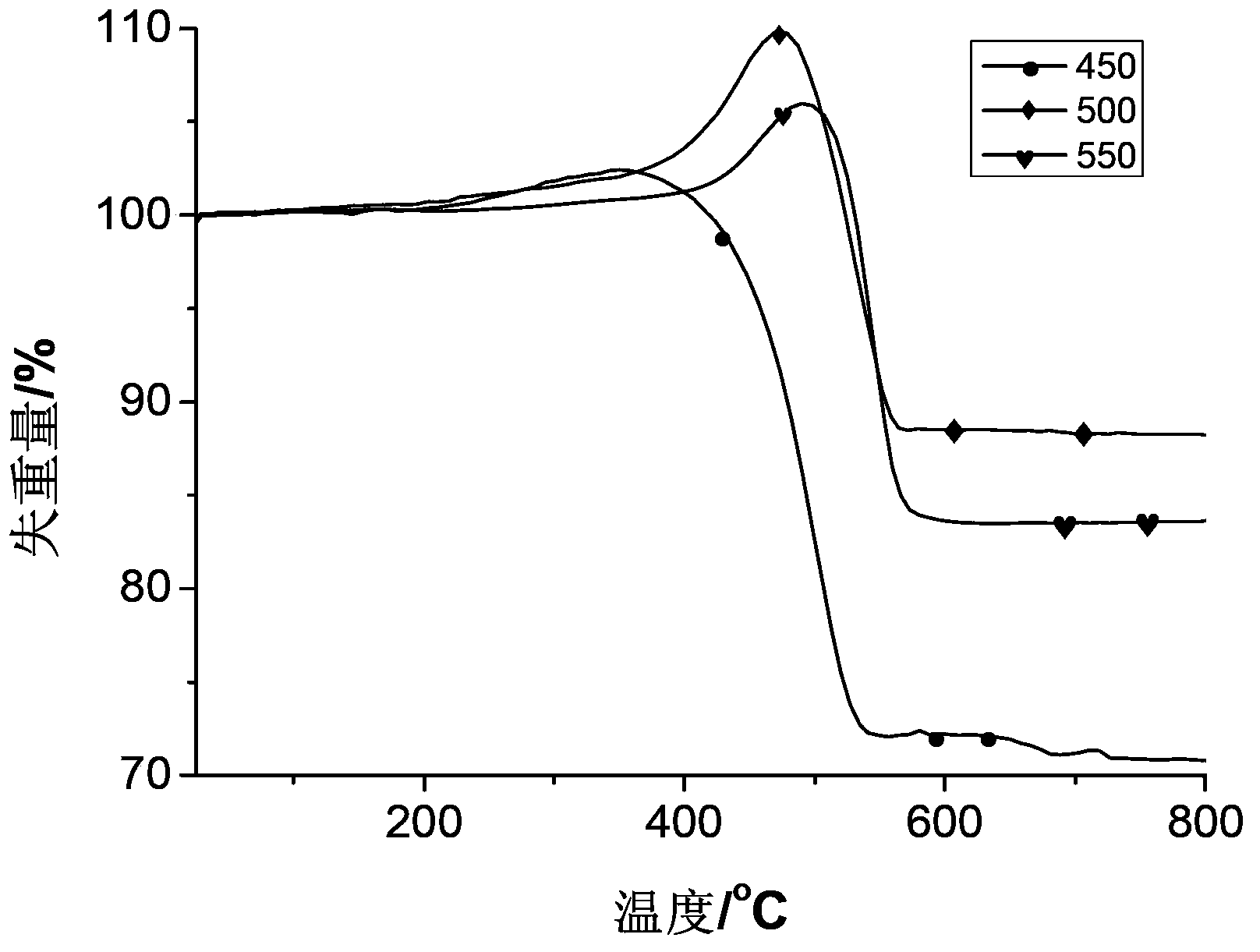

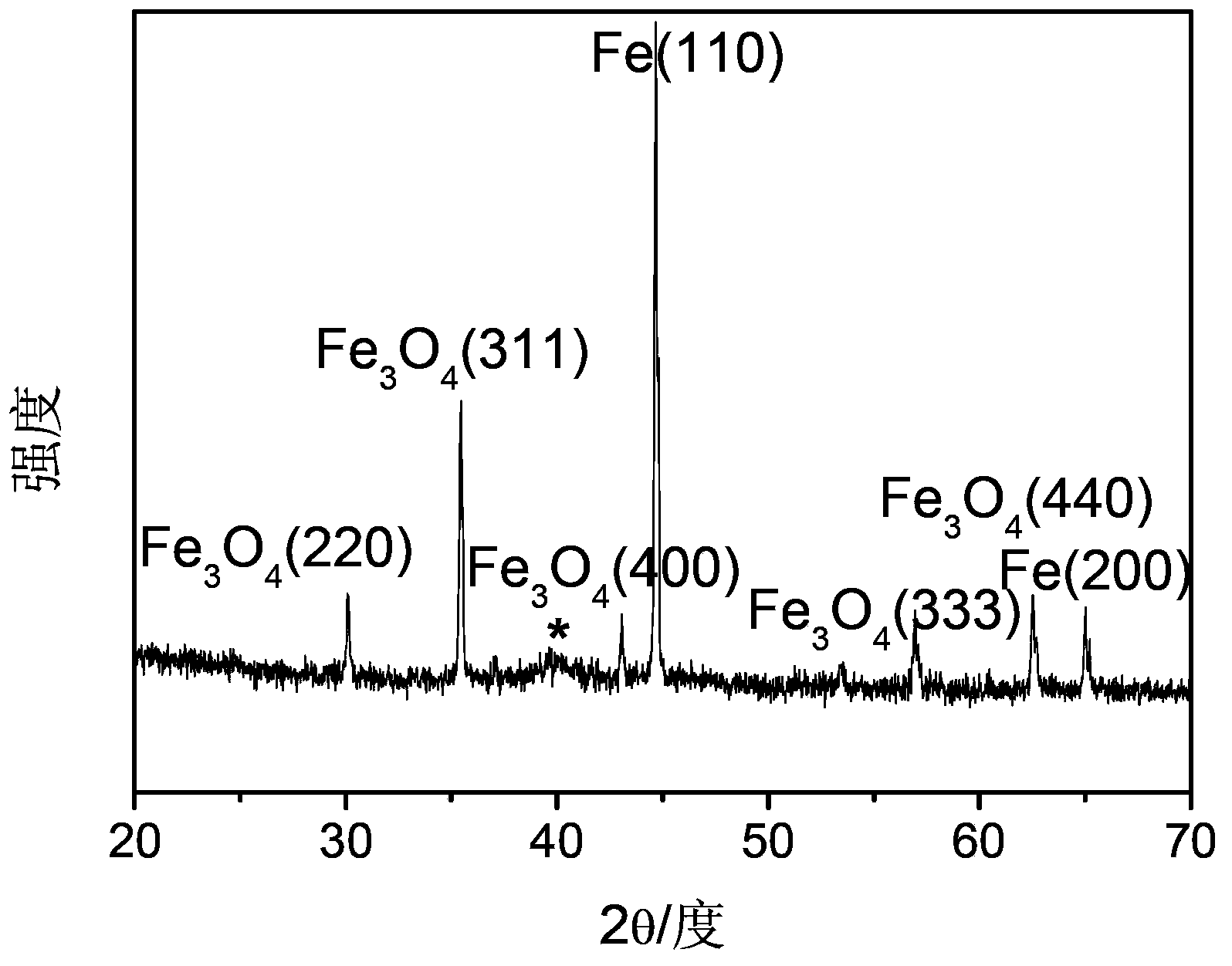

[0037] Take 1g of the iron MOF precursor obtained in Example 1 and put it into a quartz boat, use nitrogen as a protective gas in a tube furnace, program the temperature up to 450°C at 10°C per minute, keep it for 3 hours, start to cool down, and cool to room temperature Finally, take out the black magnetic iron-carbon composite material. The obtained material is tested by XRD analysis to have metal iron nanoparticles, and the average particle diameter is between 20-50nm. In the heating process, the preferred heating rate is 5°C-10°C, and ideal experimental results can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com