Method for preparing mesoporous molecular sieve Fe-MCM-41 with high iron content

A fe-mcm-41, 1fe-mcm-41 technology is applied in the field of preparation of heteroatom mesoporous molecular sieve Fe-MCM-41, which can solve the problems of uneven surface of molecular sieve and uneven distribution of metal ions, and achieve strong application Value, enhanced selectivity and activity, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

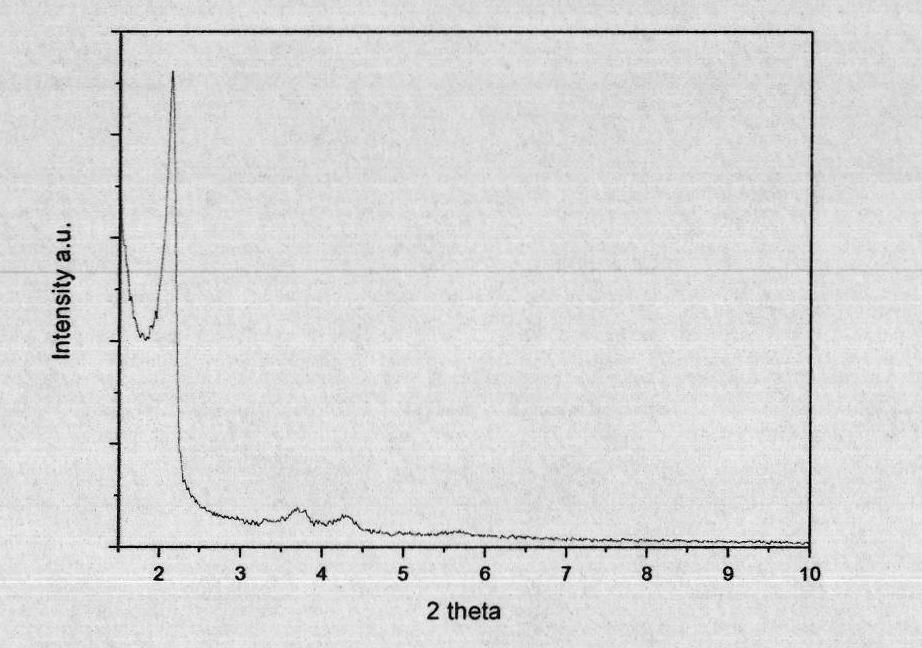

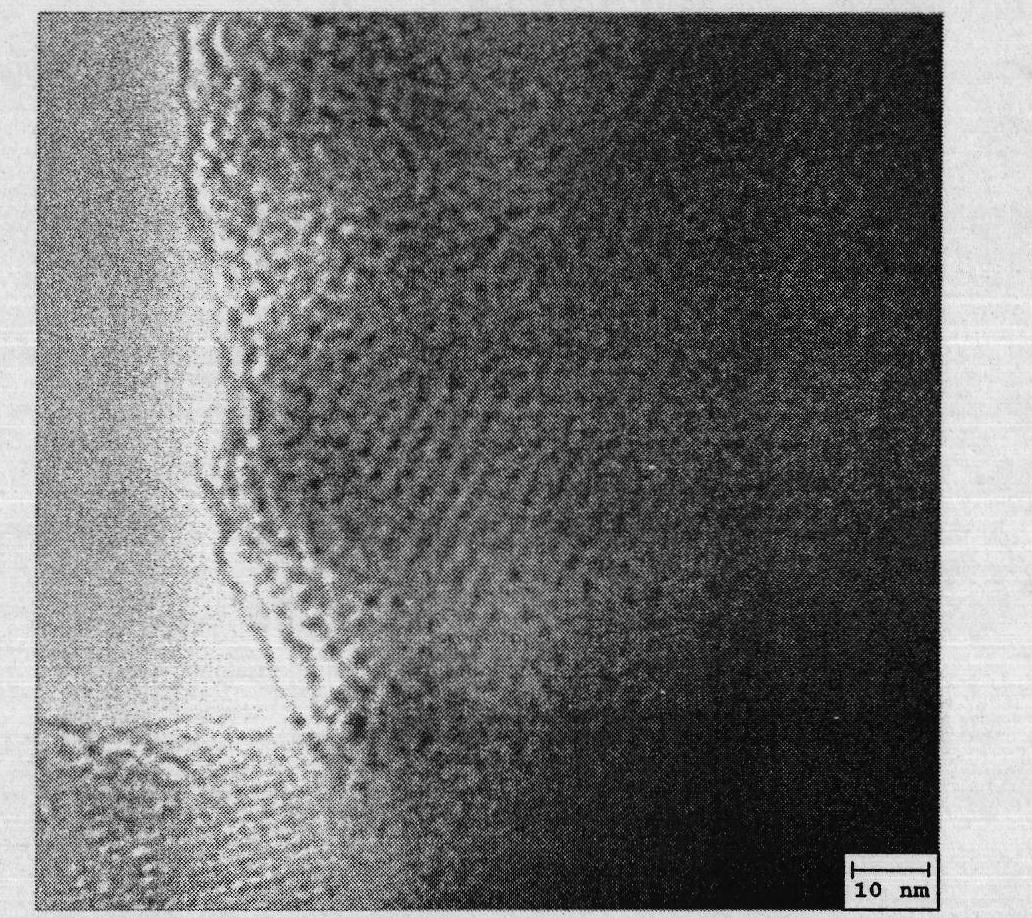

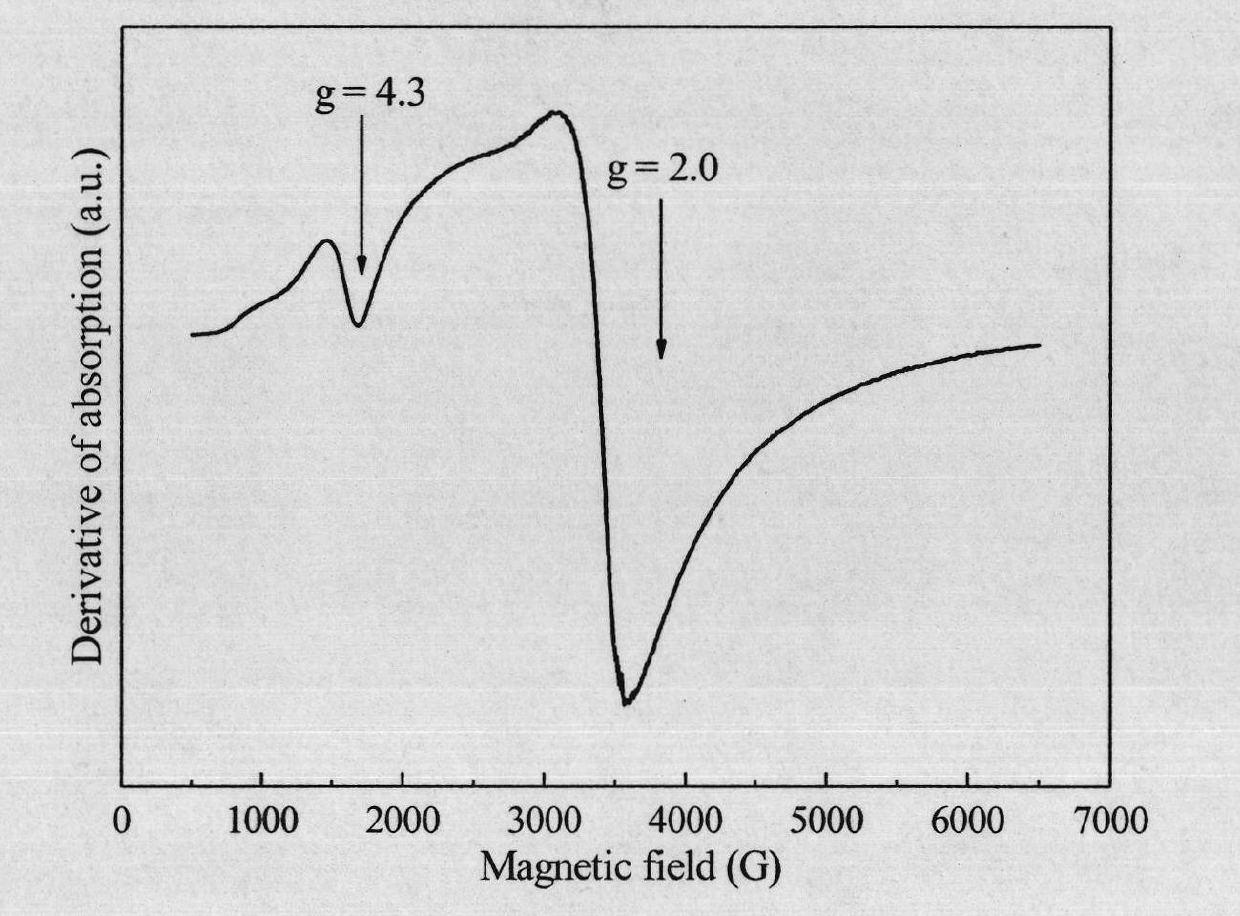

[0028] Add 5.63g CTAB to 100ml deionized water, stir for 15min, add 1.7g Fe(NO3)3.9H2O, stir for 30min, add a certain amount of nitric acid, adjust the solution pH=1, continue stirring for 30min, add 10 times to the solution A total of 13.83ml TEOS was added to the solution; after 2 hours, a certain amount of NaOH was added to adjust the pH to 9. After 3 hours of reaction, the solution was transferred to a polytetrafluoro-lined autoclave, and the crystal state was crystallized under autogenous pressure of 403K for 3 days. Then the sample was suction filtered, washed with deionized water until neutral, and dried at 373K for 6h. Program the temperature up to 550°C at a rate of 1°C min-1, keep it warm for 5 hours, and remove the template agent.

Embodiment 2

[0030] Add 3.82g SDS to 100ml deionized water, stir for 15min, then add 1.2g Fe2(SO4)3.7H2O, stir for 30min, add a certain amount of sulfuric acid, adjust the solution pH=1, continue stirring for 30min, add 10 times to the solution A total of 13.83ml TEOS was added to the solution; after 2 hours, a certain amount of NaOH was added to adjust the pH to 9. After 3 hours of reaction, the solution was transferred to a polytetrafluoro-lined autoclave, and the crystal state was crystallized under autogenous pressure of 403K for 3 days. Then the sample was suction filtered, washed with deionized water until neutral, and dried at 373K for 6h. Program the temperature up to 550°C at a rate of 1°C min-1, keep it warm for 5 hours, and remove the template agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com