Ceramic glaze which is easy to clean and is not easy to oil

A ceramic glaze, easy-to-clean technology, applied in the field of ceramic glaze, can solve the problems of difficulty in cleaning, difficult to remove, yellow glaze, etc., and achieves the effect of good easy-to-clean effect, reduced production cost, and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

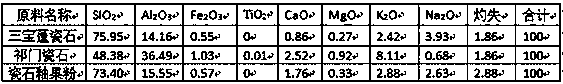

[0022] A kind of ceramic glaze that is easy to clean and not easy to be stained with oil, the mass percentage of its raw material composition is:

[0023] Bottom glaze: porcelain stone glaze powder 26%, albite 14%, limestone 3%, wollastonite 6%, Fuzhou kaolin 14%, Sanbaopeng porcelain stone 5%, Qimen porcelain stone 5%, quartz 15%, carbonic acid Magnesium 2%, dolomite 5%, barium carbonate 5%;

[0024] Surface glaze: porcelain stone glaze fruit powder 40%, lithium feldspar 18%, talc 13%, Fuzhou kaolin 6%, Sanbaopeng porcelain stone 6%, Qimen porcelain stone 6%, quartz 5%, zinc oxide 2%, lithium carbonate 2%, 2% dolomite, plus 10% titanium oxide powder.

[0025] The bottom glaze is prepared according to the following procedures: after the bottom glaze raw materials are mixed evenly, put them into a ball mill for ball milling, and pass through a 150-mesh sieve with a sieve residue of 0.2%, and apply it on the surface of the ceramic body according to a thickness of 1.2mm, and the...

Embodiment 2

[0028] A kind of ceramic glaze that is easy to clean and not easy to be stained with oil, the mass percentage of its raw material composition is:

[0029] Bottom glaze: Porcelain powder 33%, albite 12%, limestone 4%, wollastonite 8%, Fuzhou kaolin 10%, Sanbaopeng porcelain stone 8%, Qimen porcelain stone 7%, quartz 10%, carbonic acid Magnesium 4%, dolomite 2%, barium carbonate 2%;

[0030] Surface glaze: porcelain stone glaze fruit powder 31%, lithium feldspar 15%, talc 6%, Fuzhou kaolin 7%, Sanbaopeng porcelain stone 8%, Qimen porcelain stone 8%, quartz 7%, zinc oxide 4%, lithium carbonate 8%, 6% dolomite, plus 12% titanium oxide powder.

[0031] The bottom glaze is prepared according to the following procedures: after the bottom glaze raw materials are mixed evenly, put them into a ball mill for ball milling, and pass through a 150-mesh sieve with a sieve residue of 0.2%, and apply it on the surface of the ceramic body according to a thickness of 1.2mm, and then Carry out ...

Embodiment 3

[0034] A kind of ceramic glaze that is easy to clean and not easy to be stained with oil, the mass percentage of its raw material composition is:

[0035] Bottom glaze: porcelain stone glaze powder 30%, albite 10%, limestone 5%, wollastonite 5%, Fuzhou kaolin 11%, Sanbaopeng porcelain stone 6%, Qimen porcelain stone 10%, quartz 12%, carbonic acid Magnesium 4%, dolomite 4%, barium carbonate 3%;

[0036] Surface glaze: porcelain stone glaze fruit powder 34%, lithium feldspar 10%, talc 9%, Fuzhou kaolin 6%, Sanbaopeng porcelain stone 10%, Qimen porcelain stone 9%, quartz 9%, zinc oxide 4%, lithium carbonate 5%, dolomite 4%, plus 15% titanium oxide powder.

[0037] The bottom glaze is prepared according to the following procedures: after the bottom glaze raw materials are mixed evenly, put them into a ball mill for ball milling, and pass through a 150-mesh sieve with a sieve residue of 0.2%, and apply it on the surface of the ceramic body according to a thickness of 1.2mm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com