Thermal insulation agate porcelain and preparation method thereof

A technology of agate and porcelain, applied in the field of agate porcelain and its preparation, can solve the problems that hinder the popularization and application of porcelain, poor thermal insulation performance, and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

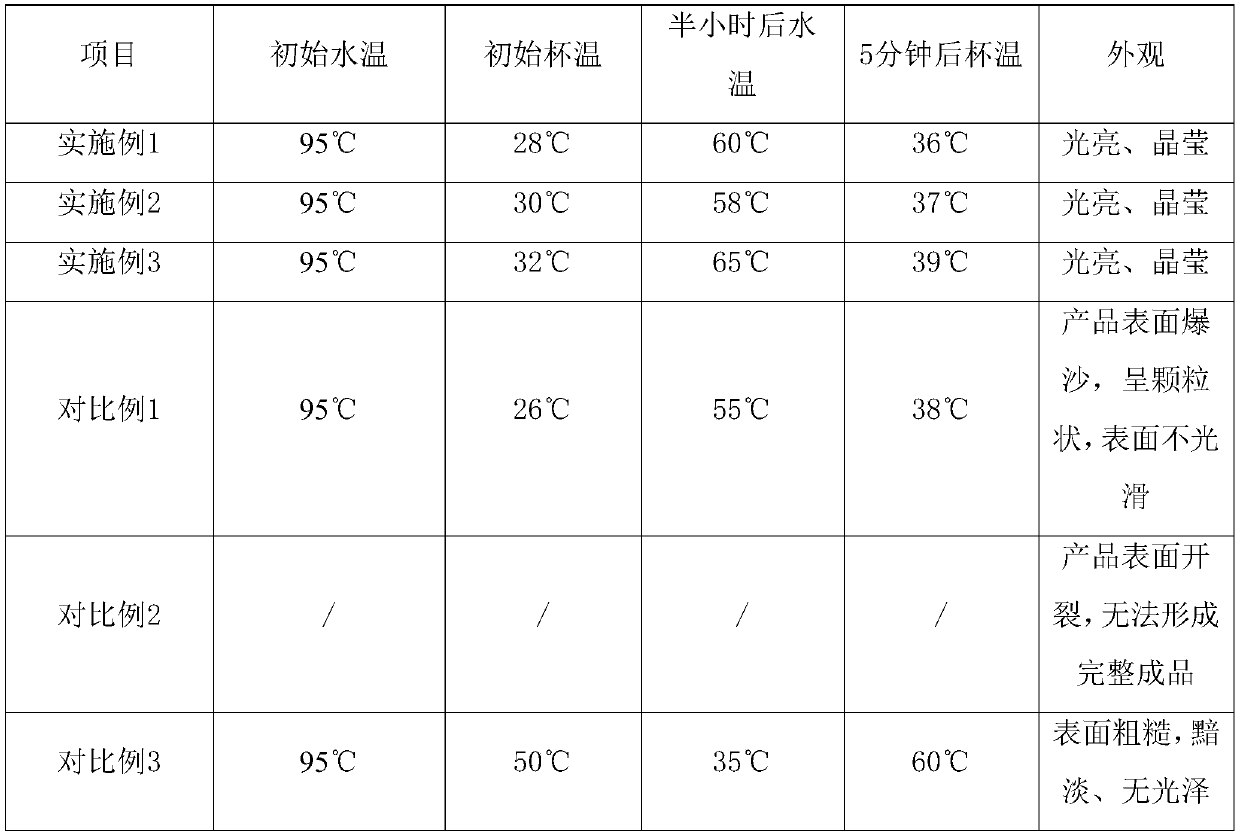

Examples

Embodiment 1

[0030] The heat insulation of the present embodiment, the agate porcelain of heat preservation, concrete formula is as follows: 60 parts of agate

[0031] Crystal 5 servings

[0032] Feldspar 6 parts

[0033] 2 parts talc

[0034] 2 parts clay

[0035] 5 parts bentonite

[0036] 3 parts kaolin

[0037] 1 piece of porcelain stone.

[0038] Among them, agate has a Mohs hardness of 7.6 and a density of 2.64g / cm 3 ;Mohs hardness of crystal is 7.0, density is 2.66g / cm 3 ;The Mohs hardness of feldspar is 6.5, and the density is 2.57g / cm 3 ; The Mohs hardness of talc is 1.0, and the specific gravity is 2.8.

[0039] Its preparation method is:

[0040] S1, agate, crystal, feldspar, talc, clay, bentonite, kaolin, and porcelain stone are respectively ball milled to form 200-mesh powder;

[0041] S2. Mix the powders obtained in step S1, and mix them uniformly by high-speed ball milling, and filter to obtain a 300-mesh mixture for later use;

[0042] S3, adding water to the mix...

Embodiment 2

[0046] The heat insulation of present embodiment, the agate porcelain of heat preservation, concrete formula is as follows:

[0047] 70 parts of agate

[0048] Crystal 10 servings

[0049] Feldspar 8 parts

[0050] Talc 6 parts

[0051] 5 parts clay

[0052] 10 parts bentonite

[0053] 8 parts kaolin

[0054] 5 pieces of porcelain stone.

[0055] Among them, agate has a Mohs hardness of 7.0 and a density of 2.57g / cm 3 ;Mohs hardness of crystal is 7.0, density is 2.66g / cm 3 ;The Mohs hardness of feldspar is 6.0, and the density is 2.54g / cm 3 ; The Mohs hardness of talc is 1.0, and the specific gravity is 2.6.

[0056] Its preparation method is:

[0057] S1, agate, crystal, feldspar, talc, clay, bentonite, kaolin, and porcelain stone are respectively ball milled to form 200-mesh powder;

[0058] S2. Mix the powders obtained in step S1, and mix them uniformly by high-speed ball milling, and filter to obtain a 300-mesh mixture for later use;

[0059] S3, adding water t...

Embodiment 3

[0063] The heat insulation of present embodiment, the agate porcelain of heat preservation, concrete formula is as follows:

[0064] Onyx 68 parts

[0065] Crystal 6 servings

[0066] Feldspar 5.5 parts

[0067] 3 parts talc

[0068] 3.5 parts of clay

[0069] 7 parts bentonite

[0070] 5 parts kaolin

[0071] 2 pieces of porcelain stone

[0072]Among them, agate has a Mohs hardness of 7.5 and a density of 2.6g / cm 3 ;Mohs hardness of crystal is 7.0, density is 2.66g / cm 3 ; The Mohs hardness of feldspar is 6.3, and the density is 2.55g / cm 3 ; The Mohs hardness of talc is 1.0, and the specific gravity is 2.7.

[0073] Its preparation method is:

[0074] S1, agate, crystal, feldspar, talc, clay, bentonite, kaolin, and porcelain stone are respectively ball milled to form 200-mesh powder;

[0075] S2. Mix the powders obtained in step S1, and mix them uniformly by high-speed ball milling, and filter to obtain a 300-mesh mixture for later use;

[0076] S3, adding water to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com