Low-temperature fired high-strength building ceramic green body and preparation method thereof

A low-temperature firing technology for architectural ceramics, which is applied in the field of ceramic materials to achieve the effects of improving strength, broad market prospects, and reducing firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

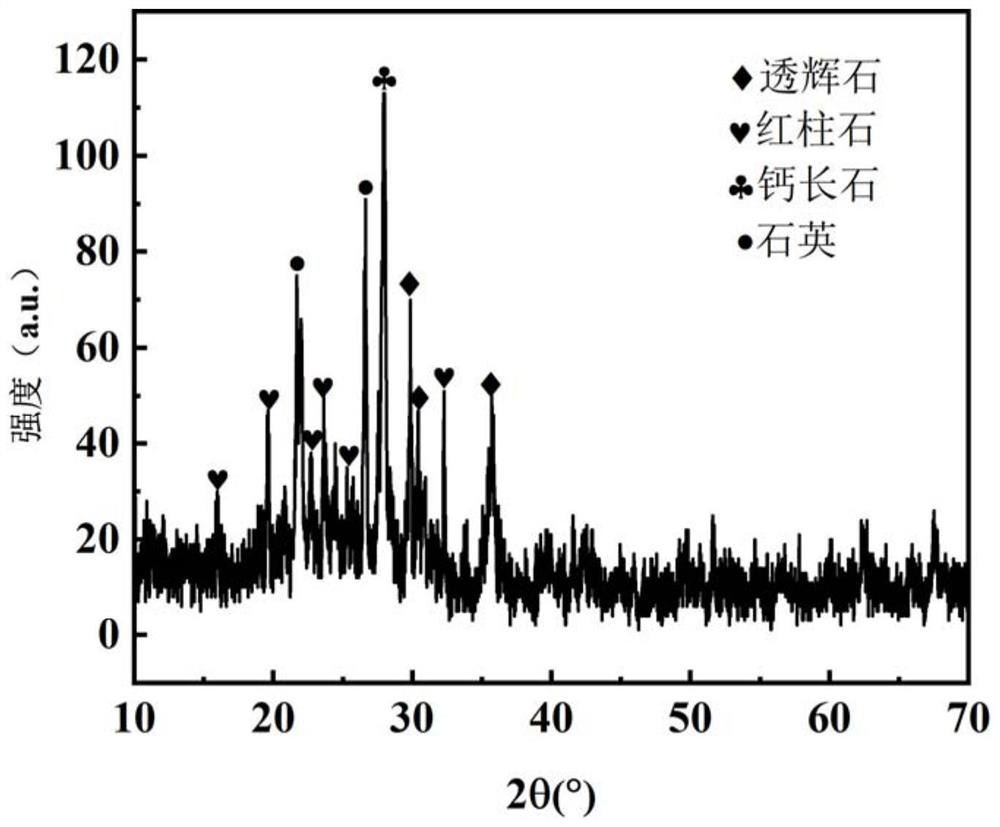

Image

Examples

Embodiment 1

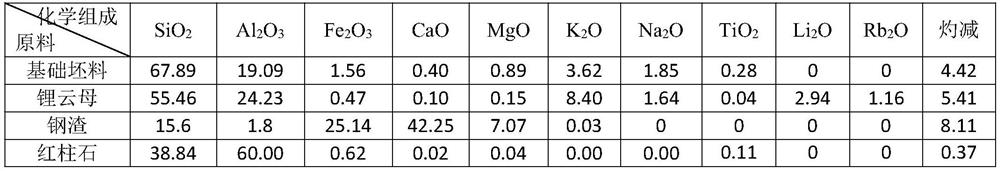

[0020] 1. A low-temperature fired high-strength architectural ceramic green body in this embodiment is composed of raw materials: 80 wt% of basic blank, 6 wt% of lepidolite, 5 wt% of steel slag, and 9 wt% of andalusite, and the particle size of each composition is 50 mesh. Among them, the raw material composition of the base blank is 32wt% of porcelain stone, 10wt% of potassium feldspar, 12wt% of albite feldspar, 21wt% of kaolin, 10wt% of black mud, 14wt% of white mud, and 1wt% of talc.

[0021] 2. The method for preparing the above-mentioned low-temperature fired high-strength building ceramic green body in this embodiment, the steps are as follows:

[0022] (1) After mixing the above-mentioned base material, lepidolite, steel slag and andalusite, carry out wet ball milling for 30 minutes (material: ball: water = 1:2:1), and put the obtained slurry in an oven and dry it at 100°C for 4 hours , after passing through a 100-mesh sieve, carry out powder granulation to obtain a mat...

Embodiment 2

[0025] 1. A low-temperature fired high-strength building ceramic green body in this embodiment is composed of raw materials: 75wt% of basic blank, 5wt% of lepidolite, 8wt% of steel slag, and 12wt% of andalusite, and the particle size of each composition is 50 mesh. Among them, the raw material composition of the base blank is 32wt% of porcelain stone, 10wt% of potassium feldspar, 12wt% of albite feldspar, 21wt% of kaolin, 10wt% of black mud, 14wt% of white mud, and 1wt% of talc.

[0026] 2. The method for preparing the above-mentioned low-temperature fired high-strength building ceramic green body in this embodiment, the steps are as follows:

[0027] (1) After mixing the above-mentioned base material, lepidolite, steel slag and andalusite, carry out wet ball milling for 30 minutes (material: ball: water = 1:2:1), and put the obtained slurry in an oven and dry it at 100°C for 4 hours , after passing through a 100-mesh sieve, carry out powder granulation to obtain a material wi...

Embodiment 3

[0030] 1. A low-temperature fired high-strength building ceramic green body in this embodiment is composed of raw materials: 70wt% of basic blank, 5wt% of lepidolite, 10wt% of steel slag, and 15wt% of andalusite, and the particle size of each composition is 50 mesh. Among them, the raw material composition of the base blank is 32wt% of porcelain stone, 10wt% of potassium feldspar, 12wt% of albite feldspar, 21wt% of kaolin, 10wt% of black mud, 14wt% of white mud, and 1wt% of talc.

[0031] 2. The method for preparing the above-mentioned low-temperature fired high-strength building ceramic green body in this embodiment, the steps are as follows:

[0032] (1) After mixing the above-mentioned base material, lepidolite, steel slag and andalusite, carry out wet ball milling for 30 minutes (material: ball: water = 1:2:1), and put the obtained slurry in an oven and dry it at 100°C for 4 hours , after passing through a 100-mesh sieve, carry out powder granulation to obtain a material w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com