Porous water-absorbing red pottery steaming block and preparation method thereof

A technology of porous water absorption and terracotta, applied in the field of ceramic products, can solve the problems of poor thermal shock resistance, easy cracking, poor thermal conductivity, etc., and achieve the effects of small thermal expansion coefficient, good thermal shock resistance and lower firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A porous water-absorbing terracotta steaming block is made of the following raw materials in parts by weight:

[0064] 300-350 parts of red loam,

[0065] 50-60 parts of diatomaceous earth,

[0066] Red jade soil 25-32 parts,

[0067] 45-55 parts of clay,

[0068] 70-82 parts of feldspar,

[0069] Lithium china stone 30~38 parts,

[0070] 14-20 parts of glass fiber,

[0071] 5-7 parts of ultra-fine stainless steel fiber.

[0072] Preferably, the porous water-absorbing terracotta steaming block is made of raw materials including the following parts by weight:

[0073] 315-345 parts of red loam soil,

[0074] Diatomaceous earth 52~57 parts,

[0075] 30-32 parts of red jade soil,

[0076] 47-50 parts of clay,

[0077] Feldspar 75~79 parts,

[0078] Lithium china stone 33~36 parts,

[0079] 16-18 parts of glass fiber,

[0080] 5.5-6.5 parts of ultra-fine stainless steel fiber.

[0081] Preferably, the porous water-absorbing terracotta steaming block is made of...

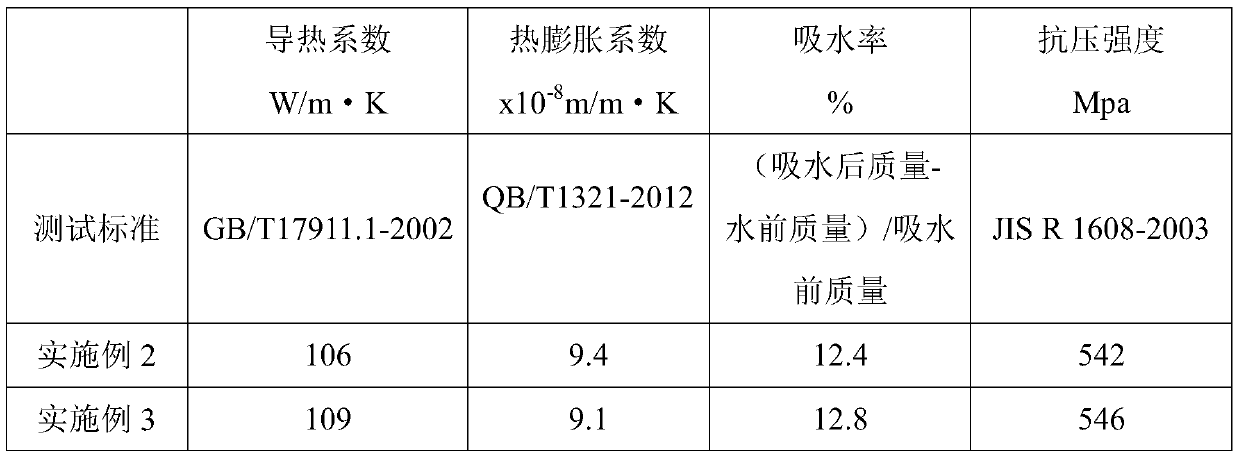

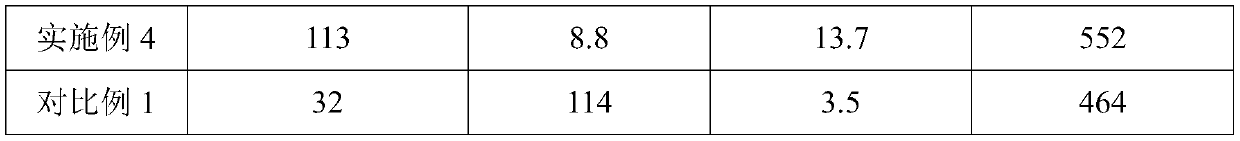

Embodiment 2

[0100] A porous water-absorbing terracotta steaming block is made of the following raw materials in parts by weight:

[0101] 315 parts of red loam,

[0102] 52 parts of diatomaceous earth,

[0103] 30 parts of red jade soil,

[0104] 47 parts of clay,

[0105] 75 parts of feldspar,

[0106] Lithium china stone 33 parts,

[0107] 16 parts of glass fiber,

[0108] Ultrafine stainless steel fiber 5.5 parts.

[0109] In this embodiment, the feldspar is a mixture of albite and potassium feldspar.

[0110] In this embodiment, the mass ratio of albite and potassium feldspar in the mixture of albite and potassium feldspar is 10:3.8.

[0111] In this embodiment, the fineness of the ultrafine stainless steel fiber is 0.05um.

[0112] In the present embodiment, the preparation method of the porous water-absorbing terracotta steaming block includes the following steps:

[0113] A, by weight, take red loam, diatomite, red jade soil, clay, feldspar, lithium china stone, glass fibe...

Embodiment 3

[0119] A porous water-absorbing terracotta steaming block is made of the following raw materials in parts by weight:

[0120] 345 parts of red loam,

[0121] 57 parts of diatomaceous earth,

[0122] 32 parts of red jade soil,

[0123] 50 parts clay,

[0124] Feldspar 79 parts,

[0125] Lithium porcelain stone 36 parts,

[0126] 18 parts of glass fiber,

[0127] Ultrafine stainless steel fiber 6.5 parts.

[0128] In this embodiment, the feldspar is a mixture of albite and potassium feldspar.

[0129] In this embodiment, the mass ratio of albite and potassium feldspar in the mixture of albite and potassium feldspar is 10:4.2.

[0130] In this embodiment, the fineness of the ultrafine stainless steel fiber is 0.07um.

[0131] In the present embodiment, the preparation method of the porous water-absorbing terracotta steaming block includes the following steps:

[0132] A, by weight, take red loam, diatomite, red jade soil, clay, feldspar, lithium china stone, glass fiber,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com