Medium and low temperature fine porcelain and its preparing method

A fine porcelain, low temperature technology, applied in the field of medium and low temperature fine porcelain and its preparation, can solve the problems of fine porcelain glaze, narrow pigment range, difficult coloring, limited application, etc., and achieves wide processing methods, bright and uniform colors, and pigment selection wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] For the preparation of low-temperature color-bodied fine porcelain in lemon yellow bodied porcelain, the mass percentage of the chemical composition of the mud is as follows:

[0024]

SIOs 2

AL 2 o 3

K 2 o

Na 2 o

CaO

MgO

Fe 2 o 3

IL

∑

Plus praseodymium zirconium yellow material

Zr-Si-Pr

63.13

22.16

2.47

1.14

1.88

1.93

0.39

8.5

101.6

4%

[0025] Blank type:

[0026]

[0027] Transparent glaze chemical composition mass percentage

[0028]

SiO 2

Al 2 o 3

Fe 2 o 3

K 2 o

Na 2 o

CaO

MgO

ZnO

BaO

∑

49

7.08

0.1

2.57

0.43

8.72

2.57

5.71

6.66

100

[00...

Embodiment 2

[0032] For the preparation of low-temperature color-bodied fine porcelain in light red bodied porcelain, the mass percentage of the chemical composition of the mud is as follows:

[0033] SiO 2

al 2 o 3

Fe 2 o 3

K 2 o

Na 2 o

CaO

MgO

IL

∑

Additional coloring

Zr-Si-Cd-

Se-S

62.48

21.2

0.386

2.46

1.16

2.98

1.94

8.6

101.2

1%

[0034] Blank type:

[0035] The mass percent of the transparent glaze chemical composition, the glaze formula, and the steps of the technological process are the same as those in Example 1. The obtained products passed the inspection by the National Daily-Use Fine Porcelain Supervision and Inspection Center. The inspection report is attached.

[0036] Test items

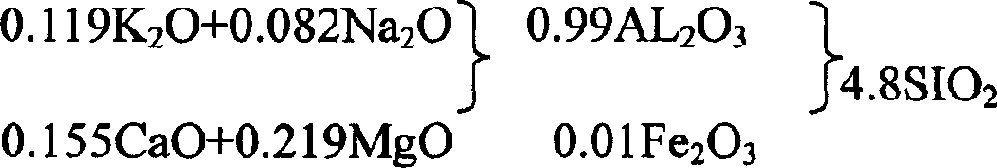

Embodiment 3

[0038] A kind of medium and low temperature fine porcelain, the raw material is composed of base material, alkali metal compound and alkaline earth metal compound, the binary basic components in the base material are porcelain stone and kaolin, and the molecular formula of porcelain stone as the main component is K 2 O3Al 2 o 3 6SiO 2 2H 2 Sericite porcelain stone of O, the three main oxides in the raw material are SiO 2 ;Al 2 o 3 ; 2 O and RO, where R 2 is an alkali metal element, R is an alkaline earth metal element, and the percentages of the total weight of the raw materials are SiO 2 50-70%, Al 2 o 3 20-30%, R 2 O and RO total 7.3-12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com