Ecological ceramic tile and preparation method thereof

A kind of ceramic tile, ecological technology, applied in the field of ecological ceramic tile and its preparation, can solve the problems of not having multiple functions, unsatisfactory effect, limited application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

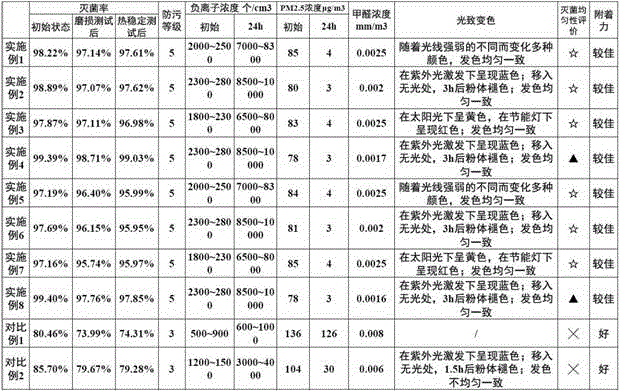

Examples

Embodiment 1

[0037] An ecological ceramic tile and a preparation method thereof, the preparation method comprising the following steps:

[0038] Step A, prepare glaze slurry: mix and grind 12% quartz, 12% feldspar, 15% borax, 6% carbonate, 35% boric acid, 5% spodumene, 1% fluoride salt, and 2% kaolin evenly, Then add 1% antibacterial compound, 3% negative ion compound and 8% photochromic compound, and grind evenly to make a mixture; spread the prepared mixture into a refractory sagger, and heat it at 1250~1320℃ Melting to obtain molten slurry; the high-temperature melting process is as follows: the room temperature is raised to 1000°C, and the heat is kept for 10 minutes; the temperature is raised to 1300°C, and the heat is kept for 30 minutes; The slurry is cooled by water quenching and broken into granules to obtain lead-free cadmium low-temperature frit; after the low-temperature frit is sieved, ground and mixed, use PVA as a temporary binder at room temperature, add gum arabic suspendi...

Embodiment 2

[0053] An ecological ceramic tile and a preparation method thereof, the preparation method comprising the following steps:

[0054] Step A, preparation of glaze slurry: 15% quartz, 5% feldspar, 20% borax, 8% carbonate, 25% boric acid, 8% spodumene, 3% fluoride salt, 3% kaolin are mixed and ground evenly, Then add 3% antibacterial compound, 5% negative ion compound and 5% photochromic compound, and grind evenly to make a mixture; spread the prepared mixture into a refractory sagger, and heat it at 1250~1320℃ Melting to obtain molten slurry; the high-temperature melting process is as follows: the room temperature is raised to 1000°C, and the heat is kept for 10 minutes; the temperature is raised to 1300°C, and the heat is kept for 30 minutes; The slurry is cooled by water quenching and broken into granules to obtain lead-free cadmium low-temperature frit; after the low-temperature frit is sieved, ground and mixed, use PVA as a temporary binder at room temperature, add gum arabic...

Embodiment 3

[0069] An ecological ceramic tile and a preparation method thereof, the preparation method comprising the following steps:

[0070] Step A, prepare glaze slurry: 18% quartz, 5% feldspar, 24% borax, 8% carbonate, 20% boric acid, 6% spodumene, 1% fluoride salt, 4% kaolin are mixed and ground evenly, Then add 5% antibacterial compound, 8% negative ion compound and 1% photochromic compound, and grind evenly to make a mixture; spread the prepared mixture into a refractory sagger, and heat it at 1250~1320℃ Melting to obtain molten slurry; the high-temperature melting process is as follows: the room temperature is raised to 1000°C, and the heat is kept for 10 minutes; the temperature is raised to 1300°C, and the heat is kept for 30 minutes; The slurry is cooled by water quenching and broken into granules to obtain lead-free cadmium low-temperature frit; after the low-temperature frit is sieved, ground and mixed, use PVA as a temporary binder at room temperature, add gum arabic suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com