Inorganic nano-material modified polyurethane resin and preparation method thereof

A technology of inorganic nanomaterials and polyurethane resin, which is applied in the field of polyurethane resin, can solve the problems of polyurethane tensile strength and tensile strength decrease, polyurethane performance instability, and damage to polyurethane force, etc., to achieve enhanced tensile strength and enhanced heat resistance , Enhance the effect of tensile strength and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

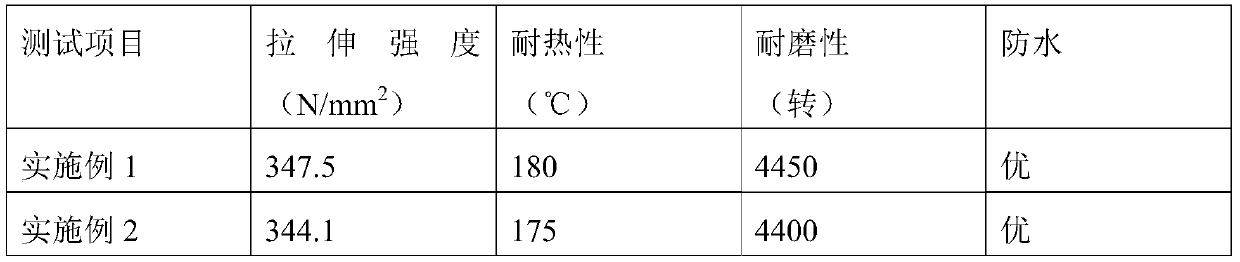

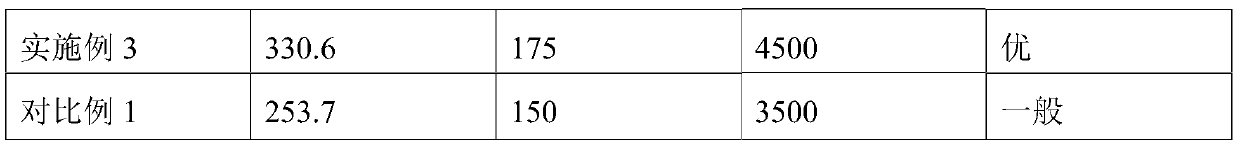

Examples

Embodiment 1

[0027] An inorganic nanomaterial modified polyurethane resin, comprising the following components in weight percentage: 7.2% of isophorone diisocyanate, 28.8% of 4,4'-dicyclohexylmethane diisocyanate, 7.2% of polycaprolactone polyol, Polycarbonate polyol 10.8%, polytetramethylene ether glycol 18%, 1,6-hexanediol 0.57%, dimethylolpropionic acid 0.86%, trimethylolpropane 0.57%, isoflurane Ketonediamine 0.4%, Diethylenetriamine 0.6%, Dimethylformamide 10%, Dimethylacetamide 10%, Nano-Silicon Dioxide 1.75%, Carbon Black 1.75%, γ-Aminopropyl Triethoxy Silane 0.43%, Vinyltris(β-methoxyethoxy)silane 1.07% and Organic Bismuth 0.05%.

[0028] A preparation method of inorganic nanomaterial modified polyurethane resin, comprising the following steps:

[0029] (1) Disperse dimethylformamide, dimethylacetamide, nano silicon dioxide and carbon black in a high-speed disperser for 30 minutes to obtain a dispersion;

[0030] (2) dehydrating polycaprolactone polyol, polycarbonate polyol and p...

Embodiment 2

[0035] A kind of inorganic nano material modified polyurethane resin, comprises the component of following percentage by weight:

[0036] Isophorone diisocyanate 8.45%, 4,4'-dicyclohexylmethane diisocyanate 29.55%, polycaprolactone polyol 7.6%, polycarbonate polyol 7.6%, polytetramethylene ether diol 22.8 %, 1,6-hexanediol 0.286%, dimethylolpropionic acid 0.571%, trimethylolpropane 0.143%, isophorone diamine 0.5%, diethylenetriamine 0.5%, dimethylformamide 18%, nano-silica 2.5%, γ-aminopropyltriethoxysilane 0.5%, vinyltris(β-methoxyethoxy)silane 1% and organic bismuth 0.05%.

[0037] A preparation method of inorganic nanomaterial modified polyurethane resin, comprising the following steps:

[0038] (1) Disperse dimethylformamide and nano silicon dioxide in a high-speed disperser for 35 minutes to obtain a dispersion;

[0039] (2) dehydrating polycaprolactone polyol, polycarbonate polyol and polytetramethylene ether glycol under vacuum at 120°C for 2 hours;

[0040] (3) Add ...

Embodiment 3

[0044]A kind of inorganic nano material modified polyurethane resin, comprises the component of following percentage by weight:

[0045] 10% isophorone diisocyanate, 30% 4,4'-dicyclohexylmethane diisocyanate, 7% polycaprolactone polyol, 10.5% polycarbonate polyol, 17.5% polytetramethylene ether glycol %, 1,6-hexanediol 0.65%, dimethylolpropionic acid 0.65%, trimethylolpropane 0.65%, isophorone diamine 0.4%, diethylenetriamine 0.6%, dimethylformamide 8%, dimethylacetamide 8%, nano-silica 1.5%, carbon black 1.5%, γ-aminopropyltriethoxysilane 1%, vinyl tris(β-methoxyethoxy)silane 2% and organic bismuth 0.05%.

[0046] A preparation method of inorganic nanomaterial modified polyurethane resin, comprising the following steps:

[0047] (1) Disperse dimethylformamide, dimethylacetamide, nano silicon dioxide and carbon black in a high-speed disperser for 30 minutes to obtain a dispersion;

[0048] (2) dehydrating polycaprolactone polyol, polycarbonate polyol and polytetramethylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com