Patents

Literature

44results about How to "Improve waterproof and breathable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic nano-material modified polyurethane resin and preparation method thereof

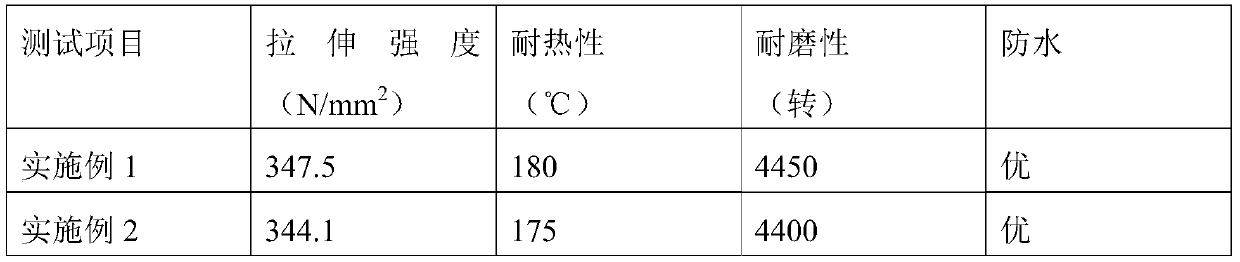

The invention discloses inorganic nano-material modified polyurethane resin. The inorganic nano-material modified polyurethane resin is prepared from components in percentage by weight as follows: 35%-40% of isocyanate, 35%-40% of a polyol compound, 1.5%-6.5% of a chain extender, 15%-20% of a solvent, 2.0%-6.0% of an inorganic nanomaterial, 1.0%-5.0% of a silane coupling agent and 0.01%-0.05% of acatalyst. After polyurethane is modified with an inorganic nano-material, stretch strength of polyurethane resin is enhanced by 30%-40%, tensile strength is improved by 30%-50%, heat resistance is improved by 10%-20%, wear resistance is improved by 20%-30%, and besides, waterproof, moisture-permeable, anti-static and self-cleaning properties of the polyurethane resin are improved.

Owner:广东大盈新材料科技有限公司

Formula and preparation process for multifunctional surface treating agent applied to aqueous leather

InactiveCN108047906ARich touch and visual experienceImprove physical performanceFireproof paintsWax coatingsWaxChemistry

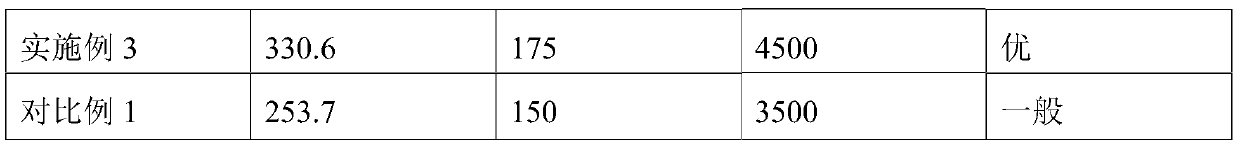

The invention discloses a formula for a multifunctional surface treating agent applied to aqueous leather. The formula comprises 3 to 35% of an aqueous polyurethane emulsion, 0.5 to 20% of a multifunctional finishing agent, 2 to 15% of aqueous wax, 0.3 to 3% of a leveling agent, 0.5 to 1.5% of a thickening agent, 0.5 to 1% of an antifoaming agent and 24.5 to 93.2% of water. The preparation processcomprises the following steps: adding all the above raw materials except the thickening agent into a container in proportion, carrying out uniform mixing through a dispersator, then carrying out filtering and adding the thickening agent to adjust viscosity so as to obtain the surface treating agent. The surface treating agent provided by the invention endows synthetic leather with special performances like antibacterial, sterilizing, anti-ultraviolet, anti-radiation, flame-retardant, temperature-adjusting, color-changing, self-cleaning and anti-doodling performances without any influence on the fastness and handfeel of the synthetic leather, and substantially prolongs the service life of the synthetic leather; a product having been treated with the surface treating agent has better handfeel and presents better visual impression; and the surface treating agent greatly improves the physical properties of the synthetic leather and allows the synthetic leather to have more excellent scrape resistance, water resistance, fire resistance and the like.

Owner:宋林涛

Waterproof and breathable shoes and preparation method thereof

InactiveCN108835768AGood waterproof and breathable performanceInhibit bacterial growthSolesSynthetic resin layered productsFilm structureAgricultural engineering

The invention discloses waterproof and breathable shoes and a preparation method thereof. Each shoe comprises a vamp and a sole; the vamp comprises an outer layer, a middle layer and an inner layer; the outer layer is in knit construction, the middle layer adopts a waterproof and breathable polyurethane film structure, and the inner layer is made of cotton fabrics; the preparation method is as follows: orderly nesting and stacking the outer layer, the middle layer coated with dotted glue at two surfaces and the inner layer in a mould-pressing mold, hot-pressing and shaping, cooling to obtain the vamp; banburying modified white carbon black, octadecanoic acid and accelerant, and then putting in the mixed natural rubber and bytadiene styrene rubber, banburying, placing, cooking, sulfurizingto obtain the sole; adhering the vamp and the sole, performing instant punching treatment to obtain the waterproof and breathable shoe. The waterproof and breathable shoe disclosed by the invention isexcellent in waterproof and breathable performance, the bacteria breeding on the foot can be effectively inhibited, and the foot odor can be masked; the use performance is excellent, the health carecan be performed on the sole of the foot can be in the process of wearing the shoes, and the service life is long; the preparation method is simple and feasible, and the production efficiency is high.

Owner:金华市博益飞科技有限公司

Soft wet-method waterproof air-permeable water-permeable polyurethane resin and preparation method thereof

The invention discloses a soft wet-method waterproof air-permeable water-permeable polyurethane resin and a preparation method thereof. The resin comprises the following components in percentage by mass: 12% to 15% of poly adipic acid-1, 4-butanediol ester glycol, 7% to 9% of diphenyl-methane-diisocyanate MDI, 1% to 2% of a mixing chain extendor, 0.5% to 0.6% of a terminating agent, 0.3% to 0.5% of a high-speed penetrating agent OT, 0.02% to 0.04% of a catalyst, 0.3% to 0.5% of filling material, 0.1% to 0.2% of a stabilizer UV-329, and the balance of an organic solvent. As the polyurethane resin and the preparation method thereof adopt the mixing chain extendor, and measures such as adding an organic solvent DMF and the filling material CMC twice, the prepared polyurethane resin has excellent waterproof moisture permeable properties ( water-fast pressure larger than and equal to 3000 mm H2O, and moisture permeable property larger than and equal to 5000 g / m 2.24 Hr), and is good in rebound resilience and peel strength, high in water-fast pressure, and soft, plump, and fine and smooth in handfeel.

Owner:江西巨联新材料有限公司

Waterproof and breathable non-woven fabric and production process thereof

InactiveCN108973280AImprove flame retardant performanceImprove light resistanceSpinning solution de-aeratingFlame-proof filament manufactureMasterbatchEngineering

The invention discloses a waterproof and breathable non-woven fabric and a production process thereof. The waterproof and breathable non-woven fabric comprises the following raw materials in parts byweight: 50-70 parts of polypropylene, 5-10 parts of polyester resin, 3-5 parts of an additive, 5-10 parts of a flame retardant, and 3-5 parts of a dyeing agent. In the invention, the production process of the waterproof and breathable non-woven fabric is strictly controlled, by strictly controlling the proportion of all components of the waterproof and breathable non-woven fabric and production process parameters, and by adding the flame retardant to the raw material additive, the flame retardant performance of the produced non-woven fabric is improved, the additional sodium thiosulfate can improve the light resistance of the fabric, meanwhile heat degradation masterbatch and a softener can effectively improve the softness of the fabric and enhance the comfortableness. Meanwhile, under thecontinuous conveying of a web forming conveyor belt, a PE polymer gas-permeable membrane is added to improve the waterproof and breathable performance of the non-woven fabric, so that the non-woven fabric is suitable for extensive promotion.

Owner:衢州市瑞昊无纺布有限公司

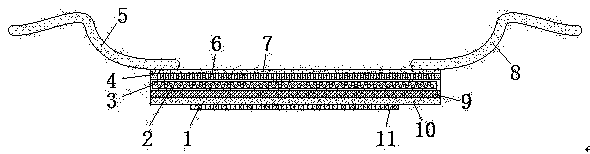

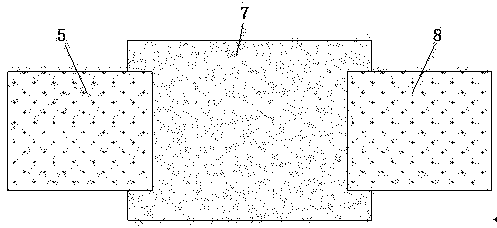

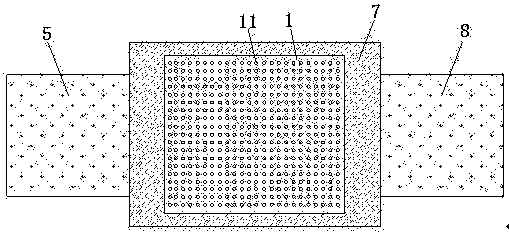

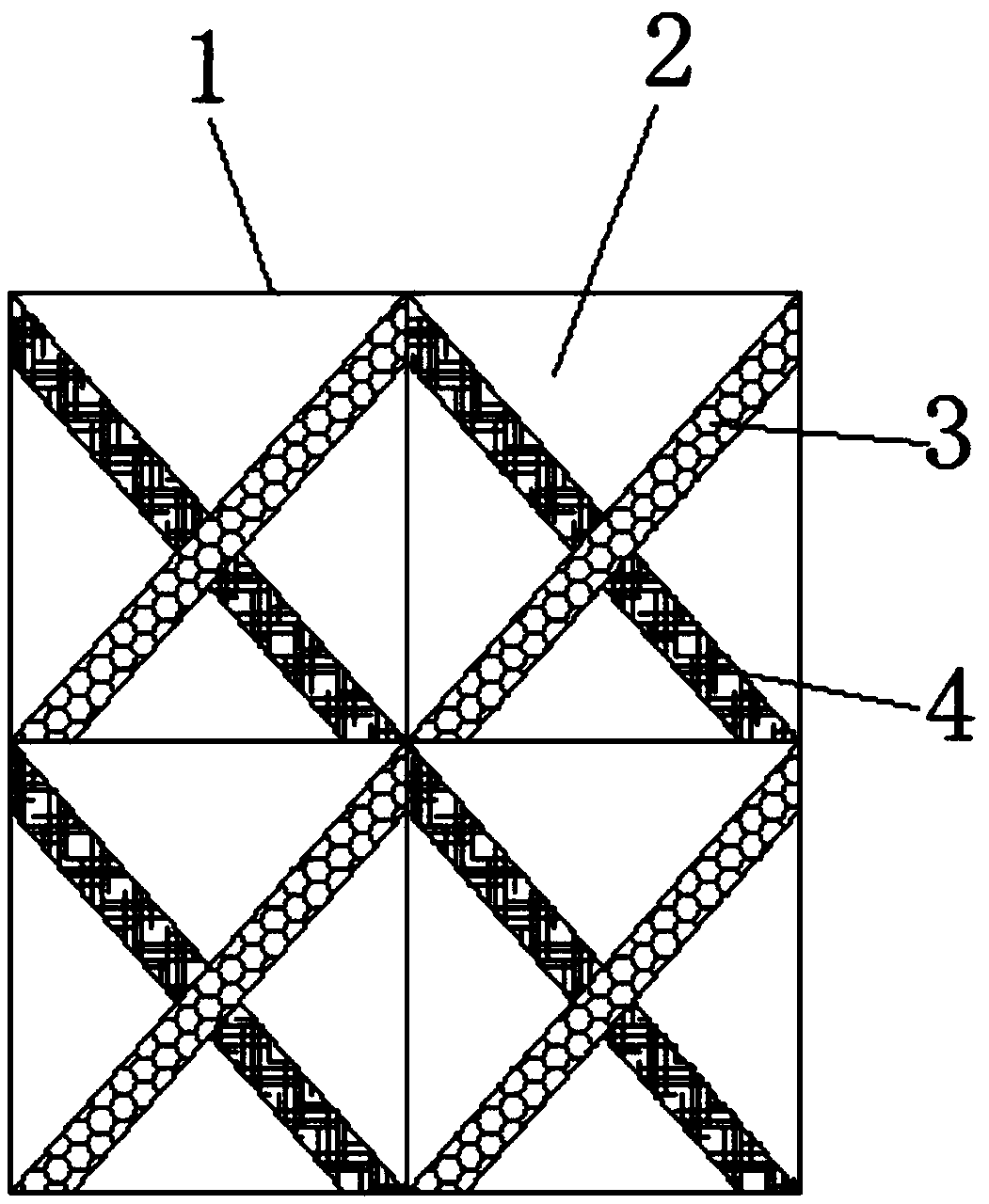

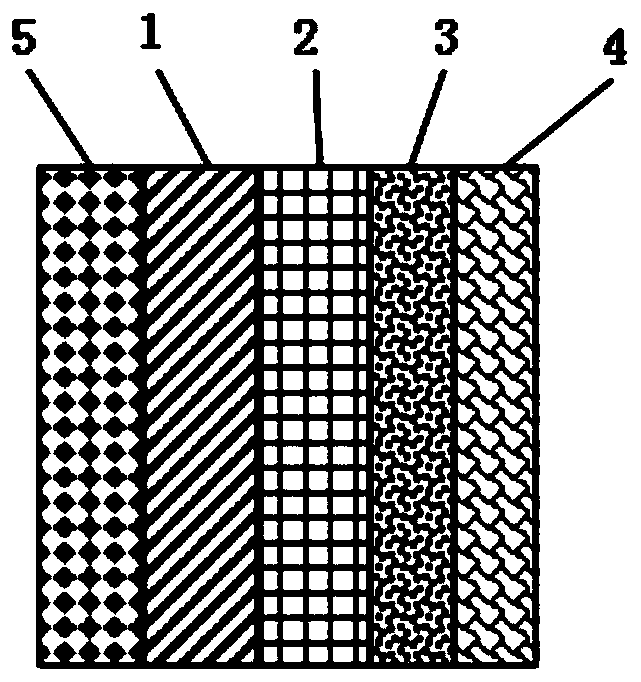

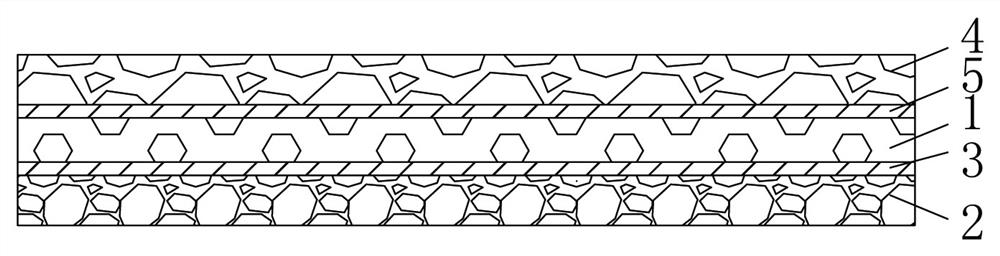

Cross composite membrane with TPU membrane and manufacturing method of cross composite membrane

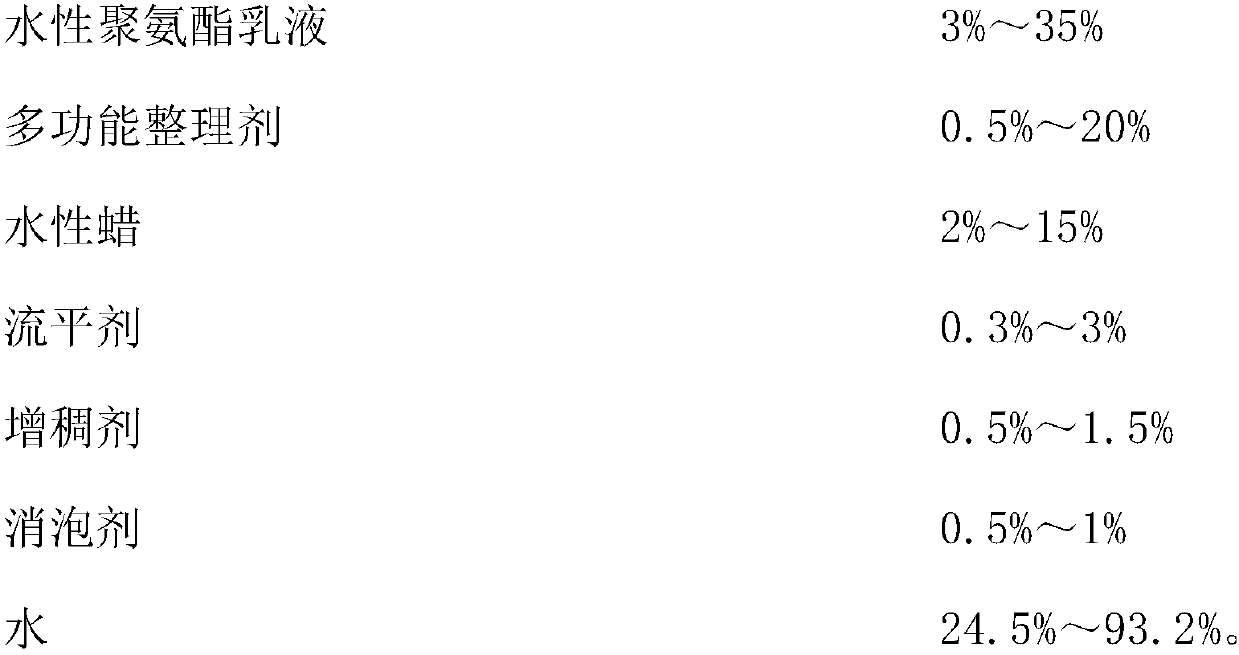

ActiveCN107471790AImprove waterproof and breathableWaterproof and breathableSynthetic resin layered productsLaminationUltimate tensile strengthMembrane configuration

The invention discloses a cross composite membrane with a TPU membrane and a manufacturing method of the cross composite membrane. The cross composite membrane comprises a first membrane layer, a second membrane layer, a third membrane layer and a fourth membrane layer, wherein the first membrane layer and the fourth membrane layer are breathable TPU membranes respectively; a first adhesive layer is connected between the first membrane layer and the second membrane layer; a second adhesive layer is connected between the second membrane layer and the third membrane layer; a third adhesive layer is connected between the third membrane layer and the fourth membrane layer; a reinforcing mesh extending to the outside is arranged in the first adhesive layer, the second adhesive layer or the third adhesive layer. Through the manner, the cross composite membrane with the TPU membrane and the manufacturing method of the cross composite membrane provided by the invention use the breathable TPU membranes to improve the overall waterproof and breathable performance of the cross composite membrane outside, use the reinforcing mesh to enhance and improve use convenience, and enable the cross composite membrane to have excellent waterproof and breathable performance, high strength, high temperature resistance, acid and alkali resistance and impact resistance by compounding different materials.

Owner:广东东美新材料有限公司

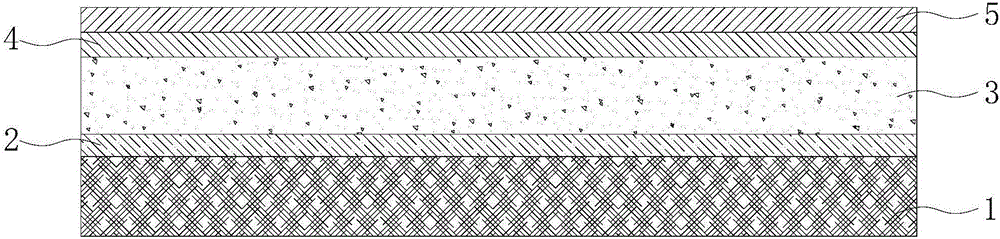

High-pressure-resistant water-base foamed raincoat leather

InactiveCN106087459AReasonable structureImprove softnessOvergarmentsTextiles and paperHollow formEnvironmentally friendly

The invention discloses high-pressure-resistant water-base foamed raincoat leather. The raincoat leather comprises base cloth and a high-pressure-resistant resin layer coating one surface of the base cloth, wherein high-pressure-resistant resin layer comprises a water-based PU bottom layer, a water-based foamed resin intermediate layer, a water-based resin upper layer and an anti-UV water-based resin surface layer which are sequentially connected from bottom to top. According to the high-pressure-resistant water-based foamed raincoat leather, a waterproof gas-permeable surface layer is a four-layer structure formed by the water-based PU bottom layer, the water-based foamed resin intermediate layer, the water-based resin upper layer and the anti-UV water-based resin surface layer, is safe and environmentally friendly and has bending resistance, high softness and tensile strength and relative high gas permeability and water resistance; the water-base foamed resin intermediate layer is of a hollow formed structure and is light, so that the leather feel and the water pressure resistance are provided; by adding a mixture of nano-TiO2 powder and nano-ZnO powder to the surface layer, the foamed raincoat leather has the effects of resisting ultraviolet light, protecting leather, blocking sunshine and resisting ageing, and the service life is prolonged.

Owner:浙江嘉科新材料科技有限公司

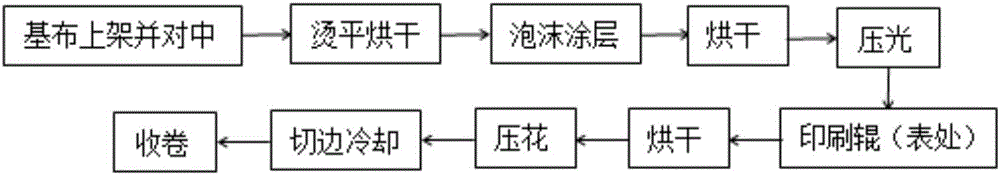

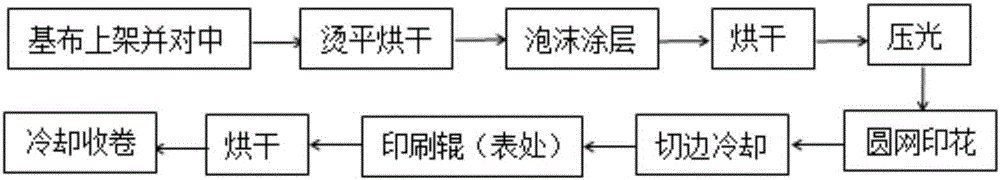

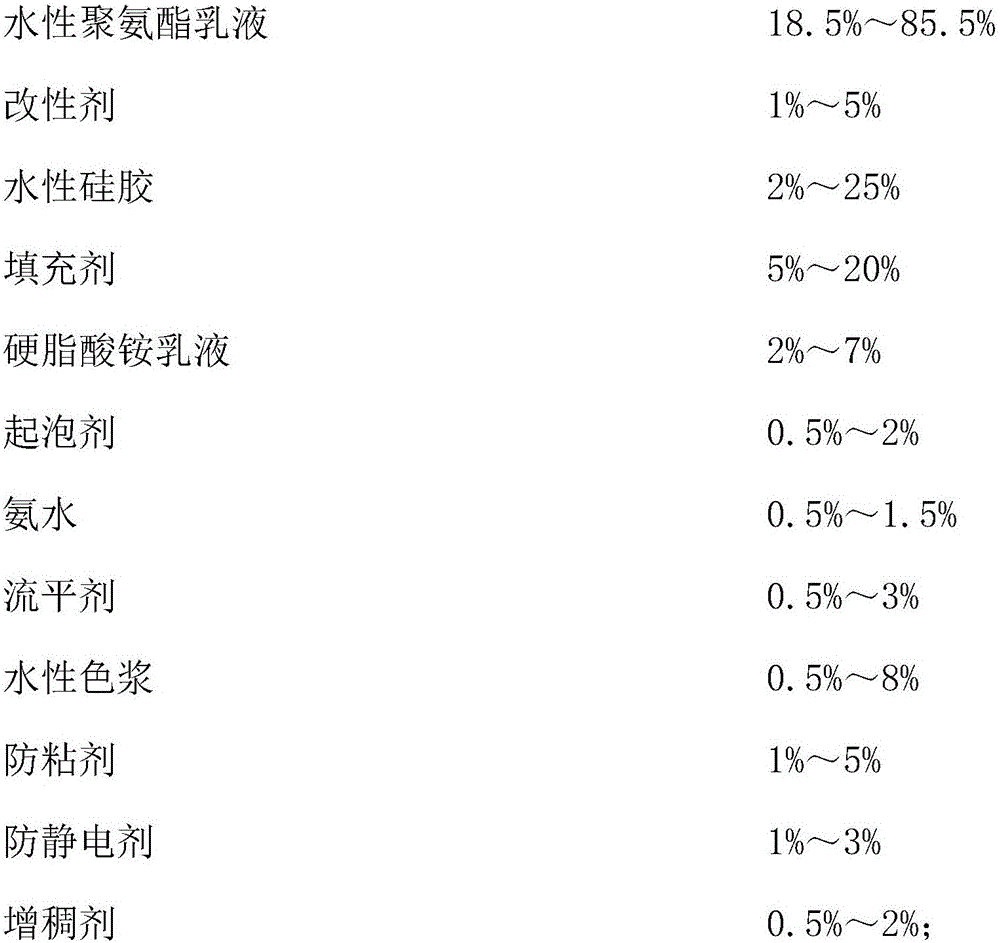

Formula and production technology of artificial waterborne polyurethane foamed synthetic leather

InactiveCN106544884ASimple processSimple and efficient operationPolyurea/polyurethane coatingsDyeing processSurface processingCoating

The invention discloses a formula of artificial waterborne polyurethane foamed synthetic leather, which comprises a thick foam coating liquid, a surface processing agent, and a rotary screen printing coating, wherein the surface processing agent includes a highlight surface processing agent or a delustring surface processing agent. Production technology of the artificial waterborne polyurethane foamed synthetic leather includes: preparing the thick foam coating liquid and the surface processing agent, putting leather-based cloth on a frame, performing ironing and drying, making the thick foam coating liquid into coating foam through an intelligent dynamic foam generator, coating the leather-based cloth with the coating foam, performing drying through an oven after the coating is completed to obtain a semi-finished product, performing calendaring, uniformly applying the surface processing agent with a printing roller, performing drying through an oven, performing embossing, then performing printing, and performing trimming, cooling and rolling. The produced waterborne foamed synthetic leather touches like real leather, is good in scratch resistance, and is waterproof and breathable. The synthetic leather allows embossing and printing to be performed, and can replace real leather and oily synthetic leather. The production technology is simple, is free of pollution or discharge, and is good in environmental protection.

Owner:宋婷婷

Composite medical dressing

PendingCN110613552AKeep dryImprove waterproof and breathable abilityNon-adhesive dressingsPlastersBreathingWoven fabric

The invention discloses a composite medical dressing. The composite medical dressing comprises a medicine application layer, water-absorbing resin balls, a water-absorbing layer, non-woven fabric, a first adhesive tape, first air holes, a waterproof and breathable layer, a second adhesive tape, a gauze layer, an antibacterial layer and second vent holes. The medical dressing is formed by compositing multiple layers, the device comprises the first adhesive tape and the second adhesive tape, during use, the adhesive tapes can be conveniently and rapidly fixed at a wound, the water-absorbing layer of the device contains water-absorbing resin balls, the water absorbing capacity of the device is better, the dryness of the device can be kept, besides, the device comprises the waterproof and breathable layer, the waterproof and breathing capacity is higher, and recovery of the wound of a user is facilitated. The medical dressing comprises the medicine application layer and the antibacterial layer, medicines in the medicine application layer can promote wound healing, and the antibacterial layer can inhibit and kill bacteria at the wound, can reduce the wound infection condition, is beneficial to wound healing and reduction of replacement times of the device.

Owner:江阴市医疗器械有限公司

Preparation method of waterproof and breathable nanofiber membrane

InactiveCN111719245AImprove waterproof and breathableImprove toughnessFilament/thread formingConjugated cellulose/protein artificial filamentsCellulosePolymer science

Owner:SUZHOU QIYAN NEW MATERIAL TECH CO LTD

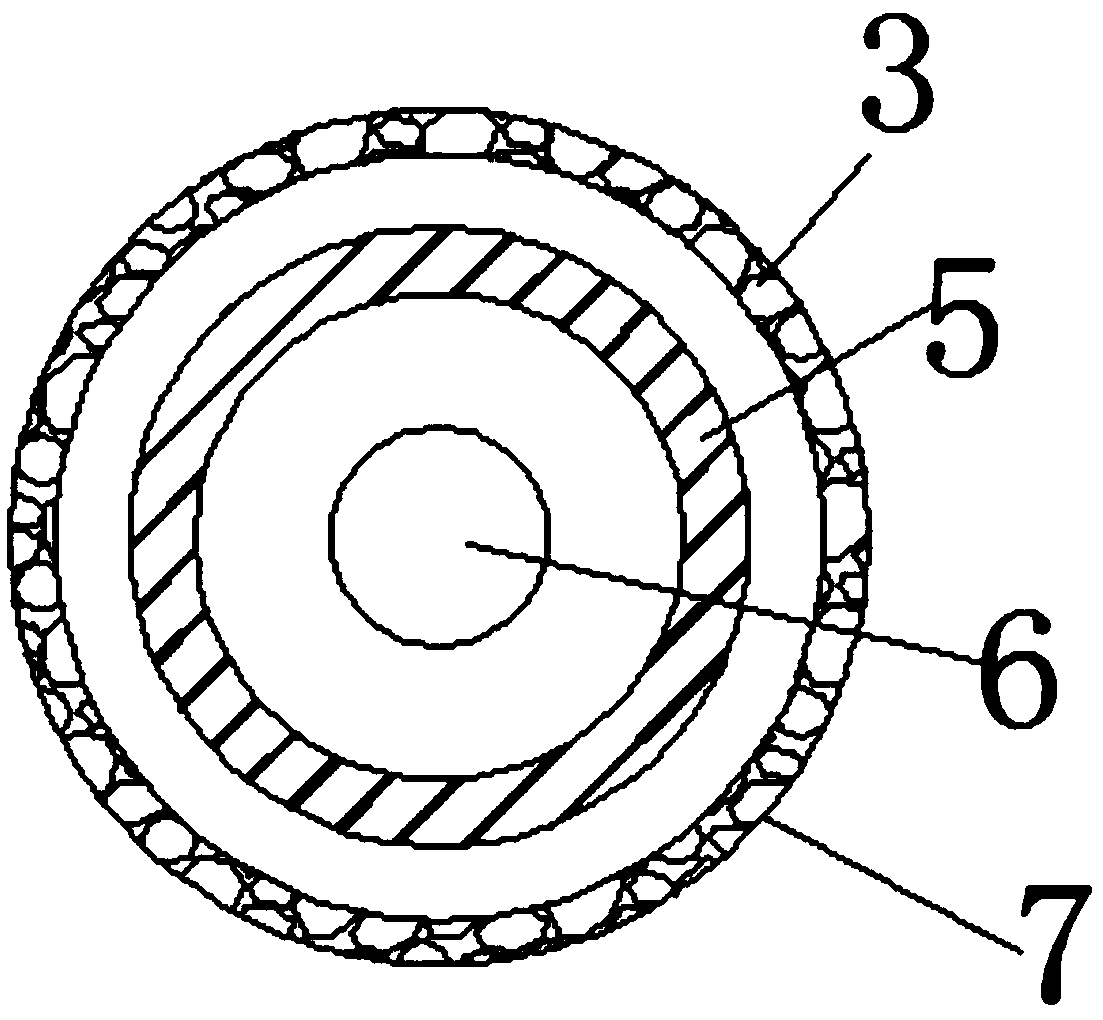

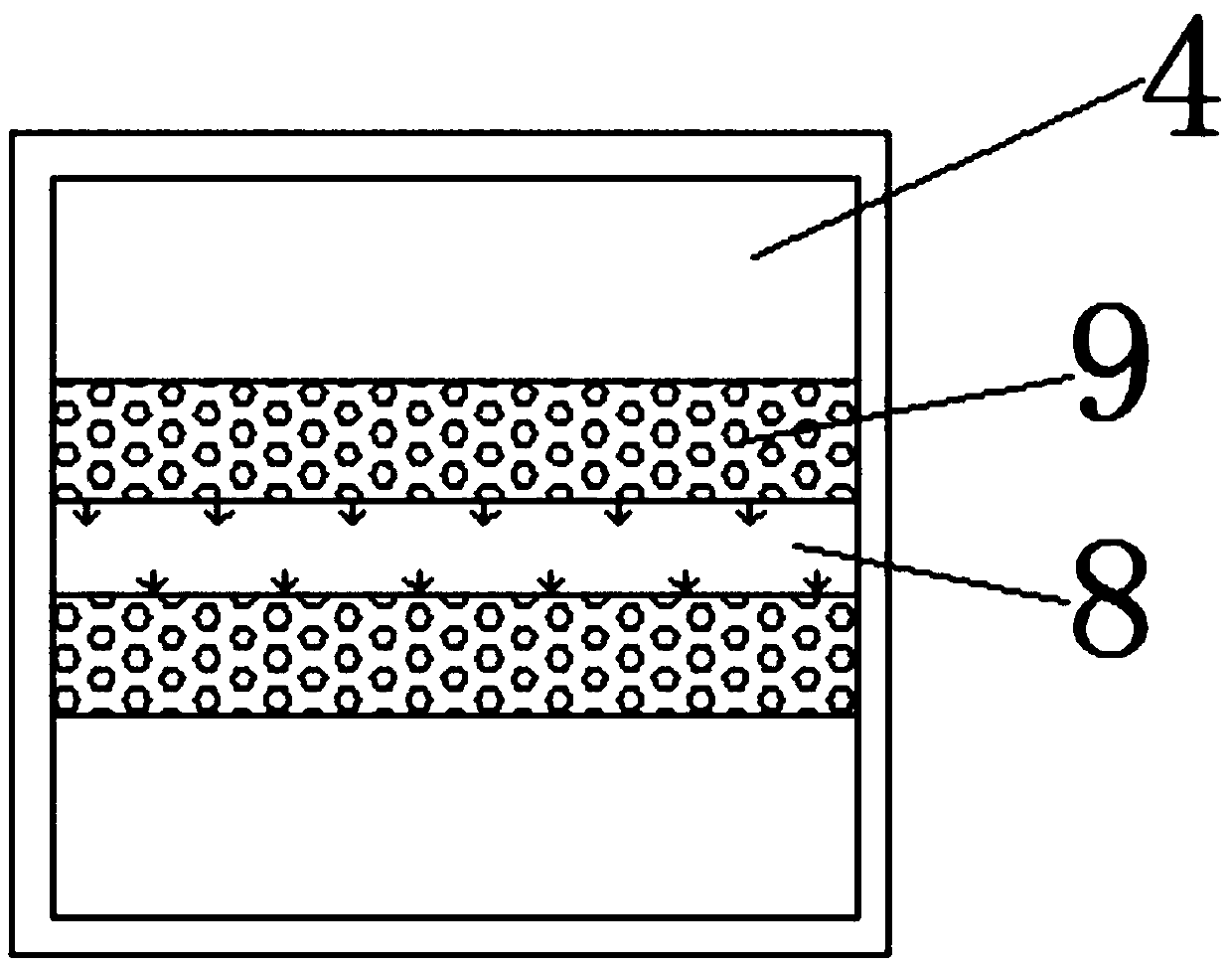

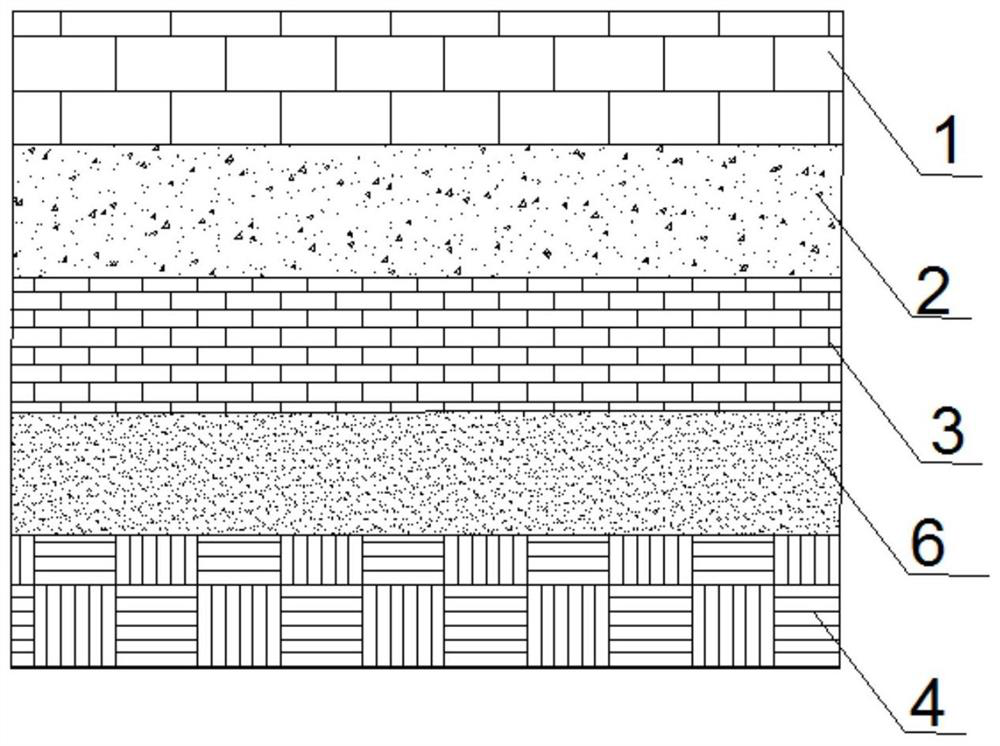

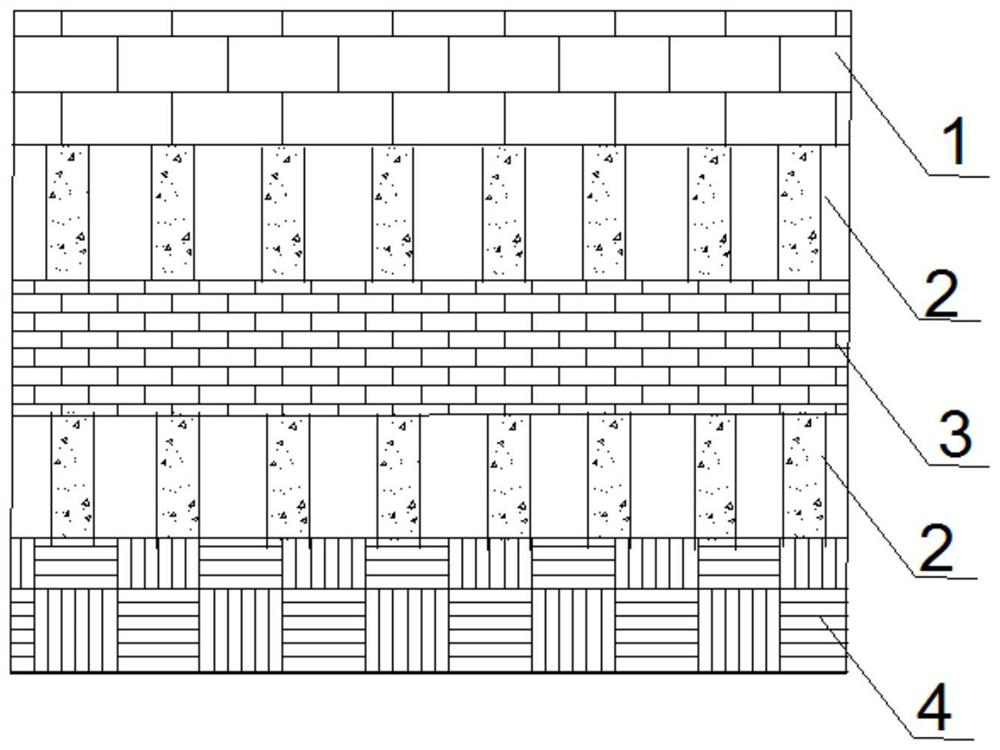

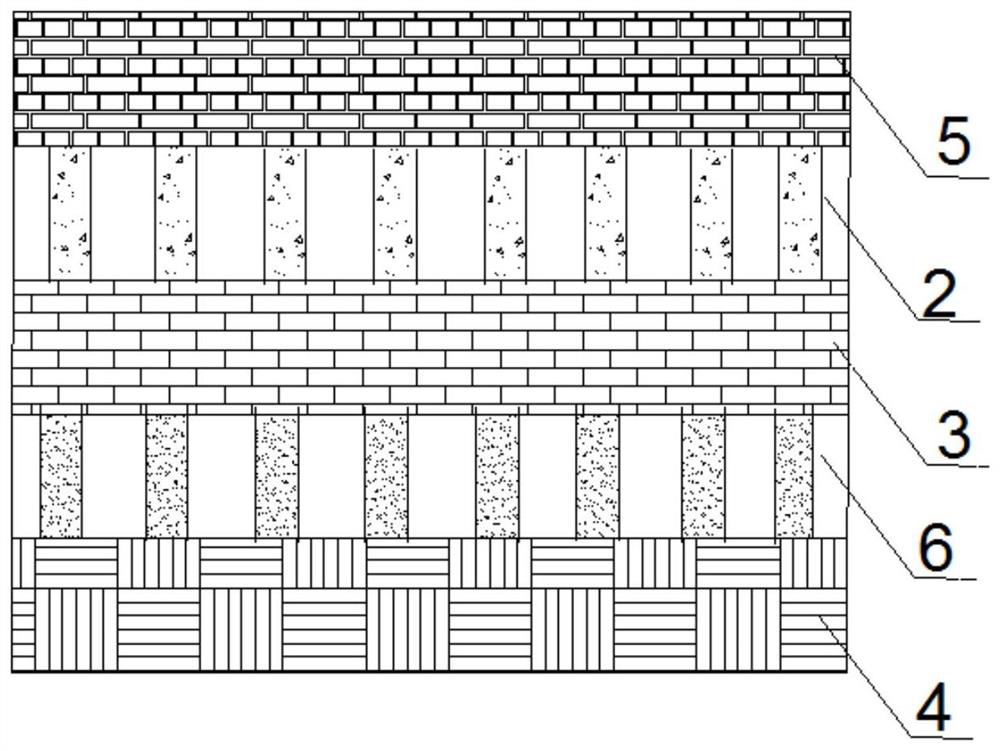

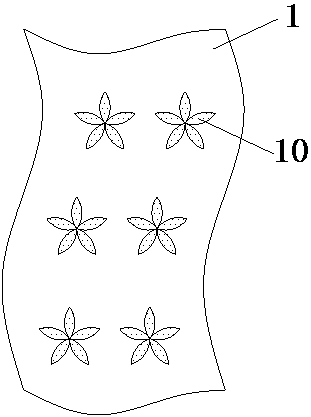

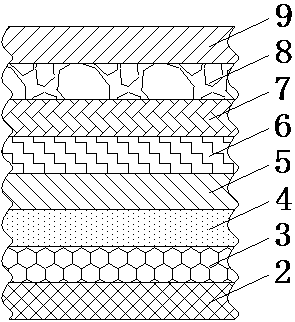

Waterproof and environment-friendly sportswear fabric with high wear resistance

InactiveCN109094155AHigh moisture absorption and quick dryingEnhanced moisture absorption and quick dryingSynthetic resin layered productsMelt spinning methodsYarnPolyester

The invention relates to waterproof and environment-friendly sportswear fabric with high wear resistance. The waterproof and environment-friendly sportswear fabric with high wear resistance comprisessportswear fabric (1), wherein the sportswear fabric (1) comprises a wear-resistant breathable layer (2), polyester fibers (3) and polyimide fibers (4), the polyester fibers (3) and the polyimide fibers (4) are arranged in the wear-resistant breathable layer (2), the polyester fibers (3) are located on the polyimide fibers (4), polyester yarn (6) is arranged in the polyester fibers (3), a bamboo fiber layer (7) is connected with the inner wall of the polyester fibers (3), and an organic cotton synthetic fiber layer (5) is arranged between the polyester yarn (6) and the bamboo fiber layer (7);furthermore, the polyester fibers are prepared from polyester as a substrate and water-absorbing compound powder as filler by melt spinning; the water-absorbing compound powder is prepared from a sodium polyacrylate and carbon nano tube mixture by vacuum dewatering.

Owner:广州巨枫科技有限公司

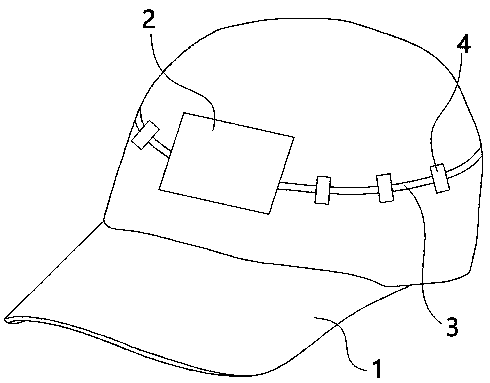

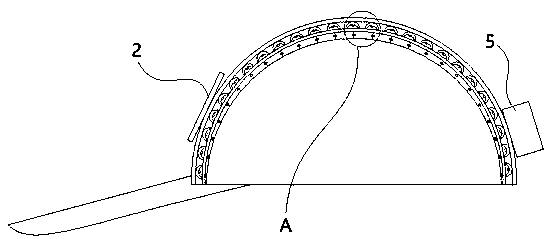

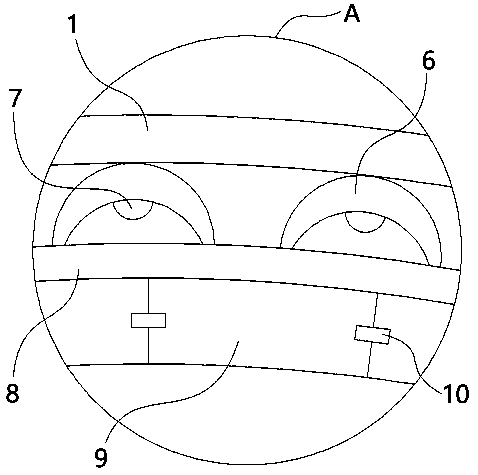

Adaptive protection helmet for skull defect patient

InactiveCN109480367AGuaranteed structural strengthImprove waterproof and breathableHelmetsHelmet coversBraced frameEngineering

The invention discloses an adaptive protection helmet for a skull defect patient, and relates to the technical field of medical devices. The adaptive protection helmet comprises a helmet body. A solarpanel is fixedly connected with one surface of the helmet body. The two sides of the solar panel are each fixedly connected with connecting belts. The other end of each connecting belt is movably connected with a triggering device. The peripheral side face of each connecting belt is fixedly connected with a plurality of hook-and-loop fasteners. One surface of each hook-and-loop fastener is fixedly connected with the helmet body. The edge of the inner surface of the helmet body is fixedly connected with a supporting frame. A plurality of buffering covers are fixedly connected between the opposite surfaces of the helmet body and the supporting frame. The appearance of each buffering cover is of an arc-shaped structure. The inner arc surface of each buffering cover is fixedly connected witha triggering switch. One surface of the supporting frame is fixedly connected with a plurality of protection air bags. The joints of the protection air bags are communicated with one another through connecting air holes. Through the cooperation of the supporting frame and the protection air bags, the adaptive protection helmet has the advantage of comprehensively buffering and protecting the headof a wearer.

Owner:张晴 +1

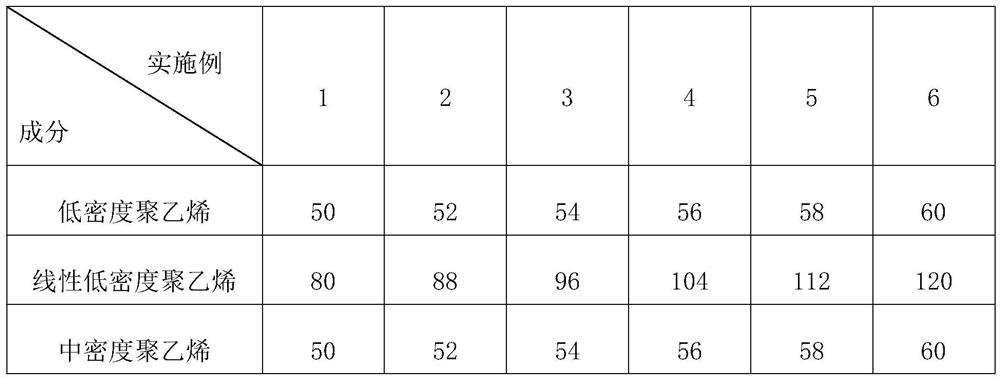

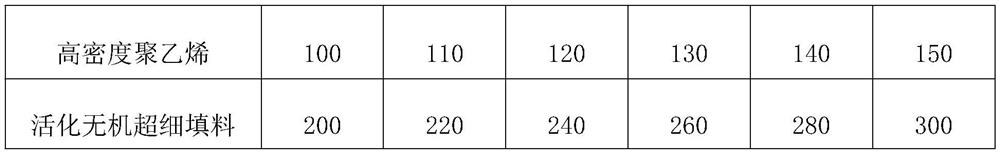

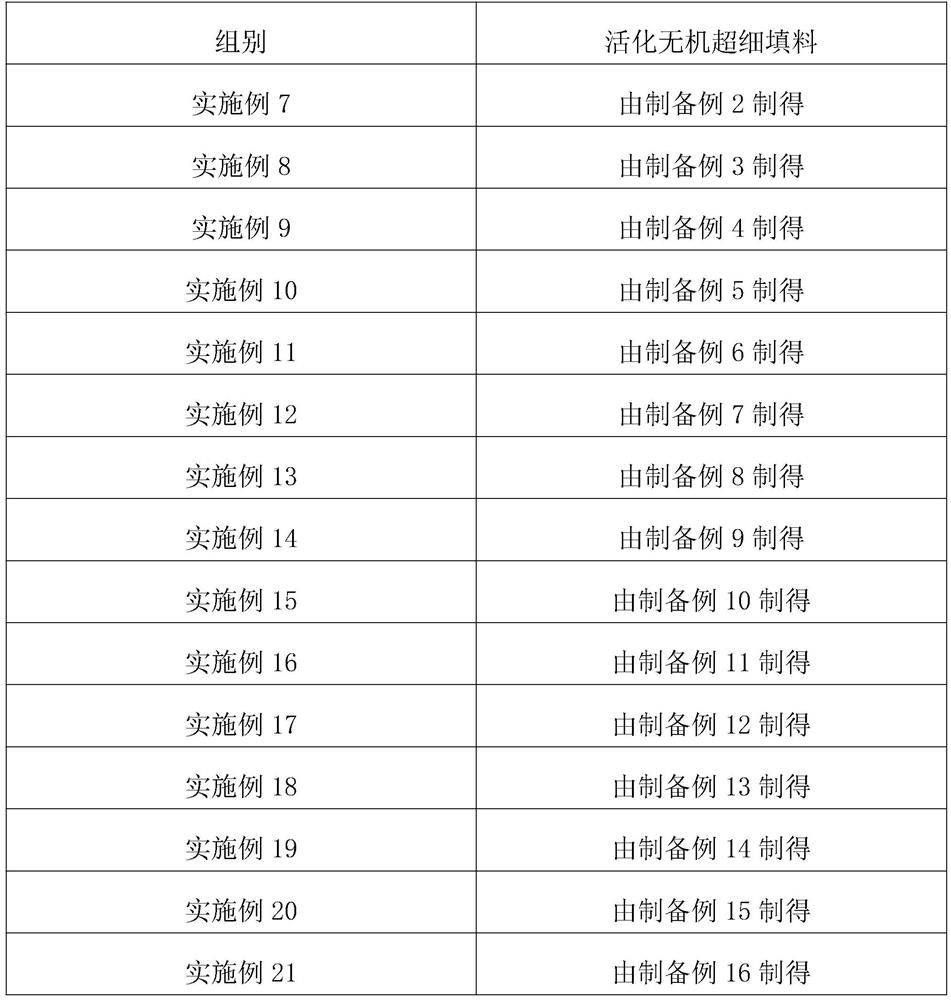

Waterproof breathable film and preparation method thereof

The invention relates to the technical field of plastic packaging, in particular to a waterproof breathable film and a preparation method thereof. A waterproof breathable film comprises the following components by weight: 50-60 parts of low density polyethylene; 80-120 parts of linear low density polyethylene; 50-60 parts of medium density polyethylene; 100-150 parts of high density polyethylene; and 200-300 parts of activated inorganic superfine filler. The preparation method of the activated inorganic superfine filler comprises the following steps of: preheating inorganic superfine filler, stirring and drying in vacuum, and adding a coupling agent after drying; and heating and mixing the inorganic superfine filler and activated sol under an alkaline condition to obtain the activated inorganic superfine filler. The preparation method of the waterproof breathable film comprises the following steps of: S1, master batch preparing; S2, film casting; S3, preheating and stretching; S4, surface treatment; and S5, cutting and forming. The waterproof breathable film can be used for waterproof layers in sanitary products such as sanitary napkins and paper diapers, and has the advantages of being waterproof and breathable.

Owner:SHANGHAI ZIHUA FILM TECH CO LTD

Functional film for preventing ammonia gas from escaping in composting process and preparation method of functional film

PendingCN112757741APrevent escapeReduce the dissipation rateAgricultural articlesBio-organic fraction processingActivated carbonWoven fabric

The invention belongs to the technical field of functional membranes and preparation thereof, and discloses a functional membrane for preventing ammonia gas from escaping in a composting process and a preparation method of the functional membrane. According to the functional membrane, a polyester fiber oxford fabric or a non-woven fabric with high yarn weaving density is selected as a first defensive line of the fabric layer and is used for protecting a second layer of polymer membrane, so that the membrane is prevented from being worn; an expanded polytetrafluoroethylene film with proper thickness and smaller pore diameter and the like are selected to improve the waterproof and air-permeable performance; activated carbon non-woven fabric capable of adsorbing gaseous ammonia molecules of unformed hydrogel liquid water drops is selected as an adsorption layer, and the adsorption layer is prepared through a gluing and hot-pressing composite technology. The functional film can adsorb a small amount of ammonia gas escaped along with water vapor and other gases, so that the ammonia resistance of the functional cover film is further improved. The membrane preparation process of the functional membrane is used for secondarily blocking ammonia molecules which are not dissolved in liquid water, so that the ammonia escape rate is further reduced. The functional film is suitable for preventing ammonia gas from escaping in the fields of stale garbage treatment and soil remediation.

Owner:北京福力欧材料科技有限公司

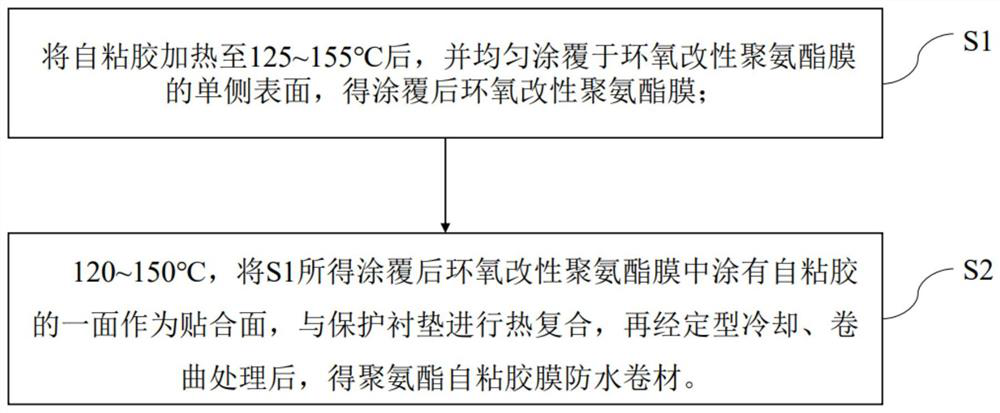

Polyurethane self-adhesive film waterproof roll as well as preparation method and application thereof

PendingCN114381212AOvercome the defect of not being able to work under high temperature conditionsImprove densification performanceProtective foundationMacromolecular adhesive additivesEpoxyPolymer science

The invention discloses a polyurethane self-adhesive film waterproof roll as well as a preparation method and application thereof. The polyurethane self-adhesive film waterproof roll sequentially comprises an epoxy modified polyurethane film, a self-adhesive layer and a protective liner from top to bottom, the preparation method of the epoxy modified polyurethane film comprises the following steps: dispersing 10-15 parts by mass of a reactive flame retardant in 20-30 parts by mass of tetrahydrofuran, uniformly mixing with 40-60 parts by mass of a polyurethane prepolymer, 15-20 parts by mass of epoxy acrylate and 5-10 parts by mass of fluorinated epoxy resin, heating to 50-55 DEG C, carrying out pre-reaction for 0.5-1 hour, heating to 70-80 DEG C, adding 1-2 parts by mass of bis (dimethylaminoethyl) ether, carrying out heat preservation and stirring reaction for 3-6 hours, and cooling to room temperature to obtain the epoxy modified polyurethane film. Pouring the mixture into a mold, carrying out hot-pressing curing for 1-3 hours at 90-110 DEG C, heating to 130-150 DEG C, and continuing hot-pressing curing for 0.5-1 hour, so as to obtain the epoxy modified polyurethane film. The thermal decomposition temperature of the prepared epoxy modified polyurethane film reaches 300 DEG C or above, and the epoxy modified polyurethane film can be used for a long time in a high-temperature environment of 150 DEG C and has high tension, high tensile force, water resistance, air permeability, obdurability, aging resistance, cold resistance and chemical corrosion resistance.

Owner:合肥中科凯辰新材料有限公司

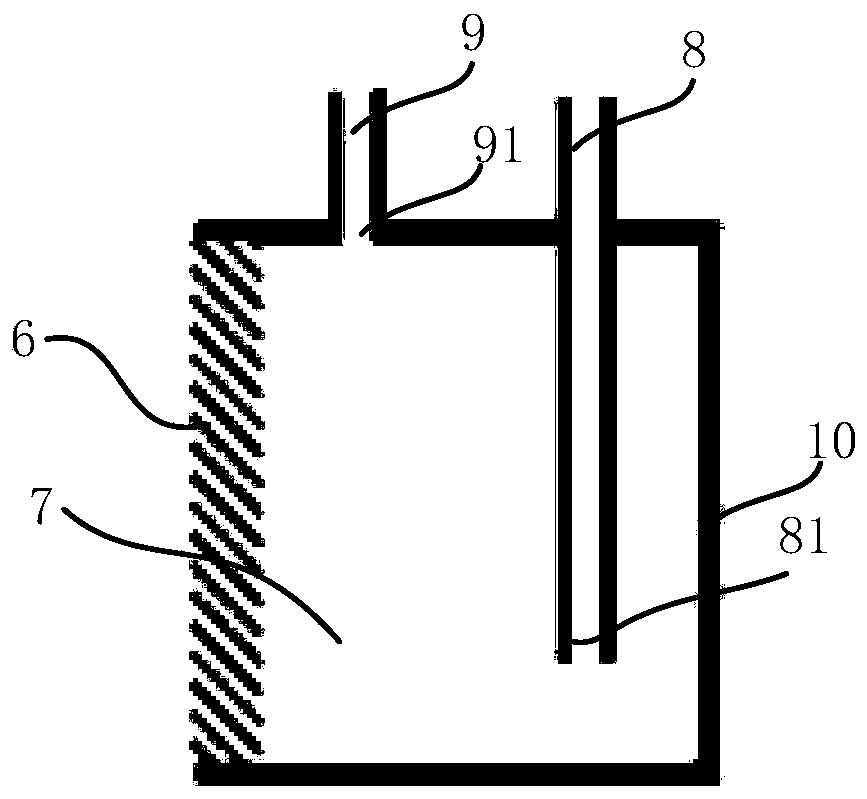

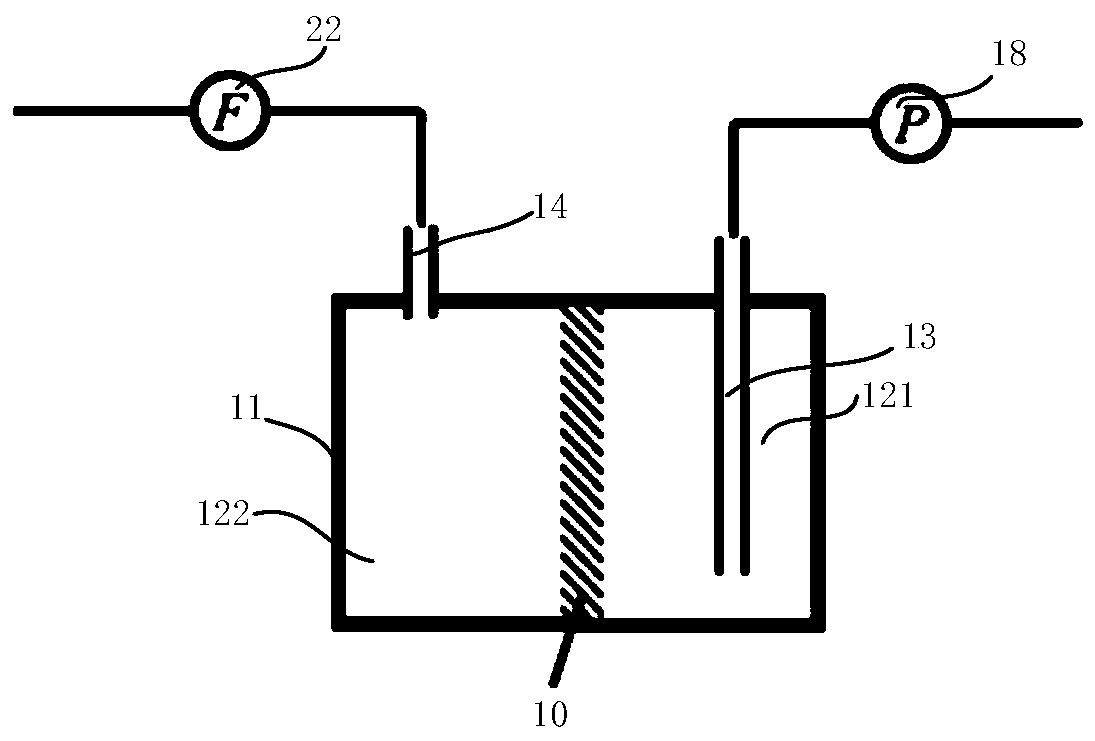

Gas diffusion cathode and preparation method and application thereof

ActiveCN110336042AImprove waterproof and breathableReduce risk of leakageReactant parameters controlFinal product manufactureCarbon layerMaterials science

The invention provides a gas diffusion cathode and a preparation method and an application thereof. The gas diffusion cathode includes a current collecting layer. A carbon layer, an adhesive layer anda waterproof and breathable film layer are arranged in turn on one side of the current collecting layer, and a catalytic layer is arranged on the other side of the current collecting layer. The waterproof and breathable performances of the gas diffusion cathode are improved, the leakage risk is reduced, and the production cost and the operation cost are reduced.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

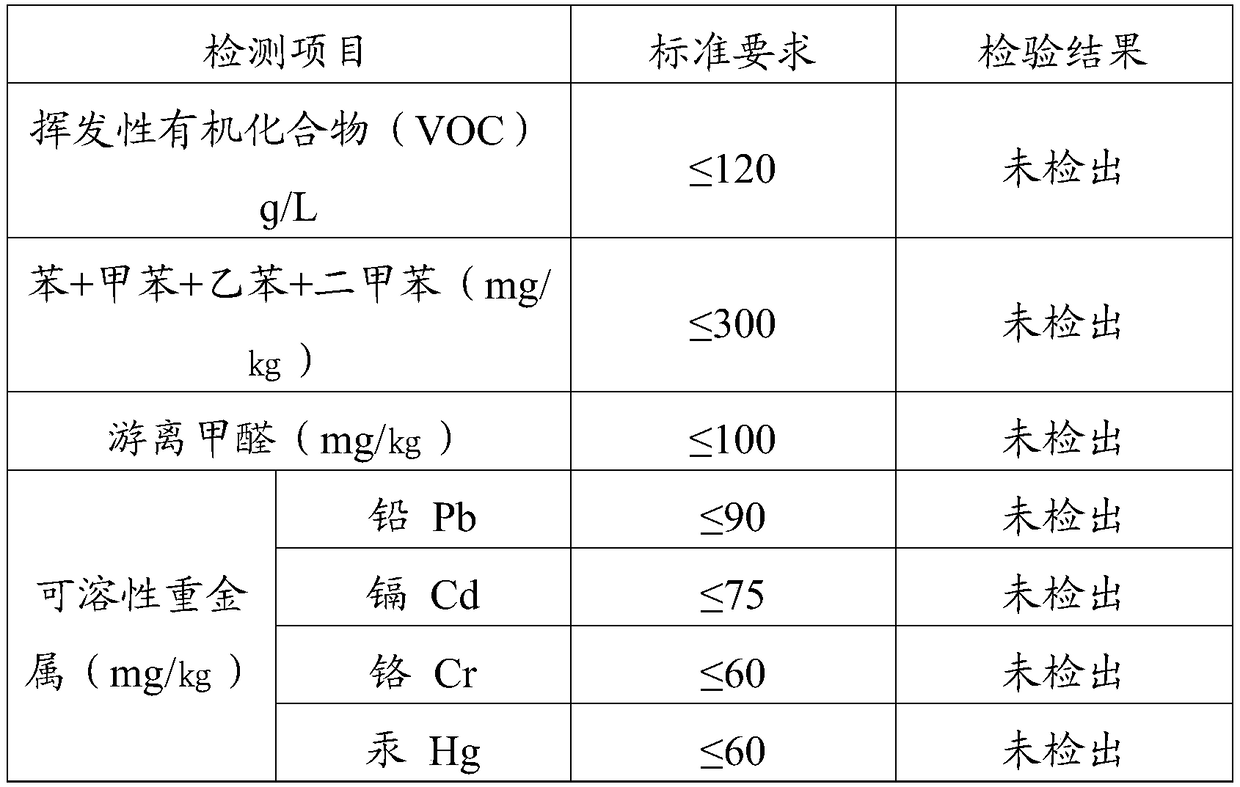

A kind of coating and preparation method thereof

ActiveCN106433338BImprove wear resistanceGood flexibilityAntifouling/underwater paintsPaints with biocidesRare earthOxygen ions

The invention provides a coating. The coating is prepared from, by weight, 1 part of nanoscale negative oxygen ion compound powder, 1 part of ozone water and 20-24 parts of micro dialysate. The nanoscale negative oxygen ion compound powder comprises 40-50 parts of tourmaline powder, 20-30 parts of titanium dioxide, 10-20 parts of zinc oxide and 1-10 parts of rare-earth complex. The micro dialysate comprises 15-20 parts of methyl sodium silicate, 20-30 parts of siloxane, 15-20 parts of polytetrafluoroethylene and 20-30 parts of water. The grain size of the nanoscale negative oxygen ion compound powder is smaller than 450 nanometers. The invention further provides a preparation method of the coating. The coating and the preparation method thereof have the advantages that according to the coating prepared through the preparation method, and through the cooperation of the nanoscale negative oxygen ion compound powder, the ozone water and the micro dialysate, the air purifying and bacterium resisting effects are good; negative oxygen ions can be released into the environment for a long time; the coating is good in abrasion resistance and toughness and high in bonding strength.

Owner:深圳市康帮达科技有限公司

Preparation method of waterproof and breathable fabric

InactiveCN111204096AGood flexibilityImprove comfortSynthetic resin layered productsCoatingsPolymer scienceAdhesive glue

The invention belongs to the technical field of textile fabrics, and particularly relates to a preparation method of a waterproof and breathable fabric. A PES hot melt adhesive film is used as a basefilm, and has a good flexibility, glue and additives are added to the upper part of the base film, the additives can improve pores in the glue and improve the breathability, the waterproof and breathable properties can be well enhanced through the performances of a waterproof ad breathable film and the performances of a mixture, the self-cleaning effect in the fabric can be improved through the effect of the mixture, and then the comfort degree of the fabric can be well improved through a fabric layer.

Owner:张威劲

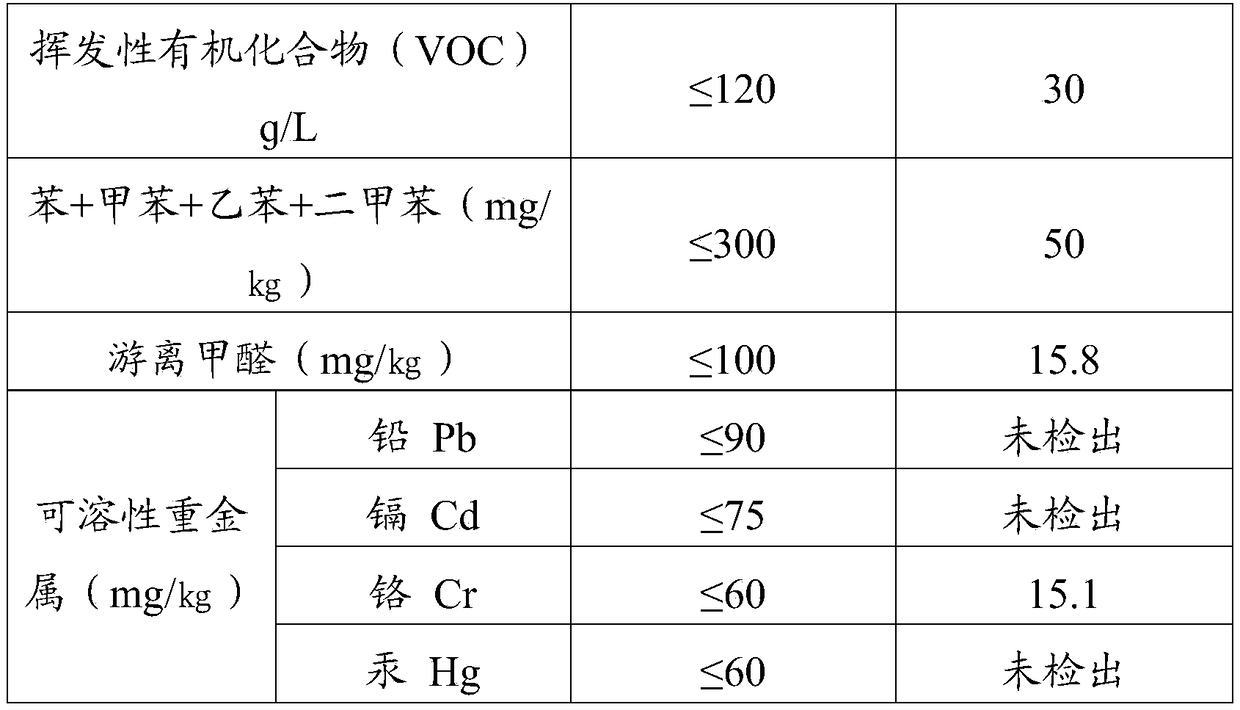

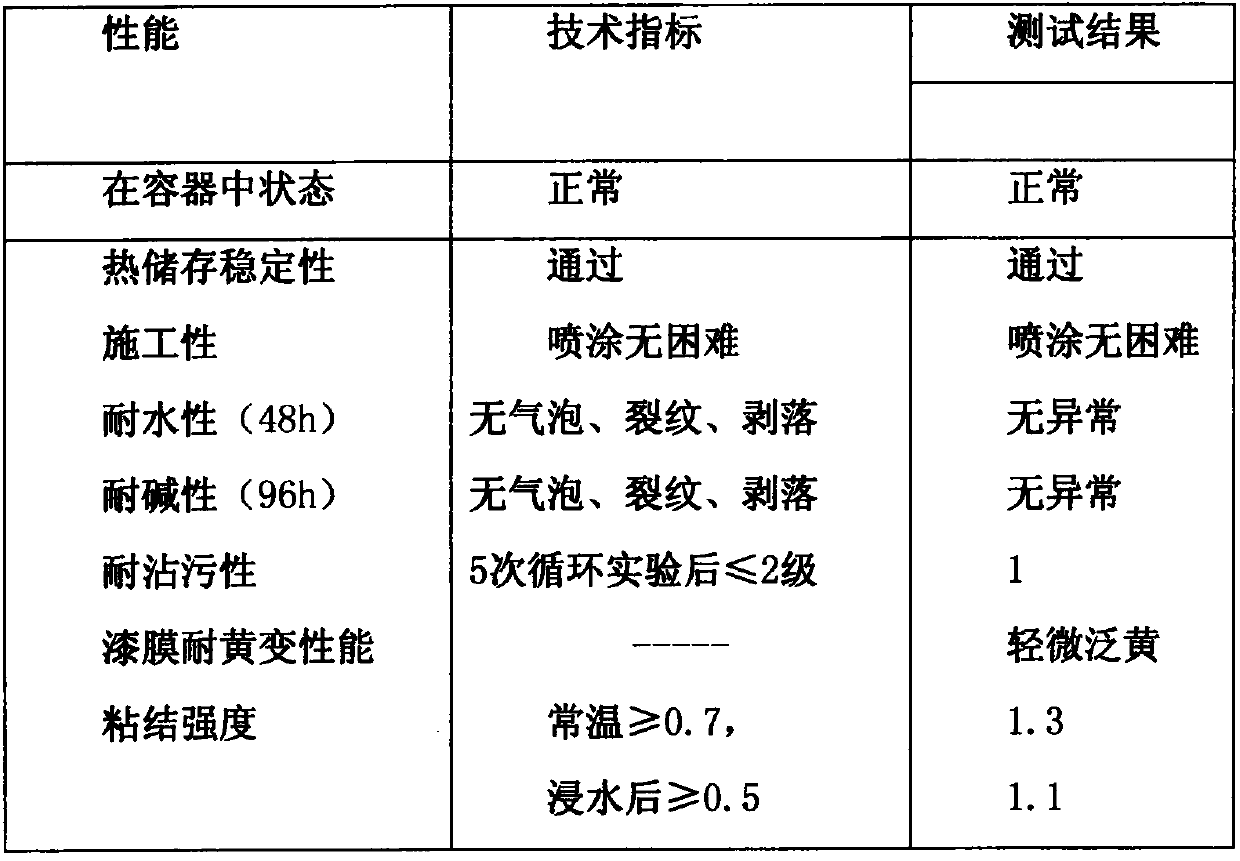

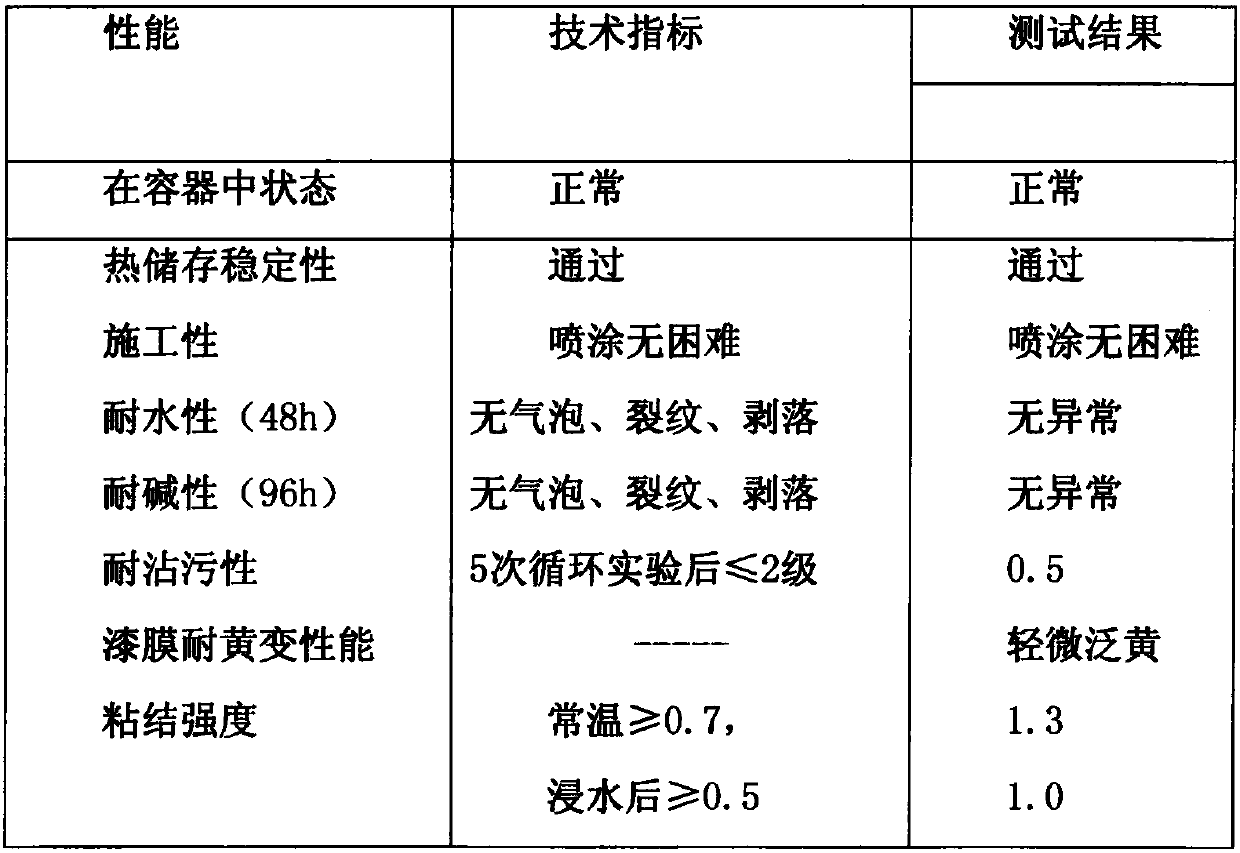

Organosilicon weatherproof batch scraped natural stone-like paint and preparation method thereof

The invention provides organosilicon weatherproof batch scraped natural stone-like paint. The organosilicon weatherproof batch scraped natural stone-like paint is characterized by being prepared from25 wt% of a component A, 3 to 5 wt% of a component B and 70 to 72 wt% of a component C, wherein the component A comprises 27 to 37.65 wt% of water, 0.8 to 1 wt% of cellulose ether, 0.15 to 0.2 wt% ofa pH value regulator, 10 to 18 wt% of film forming organosiloxane modified acrylic emulsion, 45 wt% of film forming silicone emulsion, 2.5 to 3. 5 wt% of a film forming additive, 3 to 4 wt% of a coalescent additive, 0.2 to 0.3 wt% of a defoamer, 0.3 to 0.4 wt% of a thickener and 0.4 to 0.6wt% of a bactericide; the component B comprises 94.6 to 97.6 wt% of water, 2 to 3 wt% of an organic modified thickener and 0.4 to 0.6 wt% of a bactericide; the component C comprises natural colored sand. The organosilicon weatherproof batch scraped natural stone-like paint disclosed by the invention has goodpaint film hydrophobicity, waterproofness, permeability, weather resistance and stain resistance.

Owner:鳄鱼制漆(上海)有限公司

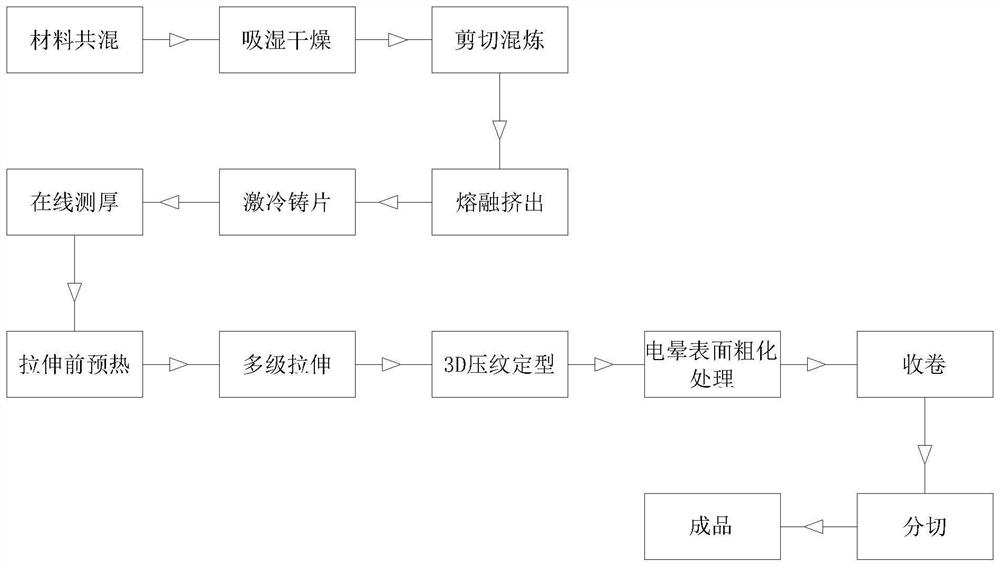

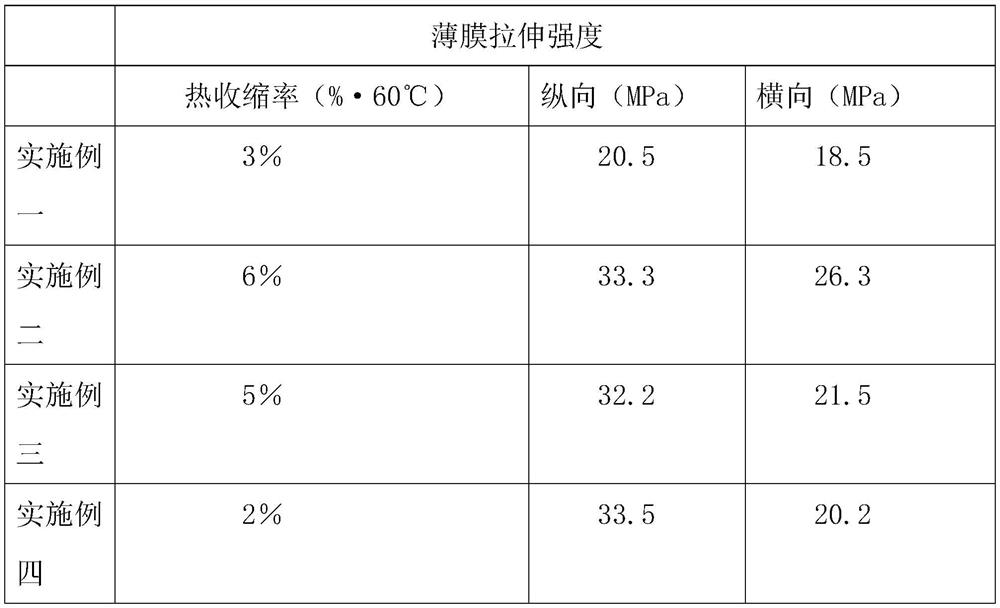

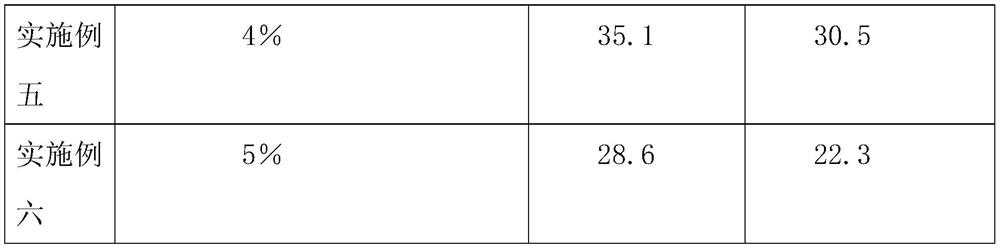

Preparation process of 3D pattern anti-leakage high-breathability film

The invention discloses a preparation process of a 3D pattern anti-leakage high-breathability film. The preparation process comprises the steps of material selection, material blending, moisture absorption and drying, shearing and mulling, melt extrusion, chilling and sheet casting, online thickness measurement, multi-stage stretching, 3D cooling and embossing, corona surface roughening treatment, rolling and product slitting. A material comprises breathable particles with constant deformation performance, breathable particles with a good tensile property, high-strength polyethylene, polyimide resin, epoxy resin, high-strength and puncture-resistant breathable particles containing nanoscale calcium carbonate and antistatic particles. The 3D embossing steel roller with a special effect is manufactured by arranging the 3D embossing steel roller and the specific rubber compression roller and utilizing the principle that light rays refract different patterns at different angles, a specific engraving process is verified and developed, and an applicable manufacturing process is formulated in cooperation with pattern requirements, so that a product can better highlight the 3D effect after being formed, and is more attractive to consumers.

Owner:FOSHAN HUAHAN SANITARY MATERIAL

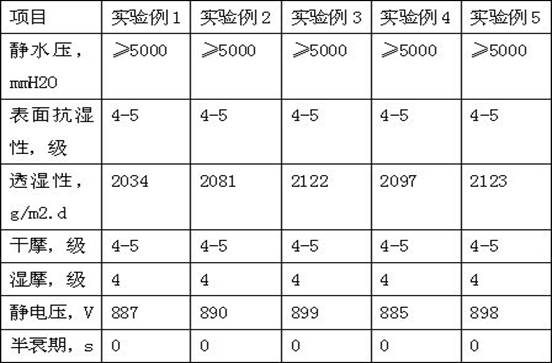

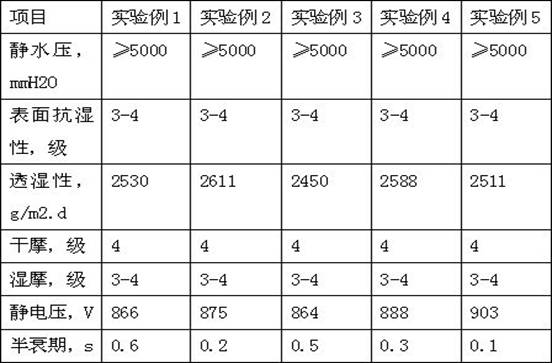

Durable antistatic, friction-resistant, waterproof and moisture-permeable, anti-seepage jacket fabric processing method

ActiveCN108824007BImprove antistatic performanceImprove friction resistanceLiquid/gas/vapor textile treatmentTextile shapingPolyesterPolymer science

The production and treatment method of the durable antistatic, friction-resistant, waterproof and moisture-permeable, anti-seepage outerwear fabrics, (1) use 20-30g / L C8 fluorine-based waterproof finishing liquid to carry out water-repellent finishing on 70D nylon or 75D polyester fabrics, two dips Two calendering, pre-baking-baking; (2) calendering finishing, (3) dry coating of fabrics with coating glue, dry weight gain 25-30g / m 2 , the coating glue is made of water-based waterproof and moisture-permeable polyurethane adhesive 80-100, water 5-15, graphene oxide sol 5-10, PTFE powder 2-4, blocked isocyanate crosslinking agent 5-10 . It is especially suitable for 70D nylon and 75D polyester fabrics. After production and treatment, the products have excellent antistatic, friction resistance, waterproof and moisture permeability, water seepage resistance, and water washing resistance. The production process is short, environmentally friendly, and easy to operate.

Owner:DANDONG UNIK TEXTILE

Production process of novel material of window roller shutter cloth with heat insulation, shading and noise reduction functions

PendingCN114228302AImprove waterproof and breathableImprove light barrierLamination ancillary operationsSynthetic resin layered productsHot meltMoisture resistance

The invention discloses a production process of a novel window roller shutter cloth material with heat insulation, shading and noise reduction functions. The production process comprises the following steps: A, performing shaping treatment on cloth to be manufactured on a shaping machine at the temperature of 150-180 DEG C; b, calendering the cloth; c, whitewashing the cloth; d, the composite TPU shading black film is attached to the cloth through a PUR hot melt adhesive or a PU adhesive; e, the composite PET aluminum laminated film is attached to the composite TPU shading black film through a PUR hot melt adhesive or a PU adhesive; f, printing colors; and G, performing high-temperature embossing operation on the cloth obtained in the step F by using an embossing machine. The shading black film is attached to the fabric, so that the waterproof and breathable performance of the fabric can be improved, and the effects of preserving heat and moisture and resisting strong sunlight and infrared irradiation can be achieved; the light barrier property, the moisture resistance, the heat resistance and the puncture resistance of the cloth can be improved by attaching the composite PET aluminum laminated film; the density of the cloth can be reduced through the multiple layers of covering films, and finally the effect of reducing noise is achieved.

Owner:绍兴爱尔法装饰布艺有限公司

A soft dry-process waterproof, breathable and moisture-permeable polyurethane resin and its preparation method

Owner:江西巨联新材料有限公司

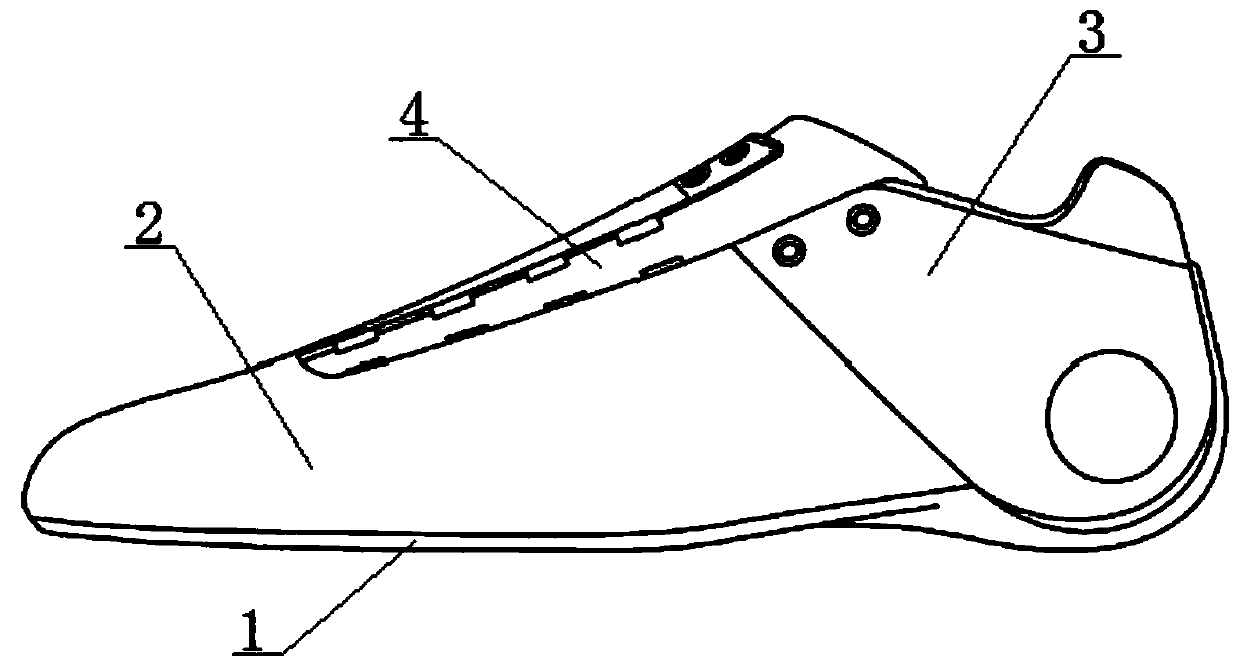

Sports shoes with waterproof and breathable functions

InactiveCN110897257AWaterproof and breathableWith waterproof and breathable functionUpperBootlegsShoe lacesEngineering

The invention discloses a pair of sports shoes with waterproof and breathable functions. Each shoe comprises a shoe base, an upper, a shoelace set and a waterproof breathable vamp. The waterproof breathable vamp is composed of a flannelette layer, a base cloth layer and a breathable waterproof layer. The flannelette layer is located on the inner side face of the corresponding waterproof breathablevamp, and the base cloth layer is located between the corresponding breathable waterproof layer and the corresponding flannelette layer. Through arranging the waterproof and breathable vamp, the sports shoes are breathable and have a waterproof effect. The base cloth layer is made of cotton cloth and has a breathable effect, and the surface of the base cloth layer is coated with the waterproof coating matched with the components, so that the surface of the base cloth layer is waterproof, a lotus leaf-like effect is formed, the waterproof breathable effect of the sports shoes is greatly improved, the comfort of athletes is improved, and the sports shoes have popularization and application values.

Owner:MINNAN INST OF SCI & TECH

Antistatic, waterproof and moisture permeable dacron cotton cloth composite fabric

InactiveCN105346171AAnti-static hasAnti-static and waterproofSynthetic resin layered productsCotton clothMoisture

The invention discloses an antistatic, waterproof and moisture permeable dacron cotton cloth composite fabric. The antistatic, waterproof and moisture permeable dacron cotton cloth composite fabric comprises a macromolecular waterproof and breathable material layer on the uppermost layer, a binding layer on the middle layer and base cloth on the bottommost layer, wherein the base cloth is a dacron cotton cloth fabric; the macromolecular waterproof and breathable material layer accounts for 24%-26% of the total amount of the antistatic, waterproof and moisture permeable dacron cotton cloth composite fabric; the binding layer accounts for 24%-29% of the total amount of the antistatic, waterproof and moisture permeable dacron cotton cloth composite fabric; and the base cloth accounts for 47%-49% of the total amount of the antistatic, waterproof and moisture permeable dacron cotton cloth composite fabric. The antistatic, waterproof and moisture permeable dacron cotton cloth composite fabric provided by the invention has the advantages of antistatic property, high waterproof property and high steam and moisture permeable property.

Owner:CHANGSHU TIANCHEN KNITTING

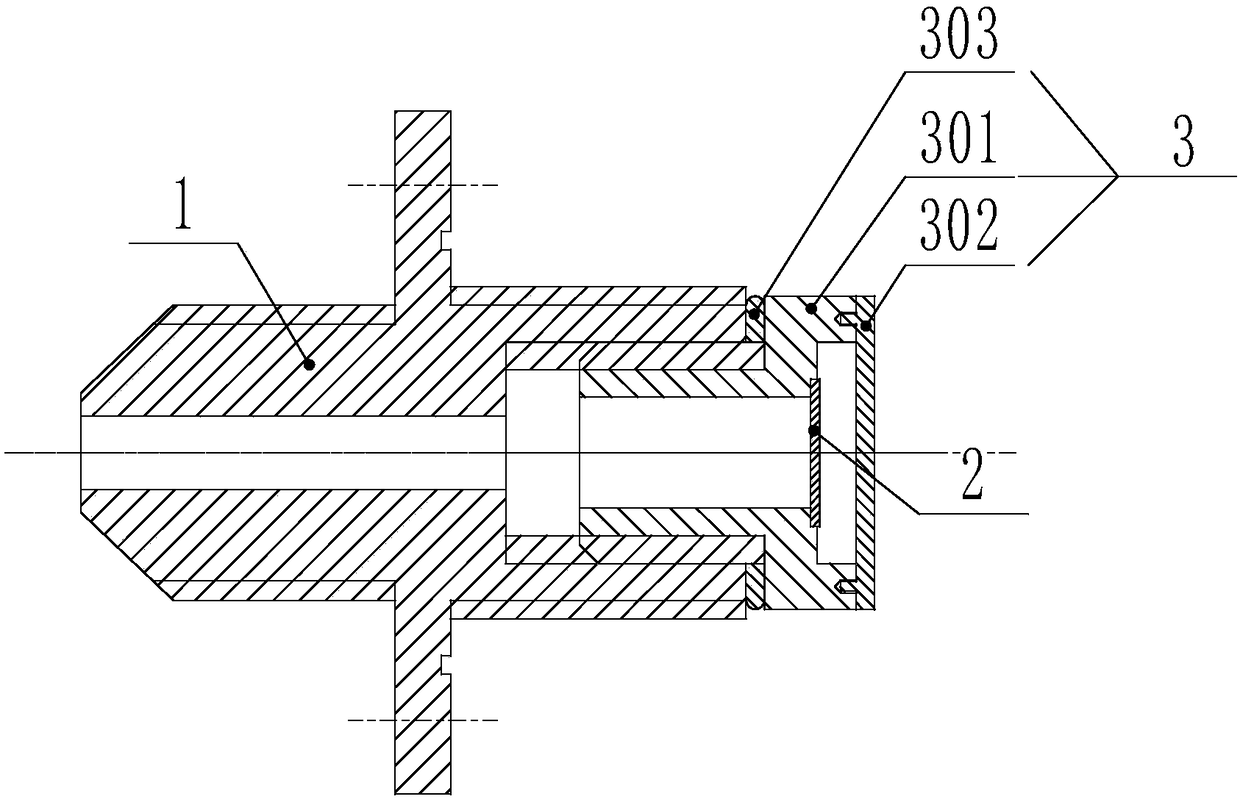

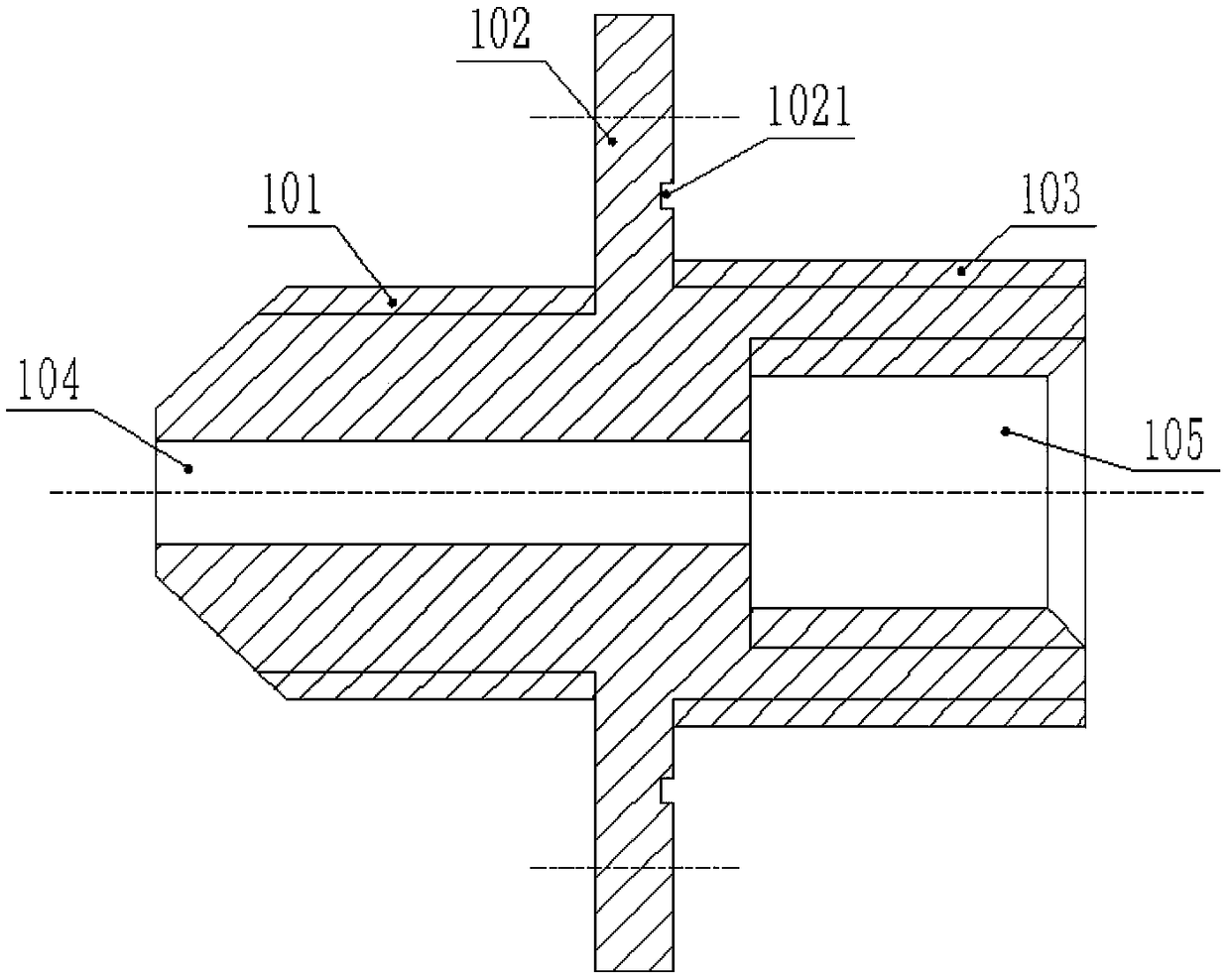

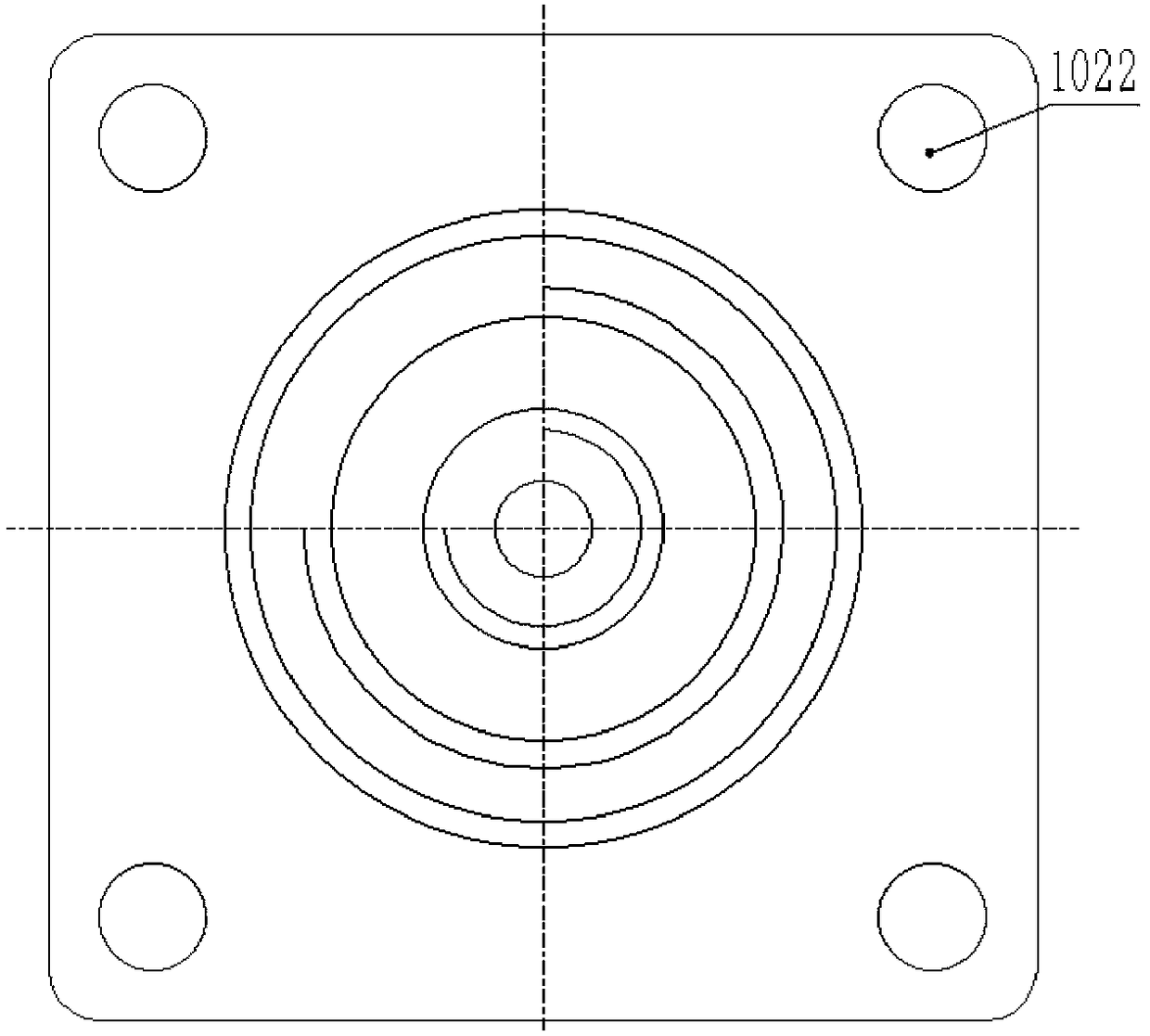

Waterproof breathable spray head

The invention discloses a waterproof breathable spray head which comprises a spray head main body, a breathable film and a fixing part. A center hole and an internal thread hole are formed in the spray head main body from the center of one end to the center of the other end in a communicating mode, the inner diameter of the internal thread hole is larger than that of the center hole, the outer surface of the spray head main body is sequentially provided with a connection section, a transition section and a first external thread section from one end to the other end, the outer contour size of the transition section is larger than that of the connection section and the first external thread section, and the breathable film is installed on the internal thread hole in the spray head main bodythrough the fixing part. The waterproof breathable spray head is convenient to assemble and disassemble, flexible to install and high in protection grade and has the efficient water and dust prevention function.

Owner:湖南鸿腾新能源技术有限公司

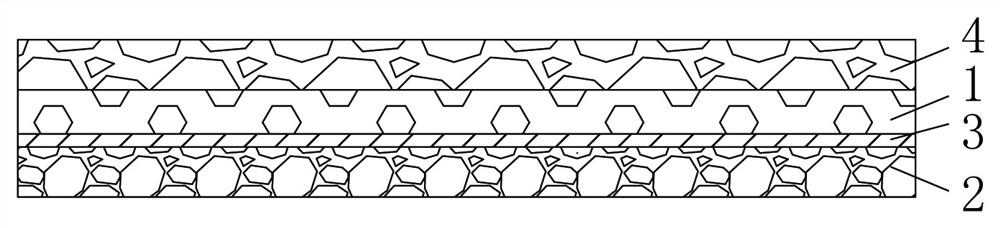

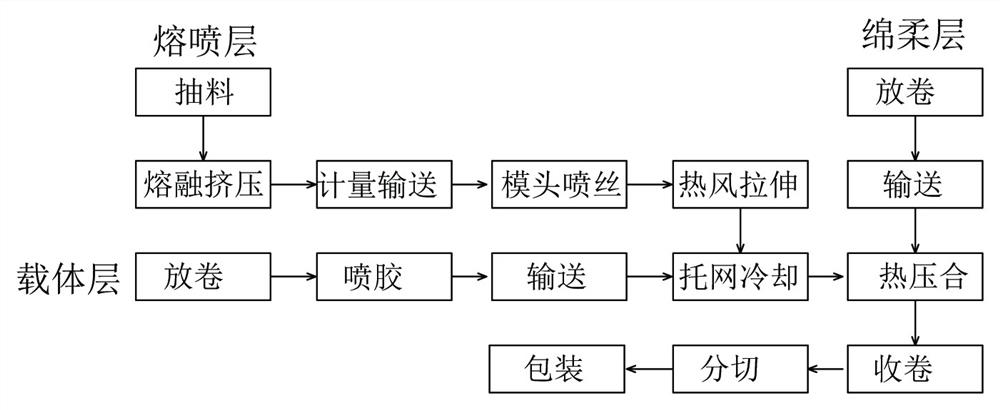

Comfortable high-breathability composite material and preparation method thereof

PendingCN112693184AImprove waterproof and breathableReduce weightPersonal careSynthetic resin layered productsMoisture permeabilityNonwoven fabric

The invention discloses a comfortable high-breathability composite material which comprises a soft cotton layer, a melt-blown layer and a carrier layer. According to a preparation method of the composite material, polypropylene master batch is extracted, heating, melting and molding are conducted, the molded raw material is extruded into filaments, hot-air stretching is conducted, a non-woven fabric is taken as the carrier layer and is glued, the stretched raw material is sprayed on the carrier layer, supporting net cooling is conducted, the raw material is cooled into the melt-blown layer, the melt-blown layer is covered with the soft cotton layer, then pressing is conducted together, and finally rolling, slitting and packaging are conducted. The moisture permeability of the formed composite material can reach 4000 g / m / 4 hr, the water pressure resistance can reach 30 mbar or above, and the formed composite material has the advantages of being high in waterproofness, breathability, light and softness. The composite material is suitable as a base film composition material of disposable hygienic products such as protective clothing, diapers, sanitary towels, breast pads and the like.

Owner:佛山市嘉信盈科技有限公司

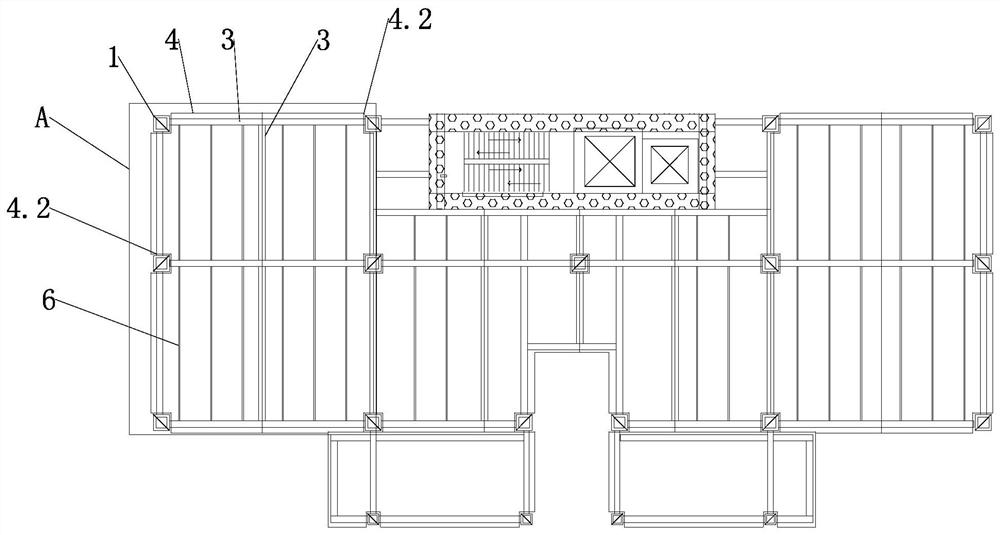

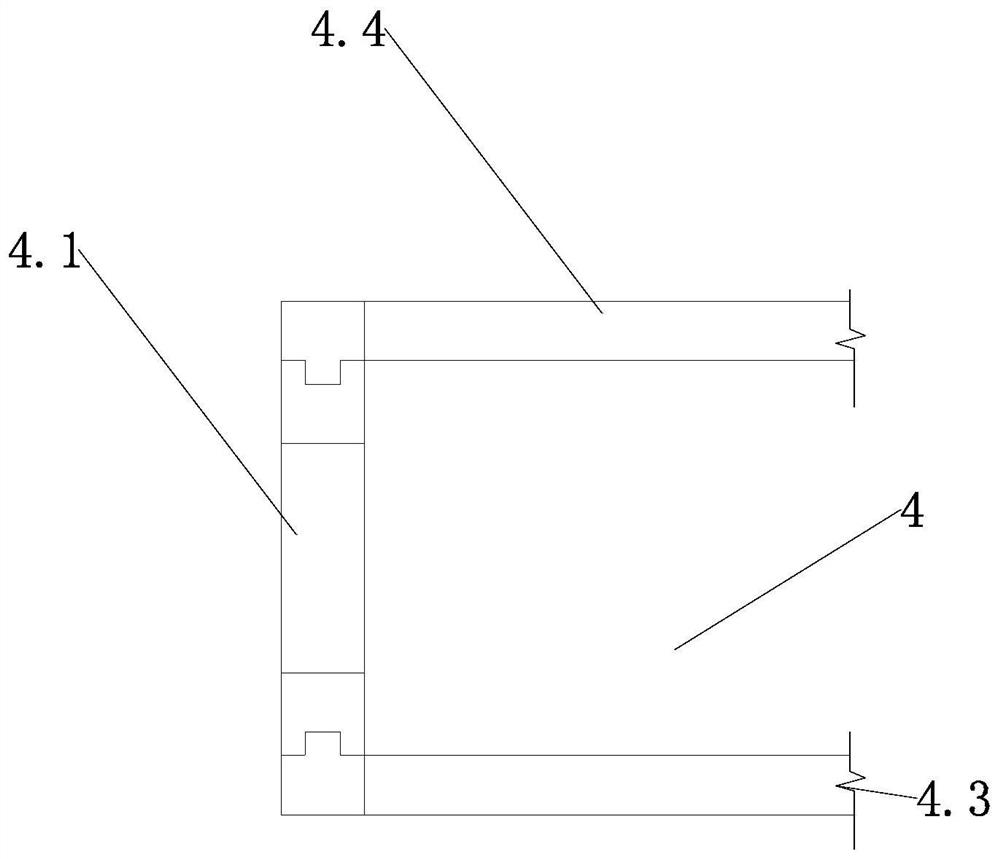

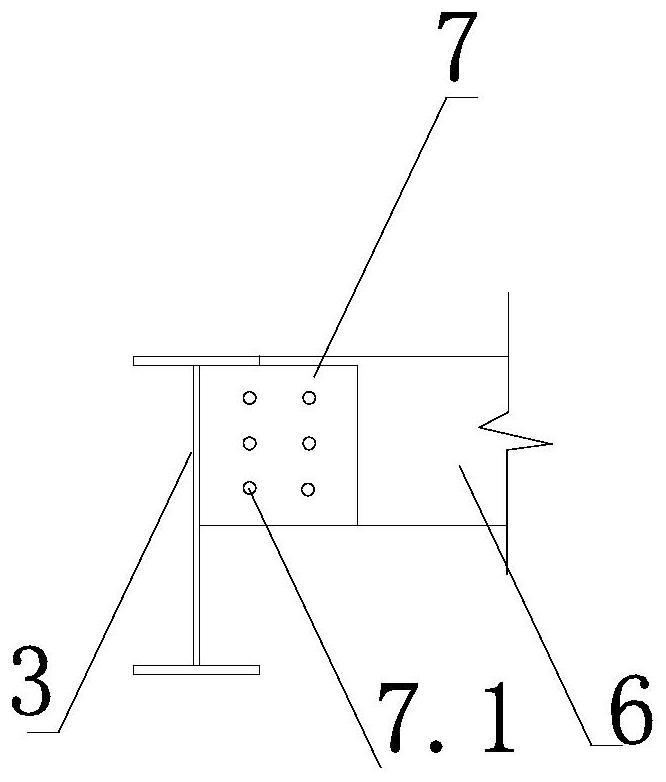

A kind of high-rise modular building and its construction method

ActiveCN108316464BImprove waterproof and breathableImprove sealing performanceWallsHeat proofingArchitectural engineeringStructural engineering

The invention discloses a high-rise modular building and a construction method thereof, comprising several layer module units, the layer module units include several steel columns, main beams, and a modular box body, the modular box body includes wall modules, box body let The column module, the bottom surface module and the top surface module, the bottom surface module and the top surface module are respectively fixedly connected with the wall module and the box letting column module, the box letting column module corresponds to the position of the steel column, and the outside of the steel column is provided with a sealing plate, The sealing plate and the steel column are fixed, and the sealing plate and the box allow the column module to enclose the steel column. The high-rise modular building disclosed by the present invention is constructed by using steel columns, main beams and modular boxes directly processed in the factory. The construction method is simple, the installation process is simple, and a temporary connecting beam is built between the steel columns to improve the safety of the installation process.

Owner:上海瀚太钢膜结构建筑有限公司

A soft wet-process waterproof, breathable and moisture-permeable polyurethane resin and its preparation method

The invention discloses a soft wet-method waterproof air-permeable water-permeable polyurethane resin and a preparation method thereof. The resin comprises the following components in percentage by mass: 12% to 15% of poly adipic acid-1, 4-butanediol ester glycol, 7% to 9% of diphenyl-methane-diisocyanate MDI, 1% to 2% of a mixing chain extendor, 0.5% to 0.6% of a terminating agent, 0.3% to 0.5% of a high-speed penetrating agent OT, 0.02% to 0.04% of a catalyst, 0.3% to 0.5% of filling material, 0.1% to 0.2% of a stabilizer UV-329, and the balance of an organic solvent. As the polyurethane resin and the preparation method thereof adopt the mixing chain extendor, and measures such as adding an organic solvent DMF and the filling material CMC twice, the prepared polyurethane resin has excellent waterproof moisture permeable properties ( water-fast pressure larger than and equal to 3000 mm H2O, and moisture permeable property larger than and equal to 5000 g / m 2.24 Hr), and is good in rebound resilience and peel strength, high in water-fast pressure, and soft, plump, and fine and smooth in handfeel.

Owner:江西巨联新材料有限公司

High-performance variable flannelette

PendingCN110406191AImprove flame retardant performanceImprove anti-static effectSynthetic resin layered productsCellulosic plastic layered productsSurface layerBiochemical engineering

The invention discloses a high-performance variable flannelette. The high-performance variable flannelette comprises a flannelette body, the flannelette body comprises a bacteriostatic layer, the surface of the bacteriostatic layer is fixedly connected with a thermal insulation layer, the surface of the thermal insulation layer is fixedly connected with a waterproof and breathable layer, the surface of the waterproof and breathable layer is fixedly connected with a first flame-retardant layer, and the surface of the first flame-retardant layer is fixedly connected with an electrostatic elimination layer. Through arrangement of the bacteriostatic layer, the thermal insulation layer, the waterproof and breathable layer, the first flame-retardant layer, the electrostatic elimination layer, araised flannelette layer, the second flame-retardant layer and a surface layer for cooperative use, the flame retardancy and electrostatic elimination property of the flannelette body can be improved,fire caused by sparks due to large static electricity generated by the flannelette body can be avoided, the phenomenon that conventional flannelettes burn in fire due to poor flame retardancy can also be effectively avoided, and the problem of poor flame retardancy of existing variable flannelettes is solved. The high-performance variable flannelette has the advantages of being high in flame retardancy and worthy of popularization.

Owner:吴江市布步高纺织整理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com