Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Has radiation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

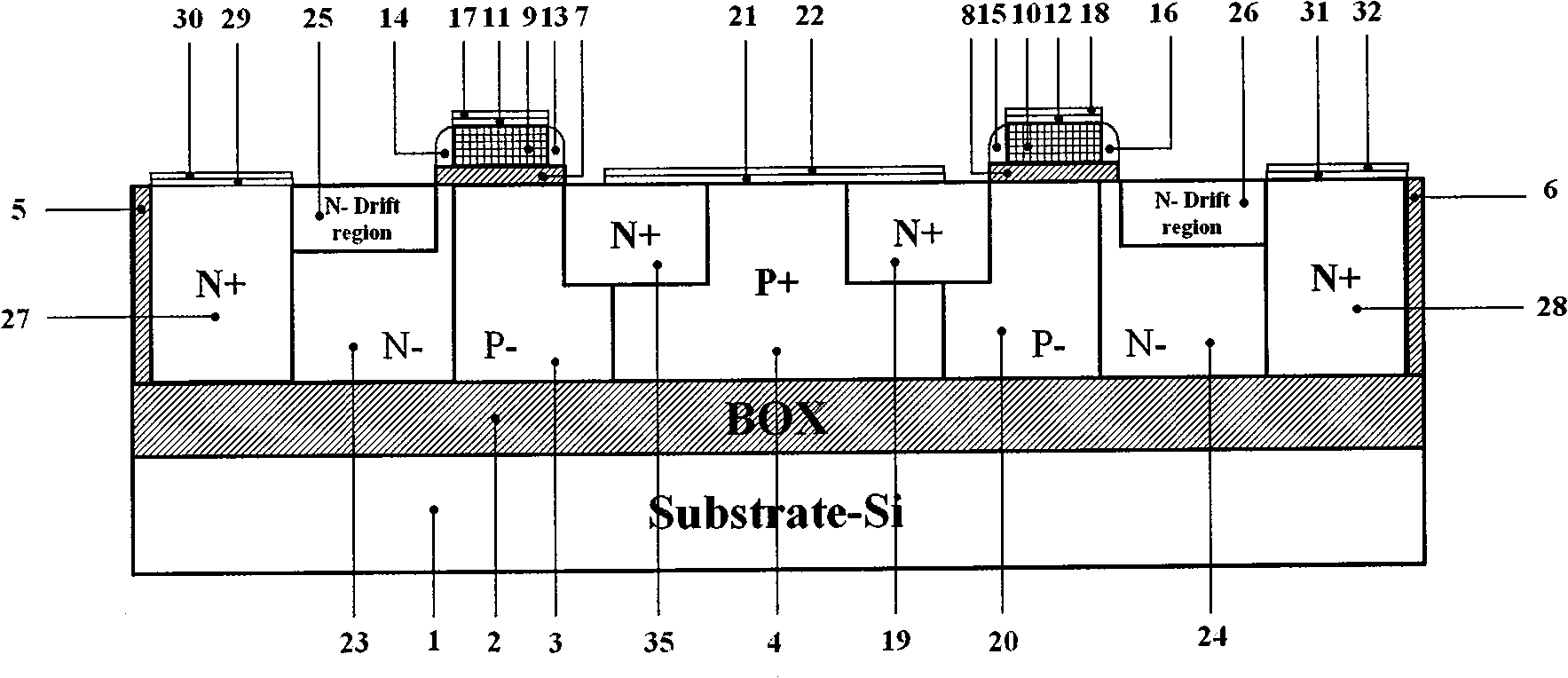

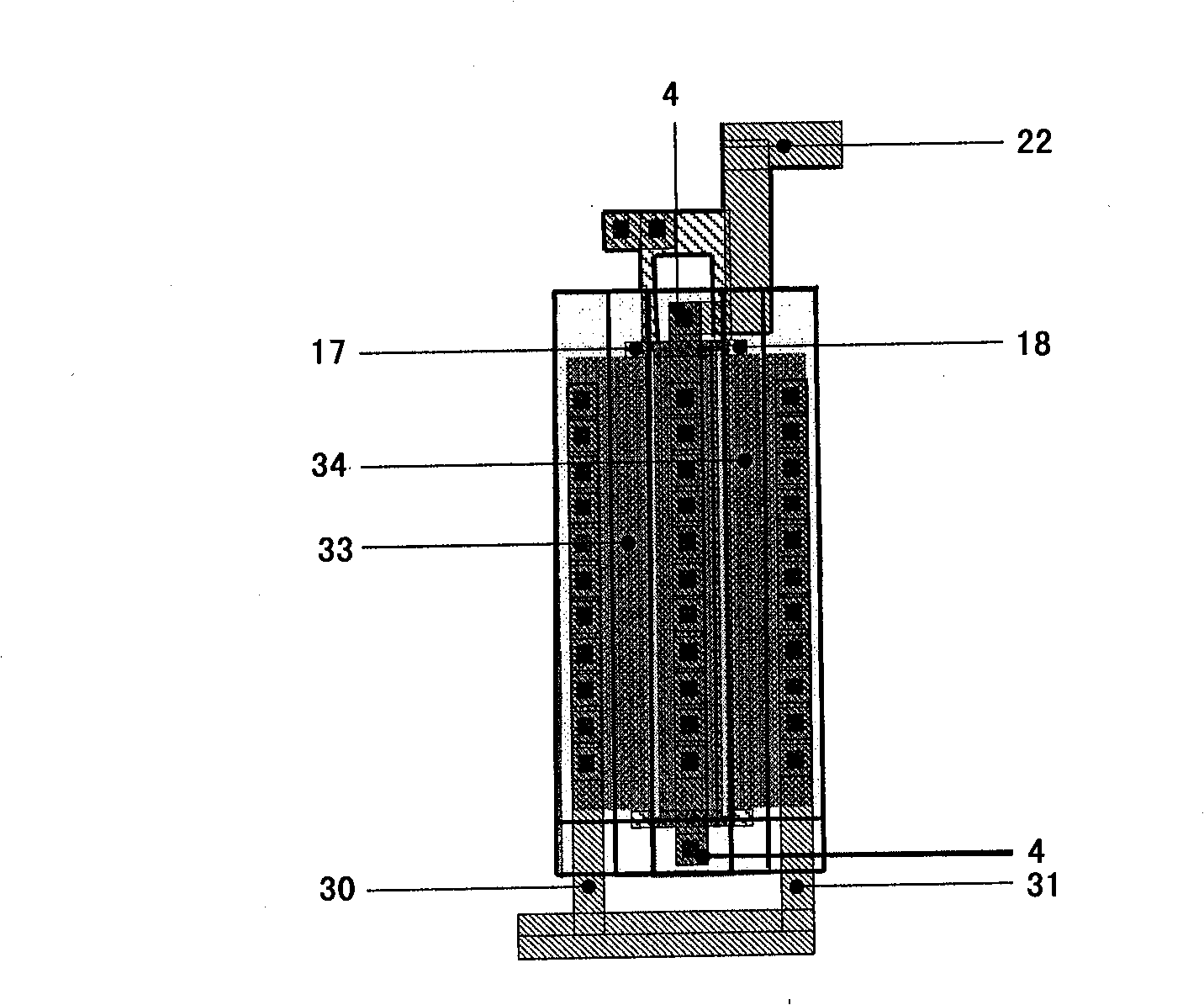

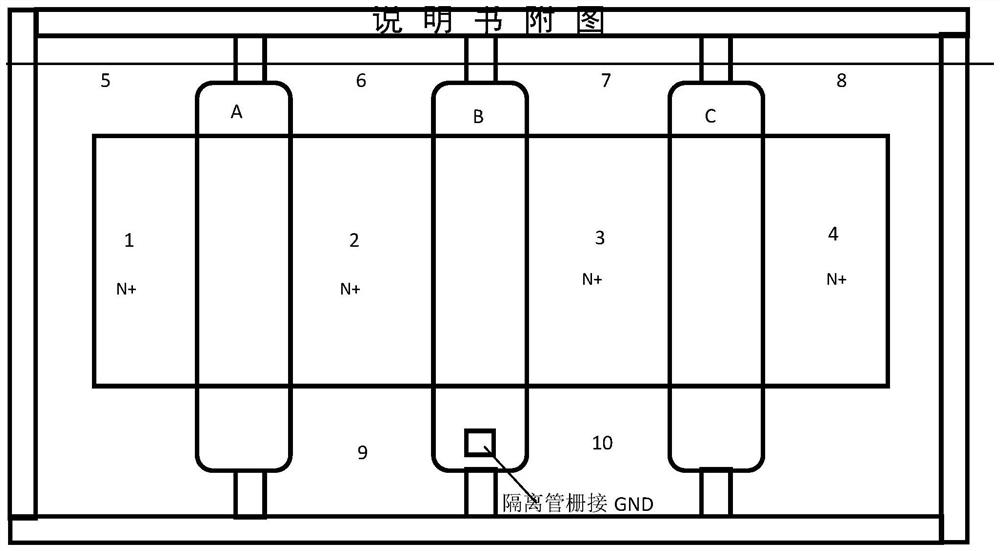

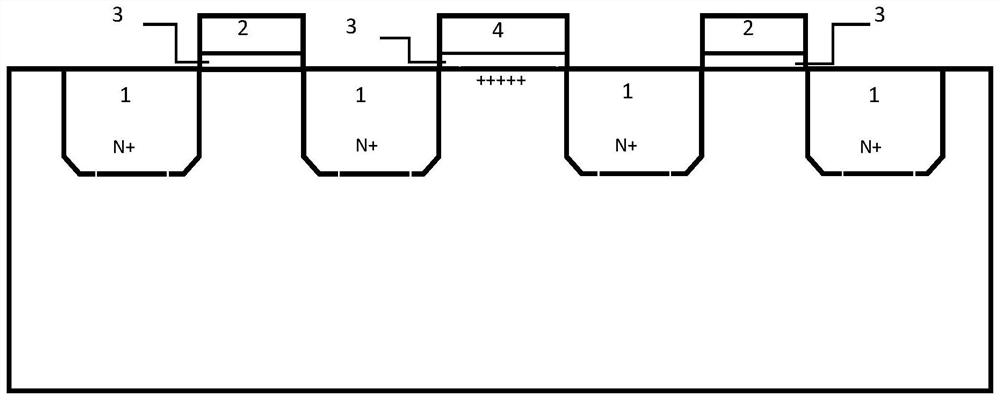

Radio frequency SOI LDMOS device with close body contact

InactiveCN101515586AIncrease working frequencyImprove breakdown voltageTransistorSemiconductor/solid-state device detailsRadio frequencyBody region

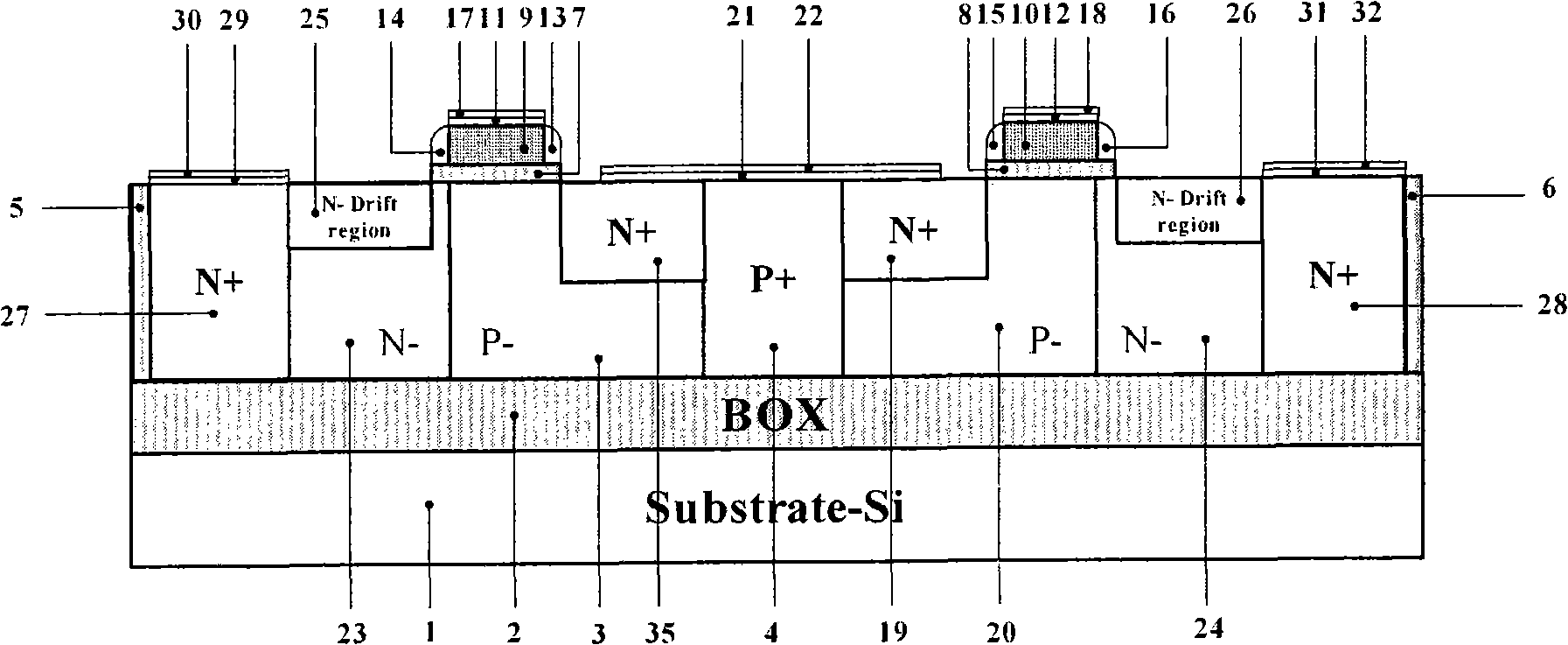

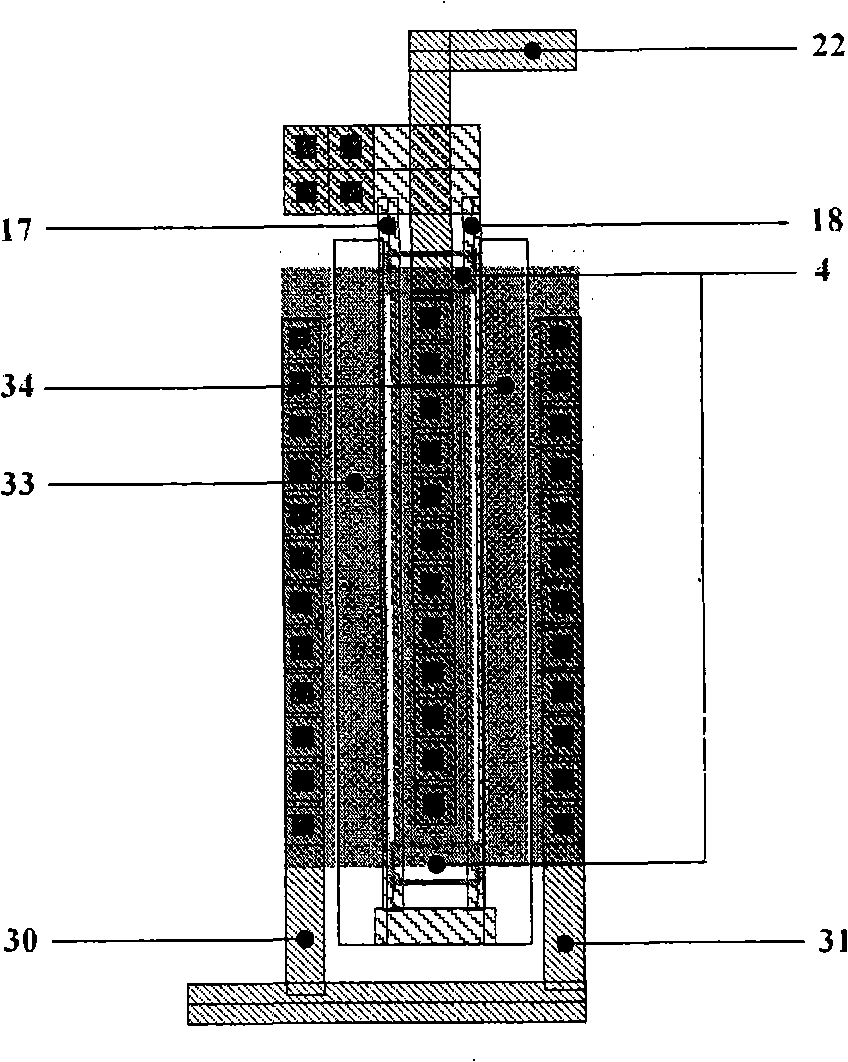

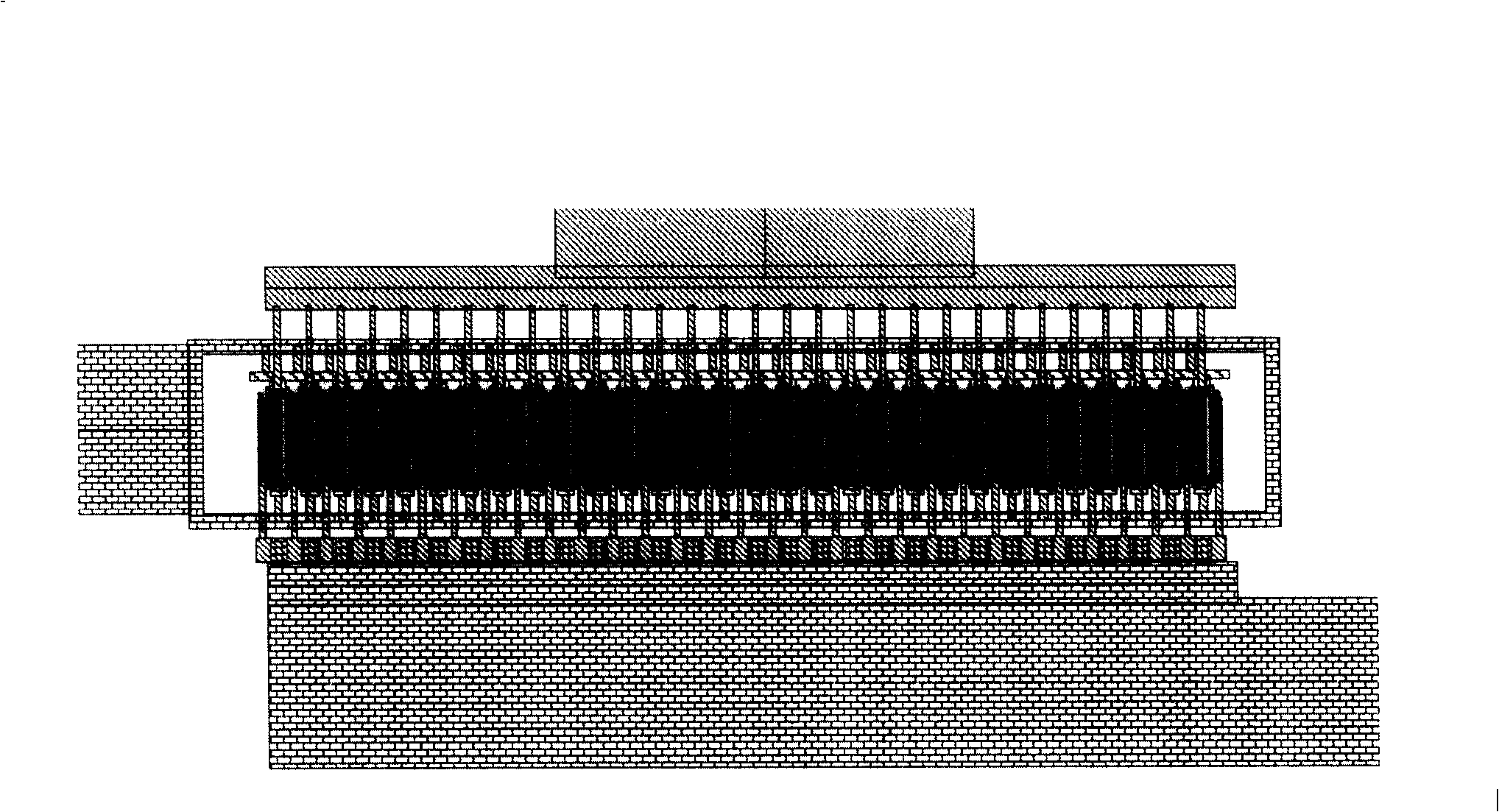

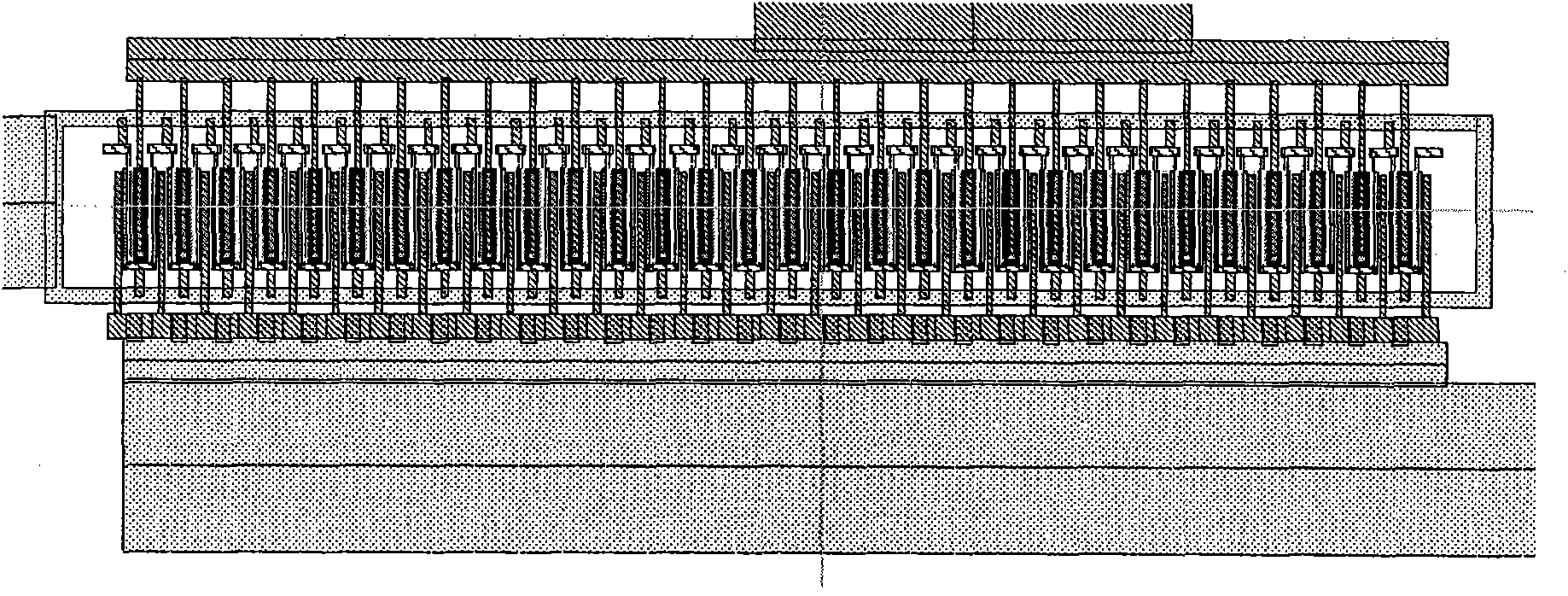

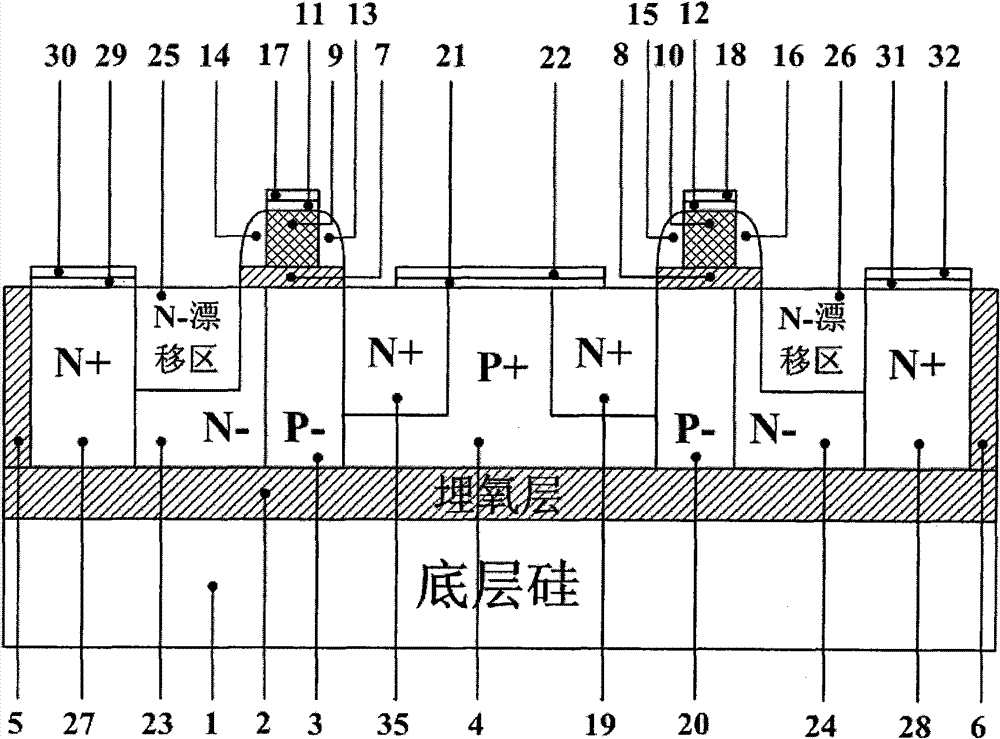

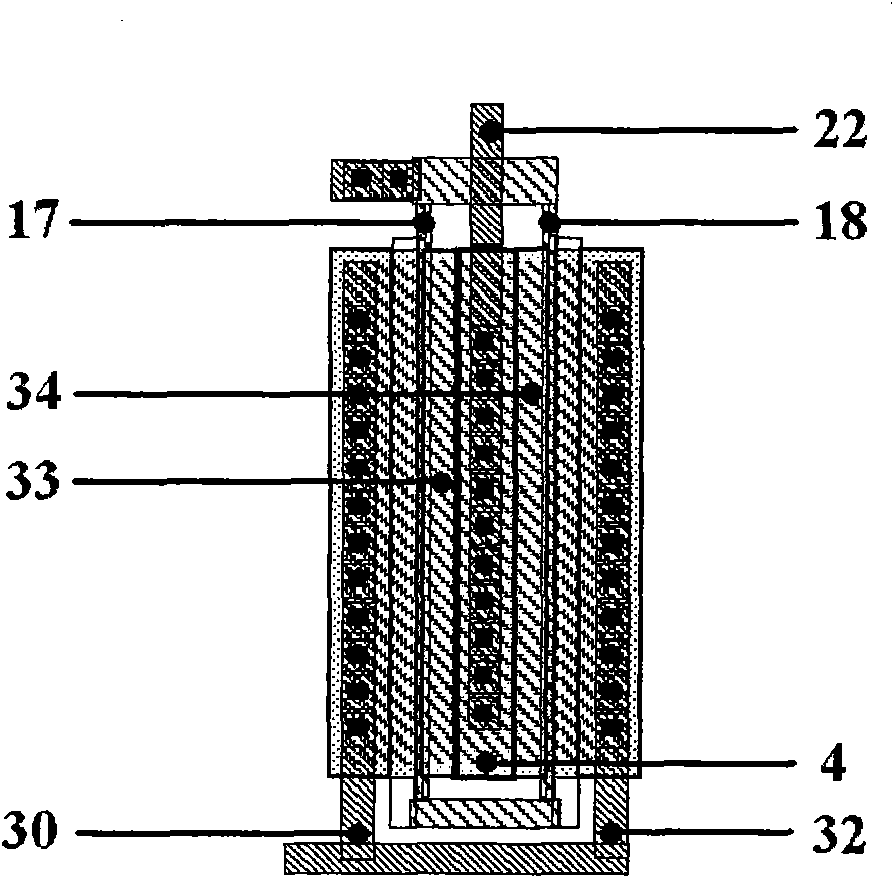

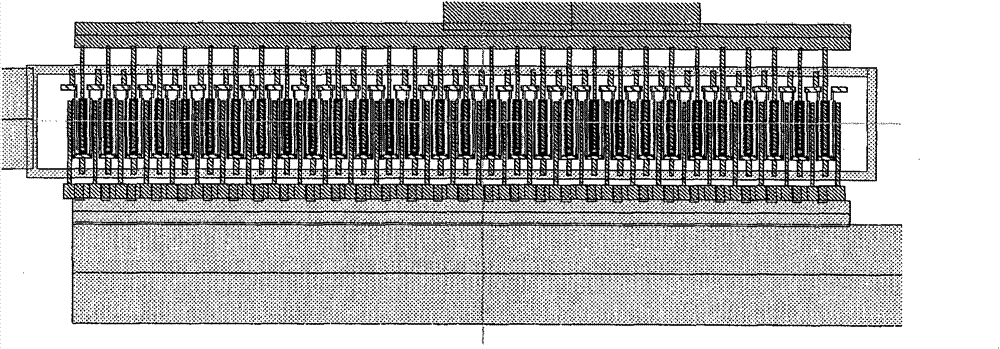

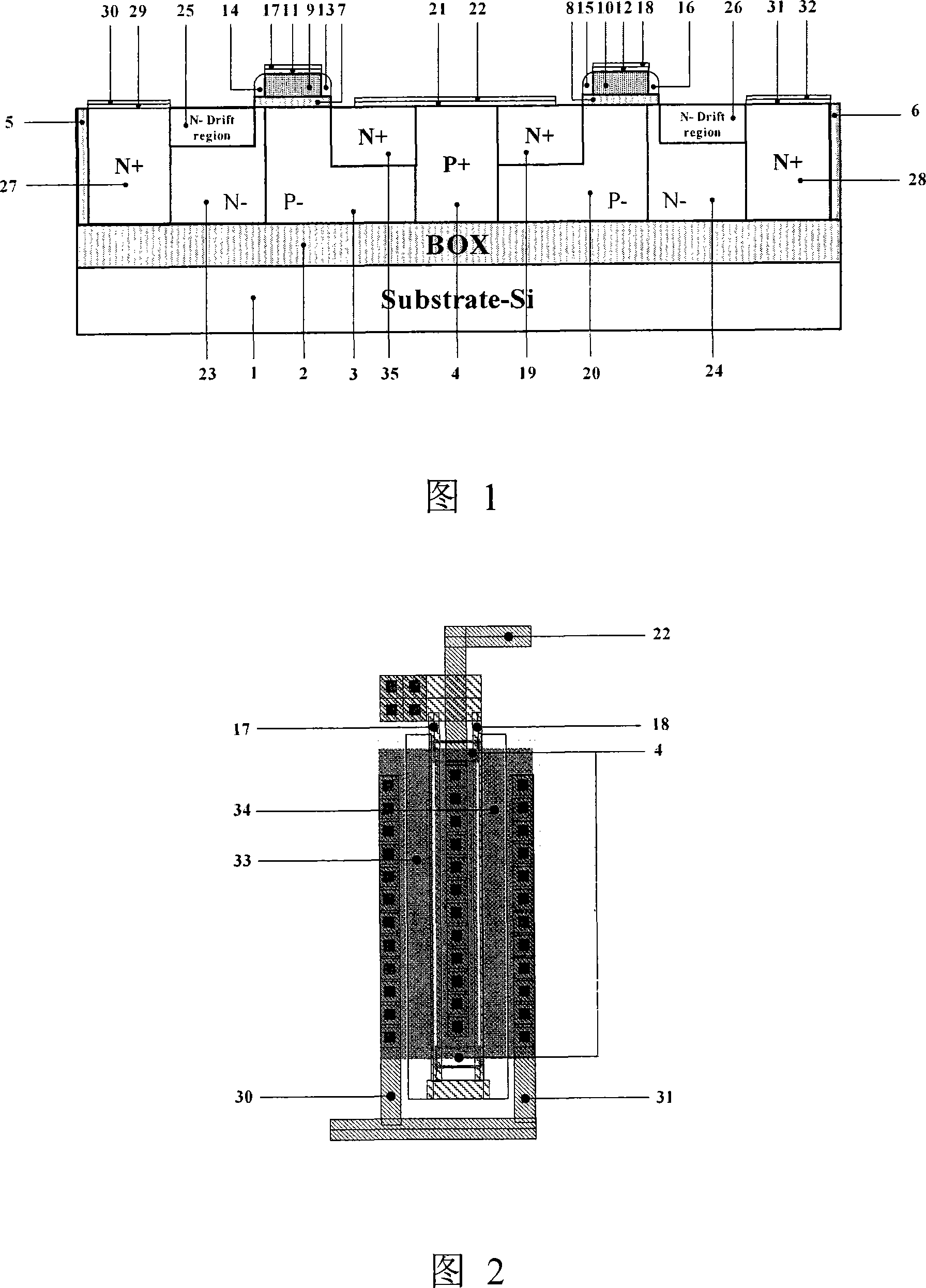

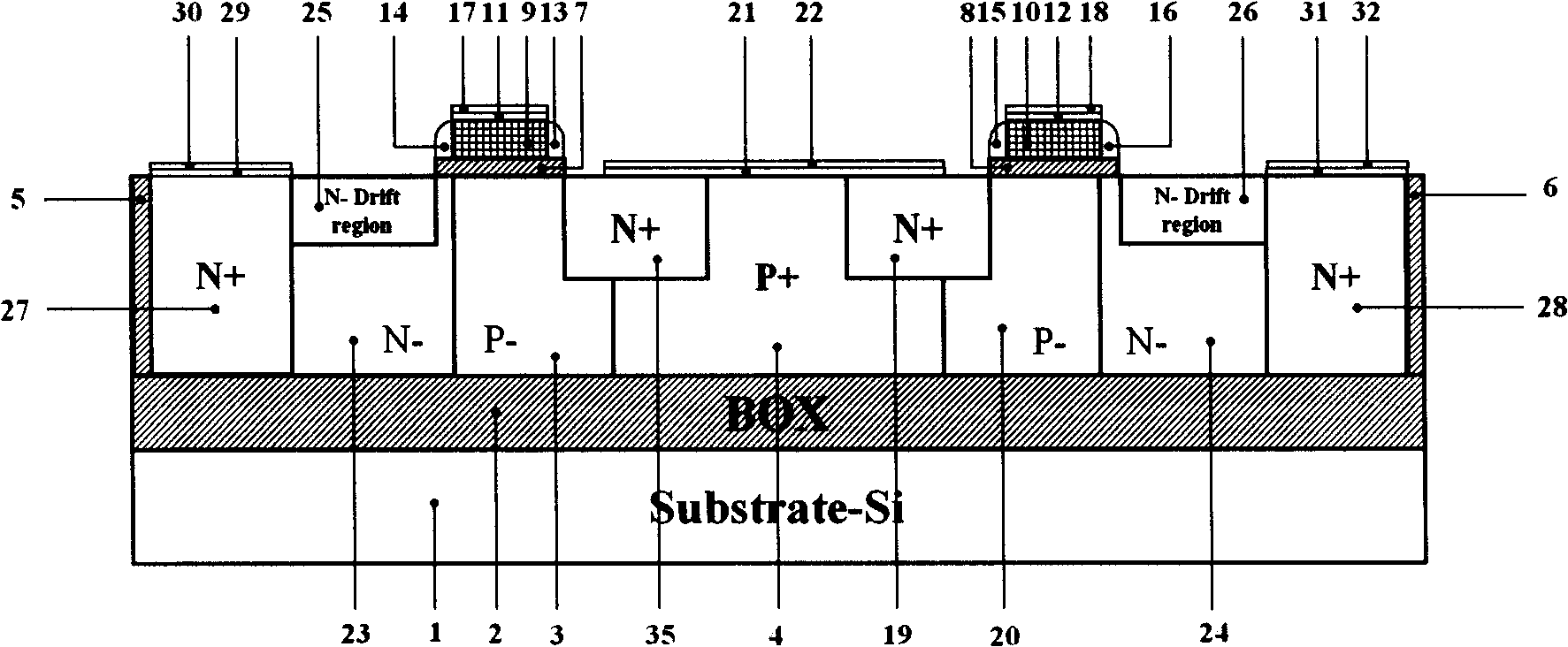

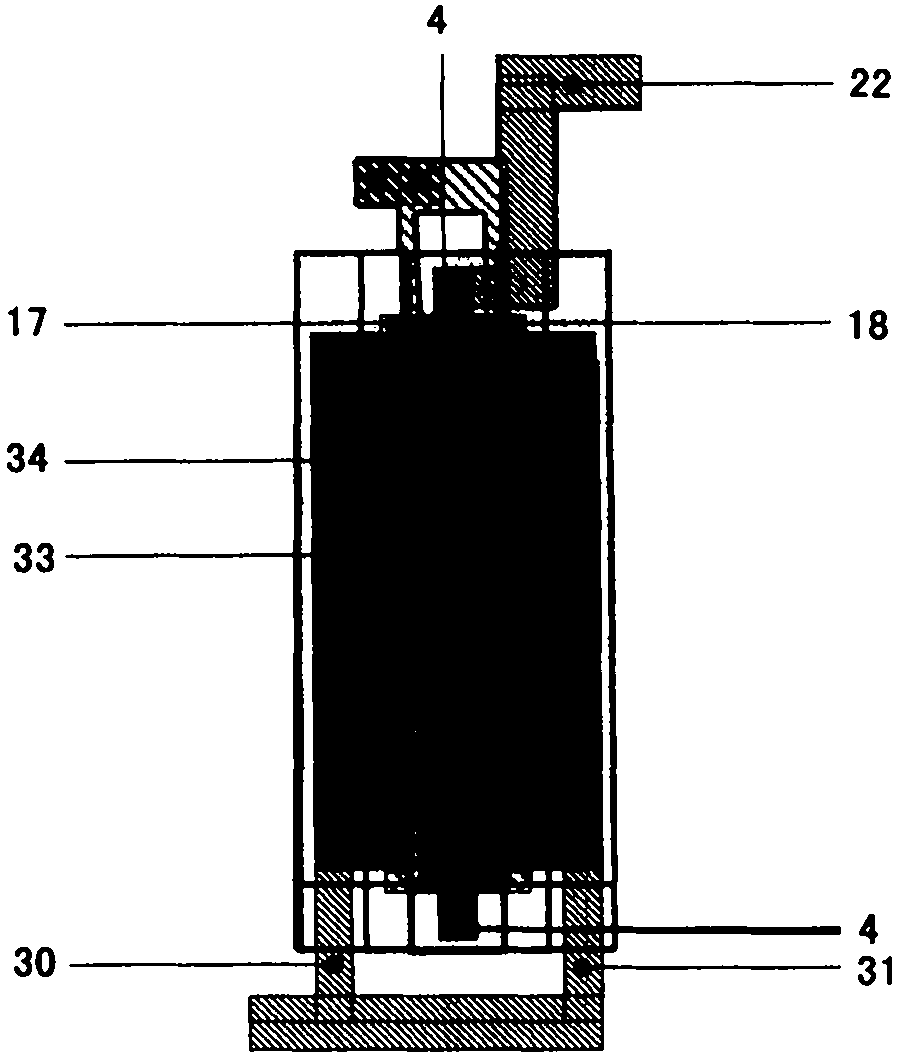

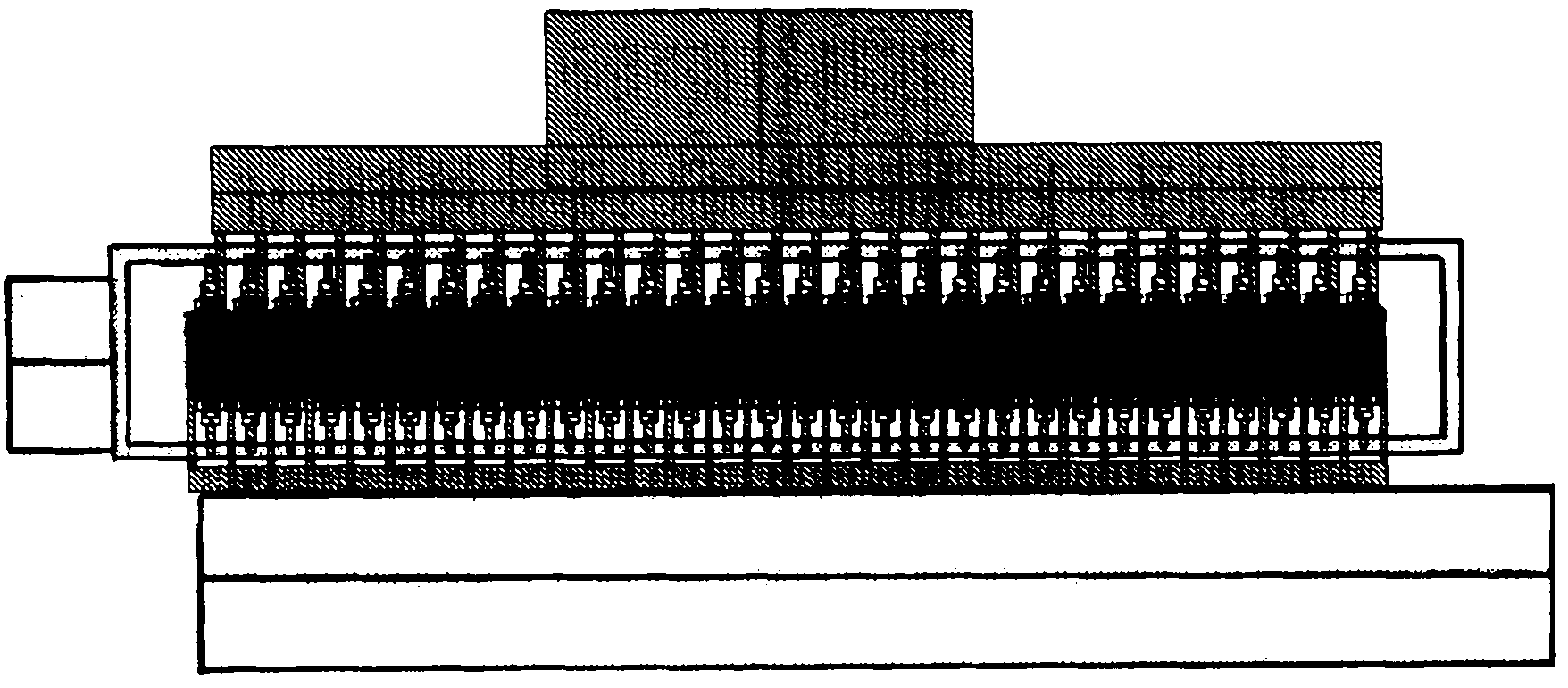

The invention relates to the field of a radio frequency power device, and discloses a radio frequency SOI LDMOS device with close body contact. The device comprises bottom layer silicon, an embedding oxidation layer, top layer silicon, a P region an N region, a gate oxidation layer, a polysilicon gate layer, a gate poly-silicide layer, a gate electrode, a silicon nitride side wall, an N drift region, a drain region, a drain region silicide layer, a drain electrode, a source region, a body contact region, a body region, a source region silicide layer and a source electrode. The radio frequency LDMOS device is manufactured on an SOI substrate, and forms the close body contact which is in short circuit with the source region by utilizing a heavily doped region in the same form as the P region; the source / body, a drain / body and the gate and the electrodes are interconnected by the silicide; a plurality of gate bars are connected in parallel in the forked mode so as to improve the driving capability of the device; a method for adjustment, back-gate injection, N region injection and N drift region injection, which is compatible with the CMOS process, is designed; and a method for hiding the silicide in the N drift region, which is compatible with the CMOS process, is designed.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

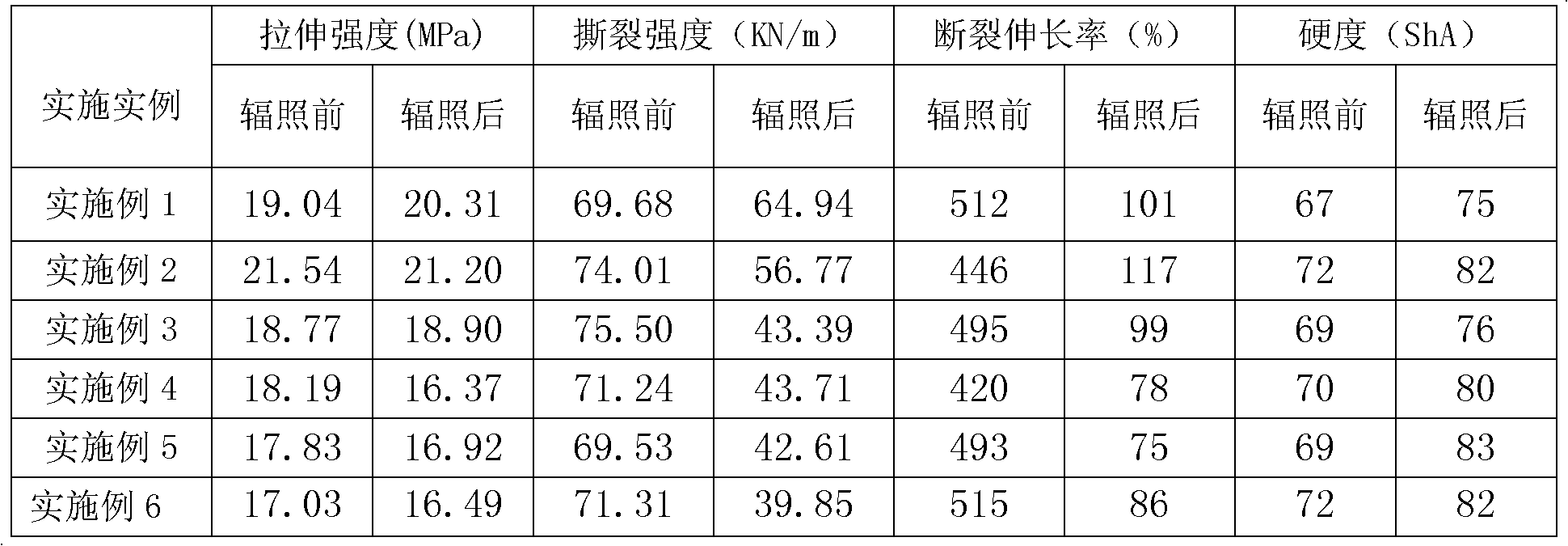

High strength rubber with radiation resistance and thermal aging resistance and preparation method thereof

ActiveCN102532626AImprove radiation resistanceImprove heat resistanceChemical industryPolymer science

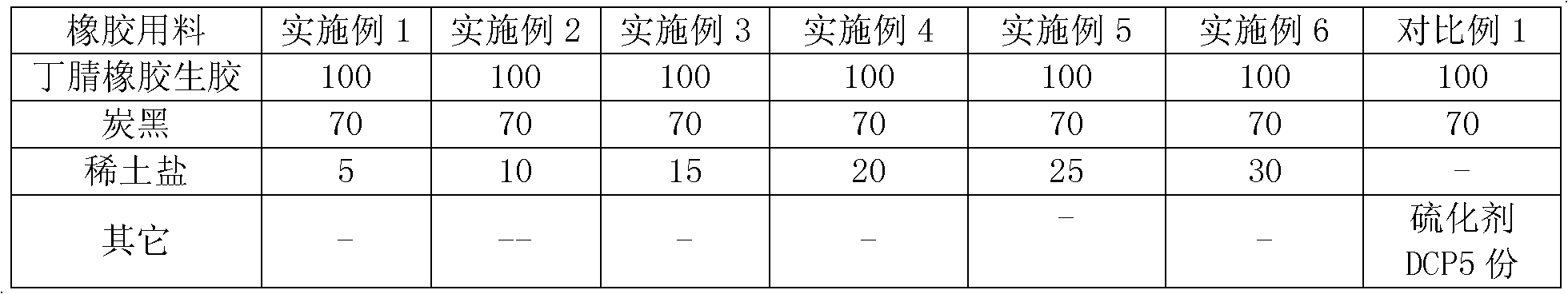

The invention discloses high strength rubber with both the radiation resistance and the thermal aging resistance, which comprises the following components in parts by weight: 100 parts of crude rubber, 1 to 50 parts of rare earth salt, 10 to 100 parts of reinforcing agent and 0 to 20 parts of other ingredients. The high strength rubber with both the radiation resistance and the thermal aging resistance of the invention has strong environmental adaptability, has tensile strength of over 16MPa and tearing strength of over 40KN / m after being irradiated under the condition of 300KGy, can be used for producing various rubber products with various radiation resistance properties, which comprise a rubber gasket, a seal part, a shock absorbing and buffering part, a spacer bush, a diaphragm and the like, can be widely applied to the environment with high energy radiation in various fields of aerospace, nuclear industry, electronic communication, chemical industry, medicine, watercraft and the like, and has good economic benefits and popularization value.

Owner:SHANDONG UNIV

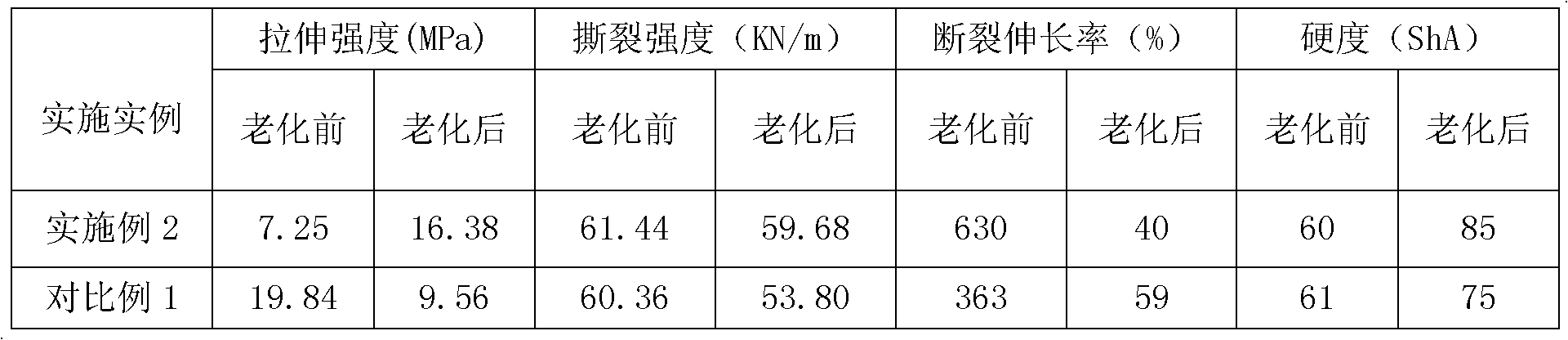

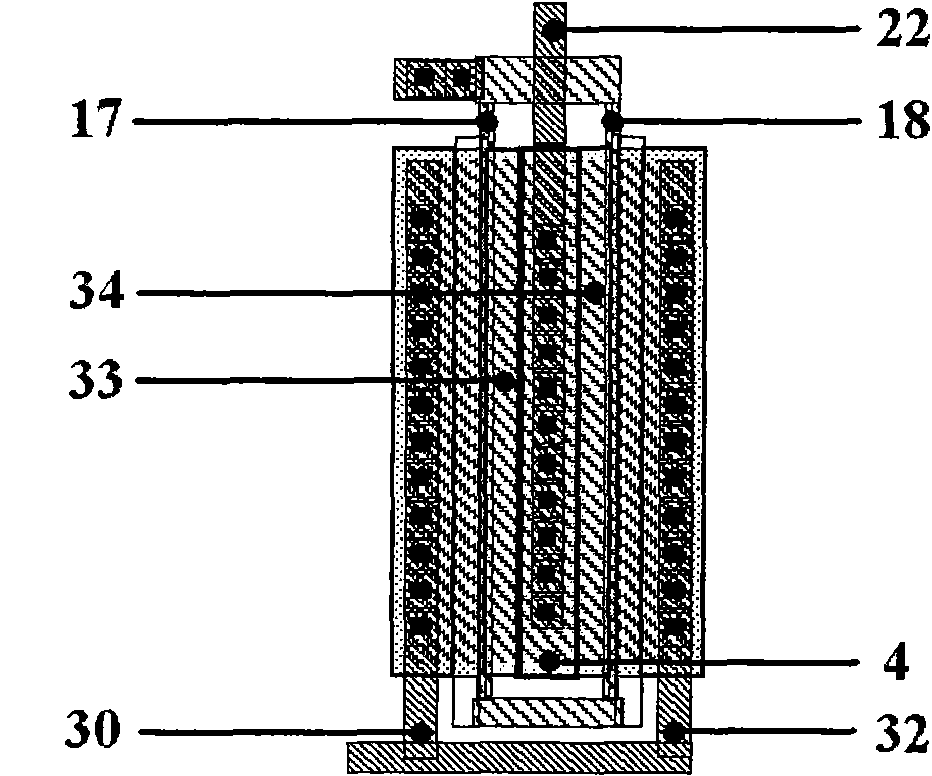

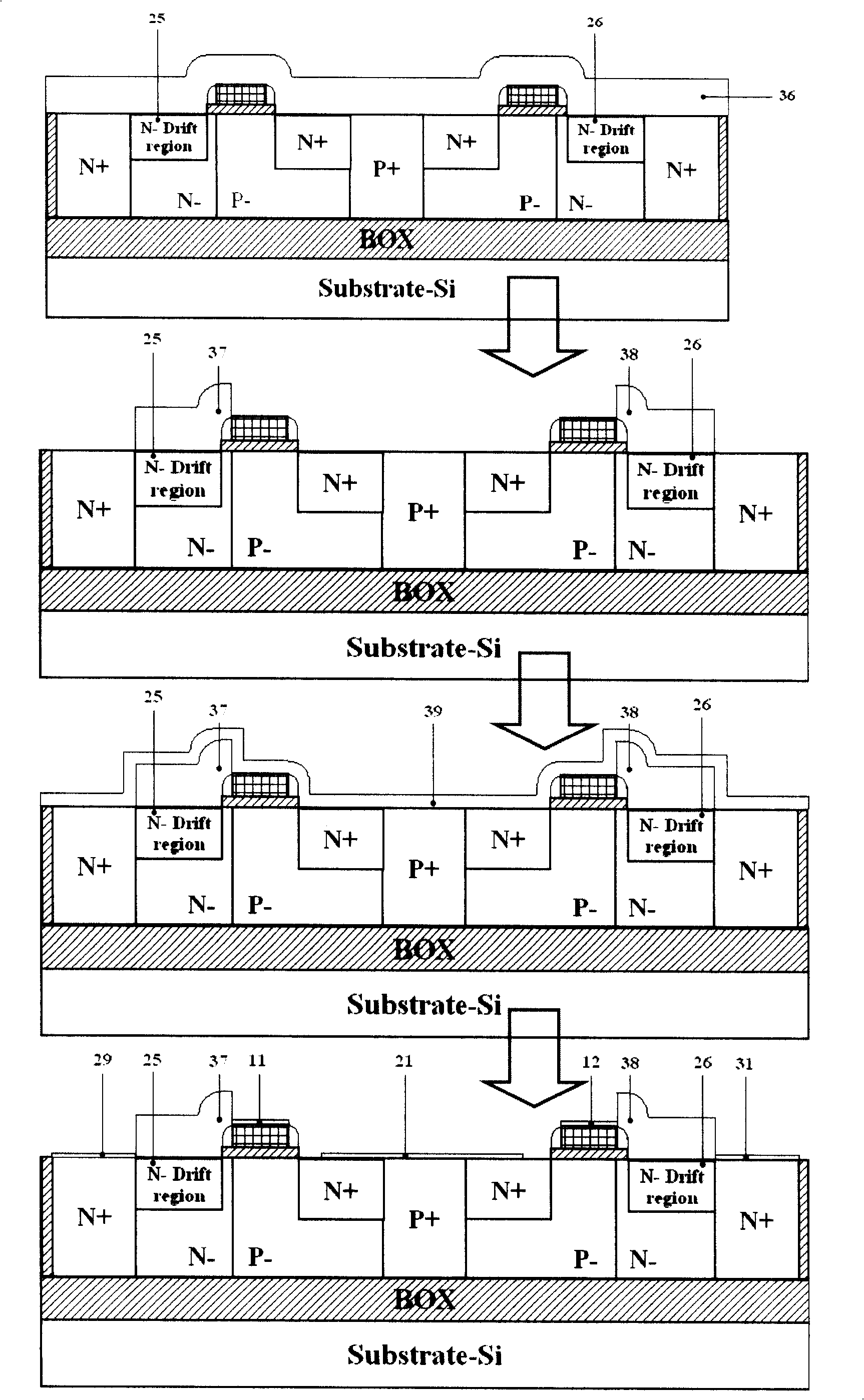

Radio frequency laterally diffused metal oxide semiconductor (LDMOS) device based on silicon on insulator (SOI) and method for injecting device

ActiveCN102054845AIncrease working frequencyImprove breakdown voltageSemiconductor/solid-state device detailsSolid-state devicesRadio frequencyPolycrystalline silicon carbide

The invention discloses a radio frequency silicon on insulator(SOI) laterally diffused metal oxide semiconductor (LDMOS) device provided with a low potential barrier body lead-out, which comprises a bottom layer silicon, a concealed oxide layer, a top layer silicon, a P-region, a N-region, a gate oxide layer, a polysilicon gate layer, a gate polycrystalline silicon carbide layer, a gate electrode, a side wall, a N-drift region, a drain region, a drain region silicate layer, a leakage electrode, a source region, a low potential barrier body lead-out region, a body region, a source region silicide layer, and a source electrode. In the invention, the radio frequency LDMOS device is manufactured on an SOI substrate, and a low potential barrier body lead-out is in a short circuit with the source region is formed by utilizing a heavily doped region homotypic with the P- region; the source / body, leakage / body as well as a gate is interconnected with each electrode by utilizing a silicide; a plurality of grate bars are in interdigital type parallel connection so as to enlarge the driving power of the device; and the invention provides a method for rectifying, back gate injection, N-region injection as well as N-drift region injection compatible with a complementary metal-oxide-semiconductor (CMOS) technology, as well as a N-drift region silicide conceal method compatible with the CMOS technology.

Owner:BEIJING ZHONGKE XINWEITE SCI & TECH DEV

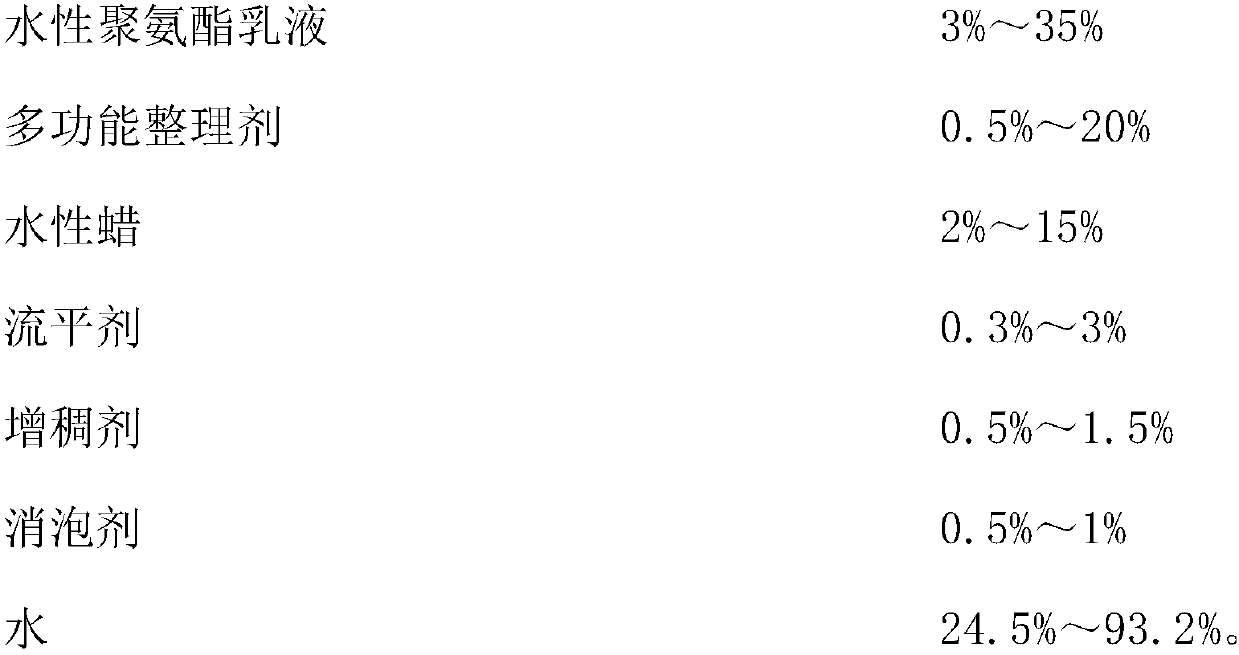

Formula and preparation process for multifunctional surface treating agent applied to aqueous leather

InactiveCN108047906ARich touch and visual experienceImprove physical performanceFireproof paintsWax coatingsWaxChemistry

The invention discloses a formula for a multifunctional surface treating agent applied to aqueous leather. The formula comprises 3 to 35% of an aqueous polyurethane emulsion, 0.5 to 20% of a multifunctional finishing agent, 2 to 15% of aqueous wax, 0.3 to 3% of a leveling agent, 0.5 to 1.5% of a thickening agent, 0.5 to 1% of an antifoaming agent and 24.5 to 93.2% of water. The preparation processcomprises the following steps: adding all the above raw materials except the thickening agent into a container in proportion, carrying out uniform mixing through a dispersator, then carrying out filtering and adding the thickening agent to adjust viscosity so as to obtain the surface treating agent. The surface treating agent provided by the invention endows synthetic leather with special performances like antibacterial, sterilizing, anti-ultraviolet, anti-radiation, flame-retardant, temperature-adjusting, color-changing, self-cleaning and anti-doodling performances without any influence on the fastness and handfeel of the synthetic leather, and substantially prolongs the service life of the synthetic leather; a product having been treated with the surface treating agent has better handfeel and presents better visual impression; and the surface treating agent greatly improves the physical properties of the synthetic leather and allows the synthetic leather to have more excellent scrape resistance, water resistance, fire resistance and the like.

Owner:宋林涛

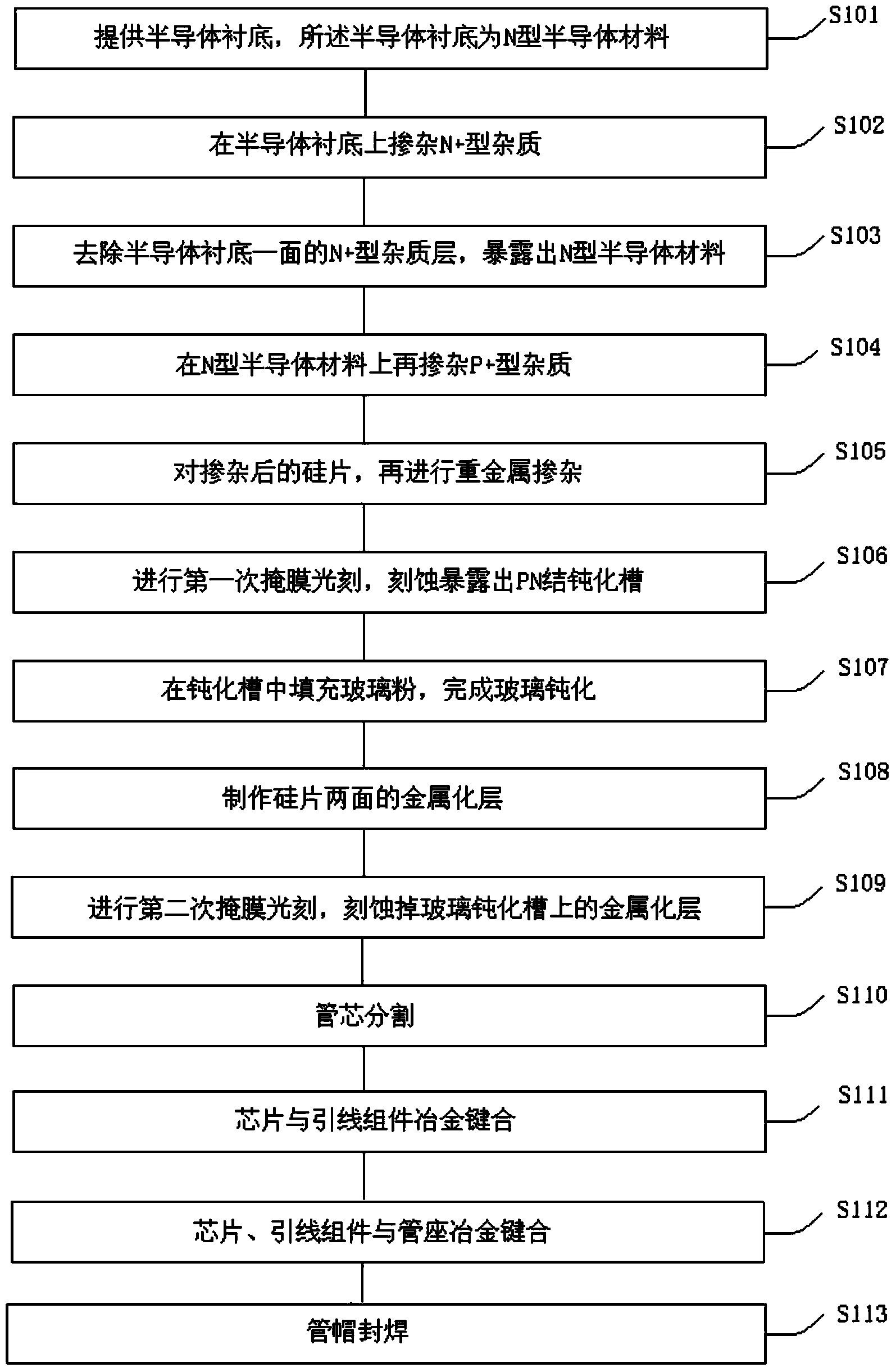

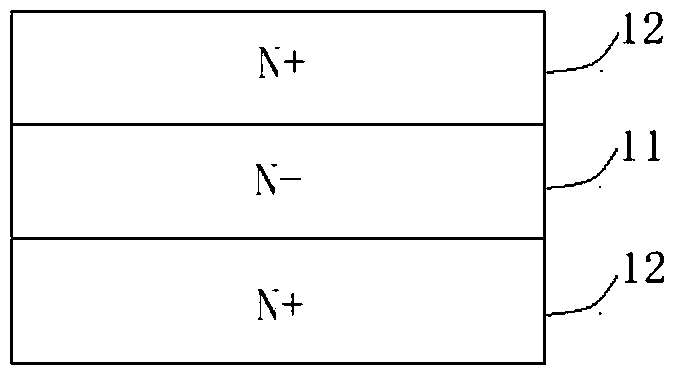

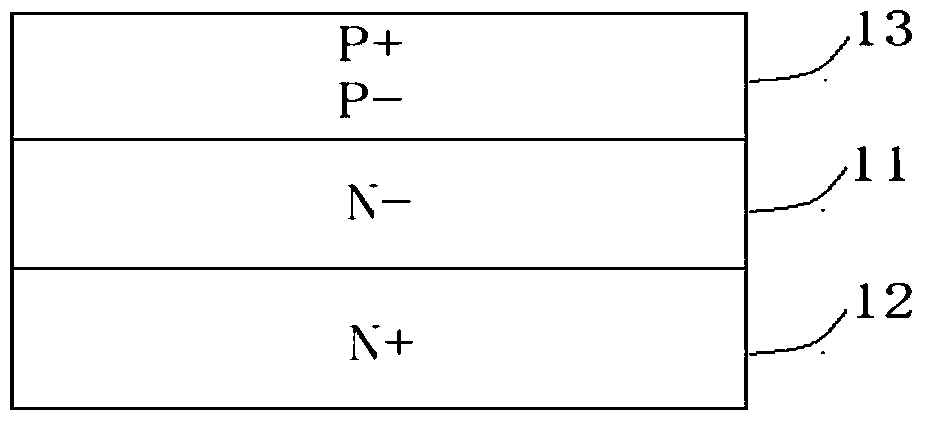

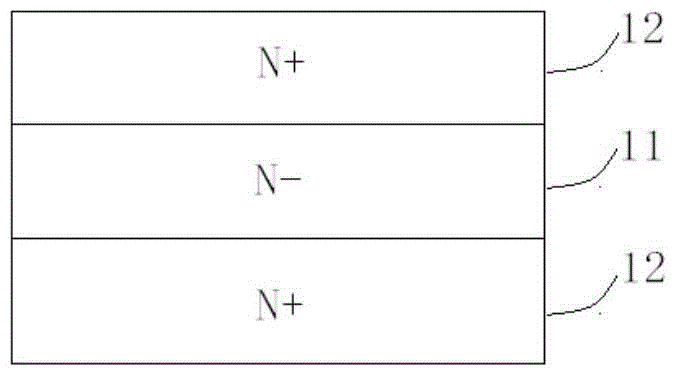

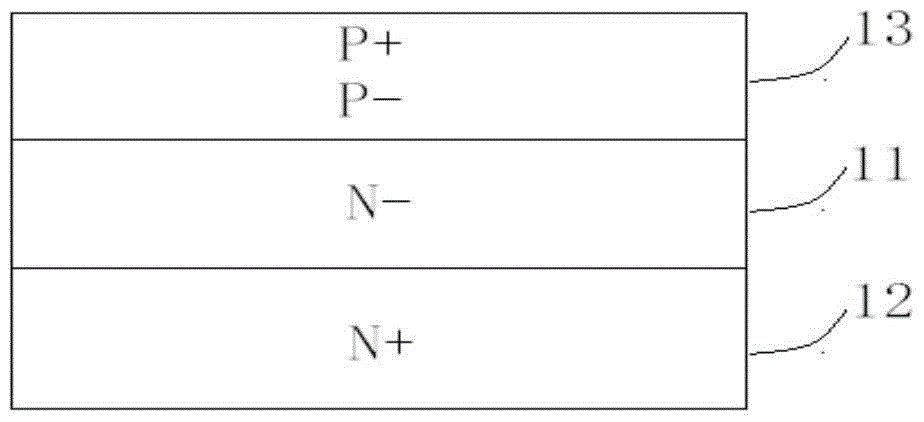

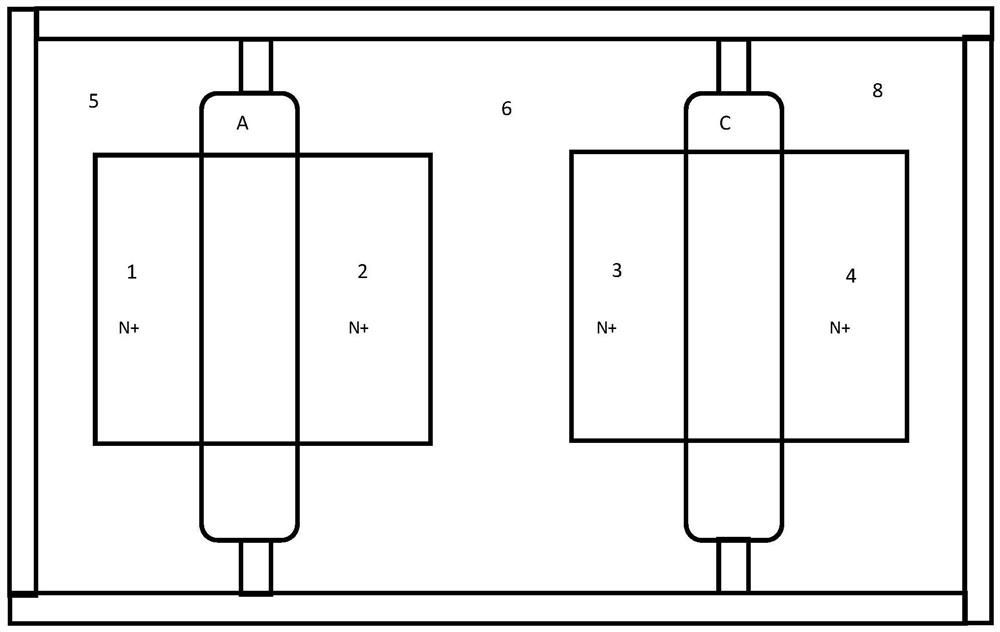

Method for manufacturing 50A high-current fast recovery diode

ActiveCN104269356AReduce reverse leakage currentImprove stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesDiffusion methodsSemiconductor materials

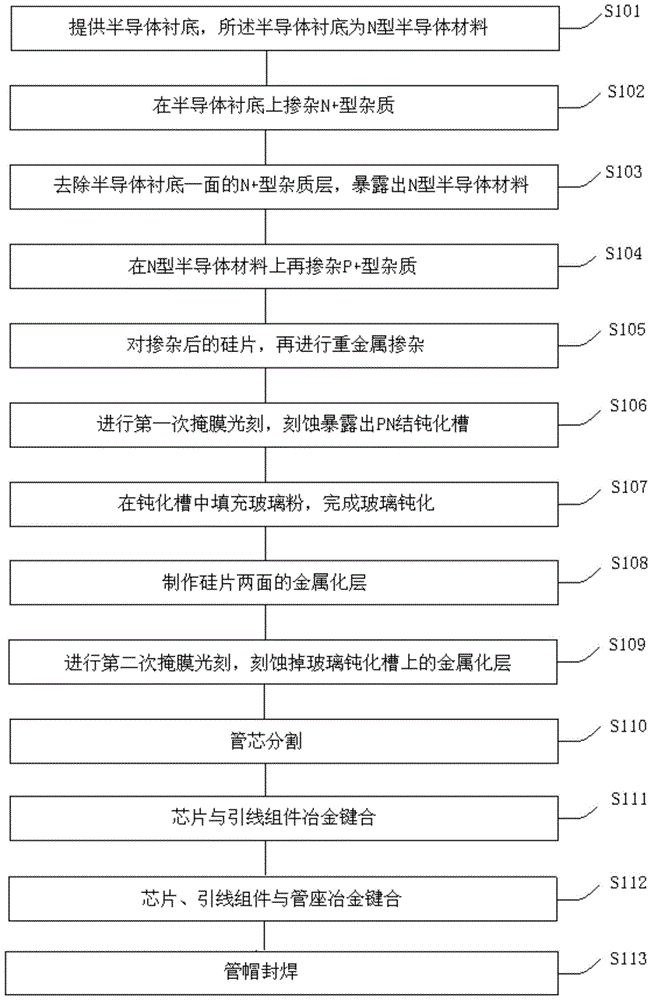

The invention discloses a method for manufacturing a 50A high-current fast recovery diode. The method for manufacturing the 50A high-current fast recovery diode comprises the steps that an N type semiconductor silicon material is provided to serve as a semiconductor substrate; the N type semiconductor substrate is doped with N+ type impurities; the N+ type impurity layer on one side of the semiconductor substrate is removed; an exposed N-type semiconductor material is doped with dual P+ type impurities; heavy metal platinum doping is conducted according to the high-temperature diffusion method; primary mask photoetching is conducted; glass powder is arranged in a passivation groove through knife coating, high-temperature sinter molding is conducted, and then PN junction glass passivation is completed; multiple metallization layers are manufactured on the two sides of a silicon wafer according to the vacuum sputtering method; secondary mask photoetching is conducted; the silicon wafer is divided into independent dies; a chip and a lead component are bonded together; the chip, the lead component and a diode holder are bonded together in a metallurgical mode through sintering; a diode cap and the diode holder are welded together in a sealed mode through percussion welding. According to the method for manufacturing the 50A high-current fast recovery diode, the manufacturing process based on the method is less influenced by the environment, the technology is mature, the stability and the repeatability are high, and the method can be widely used for volume production of high-current fast recovery diodes.

Owner:西安卫光科技有限公司

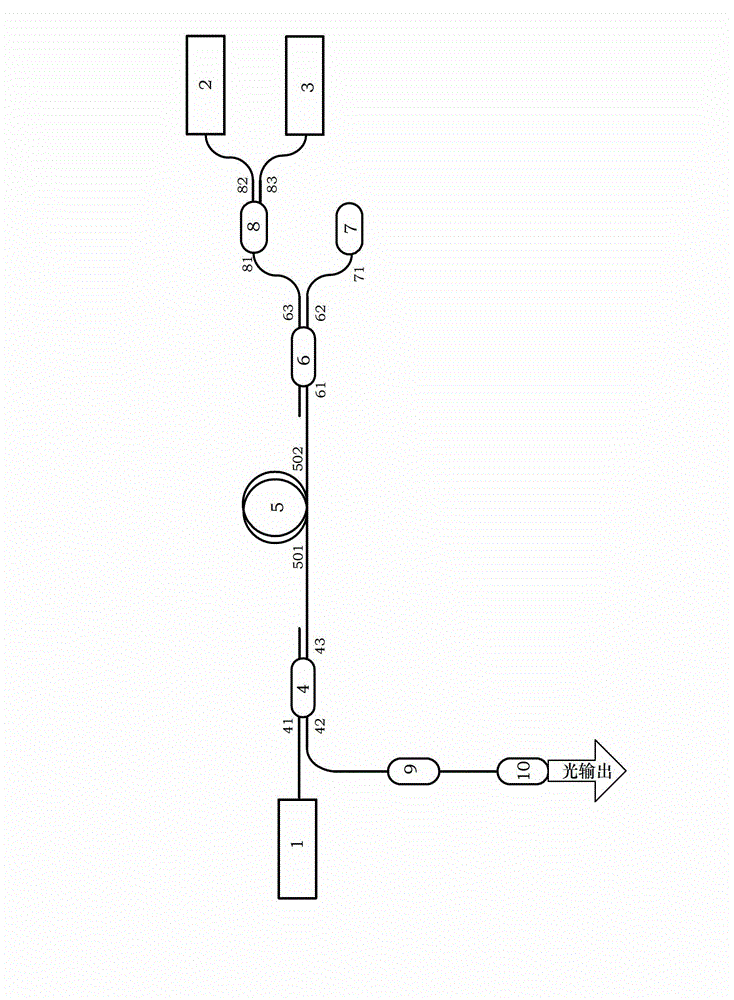

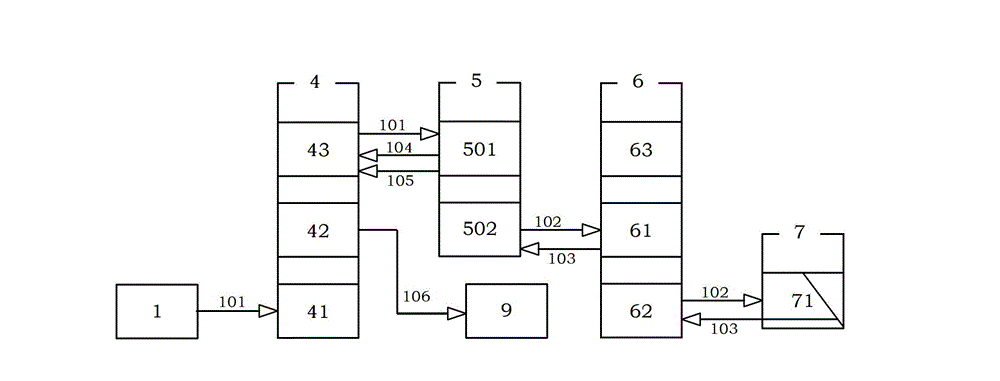

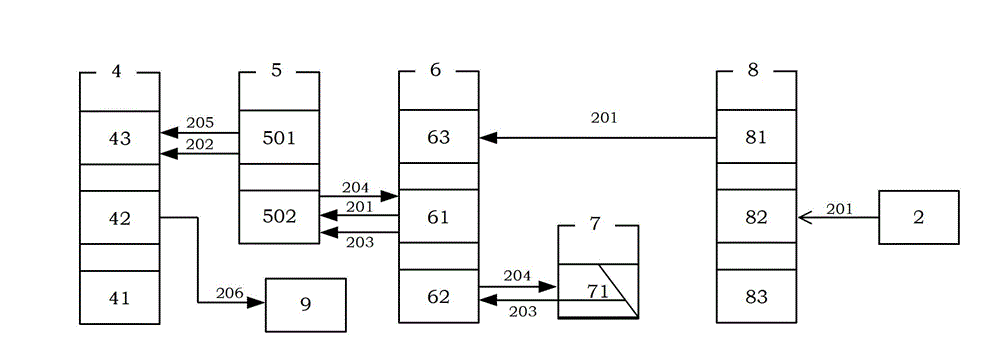

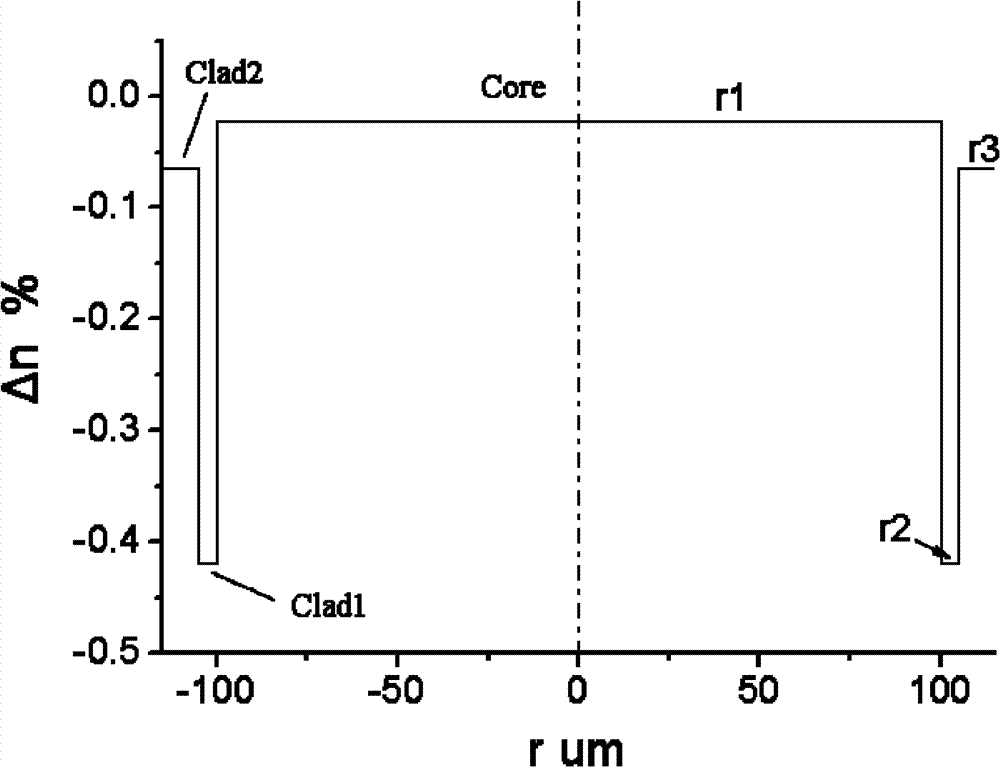

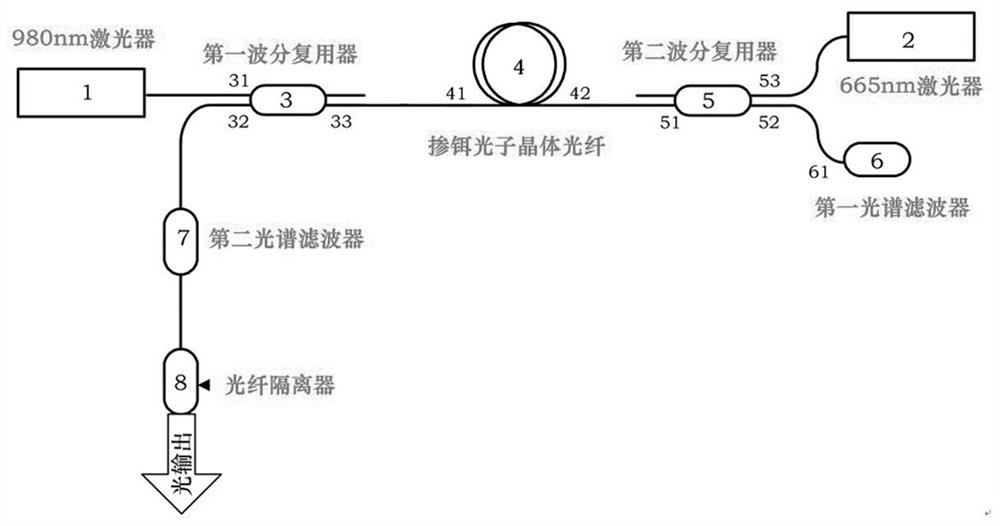

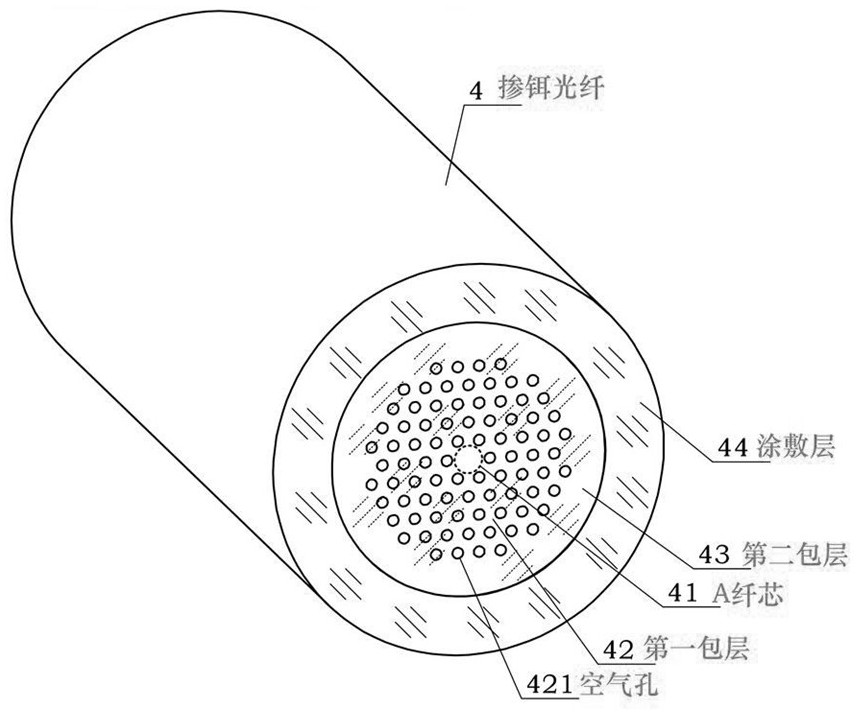

Anti-radiation wide-spectrum optical-fiber light source based on photo-bleaching

InactiveCN102751648AGuaranteed stabilityImprove radiation resistanceCladded optical fibreActive medium shape and constructionFiberMultiplexer

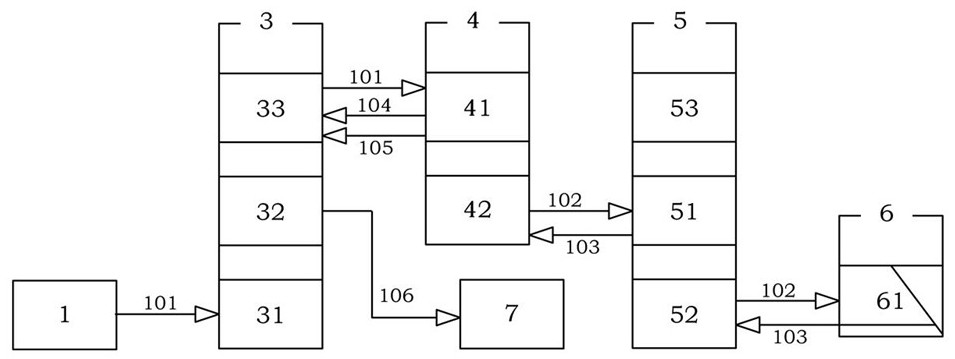

The invention discloses an anti-radiation wide-spectrum optical-fiber light source based on photo-bleaching. The optical-fiber light source is a multi-pump double-pass backward structure and adopts an erbium-doped photo crystal optical fiber as a gain medium. A tail fiber of a 980nm laser is in fusion connection with one end of a first wavelength division multiplexer; a tail fiber of a 810nm laser is in fusion connection with one end of a third wavelength division multiplexer; a tail fiber of a 665nm laser is in fusion connection with the third wavelength division multiplexer; the other two ends of the first wavelength division multiplexer are in fusion connection with a second optical spectrum filter and an erbium-doped photo crystal optical fiber; one end of the second wavelength division multiplexer is in fusion connection with the erbium-doped photo crystal optical fiber, and the other two ends of the second wavelength division multiplexer are in fusion connection with the first optical spectrum filter and the third wavelength division multiplexer; and a fiber leading-out end of the second optical spectrum filter is in fusion connection with a fiber leading-in end of an optical fiber isolator, and a fiber leading-out end of the optical fiber isolator is used as a light output end. Multiple special wavelength lasers are used for simultaneously pump to realize the effective photo-bleaching, so that the stability of the average wavelength and the output power of the erbium-doped optical fiber light source can be guaranteed under the space radiation environment.

Owner:BEIHANG UNIV

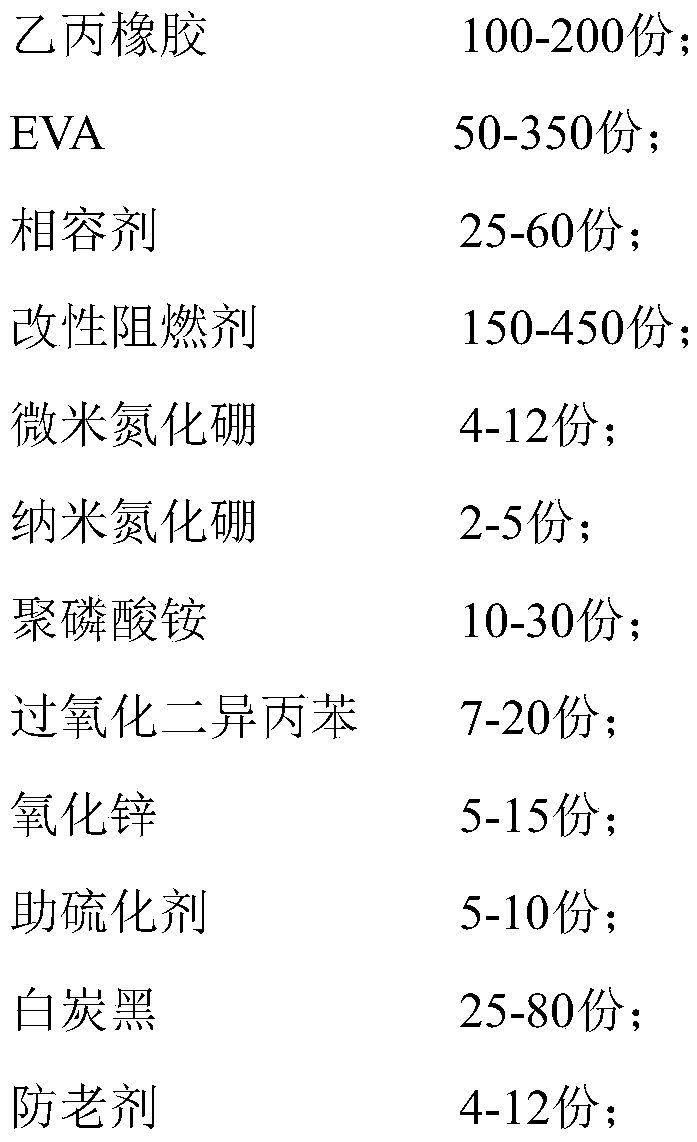

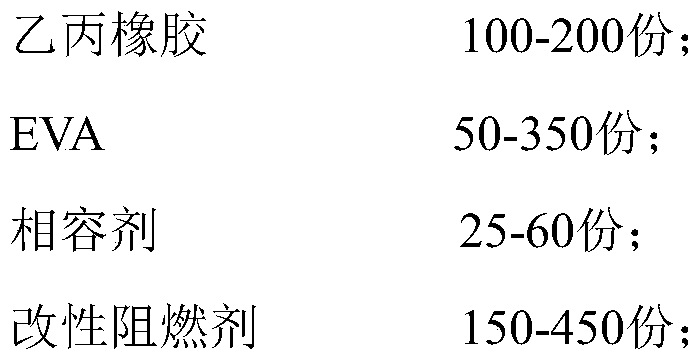

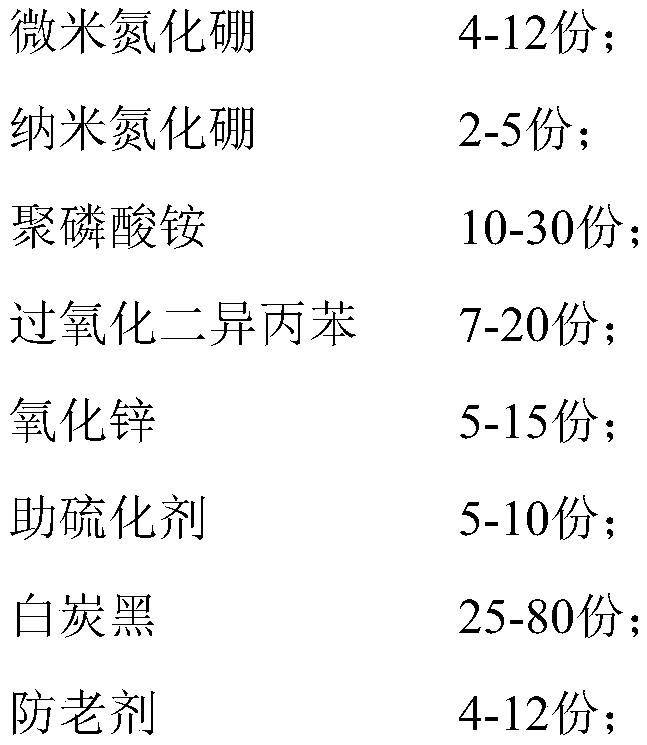

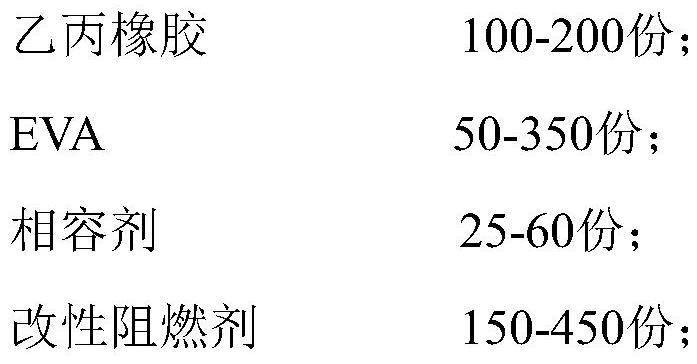

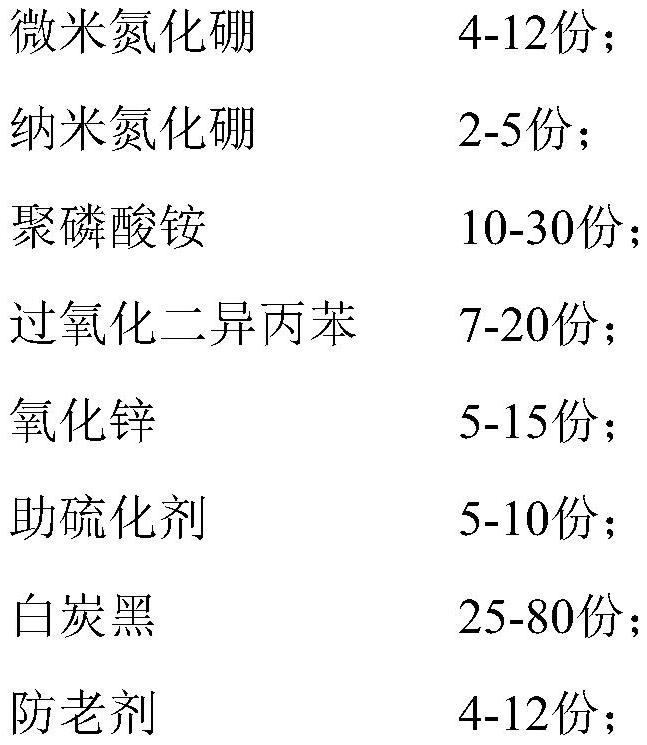

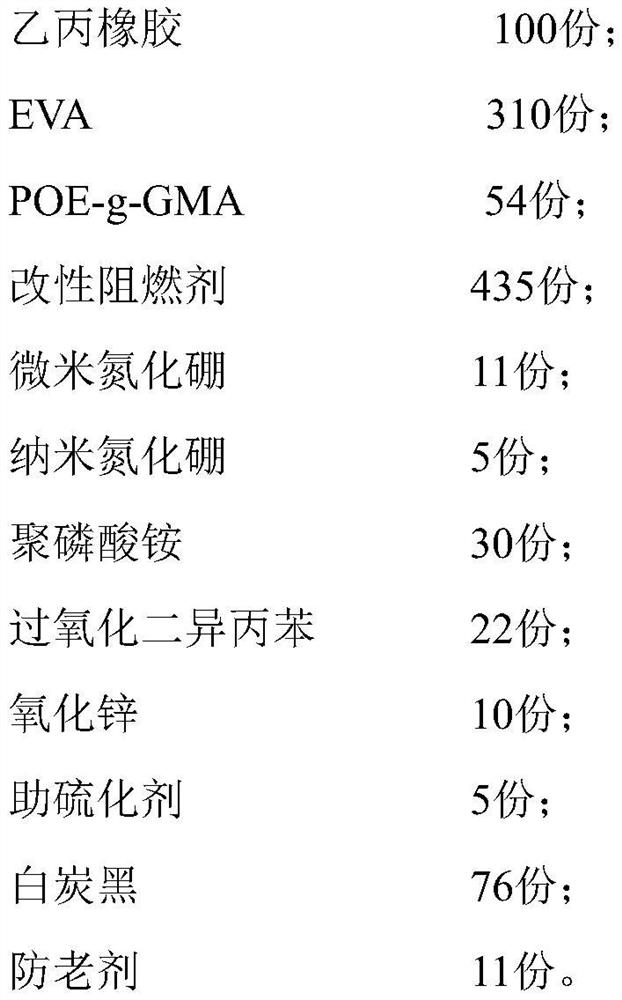

Nuclear power cable insulating material of metal hydroxide-boron nitride hybridized filler/blended rubber and preparation method thereof

The invention discloses a nuclear power cable insulating material of a metal hydroxide-boron nitride hybridized filler / blended rubber and a preparation method thereof. The preparation method comprisesthe steps that metal hydroxide with methyl methacrylate and ionic liquid copolymer being grafted on is loaded on the surface of boron nitride, and then boron nitride is blended and compounded with EVA / ethylene propylene rubber, a cross-linking agent, a compatilizer and an anti-aging agent at the proper proportions. The invention utilizes the electronic insulation property, the radiation resistance and the ultrahigh adsorption property of boron nitride to load grafted and modified metal hydroxide to compose a radiation-resistant and capacity-increasing hybridized filler based on a modified filler, and meanwhile produces the nuclear power cable insulating material with the outstanding flame resistance, radiation resistance, electrical property, free halogen and low smoke and mechanical property by utilizing the radiation resistance of ionic liquid to improve the radiation resistance of the material.

Owner:HEFEI UNIV OF TECH

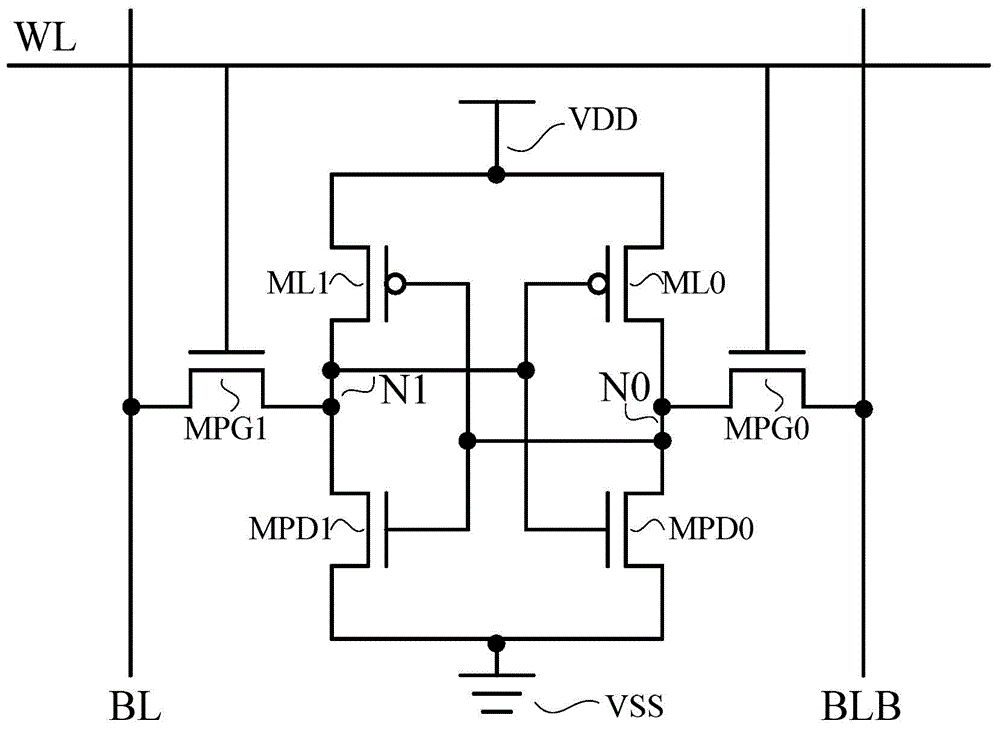

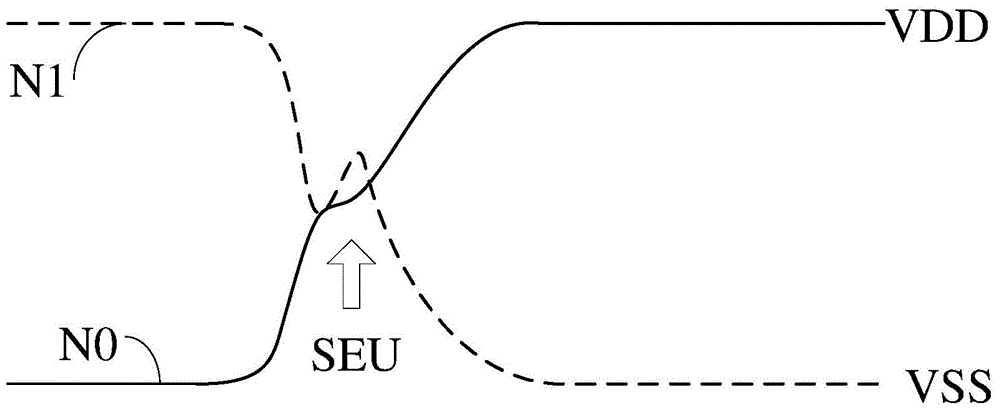

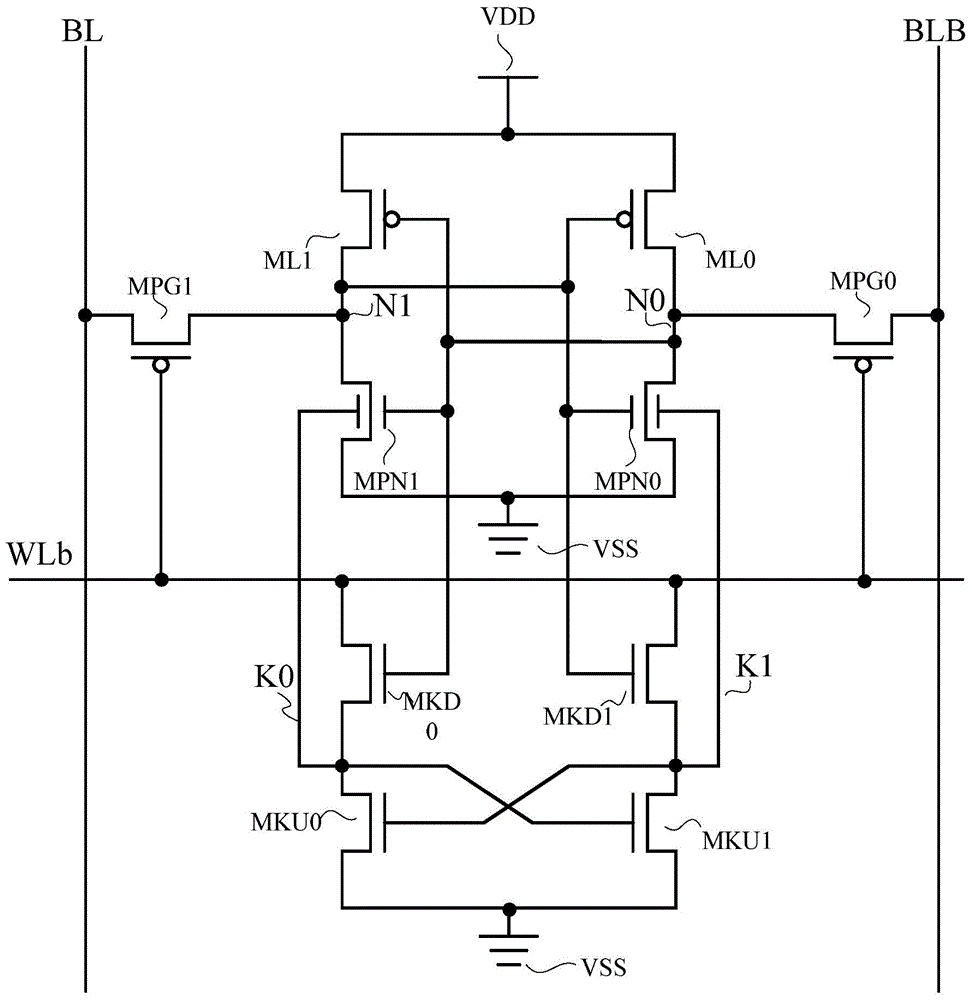

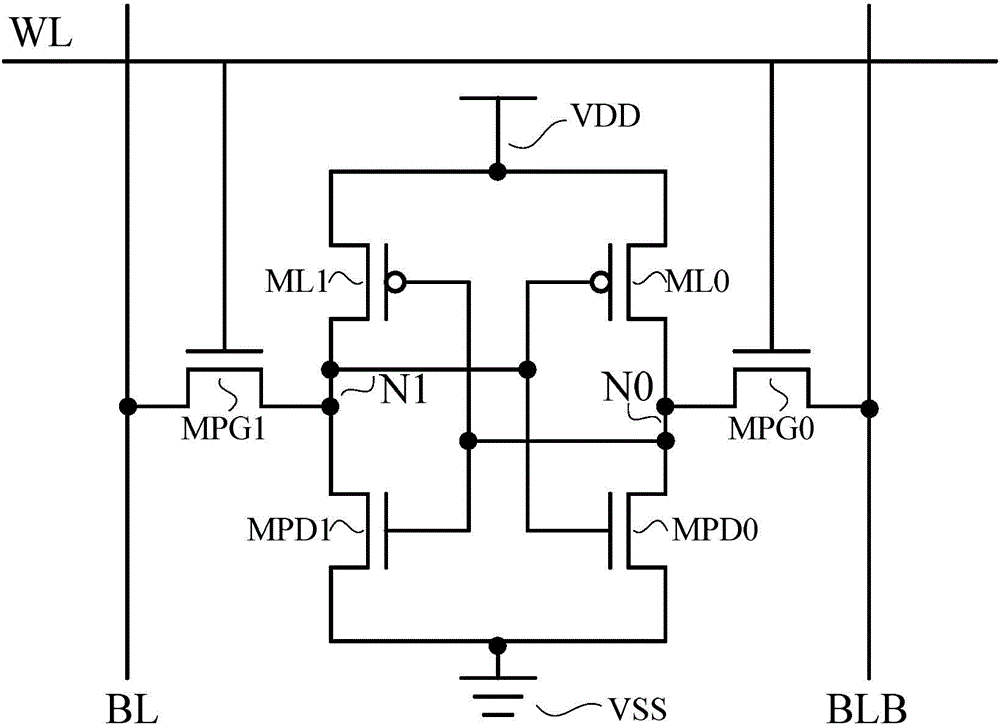

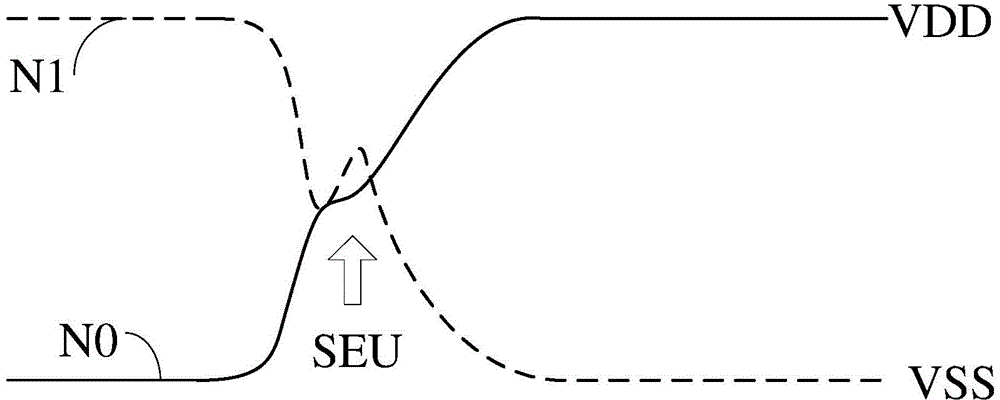

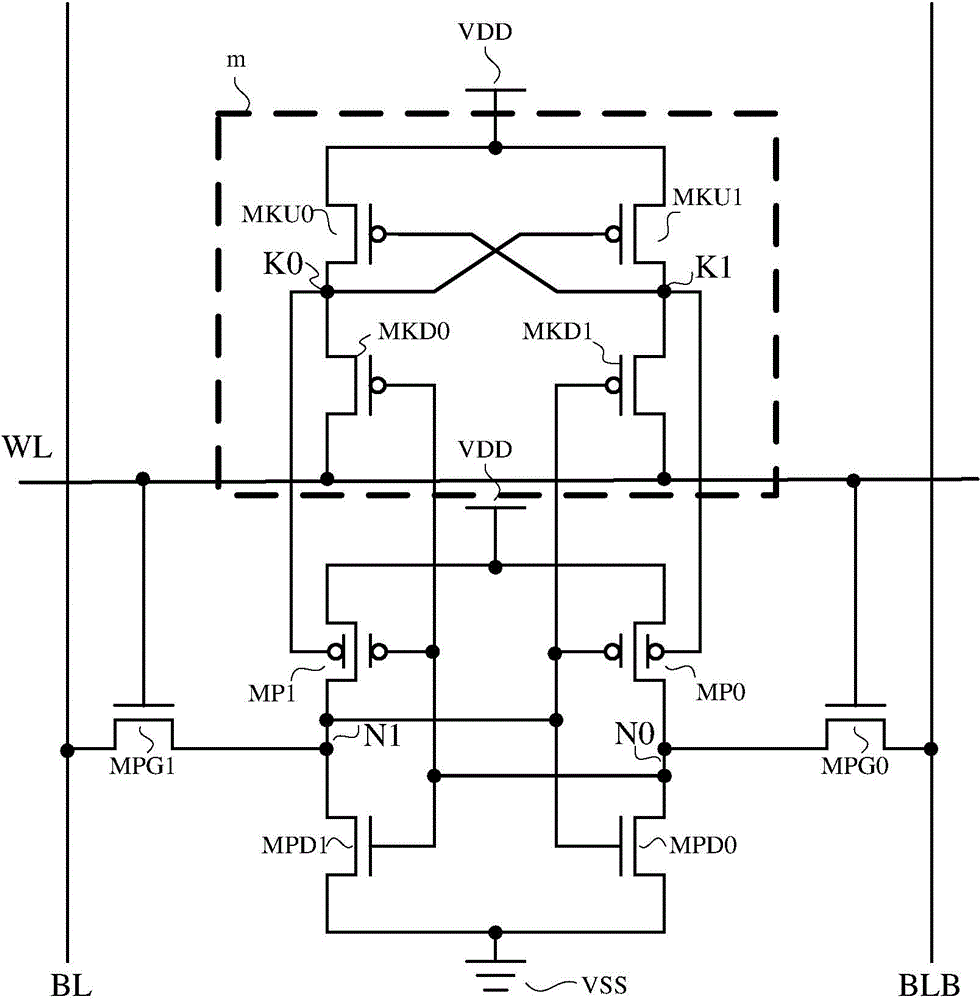

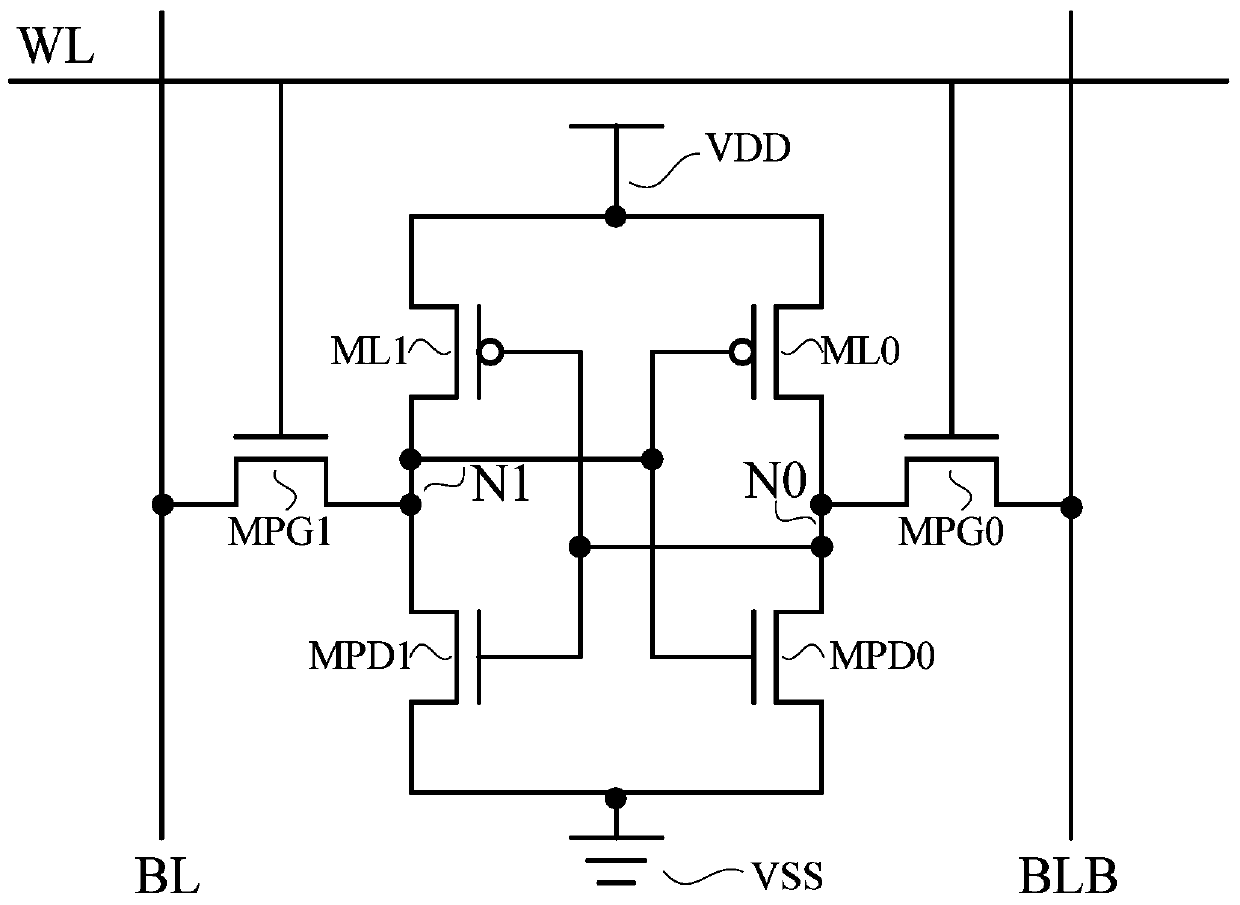

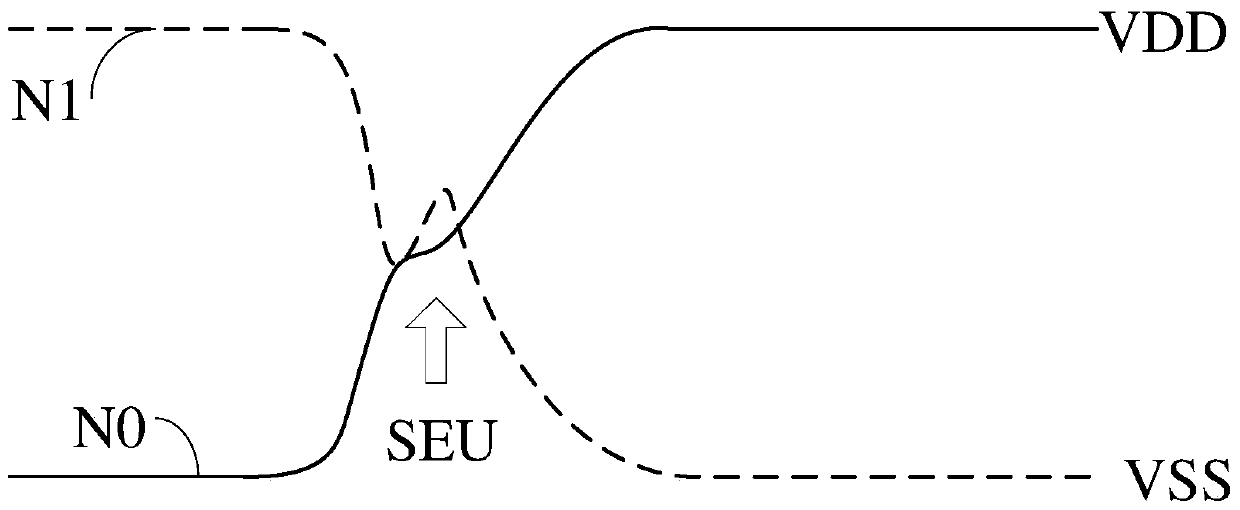

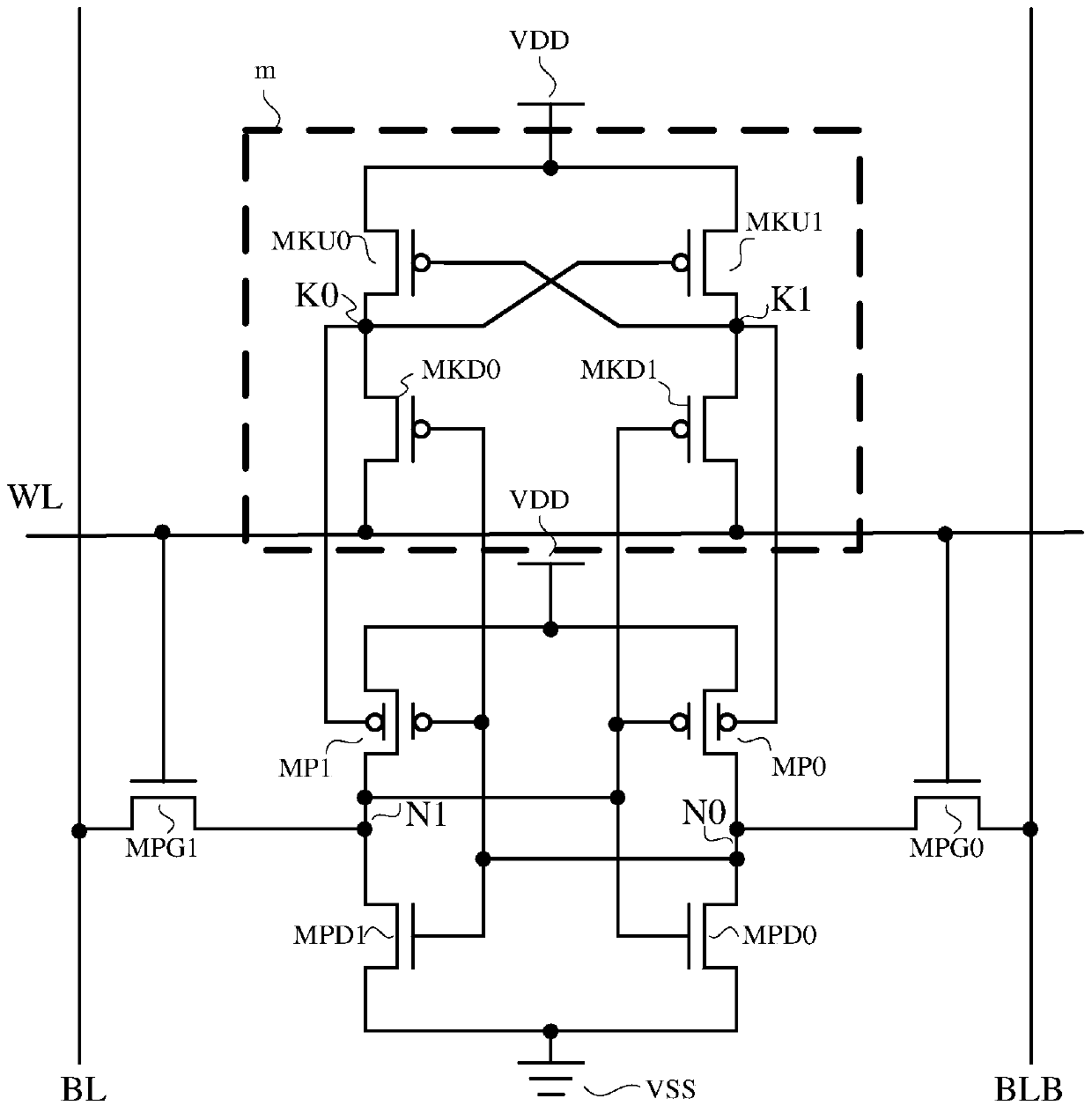

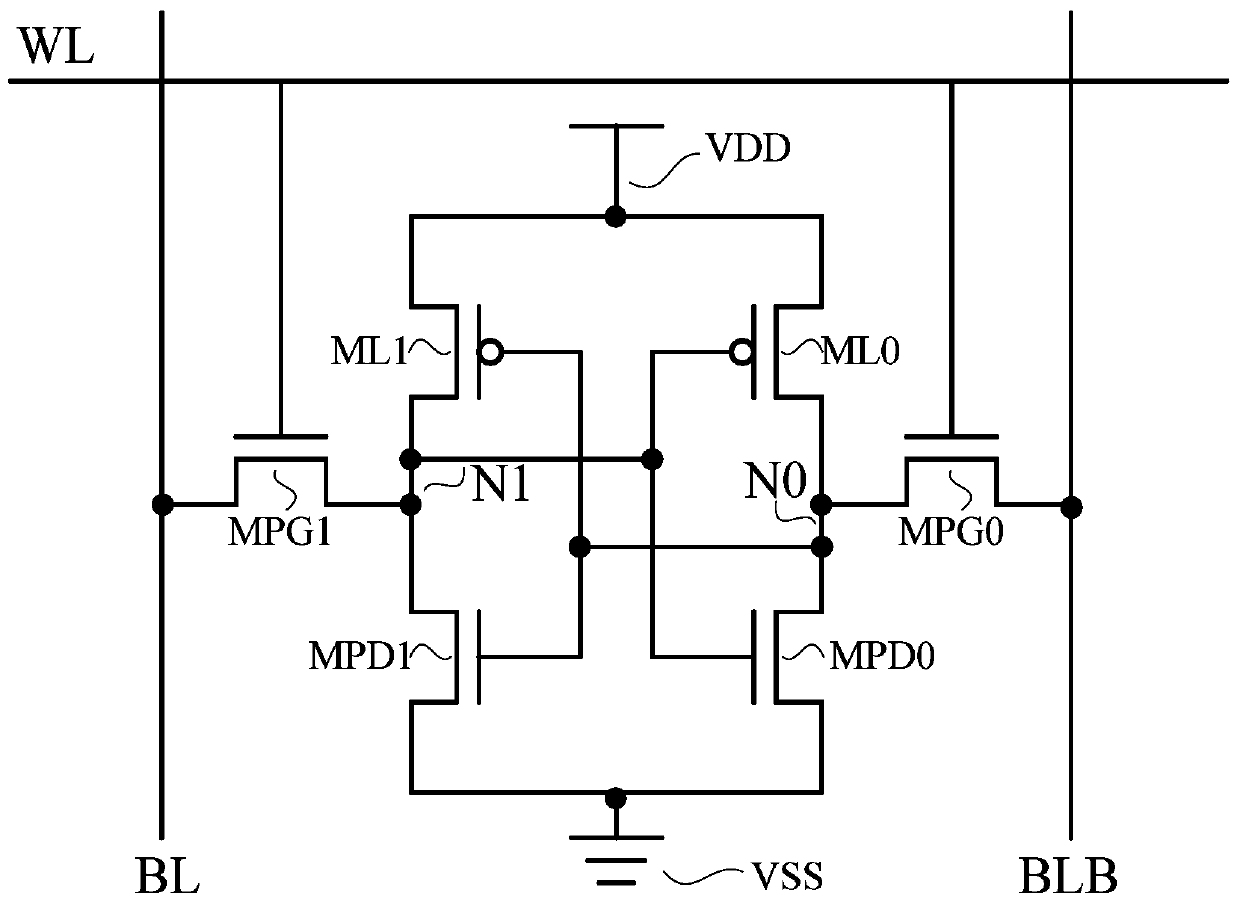

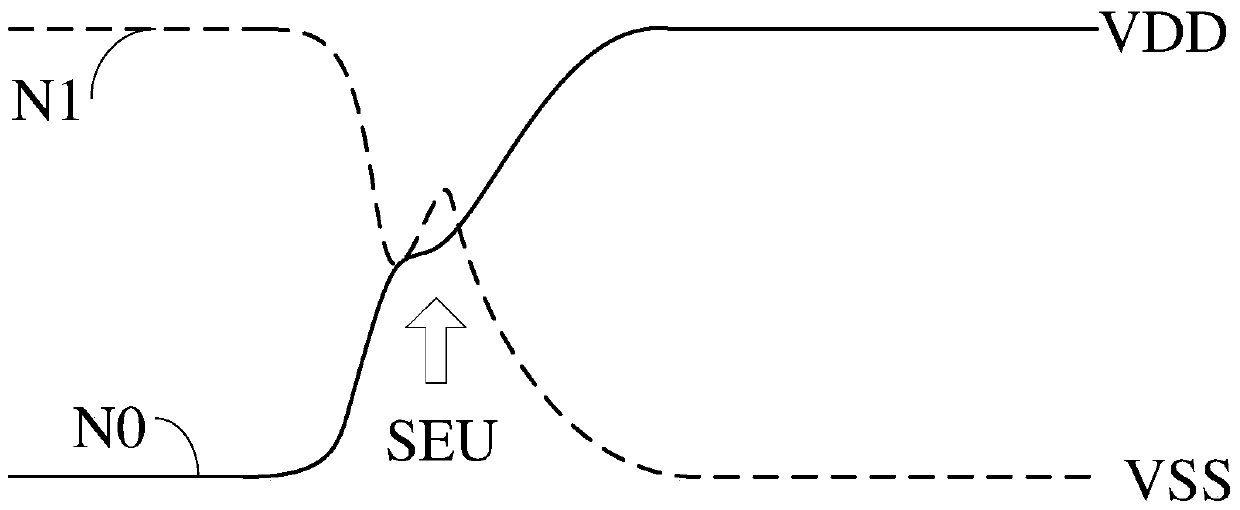

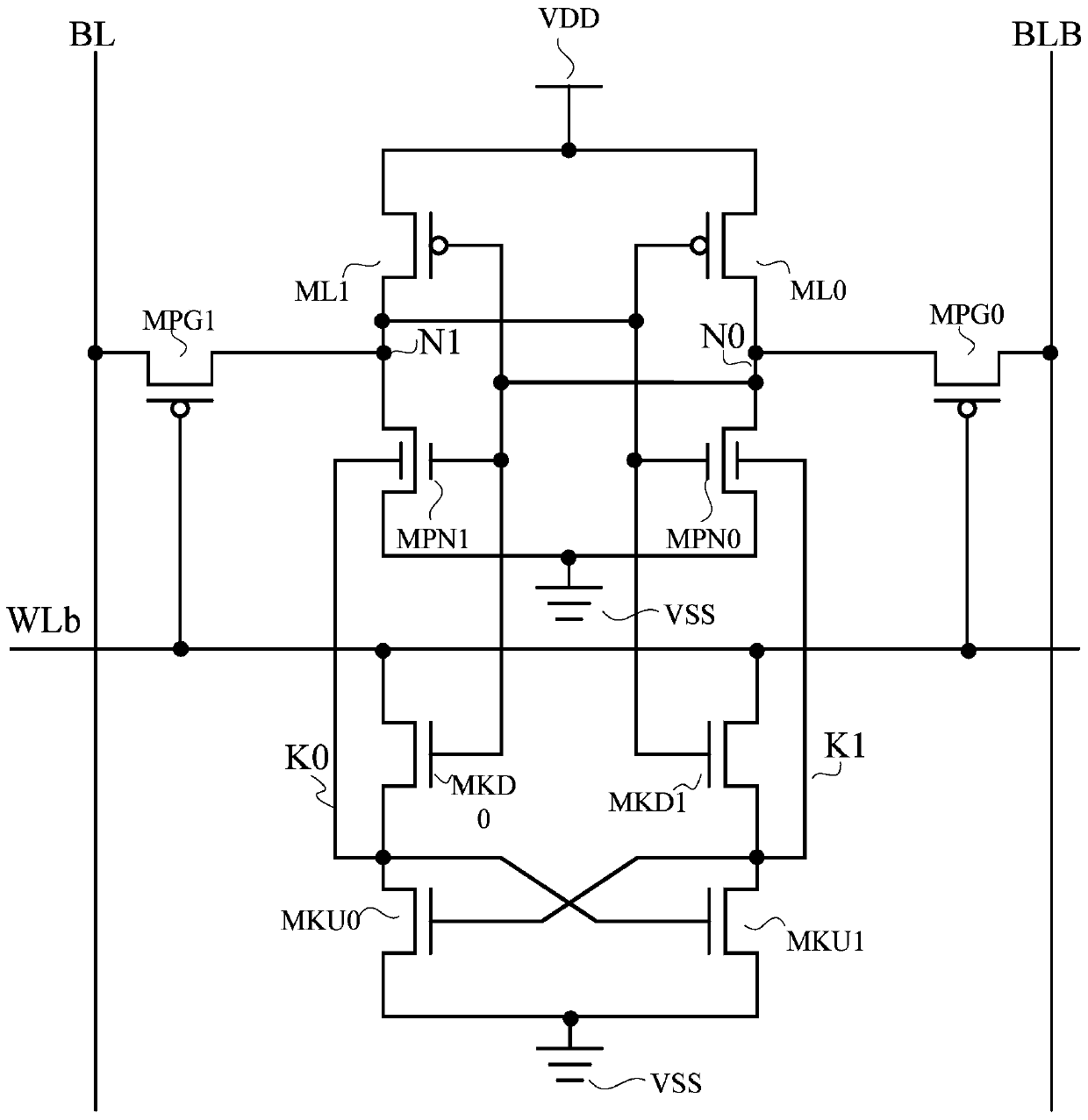

SRAM (Static random access memory) cell and memory array

ActiveCN105448324AAvoid single event inversion effectsHas radiation resistanceDigital storageRandom access memorySingle event upset

The present invention relates to a SRAM (Static random access memory) cell and a memory array. The SRAM memory cell includes a first PMOS (P-channel Metal Oxide Semiconductor) transistor, a second PMOS transistor, a first double-gate NMOS (N-channel metal oxide semiconductor) transistor, a second double-gate NMOS transistor, a first transmission transistor, a second transmission transistor and a compensation unit. The single event upset effect of the SRAM memory cell can be overcome.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

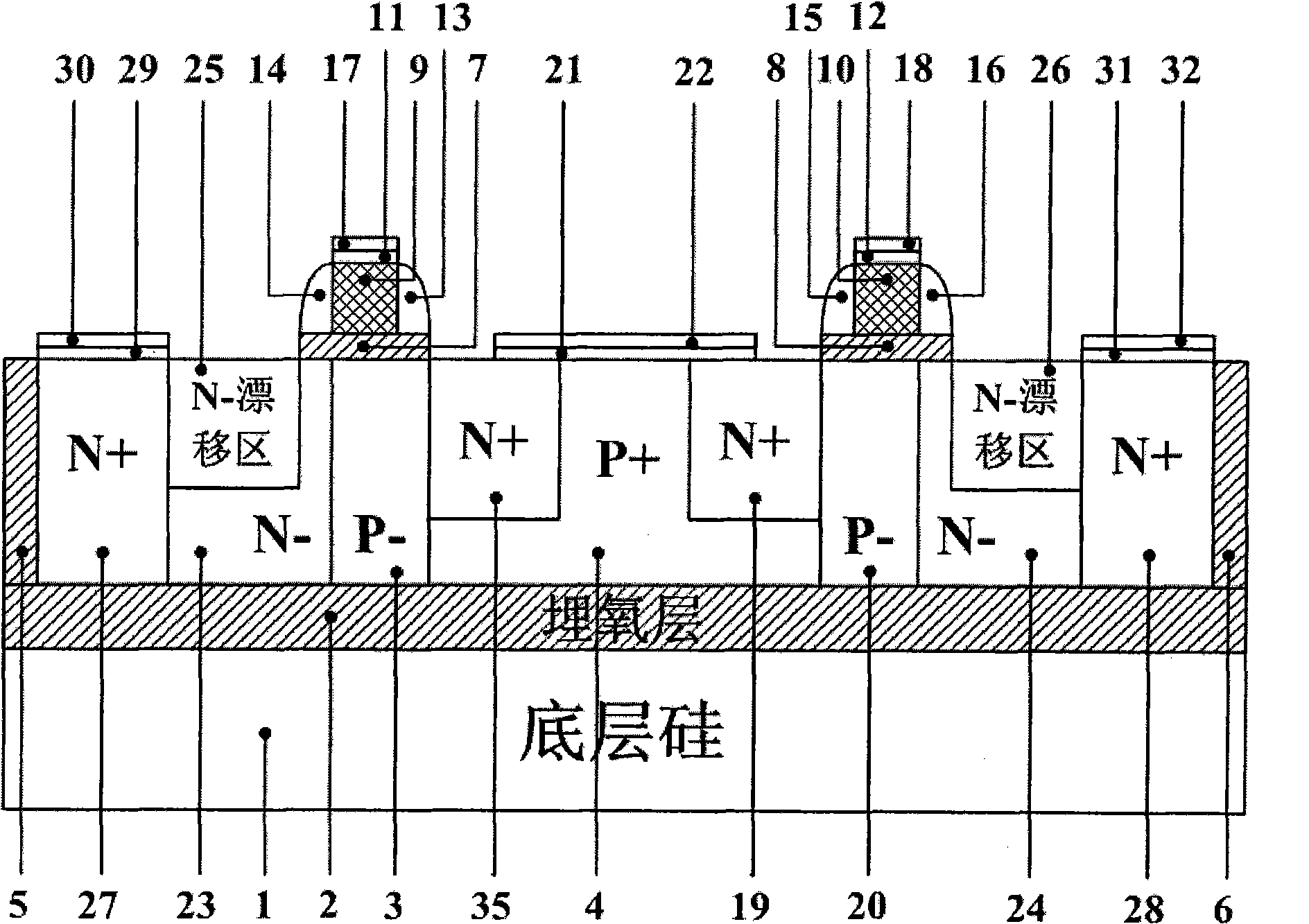

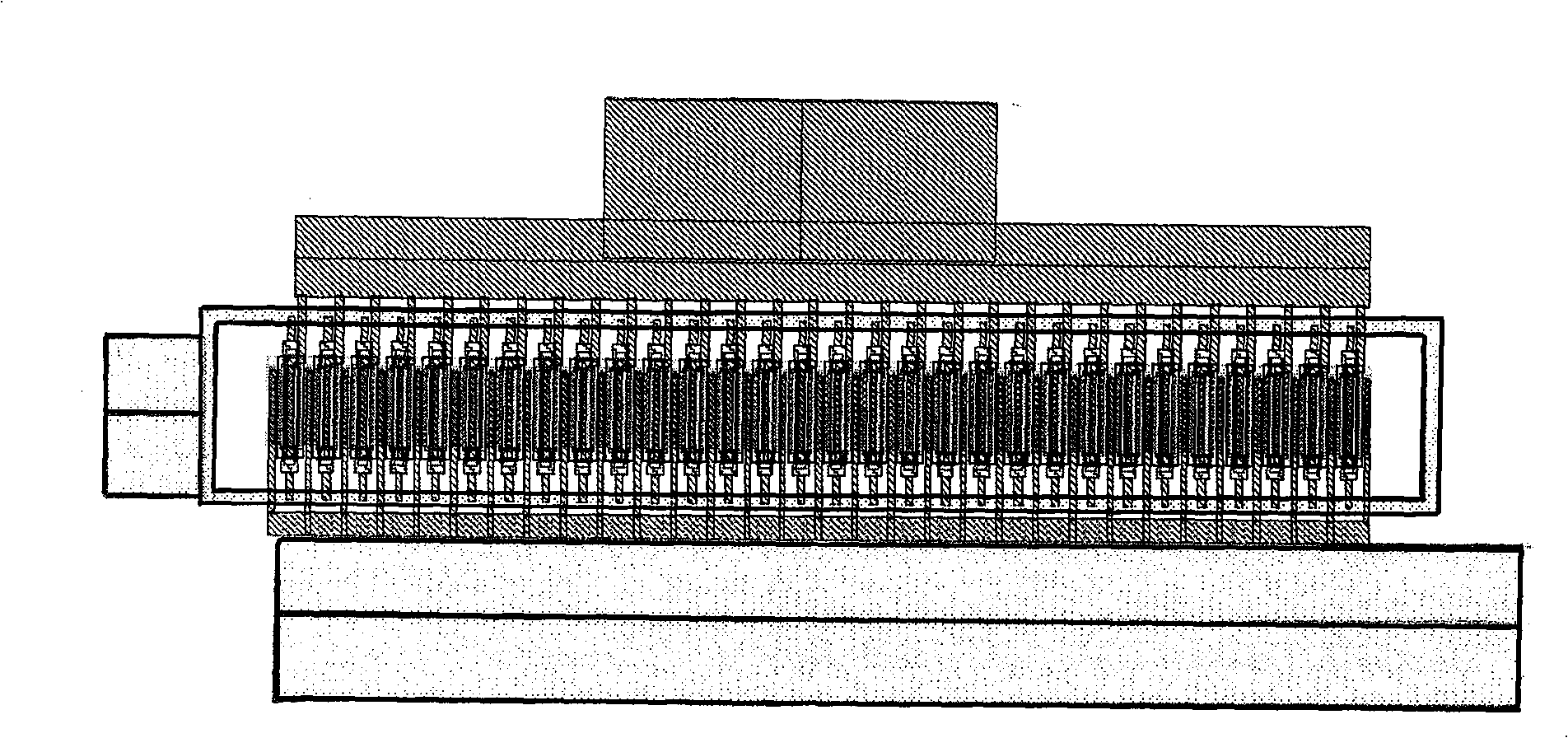

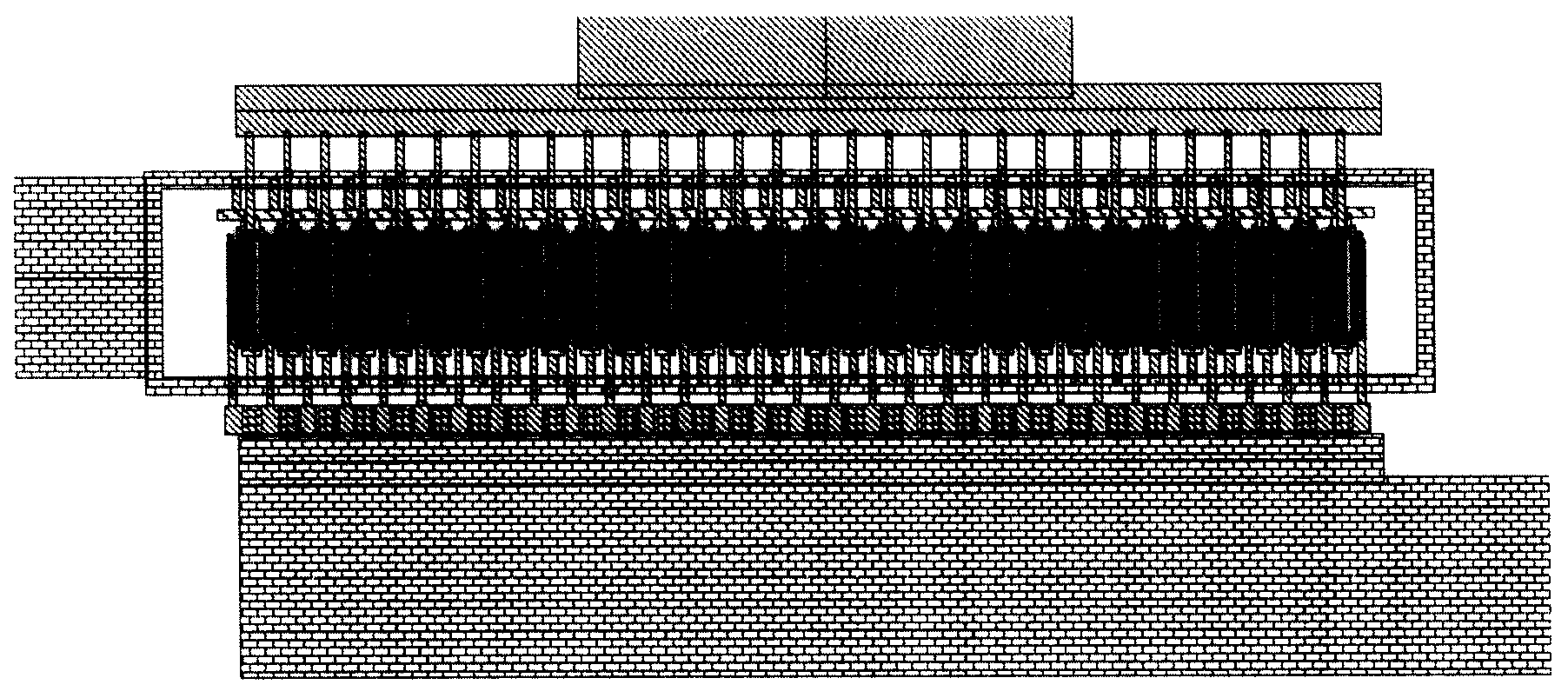

Radio frequency SOI LDMOS device with H-shaped gate

InactiveCN101515588AIncrease working frequencyImprove breakdown voltageTransistorSemiconductor/solid-state device detailsRadio frequencyPolysilicon gate

The invention relates to the field of radio frequency power devices, and discloses a radio frequency SOI LDMOS device with H-shaped gate. The device comprises bottom layer silicon, an embedding oxide layer, top layer silicon, a P region, an N region, an H-shaped gate oxide layer, an H-shaped polysilicon gate layer, an H-shaped gate poly-silicide layer, a gate electrode, a silicon nitride side wall, an N drift region, a drain region, a drain region silicide layer, a drain electrode, a source region, a body lead-out region, a source region silicide layer and a source electrode. The radio frequency LDMOS device is manufactured on an SOI substrate, and forms the body lead-out which is in short circuit with the source region by utilizing a heavily doped region in the same form as the P region; the source / body, a drain / body and the gate and the corresponding electrodes are interconnected by the silicide; and a plurality of gate bars are connected in parallel in the forked mode so as to improve the driving capability of the device. Simultaneously, the invention discloses a method for adjustment, back-gate injection, N region injection and N drift region injection, which is compatible with the CMOS process and a method for hiding the silicide in the N drift region, which is compatible with the CMOS process.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

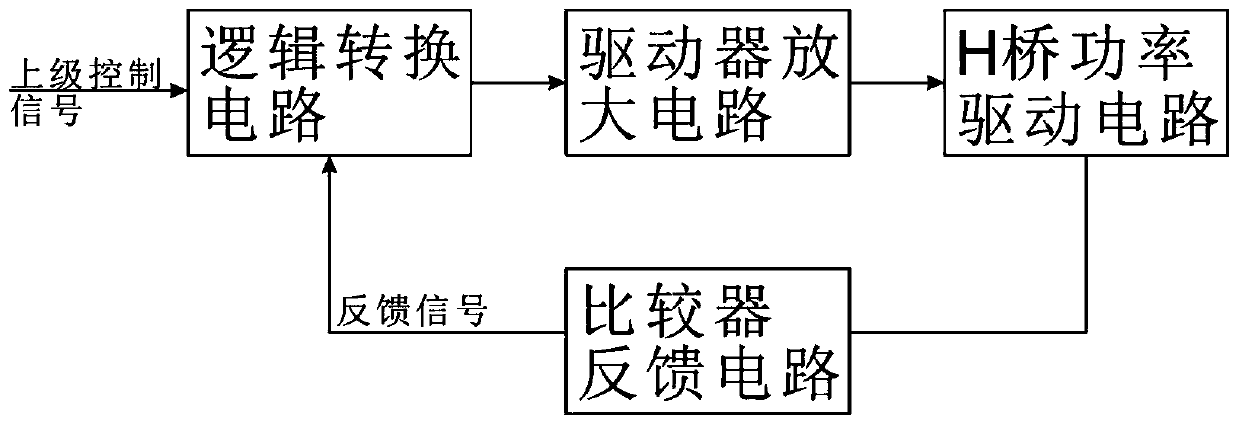

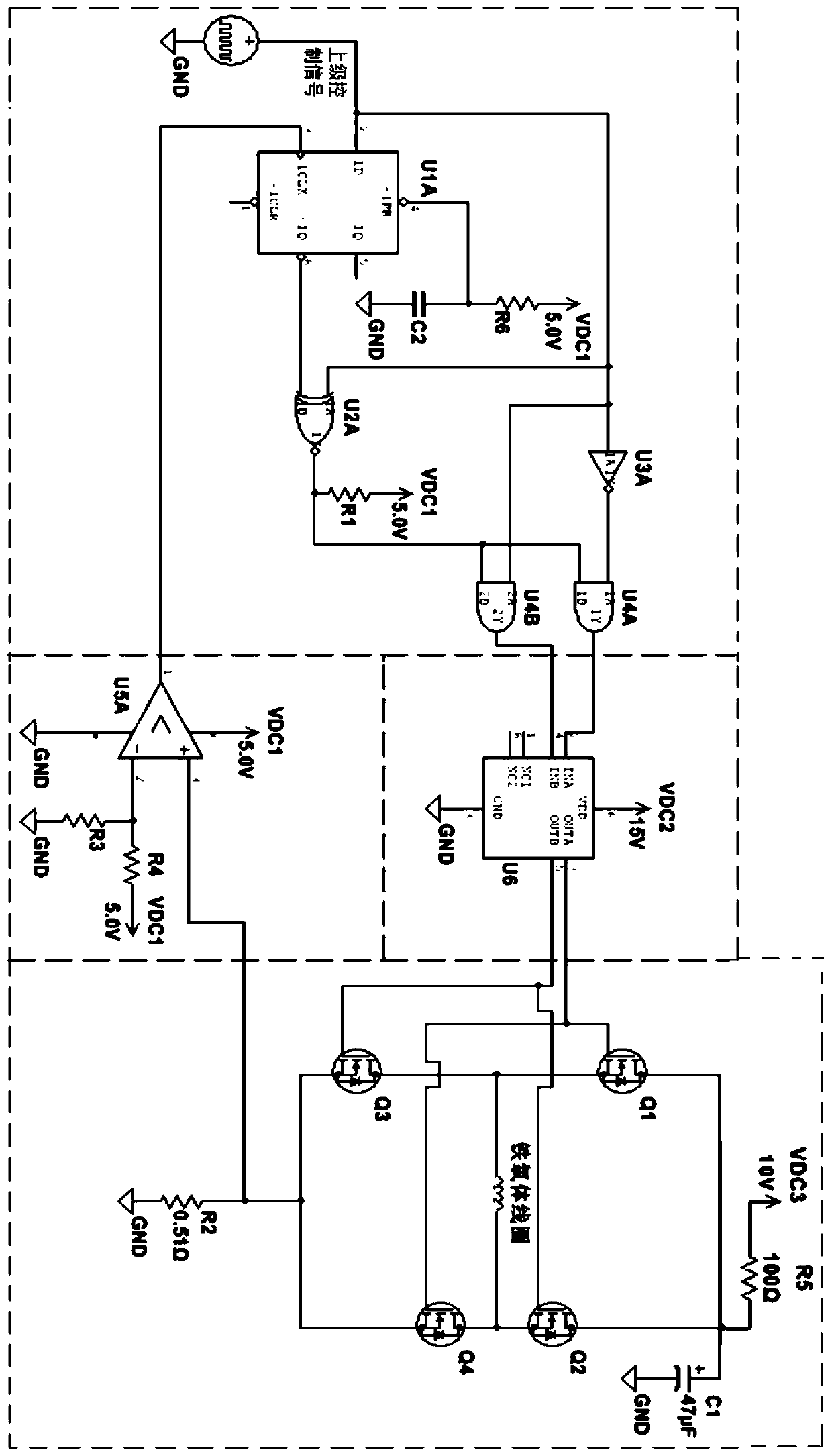

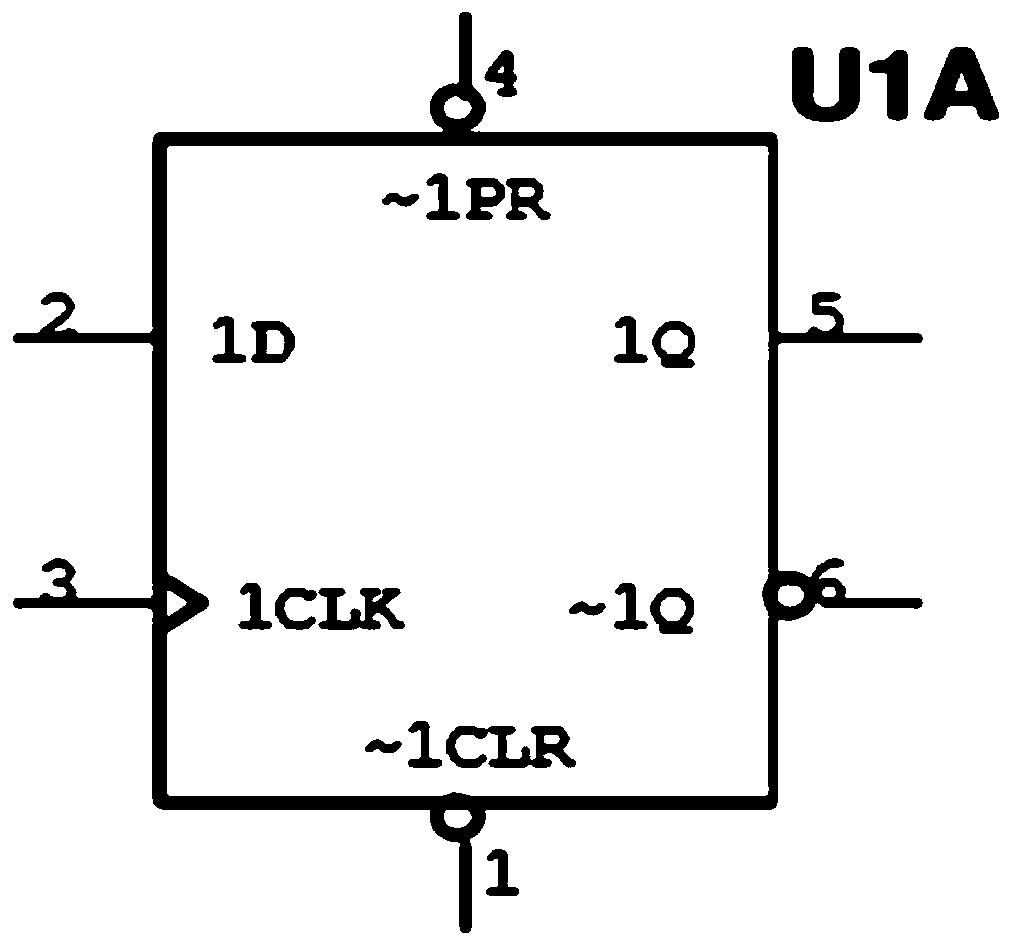

Ferrite switch driver with self-feedback latch switch-off function

PendingCN111342825AImprove driving efficiencyReduce switching lossesElectronic switchingFeedback circuitsHemt circuits

The invention discloses a ferrite switch driver with a self-feedback latch switch-off function. The ferrite switch driver comprises a logic conversion circuit, a driver amplifying circuit, an H-bridgepower driving circuit and a comparator feedback circuit. The logic conversion circuit receives a superior control signal and a feedback signal of the comparator feedback circuit, processes the signals, inputs the signals to the driver amplification circuit for amplification, and then inputs the signals to the H-bridge power drive circuit to drive the ferrite coil. Meanwhile, the comparator feedback circuit samples the current of the ferrite coil, and when the current reaches a preset value, the comparator feedback circuit sends a positive pulse to the logic conversion circuit to turn off theH-bridge power driving circuit. Under the condition that a microcontroller or an FPGA or a CPLD is not used, the ferrite coil can be effectively driven to the preset current, and automatic feedback and latch turn-off can be achieved. Compared with a ferrite switch driver using a microcontroller or an FPGA or a CPLD, the ferrite switch driver has the advantages of being simple in structure, lower in cost, higher in speed and higher in reliability.

Owner:中国电子科技集团公司第九研究所

Radiation-resistant fabric preparation process

InactiveCN109554928AHas radiation resistanceHas a blocking effectProtective fabricsBiochemical treatment with enzymes/microorganismsPolyesterRadiation resistant

The invention discloses a radiation-resistant fabric preparation process, and relates to the technical field of fabric preparation. The radiation-resistant fabric preparation process includes the following steps: step I. blending metal wires, polyester fibers and flax fibers into warp yarns and weft yarns; step II. weaving the blended warp yarns and the weft yarns into a main fabric through warp and weft. The process has the effect of adding radiation resistance to the fabric.

Owner:绍兴兆丰绒织品有限公司

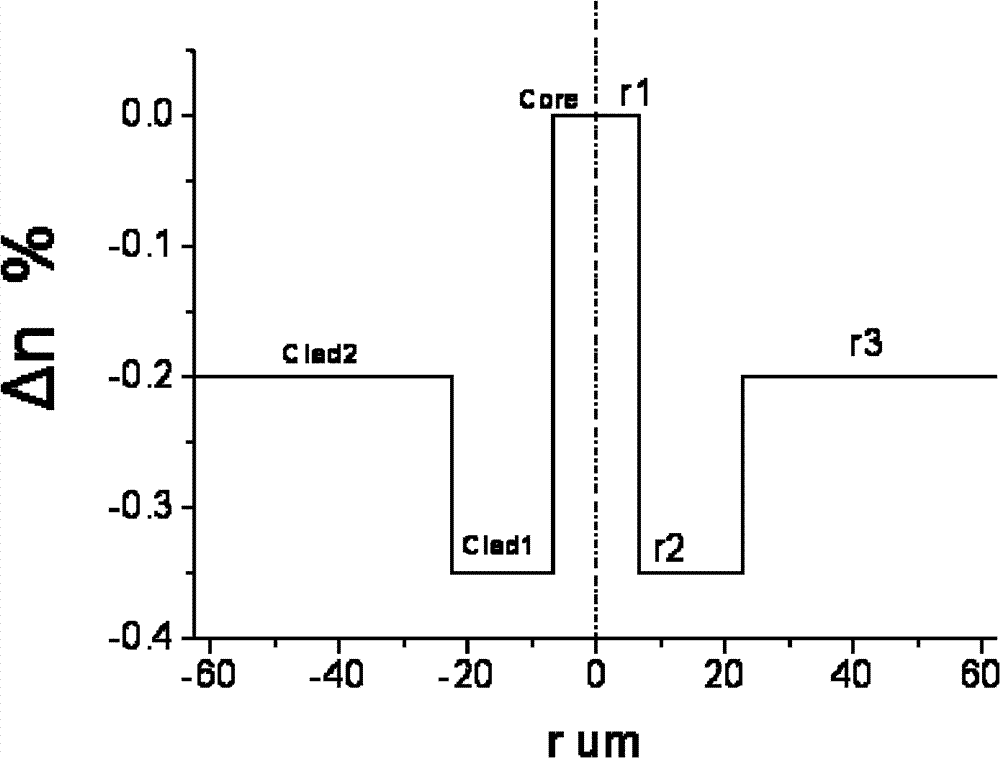

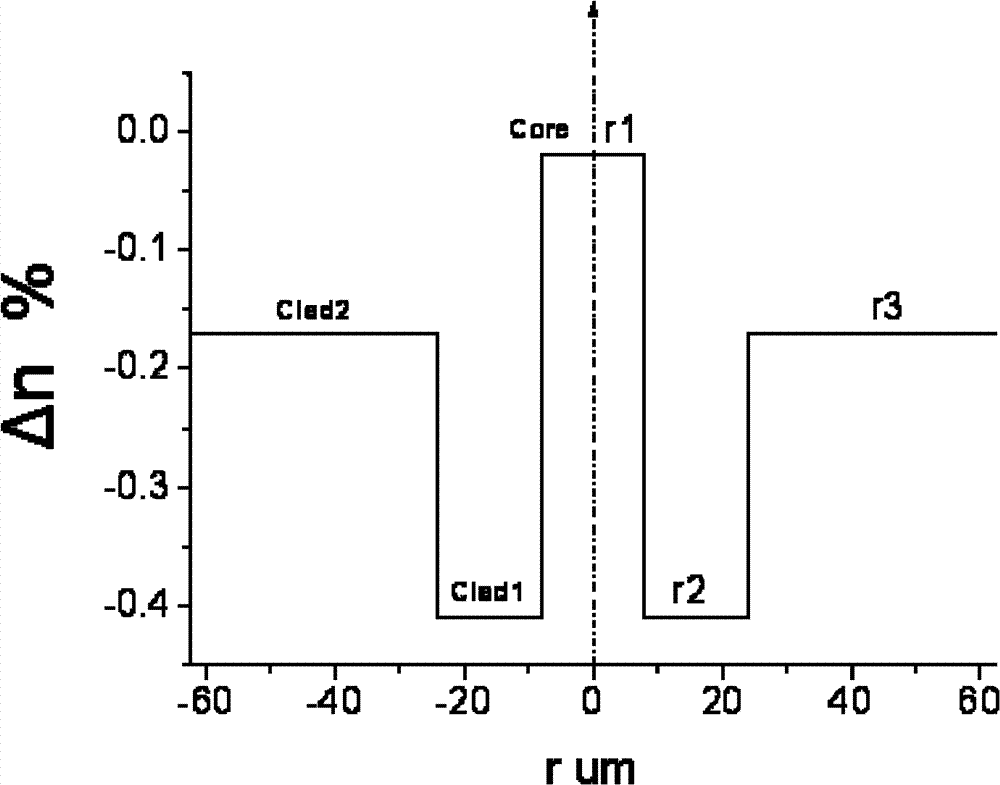

Radiation-resistant high-performance silica fiber and preparation method thereof

ActiveCN102126825BImprove radiation resistanceStrong radiation resistanceGlass shaping apparatusGlass productionCommunications systemRadiation resistant

The invention relates to a radiation-resistant high-performance silica fiber and a preparation method thereof. The radiation-resistant high-performance silica fiber provided by the invention is composed of a silica glass material based fiber core, an inner cladding and an outer cladding, wherein the fiber core contains 0-2000ppm of hydroxyl group and 0-1000ppm of fluorine, the inner cladding is doped with 10000-20000ppm of fluorine, and the outer cladding is silica glass containing 1000-6000ppm of fluorine. The radiation-resistant high-performance silica fiber provided by the invention can beprepared by adopting a combined process method of VAD (vapour axial deposition) and MCVD (modified chemical vapour deposition) or PCVD (plasma chemical vapour deposition), namely a core layer is prepared by adopting VAD firstly, and different deposition and vitrifaction technological conditions are controlled to obtain core rods with different hydroxyl group and fluorine contents, the inner cladding doped with fluorine is prepared by adopting an MCVD or PCVD process, a sleeve containing a low-refractive index inner cladding is obtained, and then the core rods and the obtained sleeve are fusedinto a prefabricated rod or combined into a prefabricated rod assembly, and finally direct wire drawing is carried out to obtain the silica fiber. The silica fiber can be used for information transmission of a communication system, especially can be used as both a radiation-resistant optical fiber to guarantee long-distance communication and an energy transmitting optical fiber for transmitting ultraviolet light under the radiation environment.

Owner:HANGZHOU FUTONG COMM TECH CO LTD +1

SRAM storage unit and SRAM storage array

The invention relates to an SRAM (Static Random Access Memory) storage unit and an SRAM storage array, wherein the SRAM storage unit comprises a first double-grid PMOS (P-channel Metal Oxide Semiconductor) transistor, a second double-grid PMOS transistor, a first NMOS (N-channel Metal Oxide Semiconductor) transistor, a second NMOS transistor, a first transmission transistor, a second transmission transistor and a compensation unit. The SRAM storage unit and the SRAM storage array have the advantage that the event upset effect of the SRAM storage unit can be overcome.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

Processing technology of vacuum forming box of new energy automobile

ActiveCN109466095ASimple processing technologyHas radiation resistanceHollow articlesSurface finishingEngineering

The invention discloses a processing technology of a vacuum forming box of a new energy automobile. The processing technology comprises the following steps: (1) manufacturing a mold; (2) manufacturingmaterials; (3) performing vacuum forming; and (4) performing surface treatment. The processed vacuum forming box is simple in processing technology, adopts the improved PVC resin material, is suitable for new energy automobiles and has certain radiation resistance, meanwhile, the protective liquid is sprayed on the surface of the vacuum forming box, so that the vacuum forming box has certain radiation resistance and scratch resistance, and is suitable for new energy automobiles.

Owner:苏州市新胜佳科技有限公司

Waterproof and rainproof material and its prepn process

The present invention relates to building material, and is especially one kind of waterproof and rainproof material and its preparation process. The waterproof and rainproof material consists of fine steel powder and water solution of sodium chloride in 20 wt% over concentration. Its preparation process includes crushing steel in an electric grinder or special grinding machine and packing the steel powder in sealing bag; and dissolving sodium chloride in water to form water solution of sodium chloride in 20 wt% over concentration. When it is used, the steel powder is first sprayed into crack in building and the water solution of sodium chloride is then poured into the crack. The present invention has low cost and no environmental pollution.

Owner:马孔亮

Radio frequency laterally diffused metal oxide semiconductor (LDMOS) device based on silicon on insulator (SOI) and method for injecting device

ActiveCN102054845BIncrease working frequencyImprove breakdown voltageSemiconductor/solid-state device detailsSolid-state devicesRadio frequencyPolycrystalline silicon carbide

The invention discloses a radio frequency silicon on insulator(SOI) laterally diffused metal oxide semiconductor (LDMOS) device provided with a low potential barrier body lead-out, which comprises a bottom layer silicon, a concealed oxide layer, a top layer silicon, a P-region, a N-region, a gate oxide layer, a polysilicon gate layer, a gate polycrystalline silicon carbide layer, a gate electrode, a side wall, a N-drift region, a drain region, a drain region silicate layer, a leakage electrode, a source region, a low potential barrier body lead-out region, a body region, a source region silicide layer, and a source electrode. In the invention, the radio frequency LDMOS device is manufactured on an SOI substrate, and a low potential barrier body lead-out is in a short circuit with the source region is formed by utilizing a heavily doped region homotypic with the P- region; the source / body, leakage / body as well as a gate is interconnected with each electrode by utilizing a silicide; a plurality of grate bars are in interdigital type parallel connection so as to enlarge the driving power of the device; and the invention provides a method for rectifying, back gate injection, N-regioninjection as well as N-drift region injection compatible with a complementary metal-oxide-semiconductor (CMOS) technology, as well as a N-drift region silicide conceal method compatible with the CMOStechnology.

Owner:BEIJING ZHONGKE XINWEITE SCI & TECH DEV

A manufacturing method of a 50A high-current fast-recovery diode

ActiveCN104269356BReduce reverse leakage currentImprove stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesDiffusion methodsSemiconductor materials

The invention discloses a method for manufacturing a 50A high-current fast recovery diode. The method for manufacturing the 50A high-current fast recovery diode comprises the steps that an N type semiconductor silicon material is provided to serve as a semiconductor substrate; the N type semiconductor substrate is doped with N+ type impurities; the N+ type impurity layer on one side of the semiconductor substrate is removed; an exposed N-type semiconductor material is doped with dual P+ type impurities; heavy metal platinum doping is conducted according to the high-temperature diffusion method; primary mask photoetching is conducted; glass powder is arranged in a passivation groove through knife coating, high-temperature sinter molding is conducted, and then PN junction glass passivation is completed; multiple metallization layers are manufactured on the two sides of a silicon wafer according to the vacuum sputtering method; secondary mask photoetching is conducted; the silicon wafer is divided into independent dies; a chip and a lead component are bonded together; the chip, the lead component and a diode holder are bonded together in a metallurgical mode through sintering; a diode cap and the diode holder are welded together in a sealed mode through percussion welding. According to the method for manufacturing the 50A high-current fast recovery diode, the manufacturing process based on the method is less influenced by the environment, the technology is mature, the stability and the repeatability are high, and the method can be widely used for volume production of high-current fast recovery diodes.

Owner:西安卫光科技有限公司

sram storage unit and storage array

ActiveCN105225690BAvoid single event inversion effectsHas radiation resistanceDigital storageComputer scienceStorage cell

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

sram storage unit and storage array

ActiveCN105448324BHas radiation resistanceSlow down the voltage leakageDigital storageEngineeringSingle event upset

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

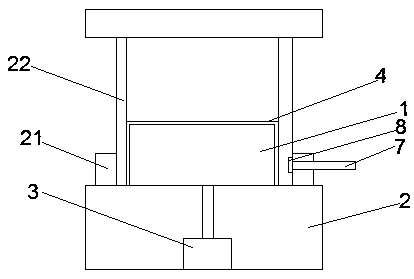

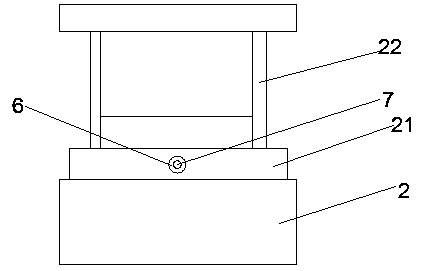

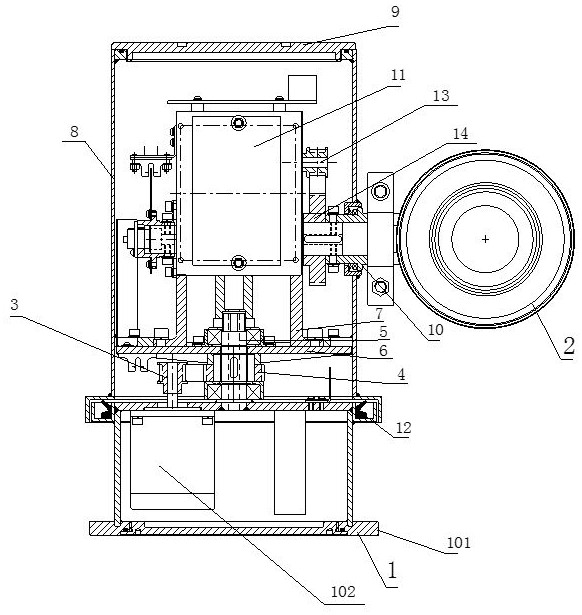

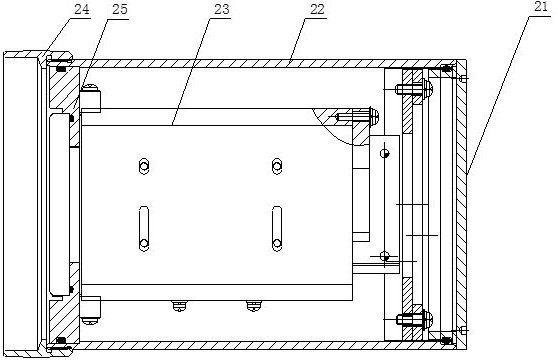

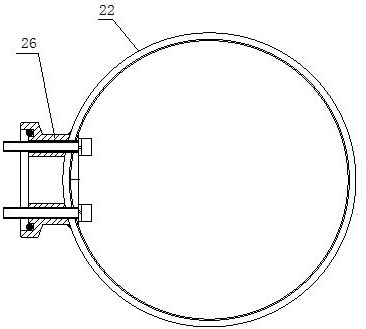

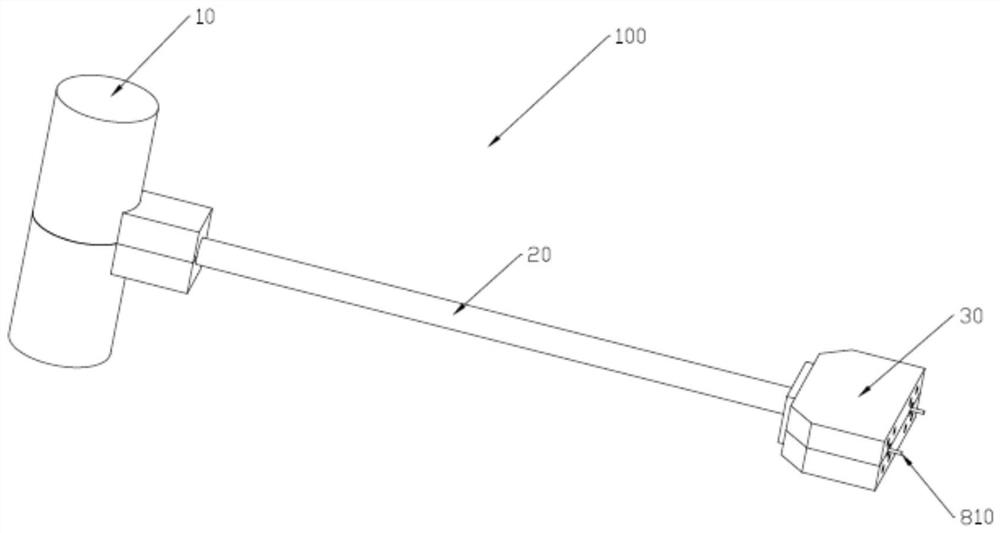

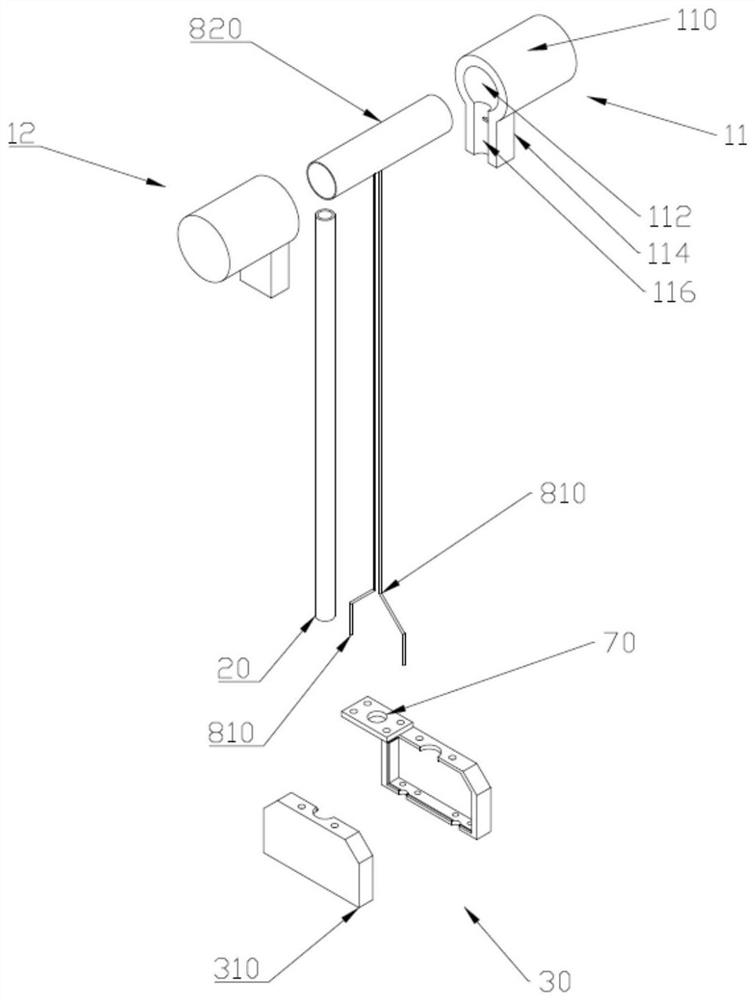

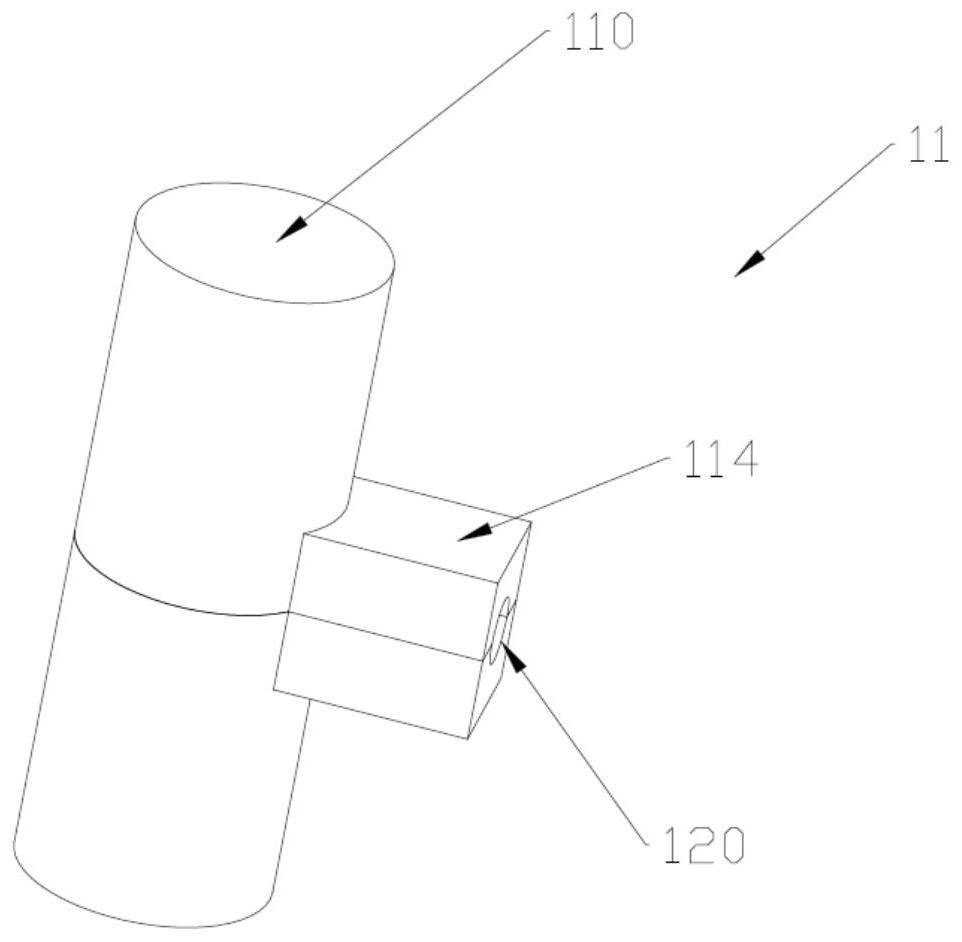

A three-dimensional positioning synchronous tracking camera system and control method

ActiveCN114339057BVariable rotation speedHigh positioning accuracyTelevision system detailsColor television detailsComputer hardware3d localization

Owner:天芯宜智能网络科技(天津)有限公司

A metal hydroxide-boron nitride hybrid filler/rubber-combined nuclear power cable insulating material and its preparation method

ActiveCN110041607BHas radiation resistanceImprove radiation resistanceNuclear powerMethacrylate methyl

The invention discloses a metal hydroxide-boron nitride hybrid filler / rubber-combined cable insulating material for nuclear power plants and a preparation method thereof. The metal hydroxide grafted with methyl methacrylate and ionic liquid copolymer is loaded On the surface of boron nitride, it is blended with EVA / ethylene propylene rubber, crosslinking agent, compatibilizer, anti-aging agent, etc. in an appropriate proportion. Based on the modified filler, the invention constructs a radiation-proof and compatibilizing hetero At the same time, the radiation resistance of the ionic liquid is used to improve the radiation resistance of the material, and a nuclear power cable insulation material with flame retardancy, radiation resistance, good electrical performance, halogen-free, low smoke, and excellent mechanical properties is produced.

Owner:HEFEI UNIV OF TECH

Radio frequency SOI LDMOS device with close body contact

InactiveCN101515586BIncrease working frequencyImprove breakdown voltageTransistorSemiconductor/solid-state device detailsBody contactRadio frequency

The invention relates to the field of a radio frequency power device, and discloses a radio frequency SOI LDMOS device with close body contact. The device comprises bottom layer silicon, an embedding oxidation layer, top layer silicon, a P<-> region an N<-> region, a gate oxidation layer, a polysilicon gate layer, a gate poly-silicide layer, a gate electrode, a silicon nitride side wall, an N<-> drift region, a drain region, a drain region silicide layer, a drain electrode, a source region, a body contact region, a body region, a source region silicide layer and a source electrode. The radio frequency LDMOS device is manufactured on an SOI substrate, and forms the close body contact which is in short circuit with the source region by utilizing a heavily doped region in the same form as the P<-> region; the source / body, a drain / body and the gate and the electrodes are interconnected by the silicide; a plurality of gate bars are connected in parallel in the forked mode so as to improve the driving capability of the device; a method for adjustment, back-gate injection, N<-> region injection and N<-> drift region injection, which is compatible with the CMOS process, is designed; and amethod for hiding the silicide in the N<-> drift region, which is compatible with the CMOS process, is designed.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Radio frequency SOI LDMOS device with H-shaped gate

InactiveCN101515588BIncrease working frequencyImprove breakdown voltageTransistorSemiconductor/solid-state device detailsRadio frequencyPolysilicon gate

The invention relates to the field of radio frequency power devices, and discloses a radio frequency SOI LDMOS device with H-shaped gate. The device comprises bottom layer silicon, an embedding oxide layer, top layer silicon, a P<-> region, an N<-> region, an H-shaped gate oxide layer, an H-shaped polysilicon gate layer, an H-shaped gate poly-silicide layer, a gate electrode, a silicon nitride side wall, an N<-> drift region, a drain region, a drain region silicide layer, a drain electrode, a source region, a body lead-out region, a source region silicide layer and a source electrode. The radio frequency LDMOS device is manufactured on an SOI substrate, and forms the body lead-out which is in short circuit with the source region by utilizing a heavily doped region in the same form as the P<-> region; the source / body, a drain / body and the gate and the corresponding electrodes are interconnected by the silicide; and a plurality of gate bars are connected in parallel in the forked mode so as to improve the driving capability of the device. Simultaneously, the invention discloses a method for adjustment, back-gate injection, N<-> region injection and N<-> drift region injection, whichis compatible with the CMOS process and a method for hiding the silicide in the N<-> drift region, which is compatible with the CMOS process.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

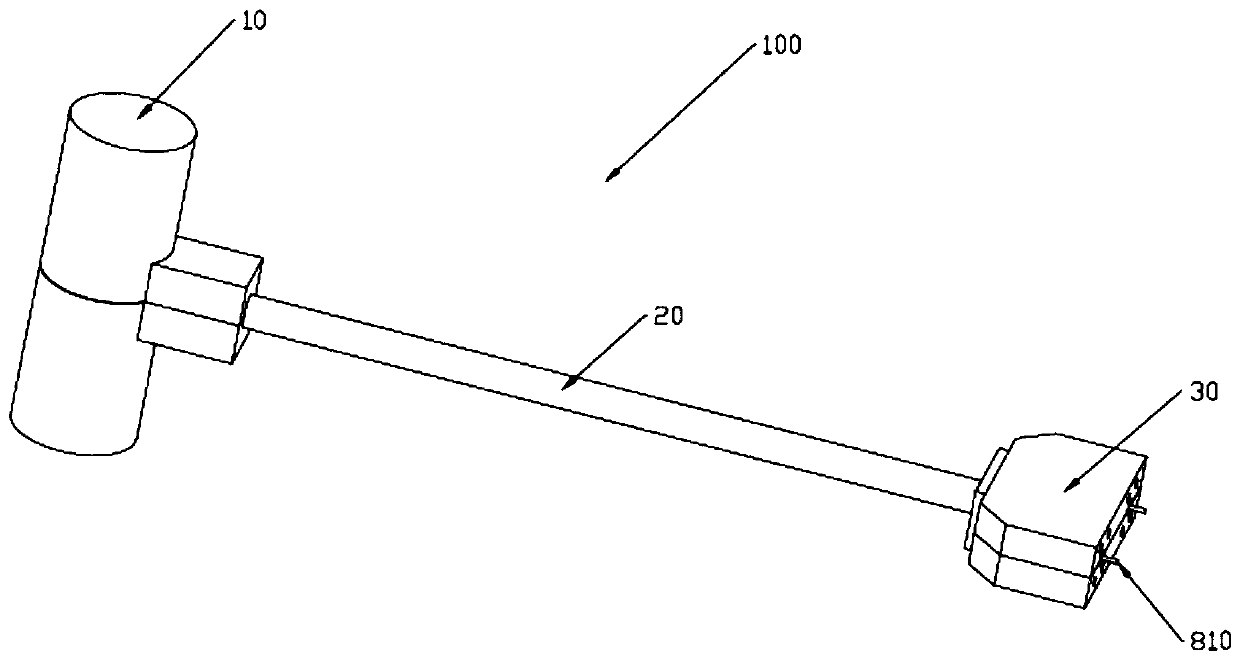

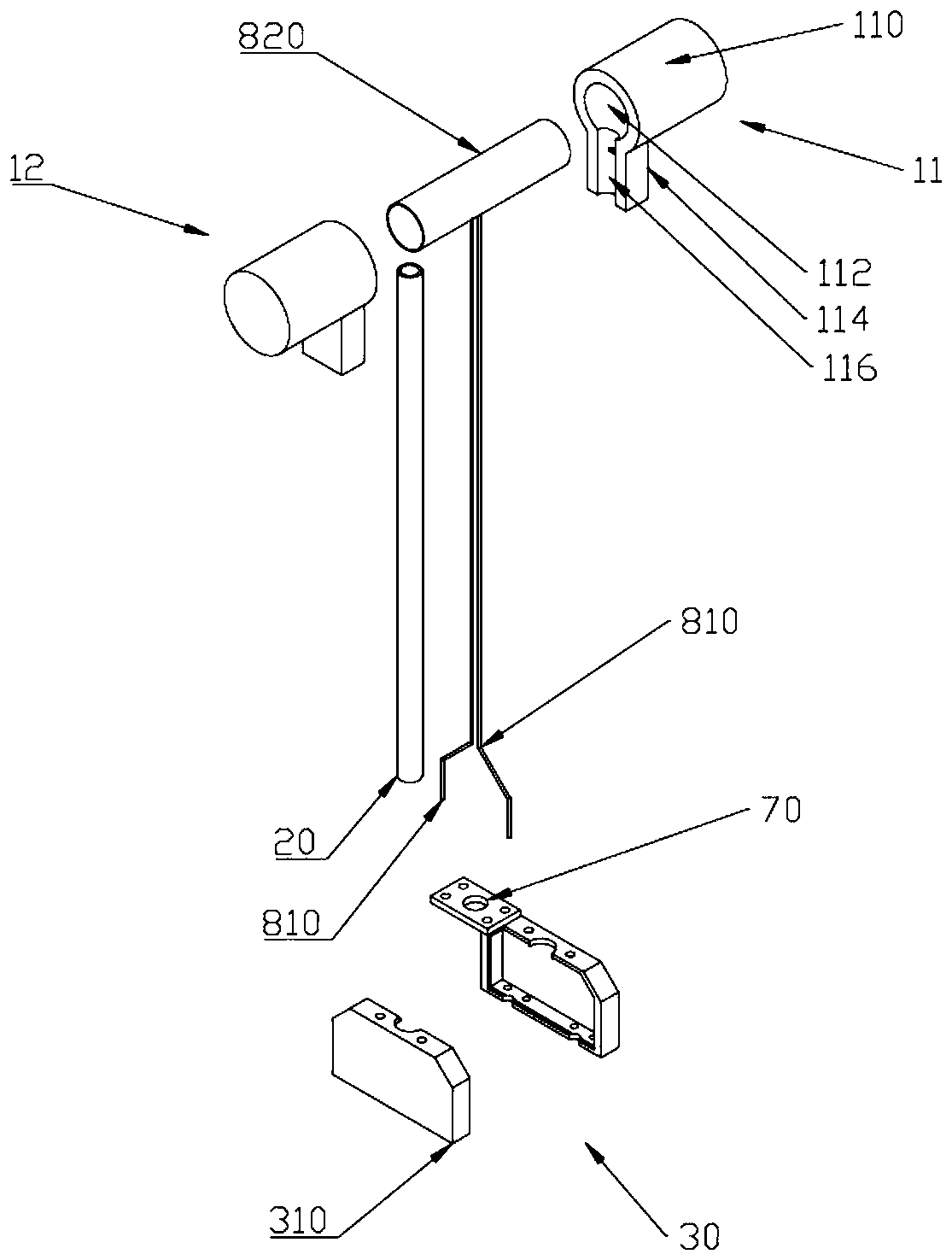

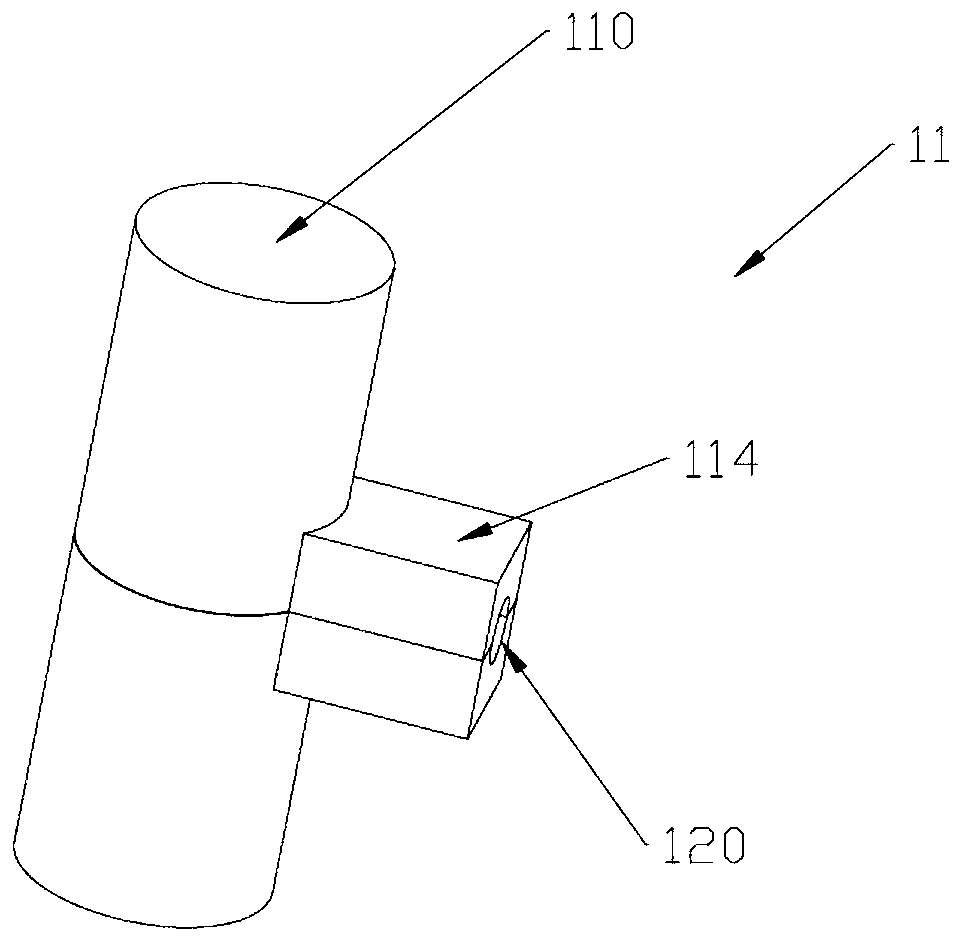

A multi-gap transient magnetic field sensor

ActiveCN110531285BAvoid serious distractionsHigh bandwidthMeasurement instrument housingMagnitude/direction of magnetic fieldsCoaxial cableHigh bandwidth

The invention discloses a multi-gap transient magnetic field sensor. The sensor comprises a shell and a cable assembly arranged in the shell. The cable assembly comprises a closed annular coil definedby a flexible circuit board and a coaxial cable. The closed annular coil is arranged at one end of the shell, and the coaxial cable is electrically connected with the closed annular coil and is led out of the other end of the shell. The invention relates to the field of magnetic field sensors and provides a multi-gap transient magnetic field sensor, the problem of electric field signal interference can be overcome, the influence of an electric field on magnetic field measurement can be effectively reduced, meanwhile, a relatively high bandwidth can be obtained, and the sensor has a certain anti-radiation effect.

Owner:TSINGHUA UNIV

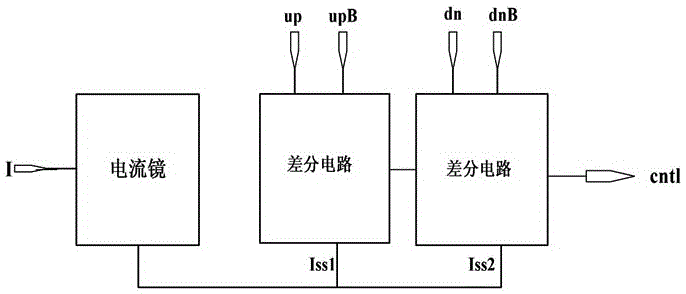

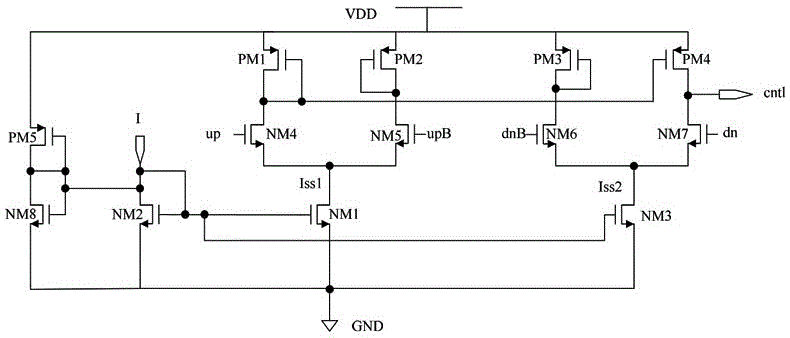

Low-jitter charge pump with radiation resistance characteristics

ActiveCN106849646AHas radiation resistanceSimple structureApparatus without intermediate ac conversionNegative feedbackAudio power amplifier

The invention discloses a low-jitter charge pump with radiation resistance characteristics. The low-jitter charge pump comprises a current mirror unit, a differential circuit unit and a push-pull amplifier, wherein input current I passes through the current mirror unit and generates bias current Iss1 and Iss2; meanwhile, an input end of the current mirror unit is connected with the input end of the push-pull amplifier and negative feedback is formed through the push-pull amplifier; and the differential circuit unit is provided with stable bias current. The low-jitter charge pump has the advantages of being simple in structure, low in cost, easy to implement and good in effect.

Owner:NAT UNIV OF DEFENSE TECH

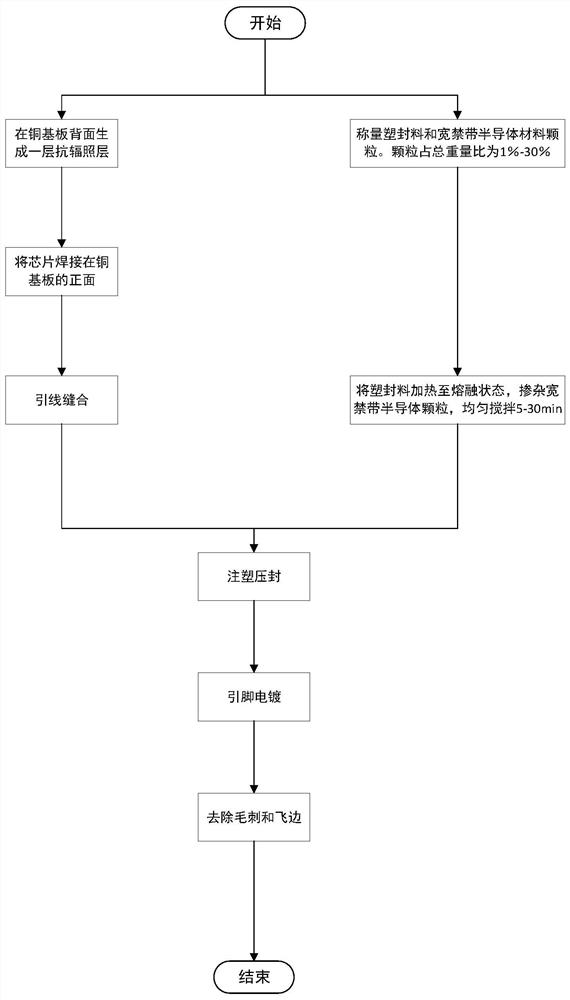

Radiation-proof packaging material for chip and radiation-proof packaging process

PendingCN113809050AIncreased absorption of radiant energyImprove radiation resistanceSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingWide-bandgap semiconductor

The invention belongs to the technical field of materials for the material nuclear industry, and particularly relates to a chip anti-radiation packaging material and an anti-radiation packaging process. The chip anti-radiation packaging material is formed by doping wide bandgap semiconductor particles in a plastic packaging material, and the weight ratio of the wide bandgap semiconductor particles is 10-75%. The chip anti-radiation packaging process comprises the following steps: firstly, growing an anti-radiation layer on the back surface of a copper substrate, welding a chip on the front surface of the copper substrate, and bonding the chip with a pin of the copper substrate; then weighing a plastic packaging material and the doped particles, putting the plastic packaging material and the doped particles into a mold with a preset stirring temperature, and uniformly stirring, so as to obtain a plastic packaging material composite material after the stirring time is ended; and finally, carrying out injection molding and press sealing on the uniformly stirred plastic packaging composite material, and carrying out pin electroplating and burr and flash removal on the plastic packaged chip. The radiation-proof performance of the whole chip and the reliability in the space environment are improved, and meanwhile, the radiation-proof capability of the back of a chip device is improved.

Owner:重庆平创半导体研究院有限责任公司

sram storage unit reinforcement method and sram storage array based on dice structure

ActiveCN112131819BSolve the impact of leakageAdd gate to GNDComputer aided designSpecial data processing applicationsMemory cellHemt circuits

Owner:58TH RES INST OF CETC

Radiation-proof erbium-doped photonic crystal fiber light source for high-precision fiber-optic gyroscope

PendingCN113381275AGuaranteed stabilityImprove radiation resistanceActive medium shape and constructionGainRelative intensity noise

The invention provides an anti-radiation erbium-doped photonic crystal fiber light source for a high-precision fiber-optic gyroscope. The fiber light source is of a multi-pumping double-pass backward structure and adopts a self-prepared erbium-doped photonic crystal fiber as a gain medium. A system light path comprises a 980nm laser, a 665nm laser, a first wavelength division multiplexer, an erbium-doped photonic crystal fiber, a second wavelength division multiplexer, a first spectral filter, a second spectral filter and an optical fiber isolator. According to the optical fiber light source disclosed by the invention, effective light fading is realized by simultaneously pumping special wavelength laser, so that the stability of the average wavelength and the output power of the erbium-doped optical fiber light source in a space irradiation environment is ensured; meanwhile, a flat spectrum filter is adopted to filter and shape an output spectrum, so that the light source has a large bandwidth, the light source has a relatively low relative intensity noise characteristic, and the light source is particularly suitable for space application of a high-precision fiber-optic gyroscope.

Owner:瑞燃(上海)环境工程技术有限公司

Multi-gap transient magnetic field sensor

ActiveCN110531285AAvoid serious distractionsHigh bandwidthMeasurement instrument housingMagnitude/direction of magnetic fieldsElectricityCoaxial cable

The invention discloses a multi-gap transient magnetic field sensor. The sensor comprises a shell and a cable assembly arranged in the shell. The cable assembly comprises a closed annular coil definedby a flexible circuit board and a coaxial cable. The closed annular coil is arranged at one end of the shell, and the coaxial cable is electrically connected with the closed annular coil and is led out of the other end of the shell. The invention relates to the field of magnetic field sensors and provides a multi-gap transient magnetic field sensor, the problem of electric field signal interference can be overcome, the influence of an electric field on magnetic field measurement can be effectively reduced, meanwhile, a relatively high bandwidth can be obtained, and the sensor has a certain anti-radiation effect.

Owner:TSINGHUA UNIV

Mesona chinensis benth polysaccharide and preparation method and applications thereof

InactiveCN102924621BHigh yieldReduce usageOrganic active ingredientsAntinoxious agentsBiotechnologyAlcohol

The invention discloses a method for preparing mesona chinensis benth polysaccharide. The method comprises the following steps that mesona chinensis benth herb is dried and crushed to obtain mesona chinensis benth herb powder, and the mesona chinensis benth herb powder is mixed with 1.0-2.0 percent of sodium carbonate water solution, and then the mixture is extracted at the temperature of 93-97 DEG C for 1.3-1.7 hours and then is filtered; the obtained filtrate is decolored with 10 percent of hydrogen peroxide at the temperature of 45-55 DEG C, and the decolored filtrate is ultrafiltered and purified by 10 K hollow fiber membrane tubes; and the ultrafiltered and purified filtrate is added into absolute ethyl alcohol with 70 percent of filtrate volume, then is centrifuged at the temperature of 4 DEG C and the rotating speed of 5,000rpm after 2-8 hours, sediment is collected and is subjected to freeze drying, and finally the mesona chinensis benth polysaccharide is obtained. The mesona chinensis benth polysaccharide obtained by the method has a radiation-proof effect.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com