A metal hydroxide-boron nitride hybrid filler/rubber-combined nuclear power cable insulating material and its preparation method

A hydroxide, cable insulation technology, applied in the field of cables, can solve the problems of poor compatibility, great influence on the mechanical properties of materials, poor dispersion, etc., to improve radiation resistance, good electrical properties, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

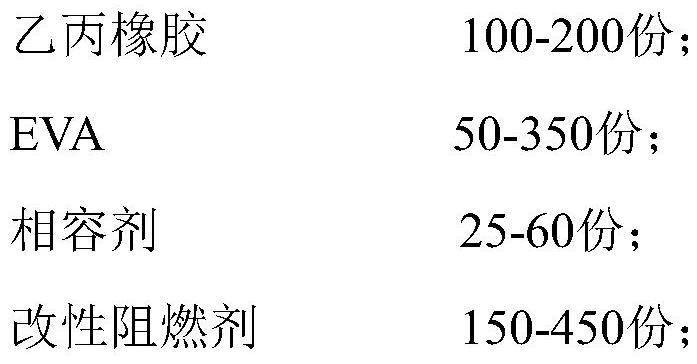

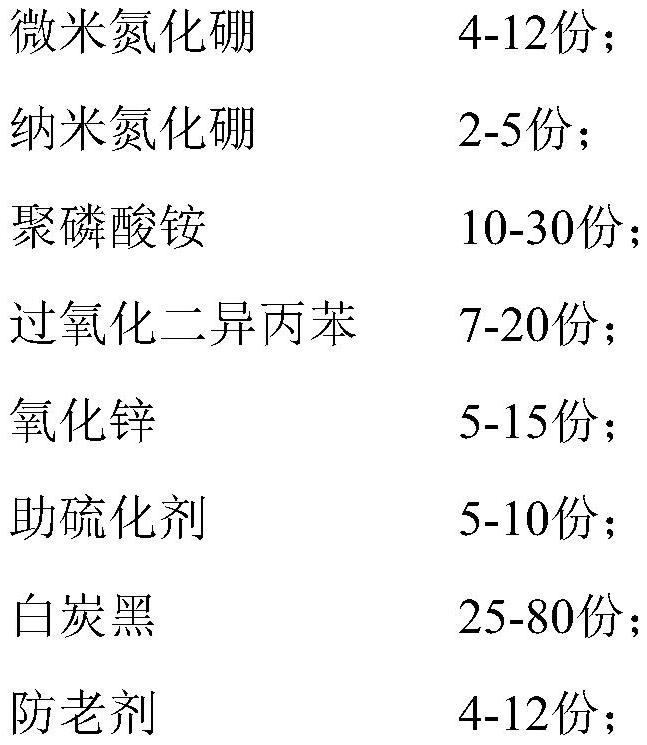

[0032] The components of the nuclear power cable insulation material in this embodiment are calculated by mass fraction as:

[0033]

[0034] The preparation method of the insulating material for nuclear power cables in this embodiment is as follows: first, the metal hydroxide grafted with methyl methacrylate and ionic liquid copolymer, micron boron nitride, nano boron nitride, ammonium polyphosphate, white carbon black and Put the anti-aging agent into the mixer, stir mechanically for 15-30 minutes until the mixture is uniform, and obtain the mixed filler; then masticate the ethylene-propylene rubber, EVA and compatibilizer in the open mill for 1-3 minutes, add the mixed filler, and ℃ for 10 minutes, then add dicumyl peroxide, zinc oxide, co-vulcanizing agent, and knead to obtain the insulation material for nuclear power cables. The performance test of its hot-press vulcanized products is shown in Attached Table 1.

Embodiment 2

[0036] The components of the nuclear power cable insulation material in this embodiment are calculated by mass fraction as:

[0037]

[0038]

[0039] The preparation method of the insulating material for nuclear power cables in this embodiment is as follows: first, the metal hydroxide grafted with methyl methacrylate and ionic liquid copolymer, micron boron nitride, nano boron nitride, ammonium polyphosphate, white carbon black and Put the anti-aging agent into the mixer, stir mechanically for 15-30 minutes until the mixture is uniform, and obtain the mixed filler; then masticate the ethylene-propylene rubber, EVA and compatibilizer in the open mill for 1-3 minutes, add the mixed filler, and ℃ for 10 minutes, then add dicumyl peroxide, zinc oxide, co-vulcanizing agent, and knead to obtain the nuclear power cable insulation material. The performance test of its hot-press vulcanized products is shown in Attached Table 1.

Embodiment 3

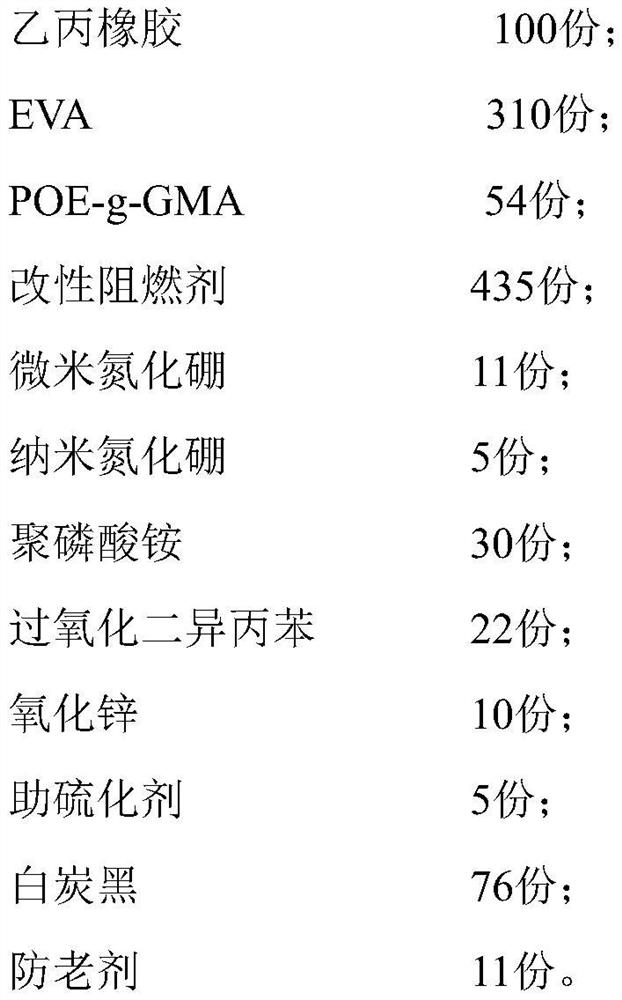

[0041] The components of the nuclear power cable insulation material in this embodiment are calculated by mass fraction as:

[0042]

[0043] The preparation method of the insulating material for nuclear power cables in this embodiment is as follows: first, the metal hydroxide grafted with methyl methacrylate and ionic liquid copolymer, micron boron nitride, nano boron nitride, ammonium polyphosphate, white carbon black and Put the anti-aging agent into the mixer, stir mechanically for 15-30 minutes until the mixture is uniform, and obtain the mixed filler; then masticate the ethylene-propylene rubber, EVA and compatibilizer in the open mill for 1-3 minutes, add the mixed filler, and ℃ for 10 minutes, then add dicumyl peroxide, zinc oxide, co-vulcanizing agent, and knead to obtain the nuclear power cable insulation material. The performance test of its hot-press vulcanized products is shown in Attached Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com