Radiation-proof packaging material for chip and radiation-proof packaging process

A packaging material and packaging process technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of inability to improve the anti-radiation performance of device plastics, unfavorable integration and portability of aerospace, and difficulty in forming strong connections, etc., to achieve Improve the radiation resistance performance, improve the absorption of radiation energy, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A chip anti-irradiation packaging material, weighing 2g of plastic packaging compound and wide bandgap semiconductor particles, doping wide bandgap semiconductor particles in the plastic packaging compound, the plastic packaging material is epoxy molding compound, and the wide bandgap semiconductor particles are silicon carbide wide For the bandgap semiconductor particles, the weight ratio of the silicon carbide wide bandgap semiconductor particles is 20%, that is, the weight of the silicon carbide wide bandgap semiconductor particles is 0.4g, and the particle size of the silicon carbide wide bandgap semiconductor particles is 10nm.

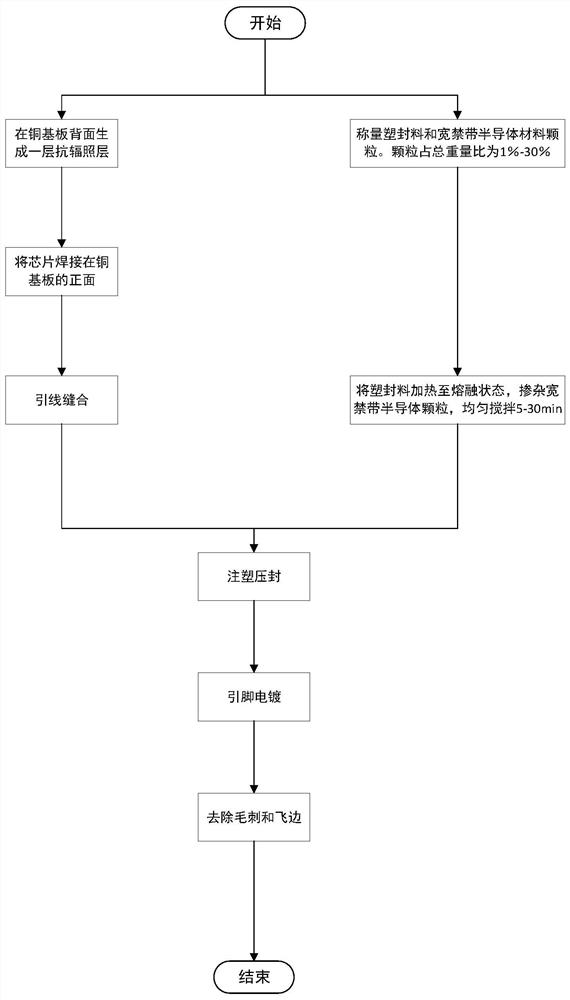

[0033] A chip radiation-resistant packaging process, comprising:

[0034] S1: grow a radiation-resistant layer on the back of the copper substrate, solder the chip on the front of the copper substrate, and bond the chip and the pins of the copper substrate at the same time; wherein, the material of the radiation-resistant layer is zirconia,...

Embodiment 2

[0039] A chip anti-irradiation packaging material, weighing 2g of plastic packaging compound and wide bandgap semiconductor particles, doping wide bandgap semiconductor particles in the plastic packaging compound, the plastic packaging material is epoxy molding compound, and the wide bandgap semiconductor particles are silicon carbide wide For the bandgap semiconductor particles, the silicon carbide wide bandgap semiconductor particles account for 10% by weight, and the particle size of the wide bandgap semiconductor particles is 200nm.

[0040] A chip radiation-resistant packaging process, comprising:

[0041]S1: grow a radiation-resistant layer on the back of the copper substrate, solder the chip on the front of the copper substrate, and bond the chip and the pins of the copper substrate at the same time; wherein, the material of the radiation-resistant layer is zirconia, and the thickness of the radiation-resistant layer is 100um, the area of the anti-radiation layer is t...

Embodiment 3

[0046] A chip anti-irradiation packaging material, weighing 2g of plastic packaging compound and wide bandgap semiconductor particles, doping wide bandgap semiconductor particles in the plastic packaging compound, the plastic packaging material is epoxy molding compound, and the wide bandgap semiconductor particles are silicon carbide wide For the bandgap semiconductor particles, the silicon carbide wide bandgap semiconductor particles account for 35% by weight, and the particle size of the wide bandgap semiconductor is 5um.

[0047] A chip radiation-resistant packaging process, comprising:

[0048] S1: grow a radiation-resistant layer on the back of the copper substrate, solder the chip on the front of the copper substrate, and bond the chip and the pins of the copper substrate at the same time; wherein, the material of the radiation-resistant layer is zirconia, and the thickness of the radiation-resistant layer is 1mm, the area of the anti-radiation layer is the area of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com