Mesona chinensis benth polysaccharide and preparation method and applications thereof

A technology of jelly jelly and polysaccharide, applied in jelly jelly polysaccharide and its preparation and application field, can solve the problems of low molecular weight of jelly jelly polysaccharide and low anti-radiation biological activity, reduce the damage of hematopoietic system and immune organs, and improve survival efficiency, improve the effect of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

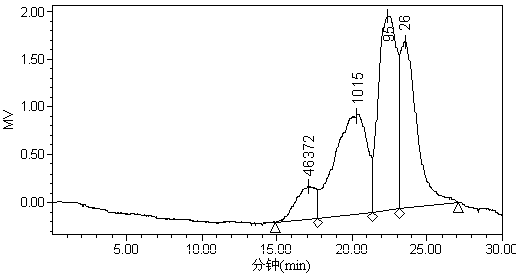

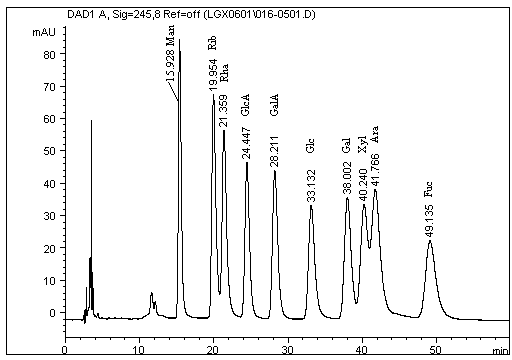

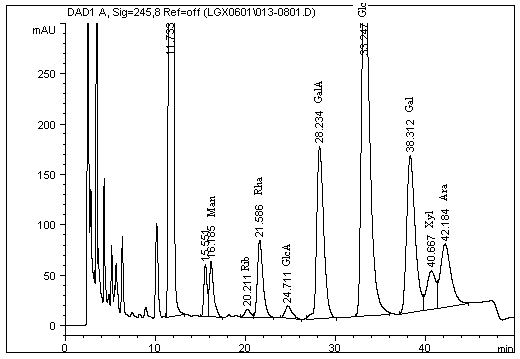

Image

Examples

Embodiment 1

[0037] A kind of jelly jelly polysaccharide, its preparation process comprises the steps:

[0038] (1) Dry and pulverize the whole jelly grass, and control the pulverization particle size to 50-100 mesh;

[0039] In a water bath, mix 9g of jellygrass whole herb powder and 250mL of 1.5% sodium carbonate aqueous solution, control the temperature at 95°C and extract for 1.5h, and filter the obtained extract with medical gauze and two layers of gauze to make jelly jelly The slag is filtered clean;

[0040] (2), decolorize the filtrate obtained in step (1) with 20mL of 10% hydrogen peroxide per 100mL, and control the temperature at 50°C during the decolorization process;

[0041] (3), step (2) After the decolorization is completed, use a 10K hollow fiber membrane tube for ultrafiltration purification;

[0042] (4), the filtrate obtained after ultrafiltration and purification in step (3) was added to anhydrous ethanol with a volume of 70% of the feed liquid, and then the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com